Color laser index carving system and its operation method

A color laser and marking technology, applied in printing, printing device, burning, etc., to achieve the effect of various colors, easy operation and fast speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

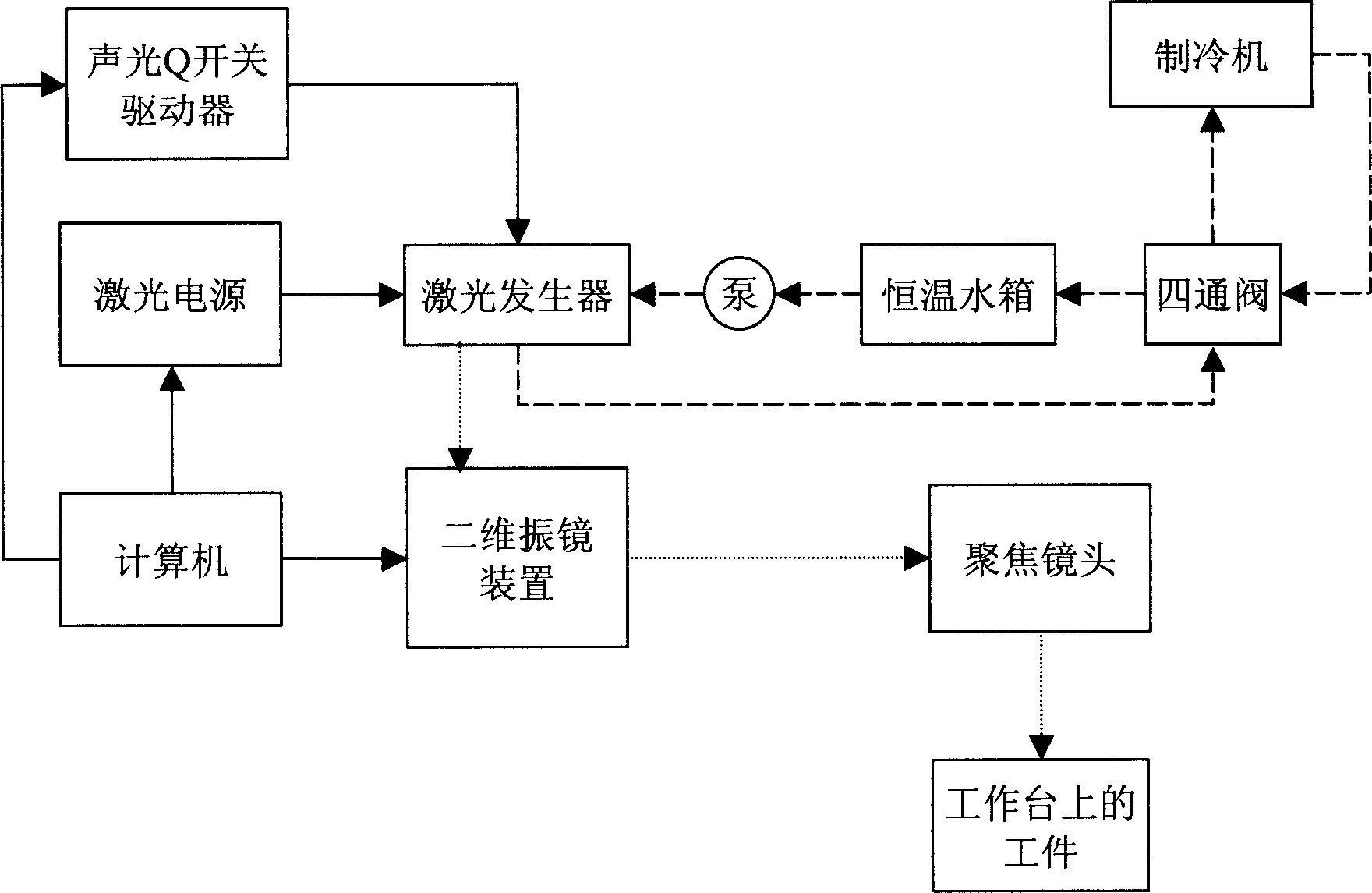

[0025] The laser marking system of the present invention is as figure 1 As shown in the figure, the solid line connector indicates the signal line connection, the dotted dotted line connector indicates the laser direction, and the dashed dotted line connector indicates the water pipe connection. The system includes a laser generator, a constant temperature water tank for cooling the laser generator and a refrigerator connected to it, a scanning device, a workbench for fixing workpieces, a focusing lens, a laser power supply, an acousto-optic Q switch driver and a computer for control. The computer is connected with the laser power supply, the acousto-optic Q switch driver, and the two-dimensional scanning galvanometer. The scanning device is a two-dimensional scanning vibrating mirror, which rotates according to computer instructions to change the direction of the laser beam emitted by the laser generator, and marks two-dimensional graphics and text on the surface of the workp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com