MQW (multiple quantum well)-growth applied GaN (gallium nitride)-based green-light LED (light emitting diode) epitaxial structure

An epitaxial structure and green light technology, which is applied in the field of GaN-based green LED growth technology, can solve the problems of reduced radiation recombination efficiency, poor lattice quality, low growth temperature, etc., and achieve effective radiation recombination improvement, increased performance, and separation Phenomena mitigation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

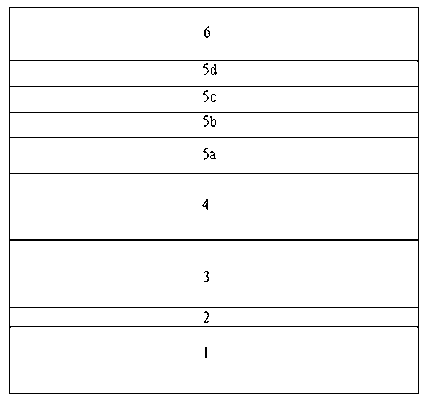

[0013] figure 1 Among them, 1 is the sapphire substrate, 2 is the GaN nucleation layer, 3 is the non-doped GaN layer, 4 is the n-type GaN layer, 5a is the GaN barrier layer, 5b is the buffer layer shallow well, 5c is the InGaN quantum well layer, 5d is a temperature-varying GaN transition layer, and 6 is a p-type GaN layer.

[0014] From figure 1 It can be seen that a GaN nucleation layer 2, an undoped GaN layer 3, an n-type GaN layer 4, a GaN barrier layer 5a, a buffer layer shallow well 5b with a low In composition, and an InGaN quantum well layer 5c are grown sequentially on the substrate 1 , a temperature-swapping GaN transition layer 5d and a p-type GaN layer 6 .

[0015] Among them, the low In composition refers to: in the InGaN material, the mass of In contained is 1%~10%.

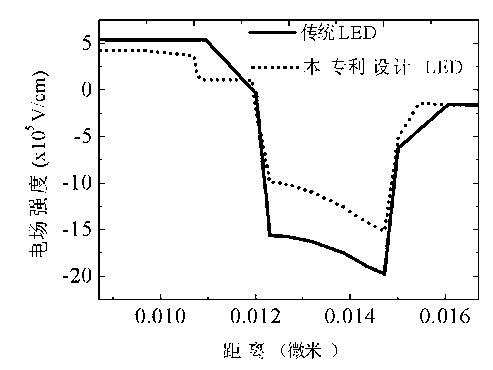

[0016] From figure 2 Among them, the curve of the LED (SQW LED) with a buffer layer shallow well with a low In composition is the simulated electric field distribution in the LED quantum well w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com