GaN-based light-emitting diode epitaxial wafer, preparation method thereof and light-emitting diode

A technology of light-emitting diodes and epitaxial wafers, applied in the field of light-emitting diodes and GaN-based light-emitting diodes, can solve problems such as large lattice mismatch and energy band changes, unfavorable holes, and affect luminous efficiency, etc., to reduce barrier peaks, Reduces obstruction and improves lattice matching

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

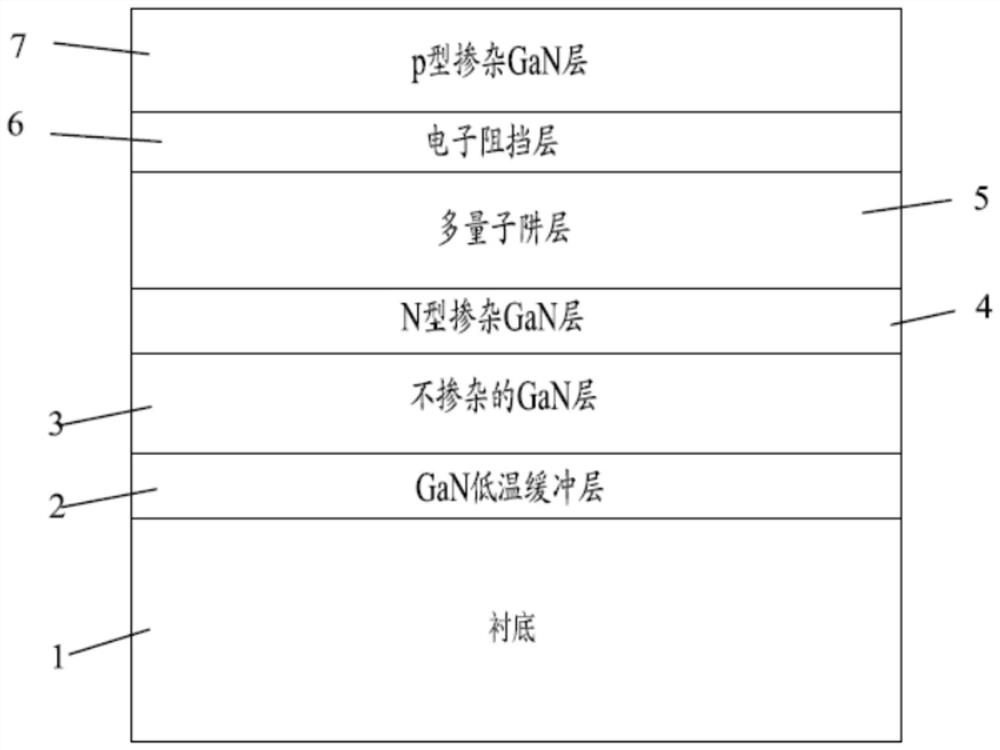

[0034] see figure 1 , shows the GaN-based light-emitting diode epitaxial wafer in the first embodiment of the present invention, including a substrate 1, and a GaN low-temperature buffer layer 2 epitaxially grown on the substrate 1 in turn, an undoped GaN layer 3, and an N-type doped GaN layer. Hetero GaN layer 4 , multiple quantum well layer 5 , electron blocking layer 6 and p-type doped GaN layer 7 .

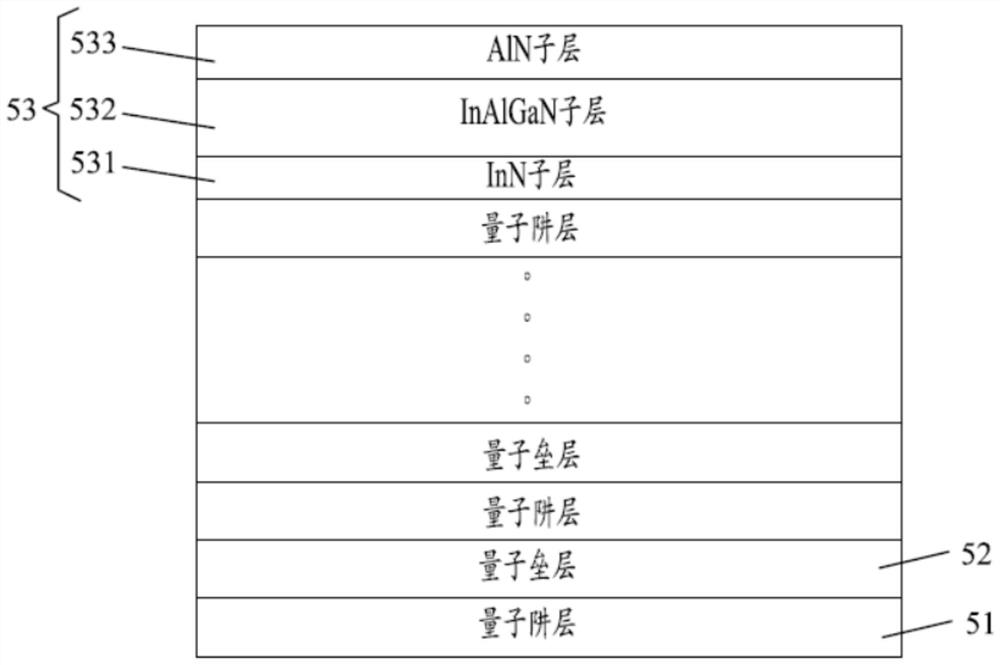

[0035] Among them, such as figure 2 As shown, the multiple quantum well layer 5 is a periodic structure in which a quantum well layer 51 and a quantum barrier layer 52 are alternately grown, and the quantum well layer 51 may be an InGaN quantum well layer specifically, and other quantum barrier layers except the last grown quantum barrier layer The layer 52 may specifically be a GaN quantum barrier layer or an InAlGaN quantum barrier layer. In this embodiment, the last grown quantum barrier layer is specifically a composite quantum barrier layer 53 , and the composite quant...

Embodiment 2

[0040] The second embodiment of the present invention provides a method for preparing a GaN-based light-emitting diode epitaxial wafer, which is used to prepare the GaN-based light-emitting diode epitaxial wafer in the first embodiment. The method specifically includes steps S21 to S28, wherein:

[0041] Step S21, providing a substrate required for epitaxial growth, preferably a sapphire substrate.

[0042] Specifically, the temperature of the reaction chamber is controlled to be 1050-1200° C., the substrate is subjected to high-temperature treatment for about 3-6 minutes in a hydrogen atmosphere, and the substrate sheet is cleaned at high temperature to reduce impurities.

[0043] In step S22, a GaN low temperature buffer layer is grown on the sapphire substrate, the growth temperature is 500°C to 700°C, and the growth pressure is 200 to 400 Torr.

[0044] Exemplarily, the growth thickness of the GaN low temperature buffer layer may be 10-30 nm.

[0045] Step S23 , growing a...

Embodiment 3

[0058] The third embodiment of the present invention provides a light-emitting diode, including the GaN-based light-emitting diode epitaxial wafer in the above-mentioned first embodiment, and the GaN-based light-emitting diode epitaxial wafer can be prepared by the preparation method of the GaN-based light-emitting diode epitaxial wafer in the above-mentioned second embodiment. Epitaxial growth is obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com