Nickel-titanium alloy medical equipment with surface coating and coating preparation method

A technology for medical devices and nickel-titanium alloys, which is applied to the field of nickel-titanium alloy medical devices with surface coating and the preparation of surface coatings of nickel-titanium alloy medical devices, can solve the problem of the decline of the mechanical properties of orthodontic wires and the increase of the temperature of the base material. , loss of superelastic properties, etc., to achieve the effect of reducing intake, improving binding force, and reducing stress difference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0053] Embodiment 1. NiTi orthodontic wire is carried out the treatment before coating preparation

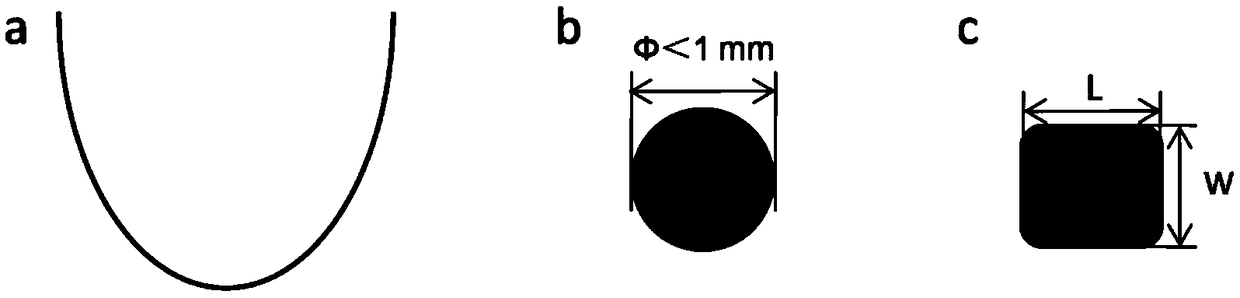

[0054] The formed NiTi orthodontic wire looks like figure 1 As shown, it is an untreated NiTi orthodontic wire commonly used in clinical practice, its diameter can range from 0.3 mm to 0.51 mm, the length L of the square wire can range from 0.4 mm to 0.65 mm, and the width W can range from 0.4 mm to 0.55 mm. Before treatment, the NiTi orthodontic wire can be treated by removing the surface oxide layer, ultrasonic cleaning, drying, etc. The specific process is as follows:

[0055] Strong acid is used as the surface polishing solution, and the composition and ratio of the solution are HF:HNO 3 :H 2 O=1:10:20, pickling until there are no bubbles escaping from the surface of the material and the liquid, or use the solution composition and ratio of HF:HNO 3 :H 2 The strong acid of O=(1.5~2.5):(8~15):(10~20) is used as the surface polishing solution, pickling for 5~10 minutes;

[...

Embodiment 2

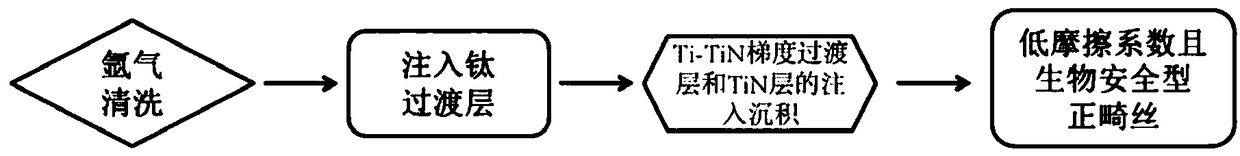

[0059] Example 2. Ion implantation deposition treatment of NiTi orthodontic wire

[0060] like figure 2 As shown, NiTi orthodontic wire was subjected to ion implantation deposition treatment.

[0061] 2-1. The plasma implantation deposition equipment used in this embodiment uses arc discharge to evaporate the target material to generate ions, which are loaded to the target platform with a pulsed negative bias voltage to realize intermittent ion implantation deposition. The specific operation is as follows:

[0062] Place the dried NiTi orthodontic wire in the plasma treatment equipment. A DC filtered arc source evaporates the titanium target, the arc source current is 60A, the target platform is loaded with a negative bias voltage of -200V, the frequency is 1000Hz, and the duty cycle is set to 20%. The surface is sputtered and cleaned by feeding argon gas, wherein the flow rate of argon gas is 30 sccm, and the cleaning time is 5-8 minutes. After cleaning, adjust the flow ...

Embodiment 3

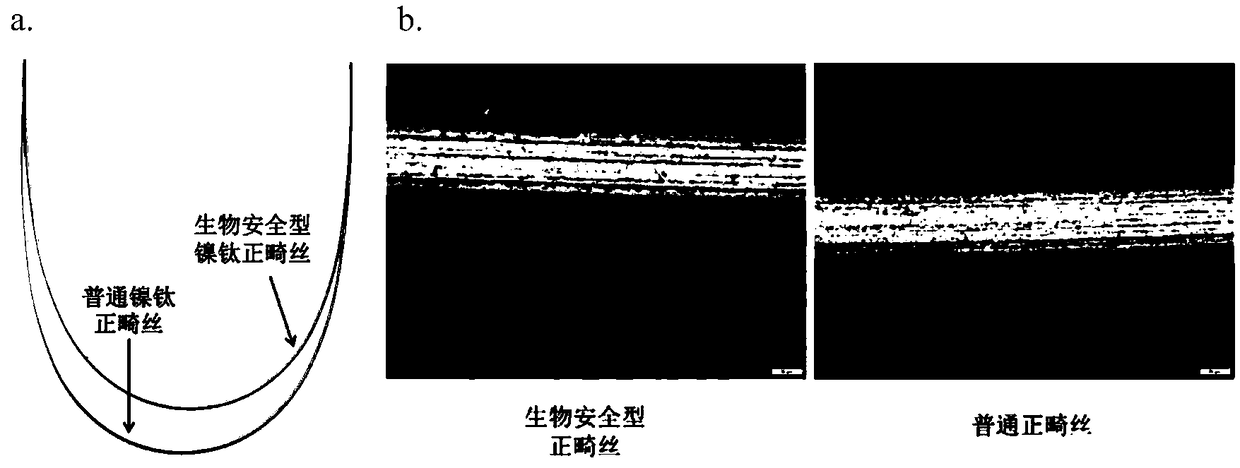

[0070] Example 3. Appearance of NiTi orthodontic wire after coating

[0071] like image 3 As shown in (a), the coated NiTi orthodontic wire has a light golden color, and the untreated NiTi orthodontic wire has a metallic primary color. The difference in color indicates successful application of the Ti-TiN coating. image 3 (b) shows the microstructure of the NiTi orthodontic wire prepared in Example 2-2 under an optical microscope, indicating that the surface of the NiTi orthodontic wire prepared by the method of the present invention is covered by a titanium transition layer, titanium-titanium nitride The coating composed of gradient transition layer and pure titanium nitride layer is tightly and uniformly wrapped.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com