Method for preparing sapphire pattern substrate

A sapphire substrate, pattern substrate technology, applied in electrical components, circuits, semiconductor devices, etc., can solve the problems of difficulty, small size of single crystal, high dissociation pressure, etc., to achieve smooth and flat surface without defects, improved crystal quality, The effect of low process cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

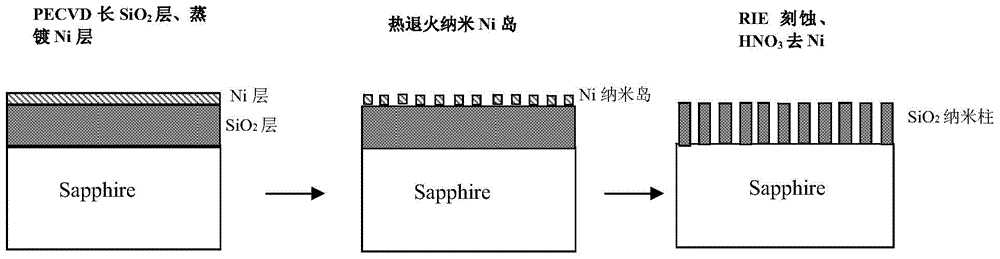

[0026] Such as figure 2 Shown, the present invention grows patterned sapphire substrate, mainly comprises the following steps:

[0027] 1) Deposit a layer of 100-300nm SiO on a sapphire substrate by PECVD 2 layer, the deposition temperature is 200-300°C.

[0028] 2) On SiO 2 A layer of 8-15nm thick Ni film is vapor-deposited on it, and Ni nano-islands are formed by rapid thermal annealing under a nitrogen atmosphere. The annealing temperature is 700-1000° C. for 1-3 minutes. The Ni nano-islands have an average diameter of 100-200 nm and a density of 3-5×10 8 / cm 2 .

[0029] 3) Using Ni nano-islands as a mask, use reactive ion etching (RIE) to etch SiO 2 layer, the etchant gas is CF 4 or CHF 3 and SF 6 , the etching rate is controlled at 50-66nm / min, and the etching time is 1-6min. SiO is obtained after etching 2 nanopillars.

[0030] 4) HNO at 50-150°C 3 Soak in the solution for 5-10min to remove the Ni film.

[0031] Specific examples are as follows:

[0032]...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average diameter | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com