Optical filter and manufacturing method of optical filter

A technology for optical filters and visible light, applied in optical filters, manufacturing tools, glass manufacturing equipment, etc., can solve problems such as difficult mechanical processing and processing methods, glass substrate strength degradation, weak strength, etc., to achieve excellent performance and improve process Productivity, effect of strengthening warpage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] Hereinafter, exemplary embodiments of the present invention will be described in detail with reference to the accompanying drawings. However, in the following description, it should be noted that when functions of conventional elements and detailed descriptions of elements related to the present invention may make the gist of the present invention unclear, detailed descriptions of these elements will be omitted.

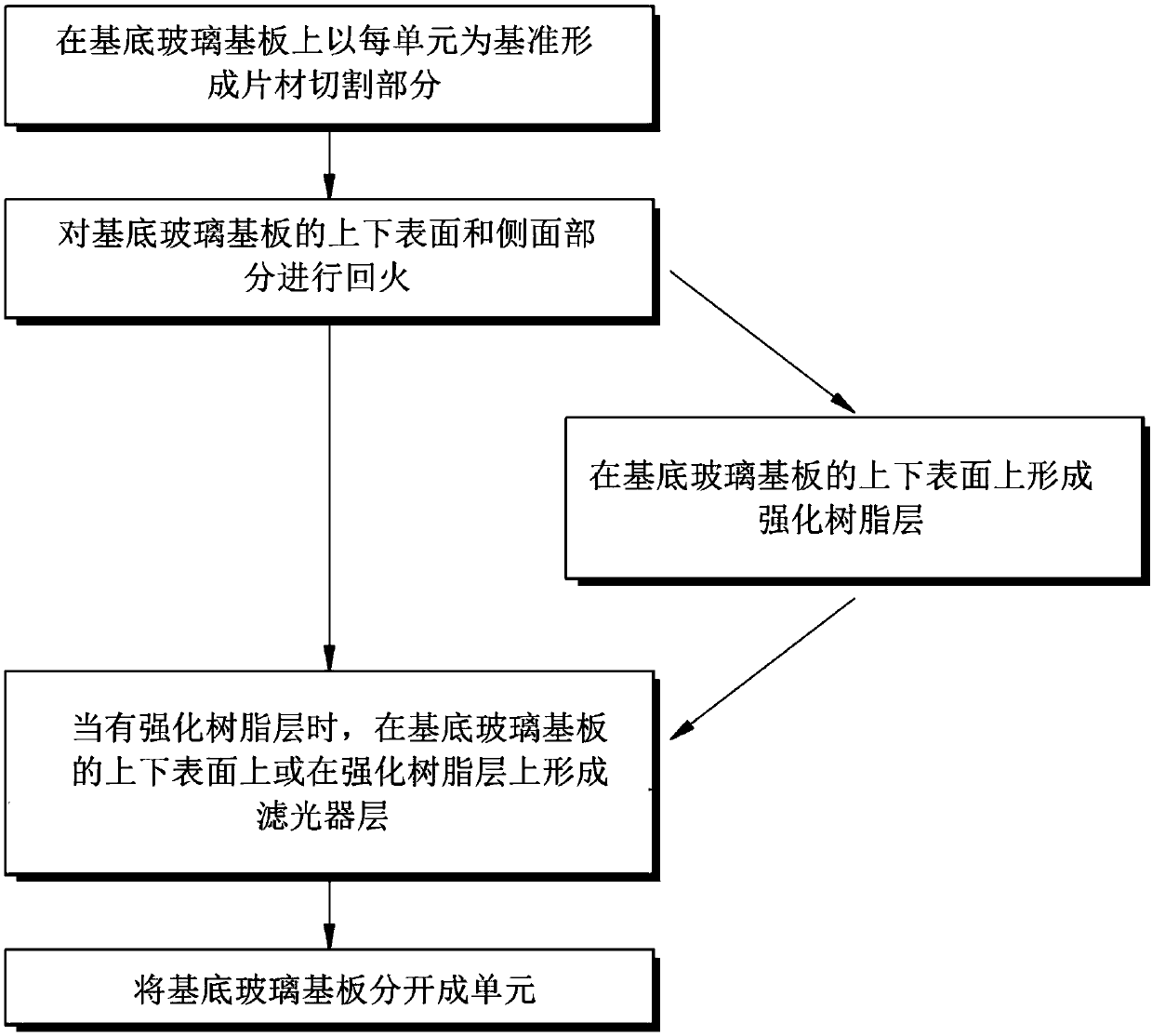

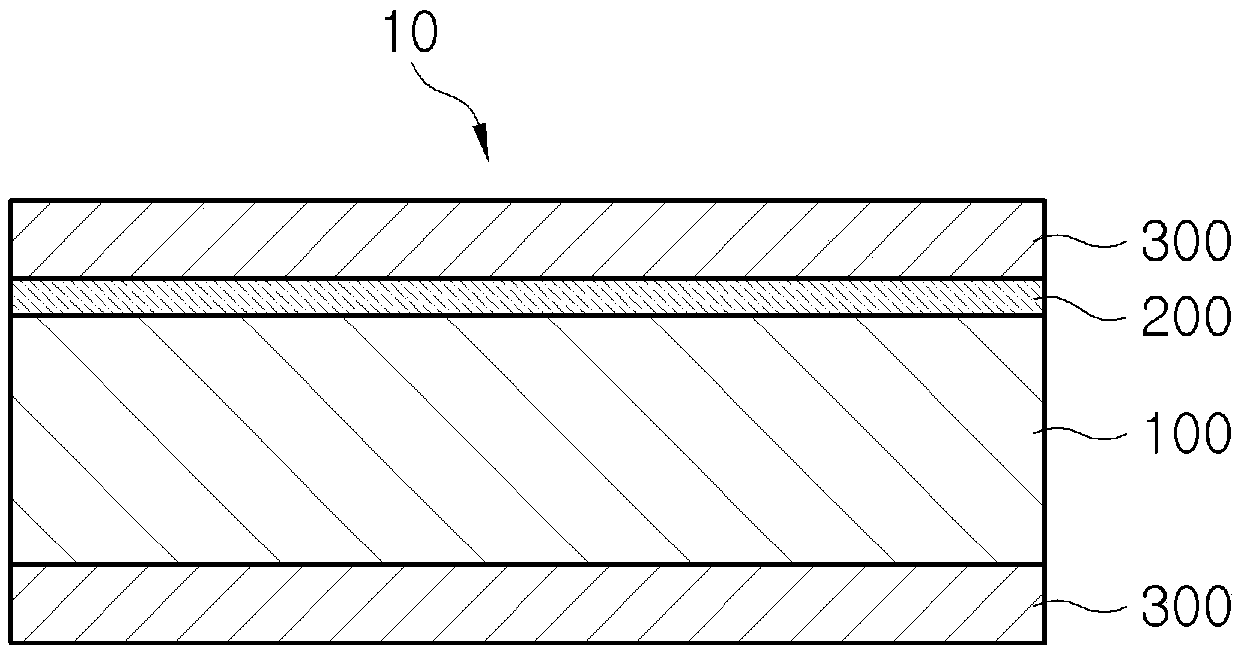

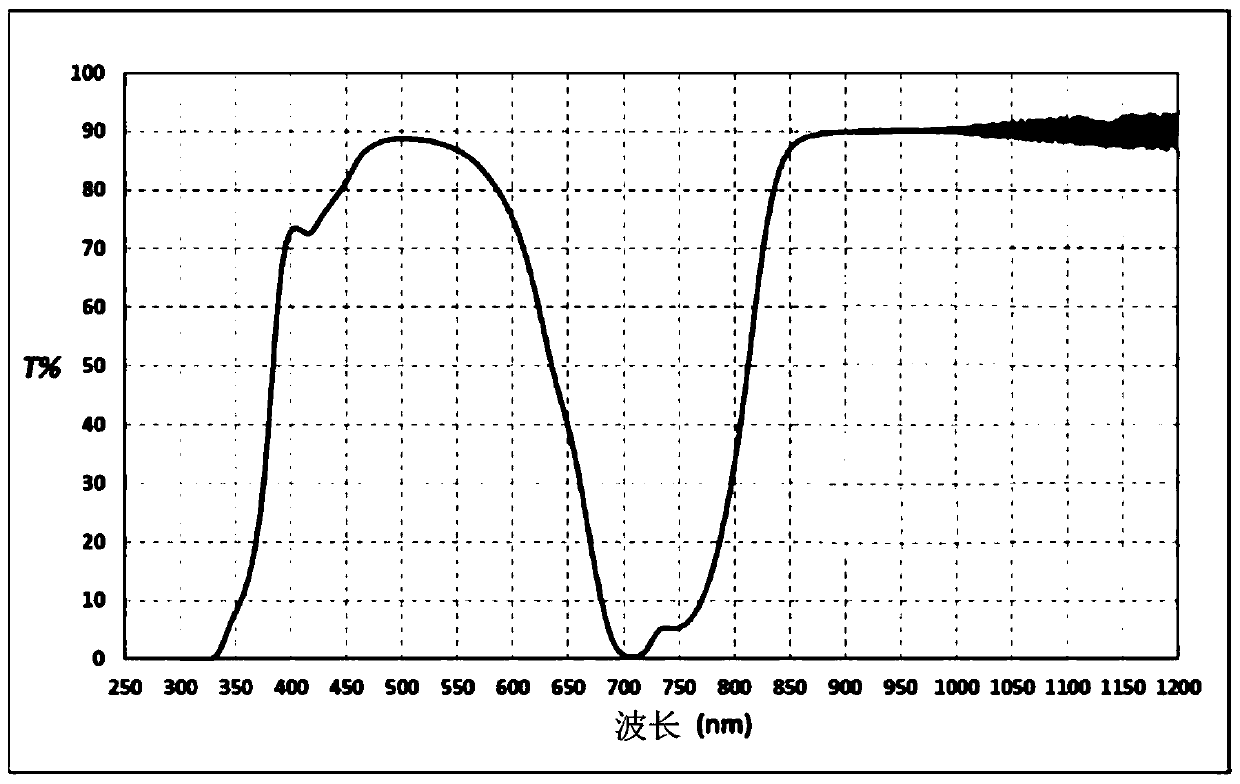

[0047] The present invention relates to an optical filter and a manufacturing method thereof, in which the optical filter is provided by using a tempered glass substrate so that the optical filter is strengthened, and the base glass substrate is tempered and mechanically processed while being maintained in a sheet state and is Filter layers are formed on the upper and lower surfaces of the glass substrate, thereby providing a strengthened filter by implementing a simple manufacturing method.

[0048] In addition, according to the present invention, a reinforced res...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com