Distributed temperature measuring optical fiber laying and burying process for concrete dam

A technology of distributed optical fiber and temperature measurement optical fiber, which is used in dams, thermometers, wall dams, etc., can solve the problem that the application of distributed temperature measurement optical fiber is few, and there is no research result of distributed temperature measurement optical fiber layout and buried construction technology in concrete dams. , practicality and applicability need to be further improved, etc., to achieve the effect of excellent optical fiber layout and buried construction technology, stable and efficient distributed optical fiber temperature measurement system, and high buried survival rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] Embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

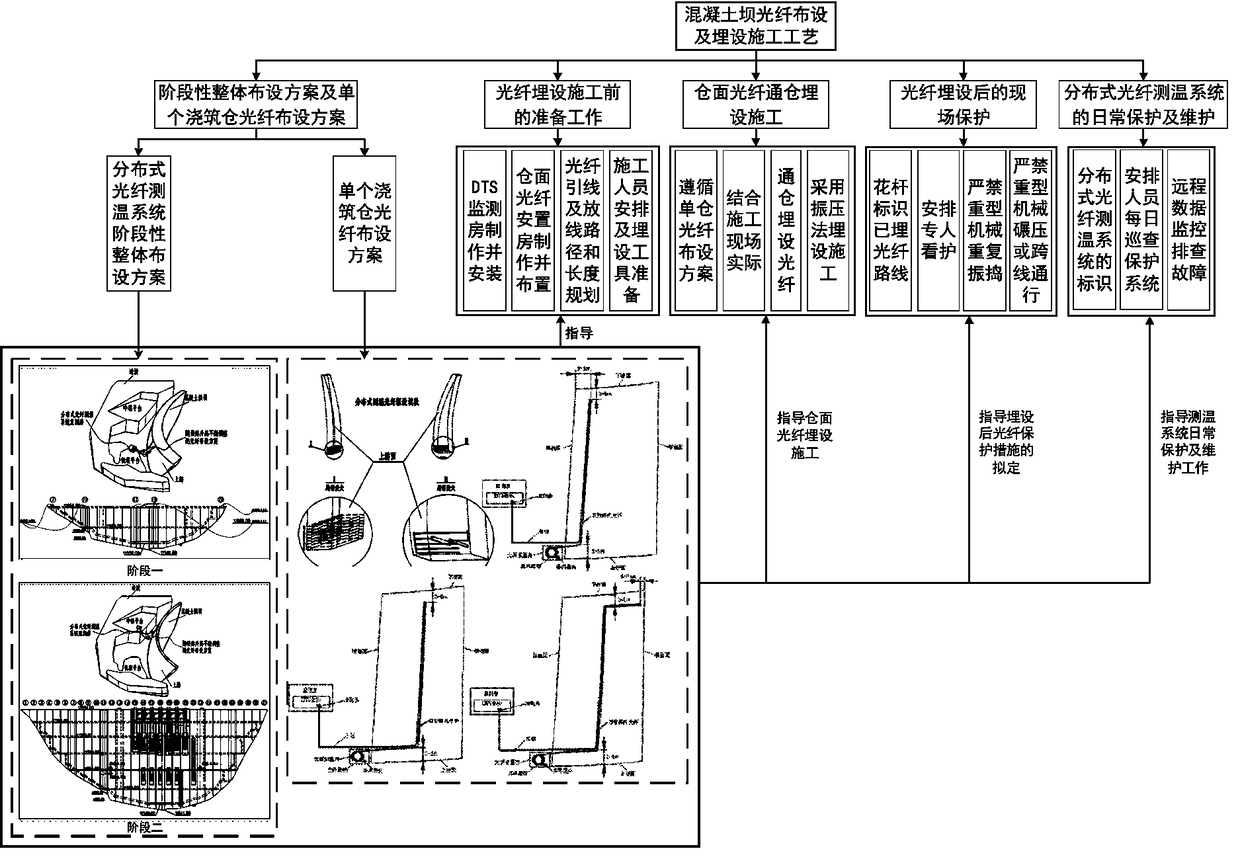

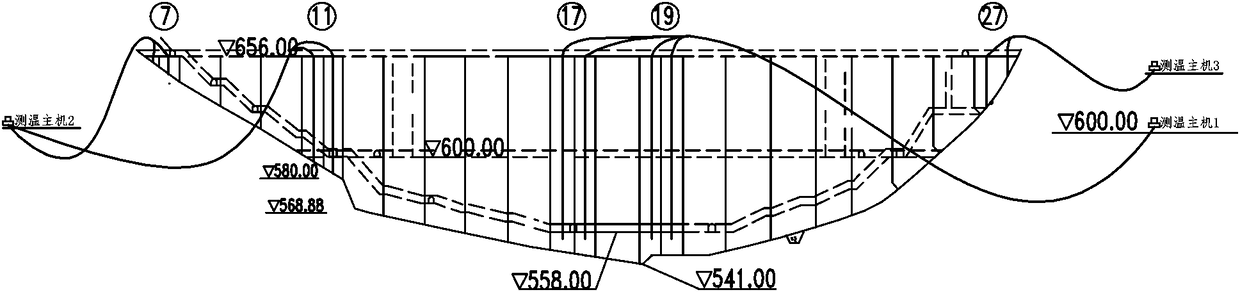

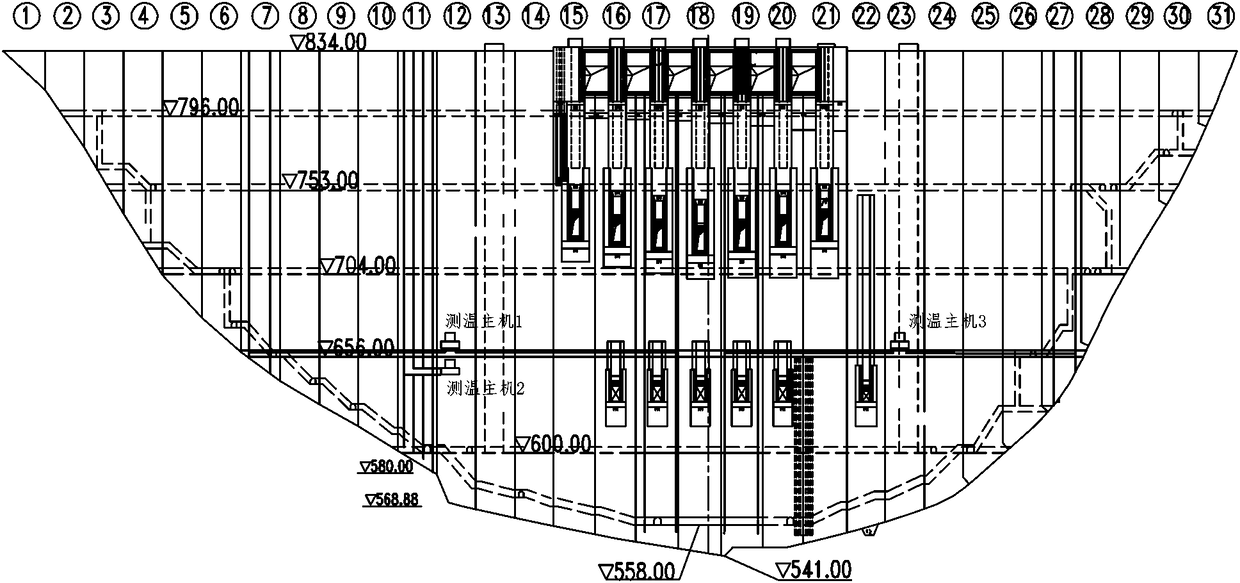

[0044] like Figure 1~Figure 13 As shown, the basic principles for the deployment and burial of distributed temperature measurement optical fibers in concrete dams are as follows:

[0045] (1) The phased overall layout plan of the distributed optical fiber temperature sensing (DTS) system and the fiber optic layout plan of a single pouring warehouse should be formulated in conjunction with the layout plan of the concrete dam construction site, the construction characteristics of the dam body, the construction platform and the structural characteristics of the foundation pit slope, etc. ;

[0046] (2) The buried position of the optical fiber should be far away from the cooling water pipe;

[0047] (3) The construction process of optical fiber embedding does not affect the construction of the warehouse surface;

[0048] (4) Comply with the principle of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com