Cable laying and installation cutting and peeling equipment

A cable laying and equipment technology, which is applied in the direction of cable laying equipment, cable installation, cable installation device, etc., can solve the problems of increasing the labor intensity of workers, failing to meet the use requirements, and low work efficiency, so as to ensure the stripping effect and fast Efficient peeling work and the effect of reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

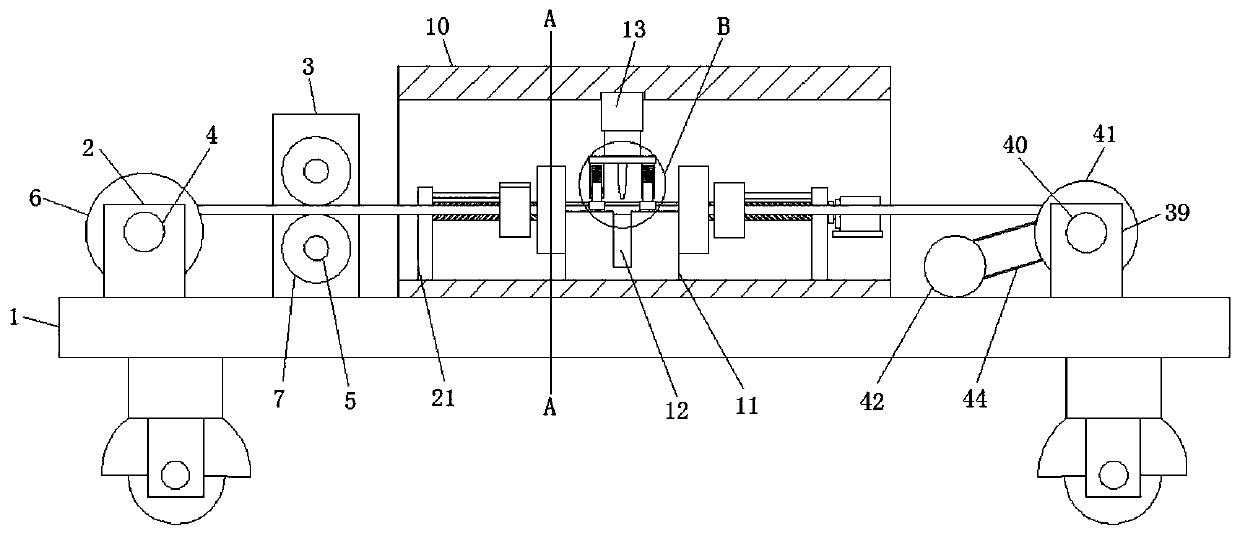

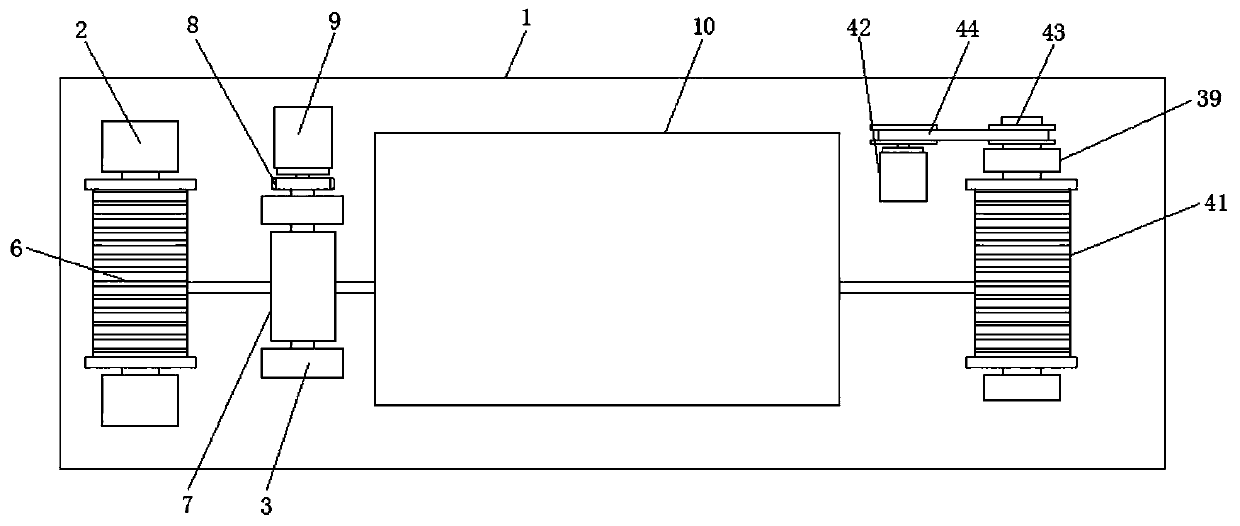

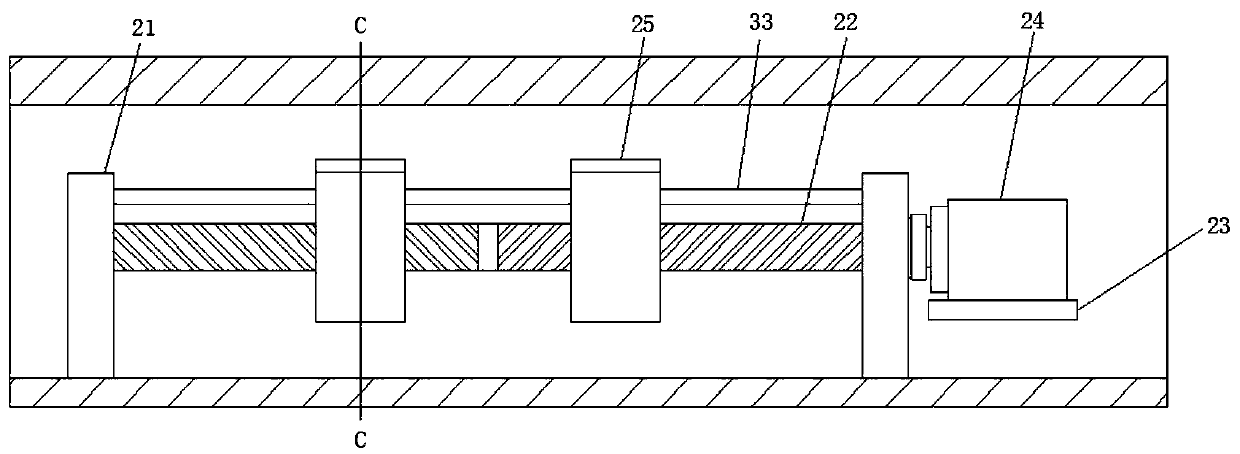

[0029] refer to Figure 1-6, a cable laying installation cutting and peeling equipment, including a workbench 1, the four corners of the lower end surface of the workbench 1 are fixedly connected with support legs by screws, the lower ends of the support legs are equipped with universal wheels, and the upper end surface of the workbench 1 is a The side is fixedly connected with a support seat 2 and a support seat 2 3 by screws, and the support seat 2 3 is located on the side of the support seat 2 close to the center of the workbench 1, and there are two support seats 2 and 2 support seats. The fixed shaft 1 4 and the fixed shaft 2 5 are rotatably connected between the two support seats 1 2 and 2 3 by rolling bearings respectively, and the outer walls of the rods of the fixed shaft 1 4 and the fixed shaft 2 5 are fixedly connected with pay-off rollers by screws respectively. 6 and conveying roller 7, and two fixed shafts 5 are provided with two and symmetrically distributed at ...

Embodiment 2

[0032] Such as Figure 1-2 As shown, this embodiment is basically the same as Embodiment 1. Preferably, the other side of the upper end surface of the workbench 1 is fixedly connected with a support base 39 by screws, and two support bases 39 are provided and symmetrically arranged on the workbench 1. At the front and rear end positions, the fixed shaft 3 40 is rotatably connected between the two support seats 39 through rolling bearings, and the outer wall of the rod of the fixed shaft 3 40 is fixedly connected with the winding roller 41 by screws, and the side of the workbench 1 close to the support seat 3 39 The rear end is fixedly connected with servomotor 3 42 by screws, and the output end of servomotor 3 42 and the rear end of fixed shaft 3 40 are all fixedly connected with belt pulley 43 by key, and conveyor belt 44 is connected between the two belt pulleys.

[0033] In this embodiment, the winding roller 41 is provided on the workbench, and the cable is temporarily wou...

Embodiment 3

[0035] Such as image 3 and 6 As shown, this embodiment is basically the same as Embodiment 1. Preferably, the upper end of the first briquetting block 19 and the side of the second briquetting block 28 and the third 30 briquetting block are provided with arc grooves matching the cables.

[0036] In this embodiment, the first pressing block 19 , the second pressing block 28 and the third pressing block 30 are provided with arc grooves matching the cables, thereby facilitating the clamping of the cables and making the cutting and pulling of the cables more stable.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com