Steel for bucket teeth of construction machinery and preparation method of bucket teeth

A technology for construction machinery and bucket teeth, applied in the field of low alloy steel, can solve the problems of short service life, poor impact toughness of construction machinery bucket teeth, easy fracture, etc., to improve hardenability, delay crack formation process, and increase surface activity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

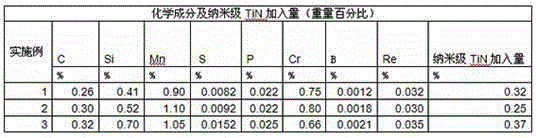

Embodiment 1

[0028] The steps for preparing bucket teeth are as follows:

[0029] First, smelting and casting:

[0030] 1) Melt the cast steel raw materials, add 0.3% ferromanganese and 0.3% ferrosilicon to pre-deoxidize and adjust the composition when the molten steel temperature rises to 1540°C-1560°C, and then take samples to analyze the chemical composition of molten steel, calculated by weight percentage Adjust to obtain molten steel with C: 0.26%, Si: 0.41%, Mn: 0.90%, Cr: 0.75%, S: ≤0.030%, P: ≤0.030%;

[0031] 2) Raise the temperature of molten steel to 1600°C-1620°C and add 0.1% pure aluminum for final deoxidation, and then stand still for 3-5 minutes after power off to remove the slag and tap the steel.

[0032] 3) Add Re-Si rare earth ferrosilicon alloy with Re content of 30%, B-Fe boron iron alloy with B content of 20% and nano-scale TiN composite modifier at the bottom of the ladle; B The mass percentage is 0.0012%, Re-Si rare earth ferrosilicon alloy: 0.032%, nano-scale TiN...

Embodiment 2

[0038] The steps for preparing bucket teeth are as follows:

[0039] First, smelting and casting:

[0040] 1) Melt the cast steel raw materials, add 0.3% ferromanganese and 0.3% ferrosilicon to pre-deoxidize and adjust the composition when the molten steel temperature rises to 1540°C-1560°C, and then take samples to analyze the chemical composition of molten steel, calculated by weight percentage Adjusted to get C: 0.30%, Si: 0.52%, Mn: 1.10%, Cr: 0.80%, S: ≤0.030%, P: ≤0.030%;

[0041] 2) Raise the temperature of the molten steel to 1600°C-1620°C, add 0.1% pure aluminum for final deoxidation, and stand still for 3-5 minutes after power off to remove the slag and tap the steel.

[0042] 3) Add Re-Si rare earth iron-silicon alloy with Re content of 30%, B-Fe boron-iron alloy with 20% B content and nano-scale TiN composite modifier at the bottom of the ladle, which is crushed into small pieces smaller than 10mm in advance, B The mass percentage is 0.0018%, Re-Si rare earth fer...

Embodiment 3

[0045] The steps for preparing bucket teeth are as follows:

[0046] First, smelting and casting:

[0047] 1) Melt the cast steel raw materials, add 0.3% ferromanganese and 0.3% ferrosilicon to pre-deoxidize and adjust the composition when the molten steel temperature rises to 1540°C-1560°C, and then take samples to analyze the chemical composition of molten steel, calculated by weight percentage Adjusted to get C: 0.32%, Si: 0.70%, Mn: 1.05%, Cr: 0.66%, S: ≤0.030%, P: ≤0.030%;

[0048] 2) Raise the temperature of the molten steel to 1600°C-1620°C, add 0.1% pure aluminum for final deoxidation, and stand still for 3-5 minutes after power off to remove the slag and tap the steel.

[0049] 3) Add Re-Si rare earth iron-silicon alloy with Re content of 30%, B-Fe boron-iron alloy with 20% B content and nano-scale TiN composite modifier at the bottom of the ladle, which is crushed into small pieces smaller than 10mm in advance, B The mass percentage is 0.0021%, Re-Si rare earth fer...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| Rockwell hardness | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com