GaN-based green light LED (light-emitting diode) epitaxial structure and manufacturing method thereof

A technology of epitaxial structure and manufacturing method, which is applied in the direction of electrical components, circuits, semiconductor devices, etc., can solve the problems of reducing the luminous efficiency of LED devices, reducing the quantum effect in the internal quantum well, and strengthening the polarization effect, so as to alleviate the stress difference , Increase the probability of radiation recombination, and improve the antistatic ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

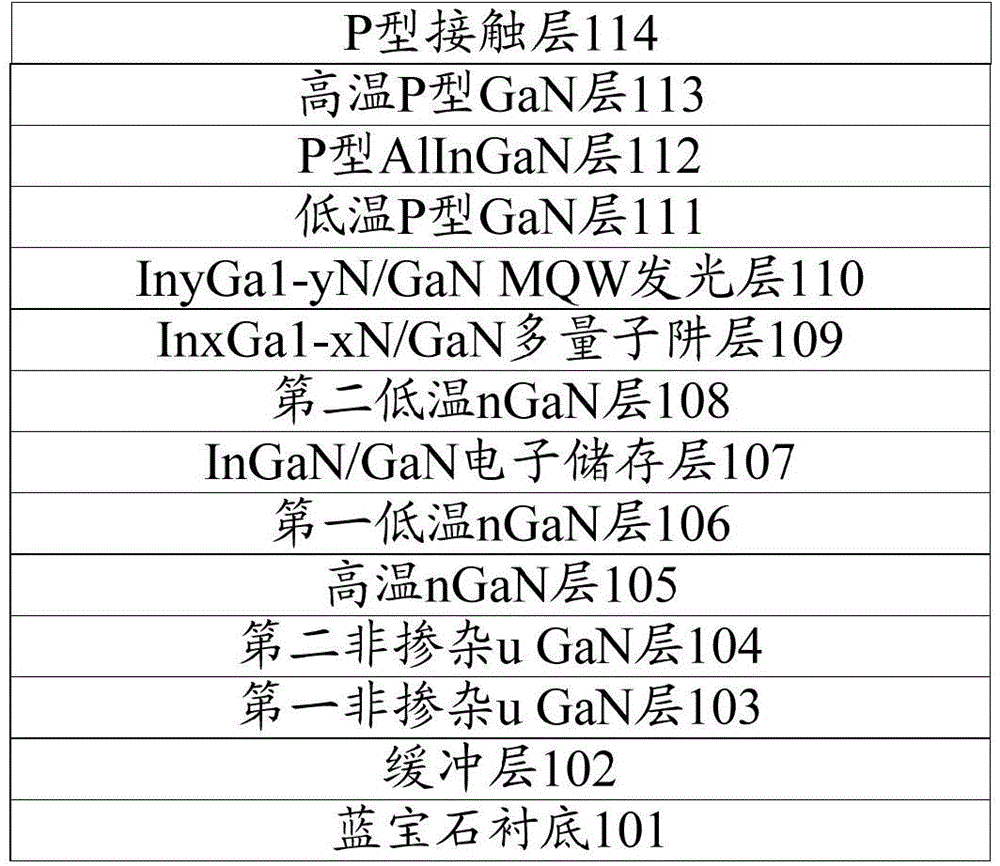

[0048] In order to improve the internal quantum efficiency of the quantum well, improve the luminous efficiency of the LED device, increase the light reflectivity and reduce the total reflection of light, the present invention provides a GAN-based green LED epitaxial structure, the structure diagram is as follows figure 1 As shown, the LED epitaxial structure includes from bottom to top: sapphire substrate 101, buffer layer 102, first undoped uGaN layer 103, second undoped uGaN layer 104, high temperature nGaN layer 105, first Low-temperature nGaN layer 106, InGaN / GaN electron storage layer 107, second low-temperature nGaN layer 108, InxGa1-xN / GaN multiple quantum well layer 109, InyGa1-yN / GaN MQW light-emitting layer 110, low-temperature P-type GaN layer 111, P-type AlInGaN layer 112, high temperature P-type GaN layer 113 and P-type contact layer 114, wherein,

[0049] The InxGa1-xN / GaN multi-quantum well layer 109 includes periodically grown InxGa1-xN / GaN well layers and Inx...

Embodiment 2

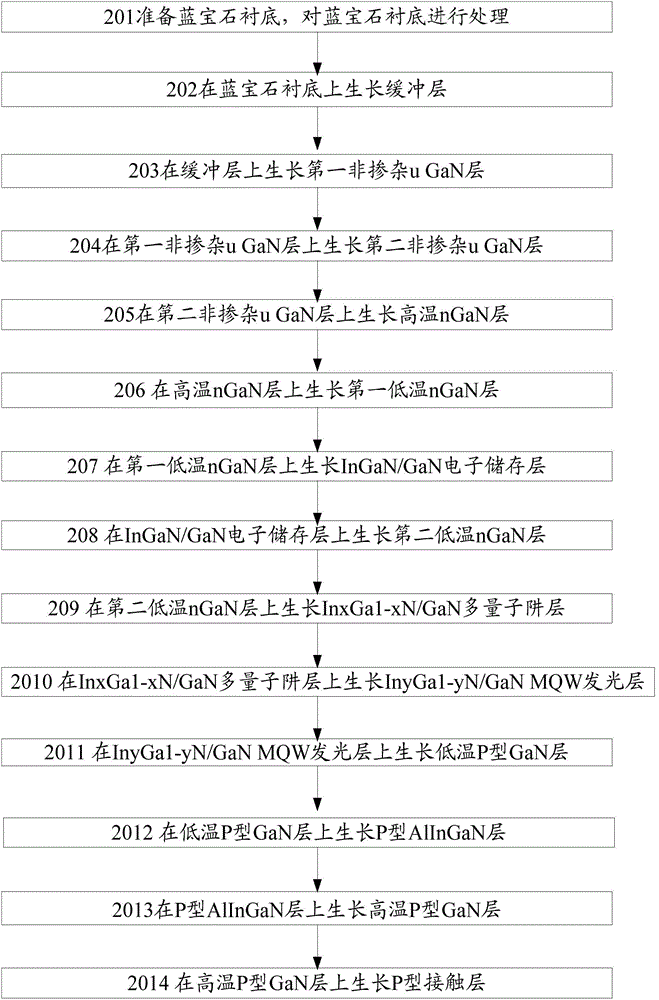

[0080] The manufacturing method of the GAN-based green LED epitaxial structure in this embodiment is carried out on Veeco K465iMOCVD equipment, and the specific process is as follows:

[0081] 1) Place the sapphire substrate in the MOCVD reaction chamber, and use H 2 , NH 3 Wait for the gas to treat the sapphire substrate at high temperature for 5-10 minutes;

[0082] 2) After the high temperature treatment is completed, the temperature in the reaction chamber is lowered to 500-600°C, the optimum temperature is 550°C, and TMGa (trimethylgallium) and NH 3 , the pressure is controlled at 300torr-650torr, and a buffer layer GaN (Nucleation) with a thickness of 15-40nm is grown on the sapphire substrate; 500s, forming a GaN crystal nucleus on the sapphire substrate;

[0083] 3) After the high temperature annealing is completed, the temperature is adjusted to 1000-1100°C, and TMGa and NH 3 , the pressure is controlled at 300torr-700torr, and the first non-doped uGaN layer with ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com