Rock burst pressure relief and danger relief method

A technology of rock burst and danger relief, applied in underground chambers, earthwork drilling, wellbore lining, etc. The effect of reducing the stress difference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] When there is no rock burst accident in the roadway bifurcation section:

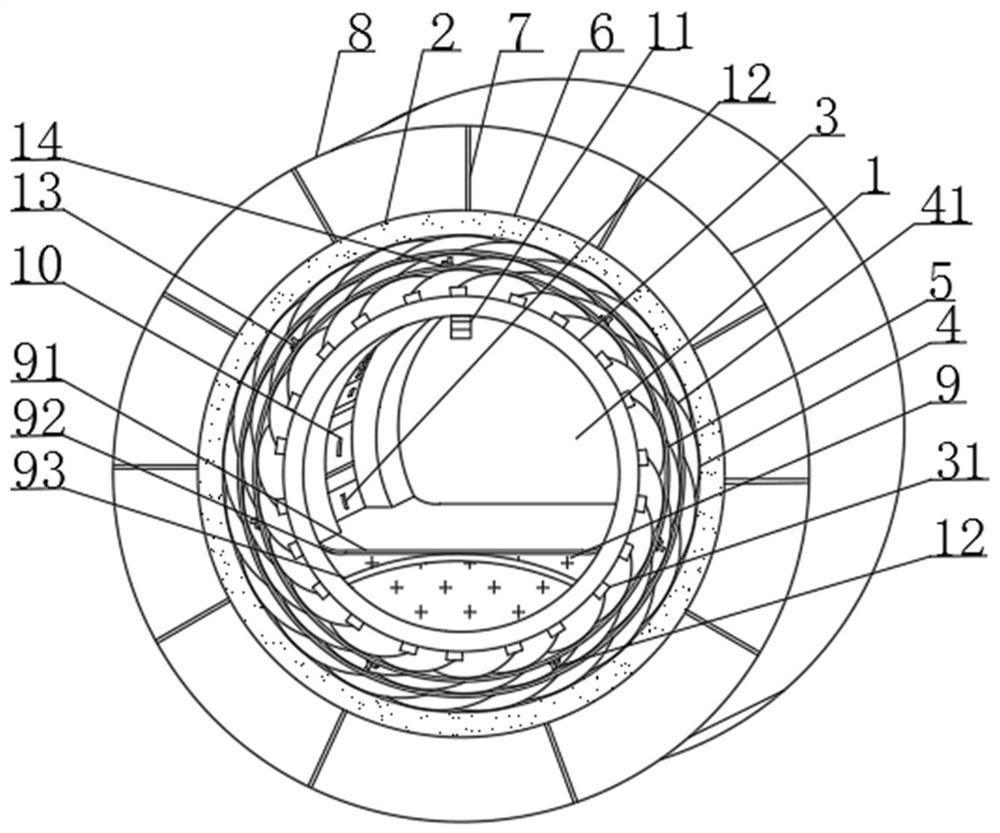

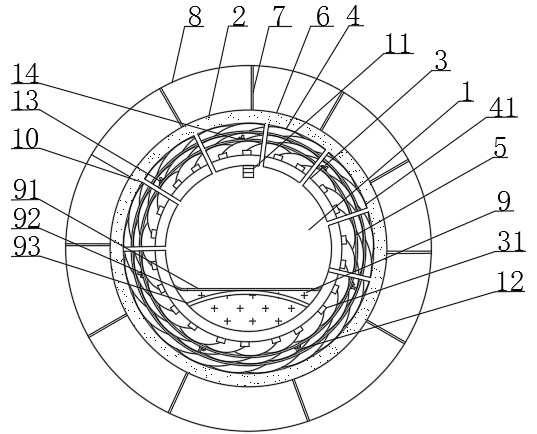

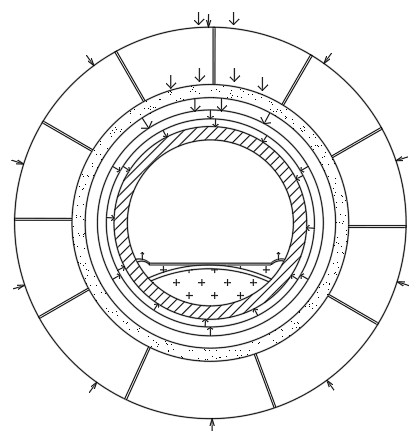

[0031] see Figure 1-8 , the present invention provides a pressure relief method for shock ground pressure, comprising roadway bifurcation section 1, the interior of roadway bifurcation section 1 is equipped with a yielding energy-absorbing supporting mechanism 2, and the outer wall of the yielding energy-absorbing supporting mechanism 2 A superficial surrounding rock anchor net supporting ring 8 is built, and an energy-absorbing support mechanism 2 is built, including an O-shaped steel scaffolding 3, a pressure decomposition pressure relief layer 4 and a partial pressure toughness cylinder 5, and a pressure decomposition pressure relief layer 4 and a pressure separation layer The compressive toughness tubes 5 are respectively provided with multiple layers, and are distributed at intervals. A number of beams 31 are installed on the outside of the O-shaped steel scaffolding 3. The outside of the b...

Embodiment 2

[0044] see Figure 1-4 , the second embodiment is basically the same as the first embodiment, the difference is:

[0045] When relatively light rock burst occurs in the high stress concentration area such as roadway bifurcation section:

[0046] The full-section anchor net sprayed concrete 6 is subjected to local impact force, and the superficial surrounding rock bolt net support ring 8 composed of the grouted anchor rod 7 and the full-section anchor net sprayed concrete 6 is deformed, and the impact force is transmitted to the energy-absorbing support Protective mechanism 2, the arc-shaped buffering pressure-dividing steel plate 41 distributed in the shape of fish scales disperses the impact force and transmits it to the pressure-dividing toughness cylinder 5, the arc-shaped buffering pressure-dividing steel plate 41 deforms under force, compresses the first pressure sensor 12, and the first pressure The sensor 12 sinks into the elastic mounting seat 14 to avoid being crushe...

Embodiment 3

[0048] see figure 1 and Figure 5 , the third embodiment is basically the same as the first embodiment, the difference is:

[0049] When severe rockburst occurs in high stress concentration areas such as roadway bifurcation sections:

[0050] The full-section anchor net sprayed concrete 6 is subjected to local impact force, and the superficial surrounding rock bolt net support ring 8 composed of the grouted anchor rod 7 and the full-section anchor net sprayed concrete 6 is deformed, and the impact force is transmitted to the energy-absorbing support Protective mechanism 2, the arc-shaped buffering pressure-dividing steel plate 41 distributed in the shape of fish scales disperses the impact force and transmits it to the pressure-dividing toughness cylinder 5, and the arc-shaped buffering pressure-dividing steel plate 41 is seriously deformed under force, oppressing the second pressure sensor 13 and the alarm 112 alarms urgently and sends a red warning light, and the emergency...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com