Alloy steel for bucket teeth and preparation method of bucket teeth

A technology of alloy steel and bucket teeth, applied in the field of preparation of alloy steel and bucket teeth, can solve the problems of high cost of bucket teeth material, short service life, poor impact toughness, etc., achieve uniform distribution of carbides, eliminate segregation and columnar crystals granules, the effect of improving performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

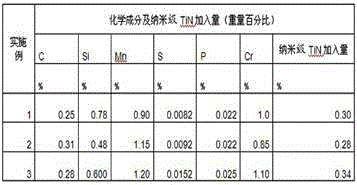

Embodiment 1

[0026] Prepare bucket teeth as follows:

[0027] First, smelting and casting:

[0028] 1) In the pre-deoxidation stage of alloy steel raw material smelting, ferromanganese and ferrosilicon are used for pre-deoxidation, and at the same time, 0.10% Ca-Si alloy deoxidizer is added. In the final deoxidation stage, 0.15%-0.20% pure aluminum is added for deoxidation to control molten steel The content of oxygen in the medium is (17-26)×10 -6 Within the interval; Sampling and analysis of the chemical composition of molten steel, adjusted according to the weight percentage of the substance to obtain molten steel with C: 0.25%, Si: 0.78%, Mn: 0.90%, Cr: 1.0%, p≤0.030, S≤0.030;

[0029] 2) Add nano-sized TiN, the addition amount is 0.30% of the molten steel weight, place it at the bottom of the casting ladle, and use the impact force of the molten steel during tapping to fully stir; Get tooth castings.

[0030] Second, the heat treatment process of bucket tooth castings:

[0031] 1)...

Embodiment 2

[0035] Prepare bucket teeth as follows:

[0036] First, smelting and casting:

[0037] 1) In the pre-deoxidation stage of alloy steel raw material smelting, ferromanganese and ferrosilicon are used for pre-deoxidation, at the same time, 0.10% Ca-Si alloy is added, and 0.15%-0.20% pure aluminum is added for deoxidation during final deoxidation, so as to control the oxygen content in molten steel Content in (17-26)×10 -6 Within the interval; Sampling and analysis of the chemical composition of molten steel, adjusted according to the weight percentage of the substance to obtain molten steel with C: 0.31%, Si: 0.48%, Mn: 1.15%, Cr: 0.85%, p≤0.030, S≤0.030;

[0038] 2) Add nano-sized TiN, the addition amount is 0.28% of the molten steel weight, place it at the bottom of the casting ladle, and use the impact force of the molten steel when tapping to fully stir; Get tooth castings.

[0039] Second, the heat treatment process of the bucket tooth casting: the method is the same as t...

Embodiment 3

[0041] Prepare bucket teeth as follows:

[0042] First, smelting and casting:

[0043] 1) In the pre-deoxidation stage of alloy steel raw material smelting, ferromanganese and ferrosilicon are used for pre-deoxidation, at the same time, 0.10% Ca-Si alloy is added, and 0.15%-0.20% pure aluminum is added for deoxidation during final deoxidation, so as to control the oxygen content in molten steel Content in (17-26)×10 -6 Within the interval; Sampling and analysis of the chemical composition of molten steel, adjusted according to the weight percentage of the substance to obtain molten steel with C: 0.28%, Si: 0.60%, Mn: 1.20%, Cr: 1.10%, S≤0.030, P≤0.030;

[0044]2) Add nano-sized TiN, the addition amount is 0.34% of the molten steel weight, place it at the bottom of the casting ladle, and use the impact force of the molten steel during tapping to fully stir; Get tooth castings.

[0045] Second, the heat treatment process of the bucket tooth casting: the method is the same as ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com