High-speed dynamic focusing laser vibrating mirror module group

A dynamic focusing, laser galvanometer technology, applied in laser welding equipment, optics, optical components, etc., can solve the problems of insufficient overall design, insufficient processing accuracy, large product volume, etc., to improve marking quality and marking effect, improve production efficiency, reasonable layout effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

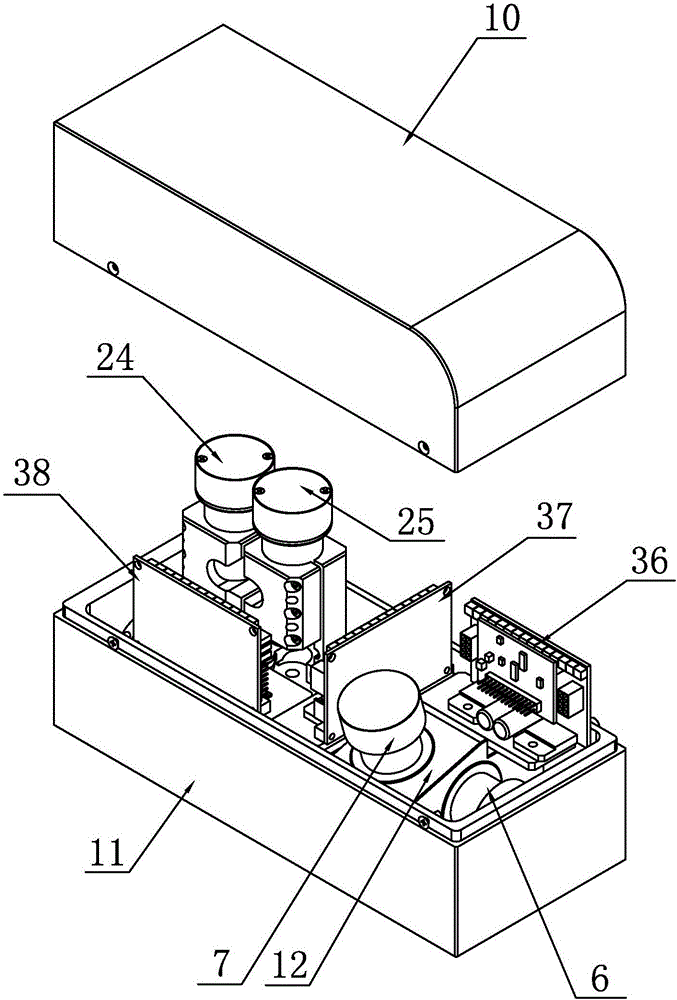

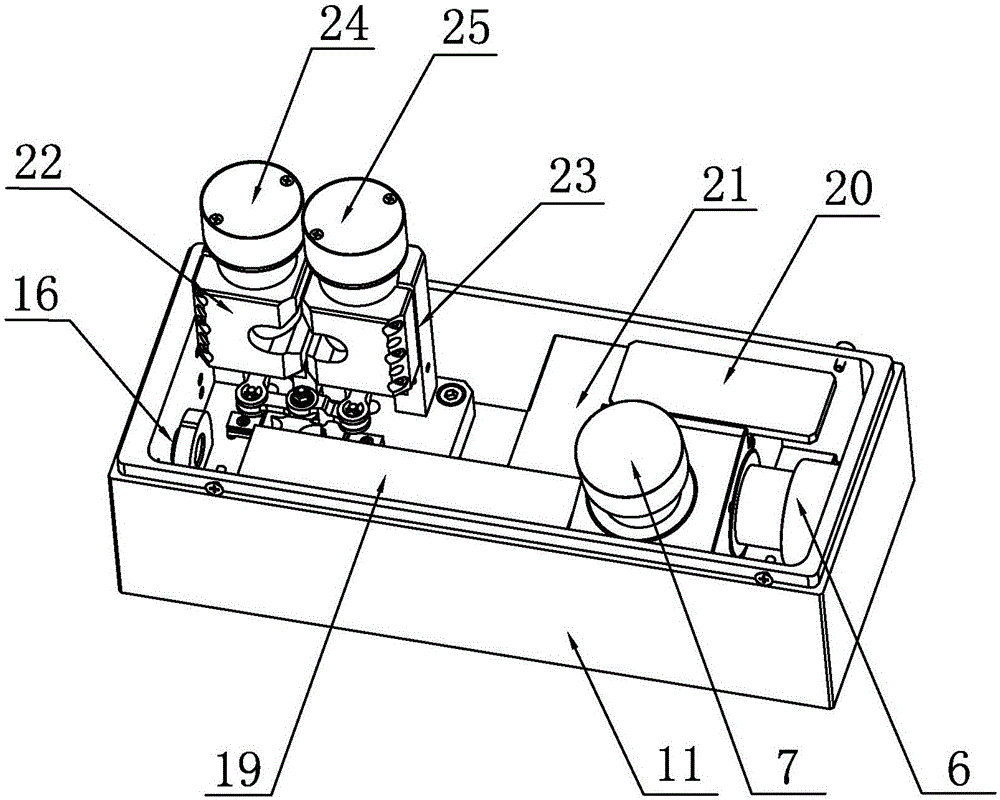

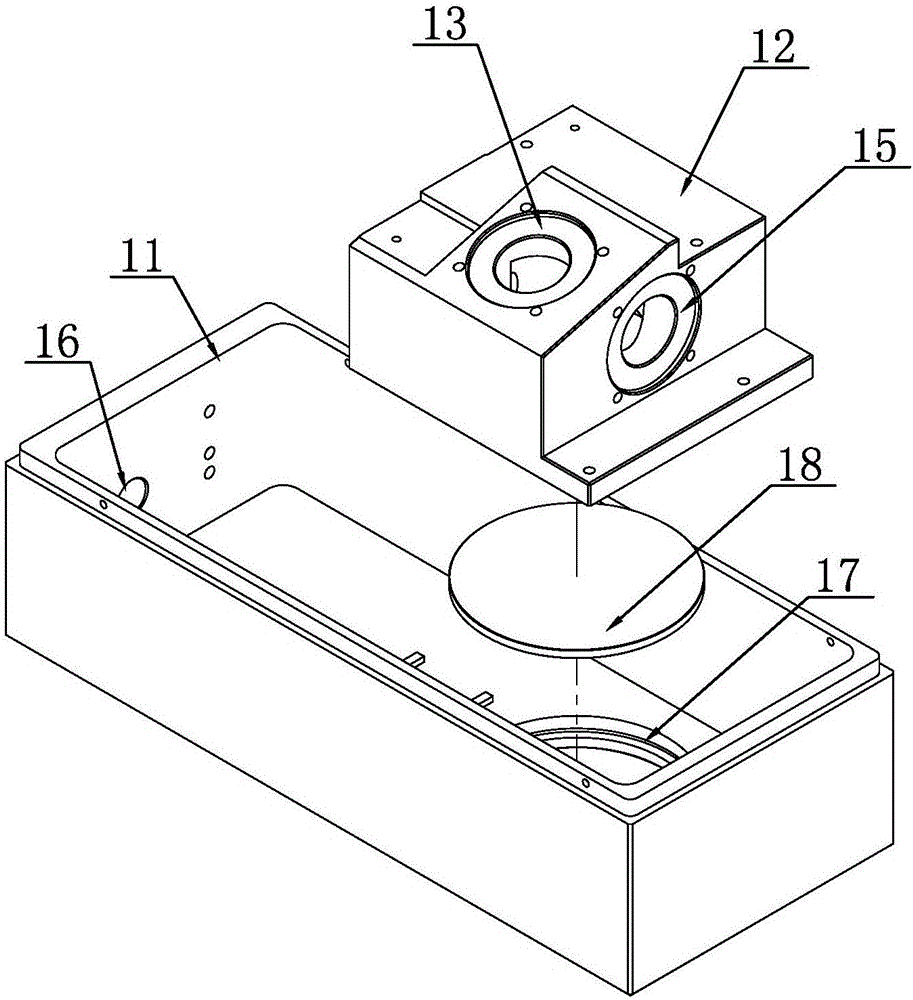

[0032] Such as figure 1 , figure 2 , image 3As shown, the high-speed dynamic focusing laser vibrating mirror module of the present invention includes a housing, a dynamic focusing module, an X scanning vibrating mirror 7 and a Y scanning vibrating mirror 6 . The casing is a rectangular parallelepiped structure, and the casing includes a first casing 10 and a second casing 11. A circular protective window 17 is opened on the first side wall of the second casing 11, and a protective window is embedded in the protective window 17. Lens 18, the second side wall of the second housing 11 opposite to the first side wall of the second housing 11 is open, the first housing 10 is mated with the open side of the second housing 11, the second A laser incident hole 16 is opened on the third side wall of the second housing 11 , and the laser beam enters the interior of the second housing 11 through the laser incident hole 16 . The inside of the second housing 11 is provided with an inn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com