Cable unwinding rack

A pay-off frame and cable technology, which is applied in the direction of conveying filamentous materials, thin material handling, transportation and packaging, etc., to achieve the effect of easy sliding, improving stability and avoiding shaking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

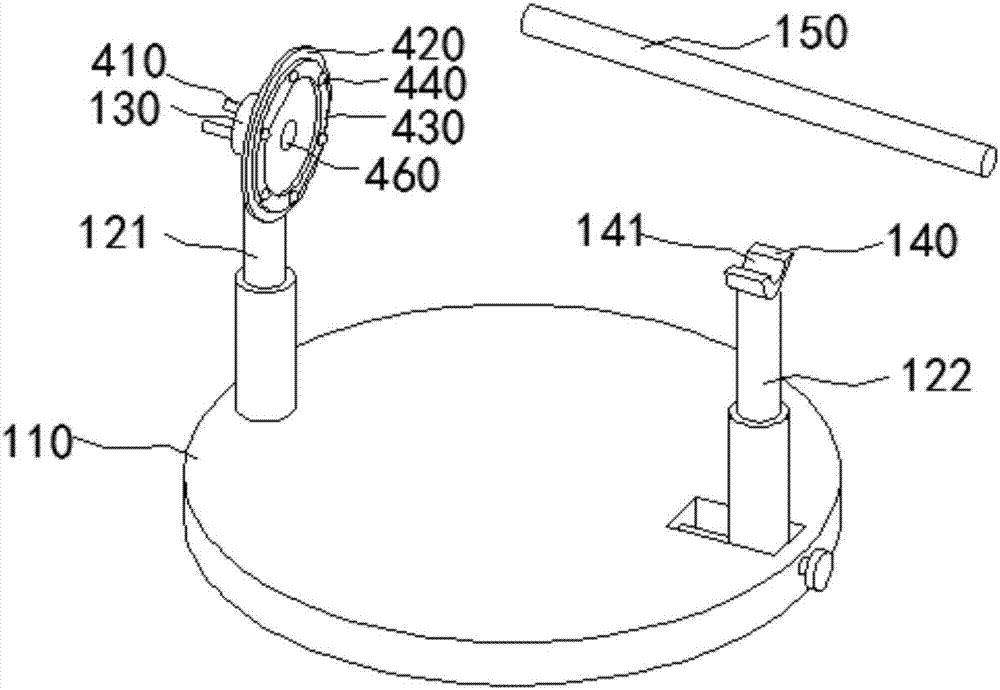

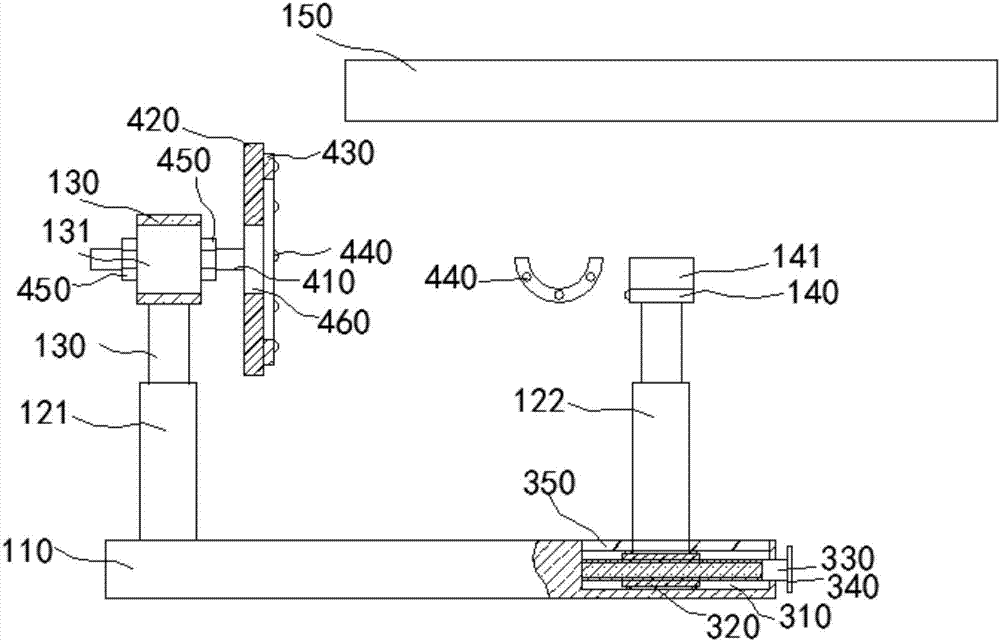

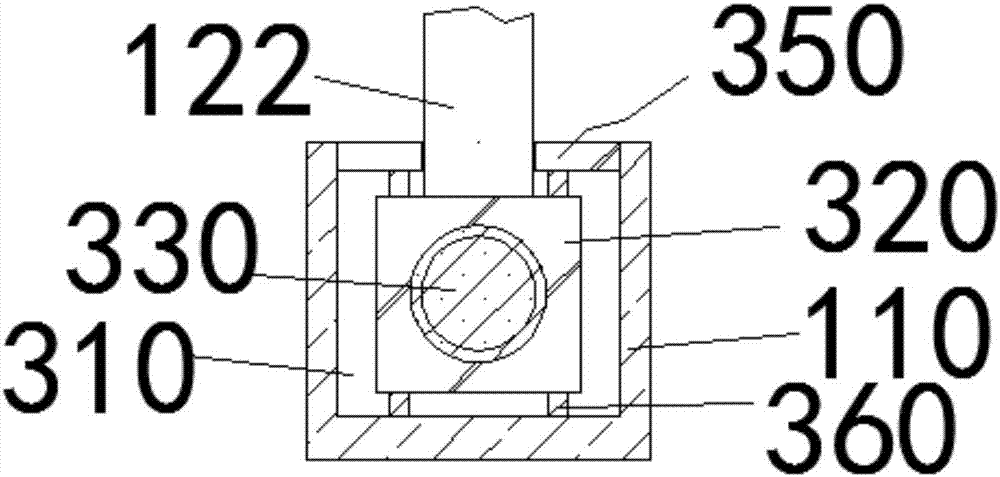

[0026] Such as Figure 1~3 As shown, the present embodiment provides a cable pay-off rack, which includes a base 110, a first support rod 121 and a second support rod 122 are vertically provided above the base 110; Seat 130, the first mounting seat 130 is rotatably connected with the first support rod 121 along the circumferential direction of the first support rod 121; the second support rod 122 top is provided with a second mounting seat 140, and the second mounting seat 140 is connected with the second supporting rod The rod 122 is fixedly connected; the first mounting seat 130 and the second mounting seat 140 are provided with a bearing cross bar 150 for carrying the cable tray, and the first mounting seat 130 is provided with an installation channel for matching with the corresponding end of the bearing cross bar 150 The hole 131, the second mounting seat 140 is provided with a mounting groove 141 for matching with the corresponding end of the bearing cross bar 150;

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com