Composite material brake disc

A composite material, brake disc technology, applied in the direction of brake disc, brake type, brake components, etc., can solve the problem of poor bonding force between the substrate and the wear-resistant layer, and achieve increased wear resistance, good wear resistance and Toughness, uniform distribution effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] It should be noted that, in the case of no conflict, the embodiments in the present application and the features in the embodiments can be combined with each other. The present invention will be described in detail below with reference to the accompanying drawings and examples.

[0044] The present application will be described in further detail below in conjunction with specific examples, and these examples should not be construed as limiting the scope of protection claimed in the present application.

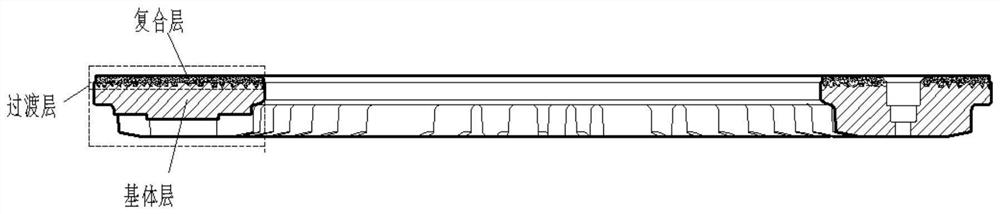

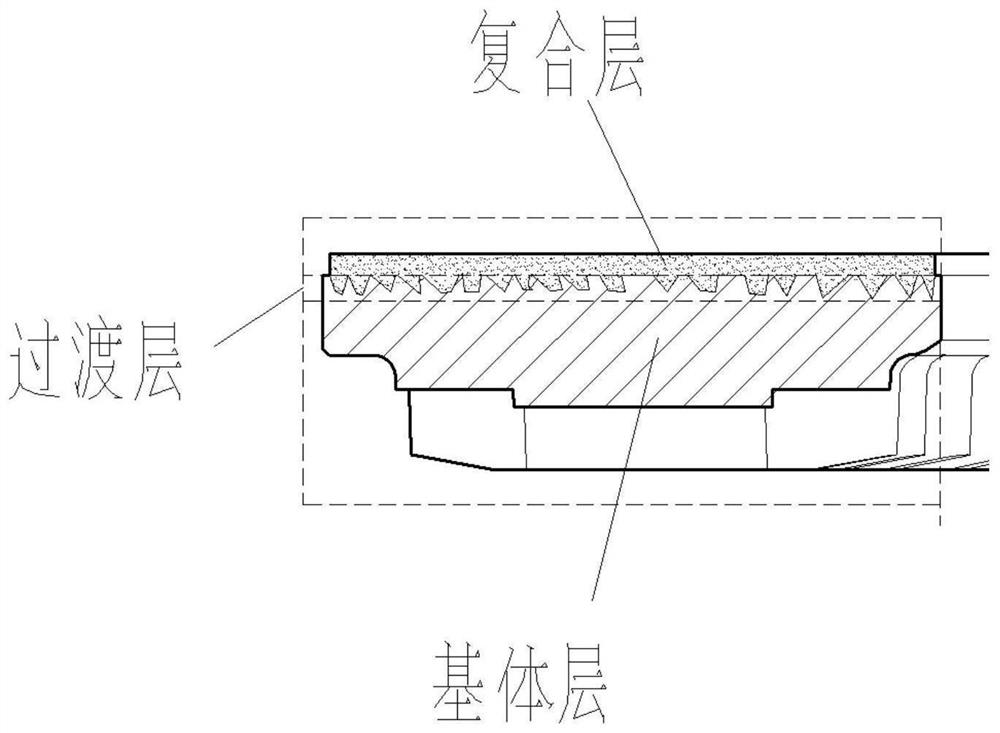

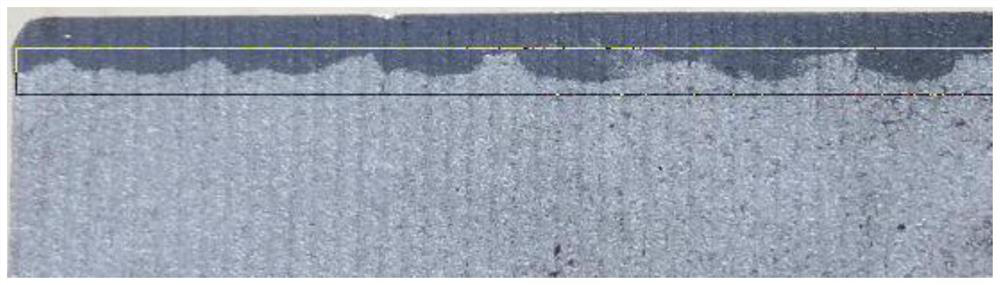

[0045] see figure 2, the composite material brake disc of the present invention is prepared by a friction stir processing method from a base layer and a composite layer of two different materials. Wherein, the base layer is an aluminum-silicon alloy or an aluminum-silicon-copper alloy, which mainly plays a bearing role. The Al-Si alloy or Al-Si-Cu alloy may be a hypoeutectic alloy, eutectic alloy or hypereutectic alloy. In this embodiment, a small amount of ceramic ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com