Patents

Literature

34results about How to "Reduce the difficulty of dispersion" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

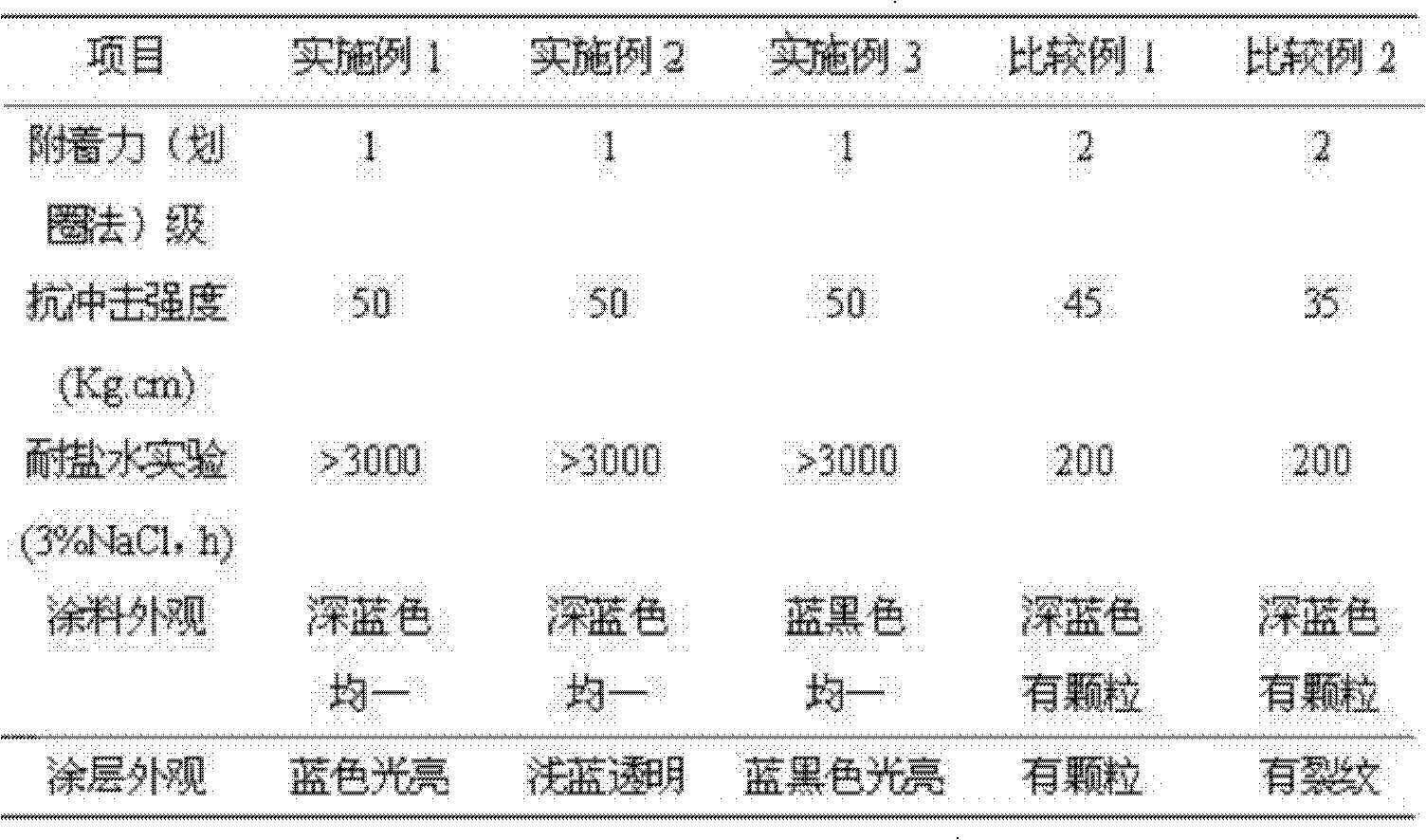

Polyaniline epoxy anti-corrosive paint and preparation method thereof

ActiveCN102101962AImprove mechanical propertiesImprove aging resistanceAnti-corrosive paintsEpoxy resin coatingsIsobutanolXylylene

The invention discloses a polyaniline epoxy anti-corrosive paint and a preparation method thereof. The polyaniline epoxy anti-corrosive paint comprises a component A and a component B, wherein the component A comprises the following ingredients in percentage by mass: 40-60% of epoxy resin, 35-45% of mixed solvent and 5-15% of polyaniline / attapulgite nano composite material; and the component B comprises the following ingredients in percentage by mass: 30-60% of amine curing agent and 40-70% of anhydrous alcohol. The preparation method comprises the following steps: mixing phenylmethane or xylene with n-butyl alcohol, isobutanol or tert-butyl alcohol to obtain a mixed solvent, and mixing the component A and the component B in the weight ratio of 1:(0.5-1.2) for 0.5-1 hour. The mechanical properties, ageing resistance and corrosion resistance of the whole paint system are obviously enhanced, so that the metal surface is passivated to form a compact and stable oxide film, thereby preventing the metal from being further oxidized.

Owner:溧阳常大技术转移中心有限公司

Ecological environment-friendly sepiolite functional wall material and preparation method thereof

The invention discloses an ecological environment-friendly sepiolite functional wall material. The wall material is prepared from the following raw materials in parts by weight: 5-35 parts of sepiolite, 0.1-5.0 parts of surfactant, 10-50 parts of inorganic mineral filler, 5-40 parts of a gelling material, 0.5-5.0 parts of functional additives, 0.5-5.0 parts of an antimildew antibacterial material,5-25 parts of titanium dioxide, 0.1-5.0 parts of pigment and 0.2-5.0 parts of cellulose. The preparation method comprises the following steps: (1) preparing an aqueous solution having a concentrationof 1 percent from the surfactant, stirring the high-purity sepiolite in an electrical heating variable-frequency dispersing machine, completely and uniformly spraying the aqueous solution to the surface of the sepiolite, increasing the temperature in a tank, drying until the moisture is lower than 5 percent, and filtering through a 120-mesh vibrating screen to obtain modified sepiolite; (2) stirring the functional additives, antimildew antibacterial material, titanium dioxide, pigment and cellulose into a high-speed mixer, and stirring the modified sepiolite, inorganic mineral filler, gellingmaterial and surfactant in a stirring container; and (3) adding clear water into a drum in 0.9 time mass of the powder, pouring the wall material powder into the water, and dispersing the powder withthe high-speed stirrer into paste. The ecological environment-friendly sepiolite functional wall material has high adsorption capacity on harmful gases.

Owner:湘潭海泡石科技有限公司

Conductive paste for PERC solar cell, preparation method and application thereof

InactiveCN106448806ALow toxicityReduce corrosionNon-conductive material with dispersed conductive materialPhotovoltaic energy generationConductive pasteOrganic solvent

The invention provides a preparation method of a conductive paste for a PERC solar cell and application thereof. An aluminum-silicon mixed conductive paste containing doping elements according to the present invention comprises 60 to 85 percent of aluminum powder, 5 to 25 percent of doped silicon nanoparticles, 0.1 to 5 percent of inorganic binder and 15 to 35% of organic carriers, wherein the organic carriers are mainly composed of an organic solvent, a thickening agent and a plasticizer. Compared with existing aluminum conductive paste products, the conductive paste for the PERC solar cell of the invention is printed on the back of the a battery sheet, and in a cell sintering process, on one hand, back holes can be reduced to promote the formation of a silicon aluminum alloy layer and reduce contact resistance; on the other hand, the back field doping concentration and the junction depth can be increased, and the composite rate on the back surface can be reduced in order to improve the PERC cell photoelectric conversion efficiency.

Owner:YANCHENG INST OF TECH

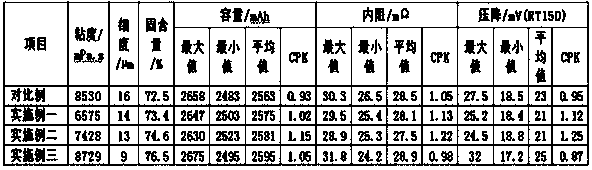

Lithium ion battery and positive electrode slurry stirring method therefor

InactiveCN110165146AImprove production pass rateHigh product consistencyCell electrodesTransportation and packagingDispersityManganate

The invention provides a lithium ion battery and a positive electrode slurry stirring method therefor, and belongs to the technical field of lithium ion batteries. The positive plate of the lithium battery comprises a positive current collector and positive slurry coated on the positive current collector, wherein the positive electrode slurry contains a positive electrode active substance, a conductive agent and a binder; the positive electrode active substance is a mixture of lithium nickel cobalt manganate, lithium iron phosphate and lithium manganite; a mixer circulating water temperature control regulating system comprises a temperature frequency conversion regulating switch and a circulating water heating system in the stirring process of the positive electrode slurry of the lithium ion battery, and the circulating water temperature of the circulating water heating system is set to be 45-75 DEG C. The dispersity of the lithium battery positive electrode slurry is improved, the stirring time is shortened, the production qualification rate and the consistency of the lithium batteries are improved, and the lithium battery positive electrode slurry has higher convenience and operability and economic and practical values.

Owner:HENAN FUSEN NEW ENERGY TECH

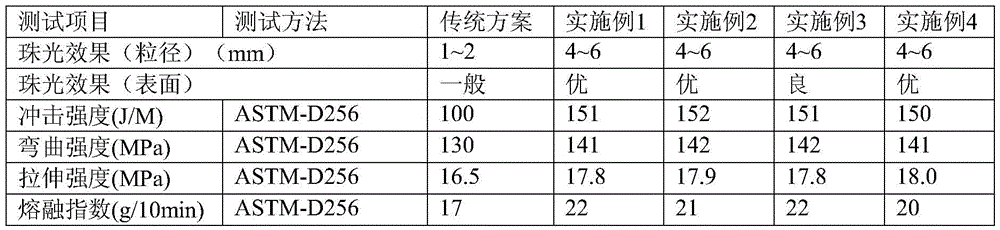

Novel pearly-luster ABS material and processing method

InactiveCN105482352AGood pearlescent effectImprove mechanical propertiesAntioxidantMechanical property

The invention discloses a novel pearly-luster ABS material. The novel pearly-luster ABS material is prepared from, by weight, 70-85% of ABS resin, 5-10% of pearlescent pigment particles, 5-10% of compatilizer, 0.5-1% of lubricant, 0.2-0.5% of antioxidant and 3-5% of flexibilizer. The components are evenly mixed in a high-speed mixer and a low-speed mixer, and are molten through a single screw extruder for extrusion and granulation. The pearly-luster ABS material produced through the processing method has a good pearly luster effect, and the mechanical performance is greatly improved compared with the prior art.

Owner:厦门美佳美新材料科技有限公司

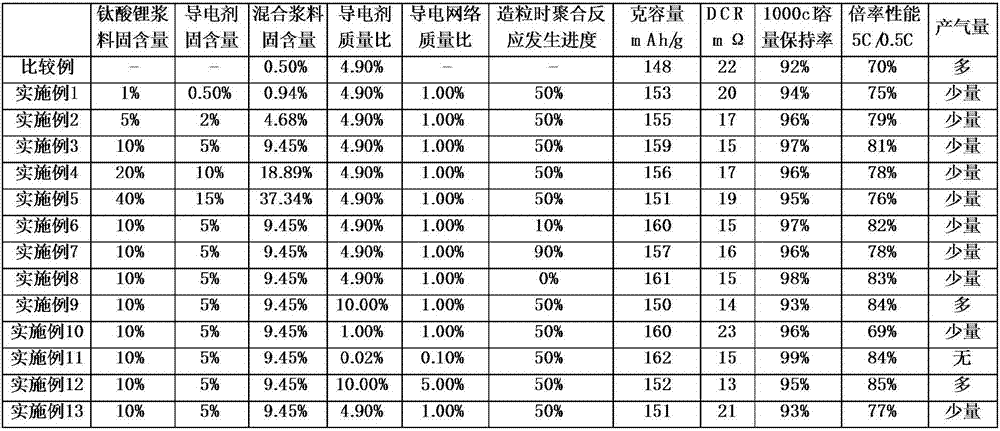

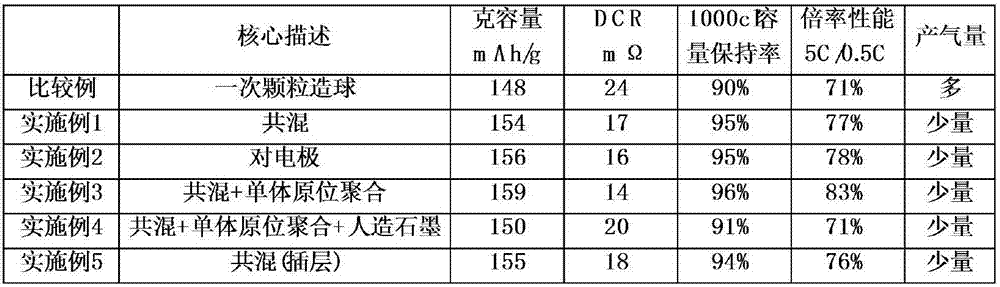

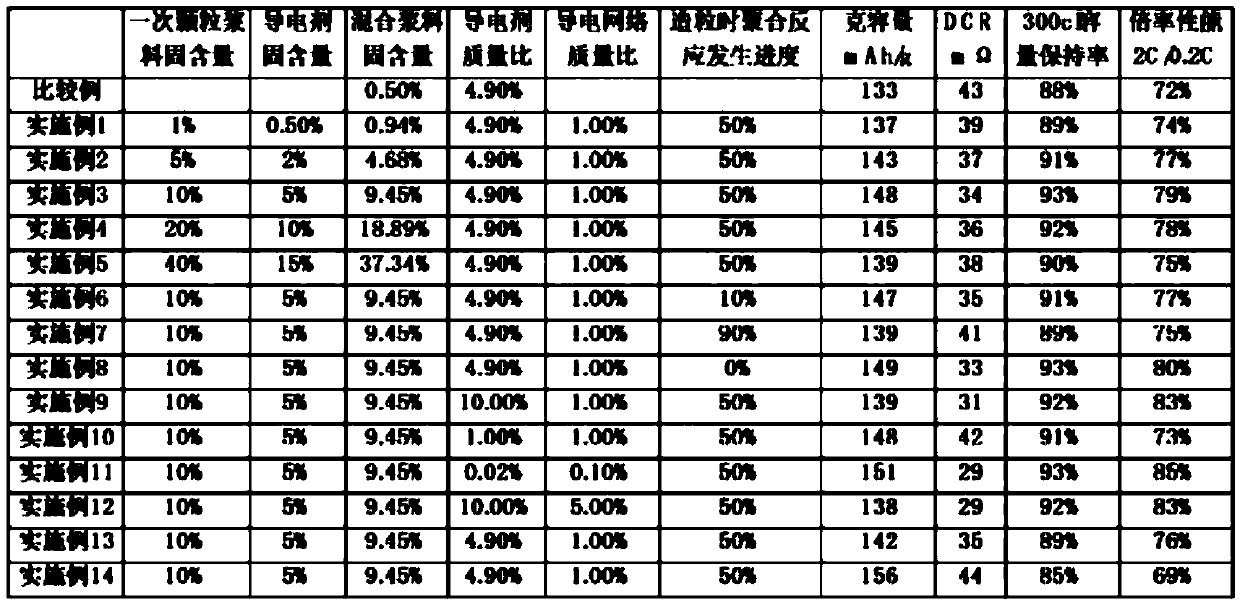

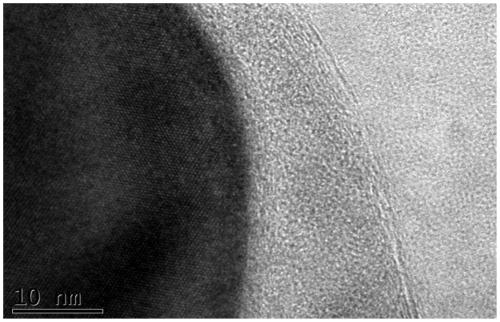

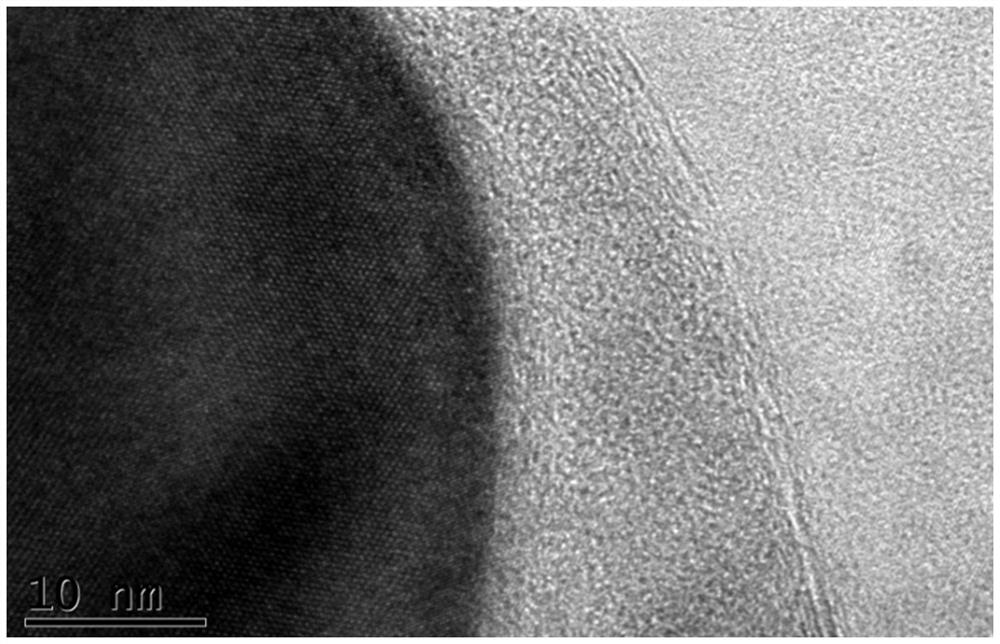

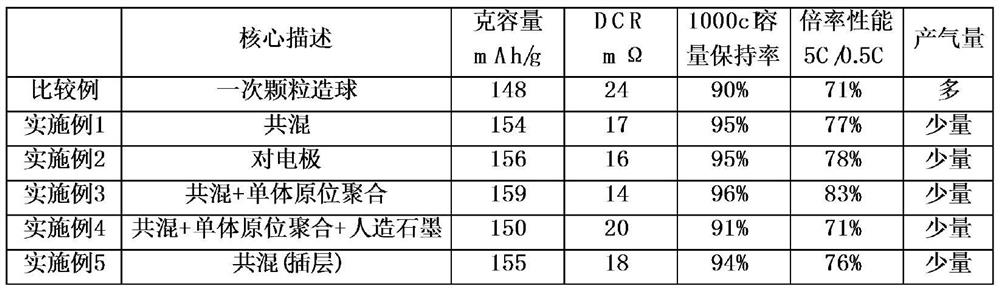

Silicon-carbon negative electrode material and preparation method therefor

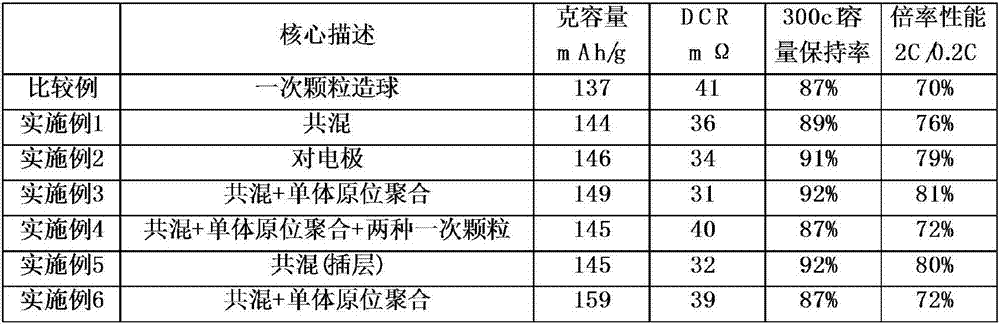

ActiveCN107069016AEvenly dispersedReduce the difficulty of dispersionCell electrodesSecondary granulePrimary granule

The invention belongs to the field of energy storage research, and particularly relates to a silicon-carbon negative electrode material. The silicon-carbon negative electrode material comprises a core structure and a shell structure; the core structure comprises a secondary granule structure which is formed by performing tight stacking after nanometer primary granules are uniformly dispersed in a conductive agent; the nanometer primary granules comprise nanometer silicon-based granules; a conductive network is distributed between the nanometer silicon-based granules, between the conductive agents, and between the nanometer silicon-based granules and the conductive agents; and the conductive network is tightly connected with the nanometer silicon-based granules and the conductive agents, thereby ensuring the excellent electrochemical performance of the silicon-carbon negative electrode material.

Owner:GUANGDONG ZHUGUANG NEW ENERGY TECH

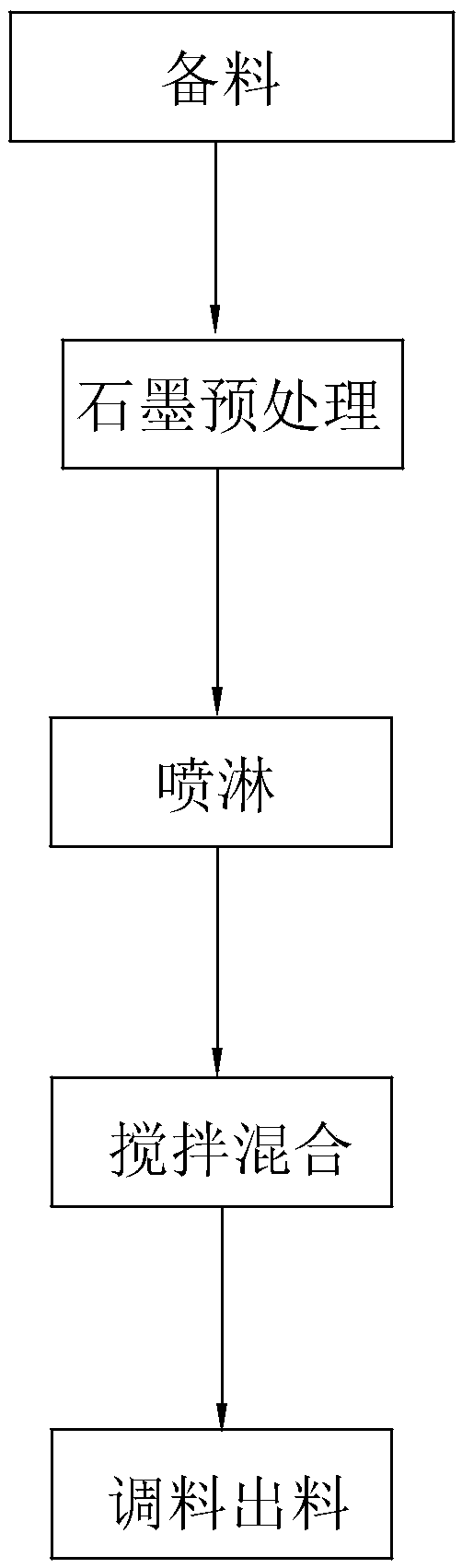

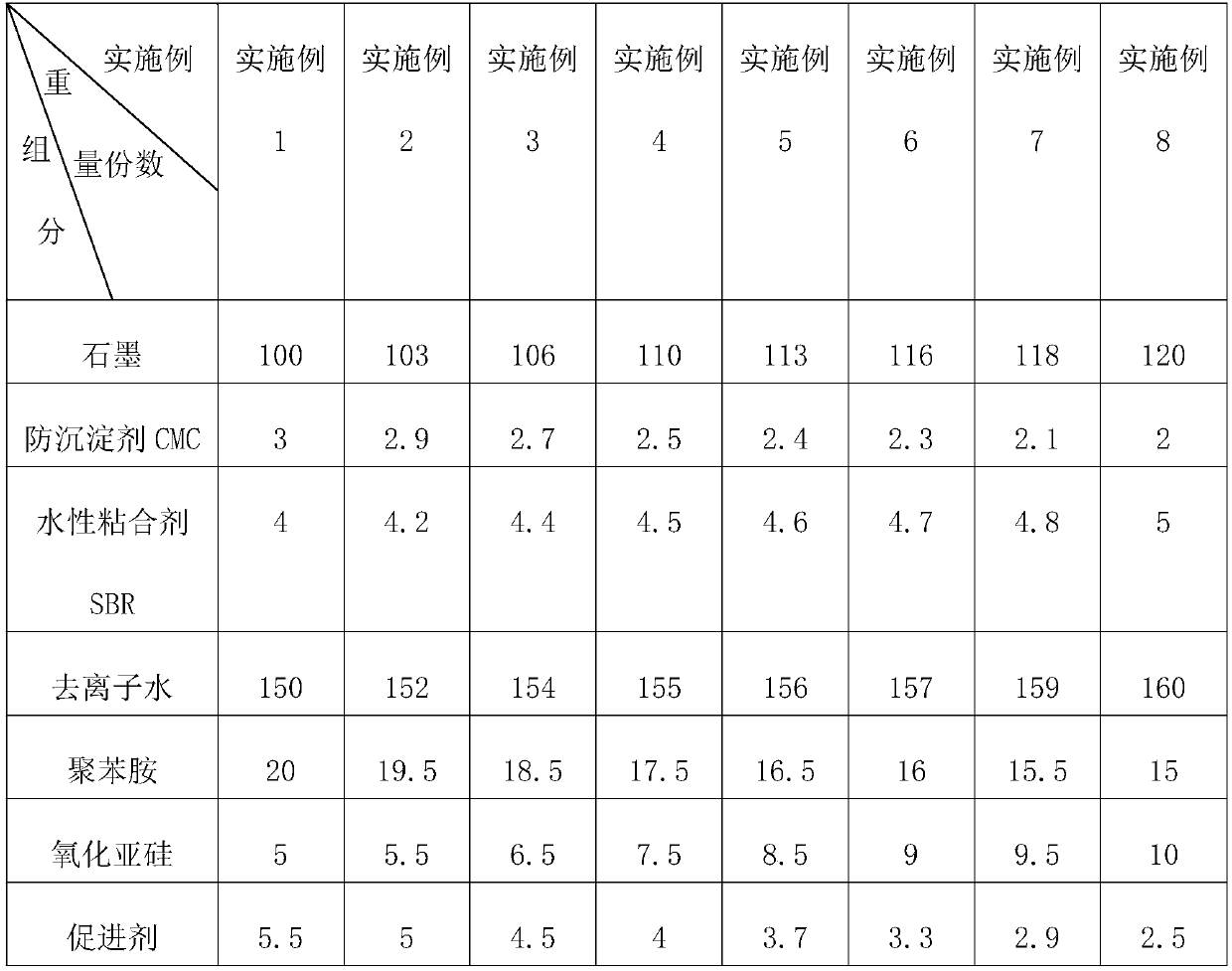

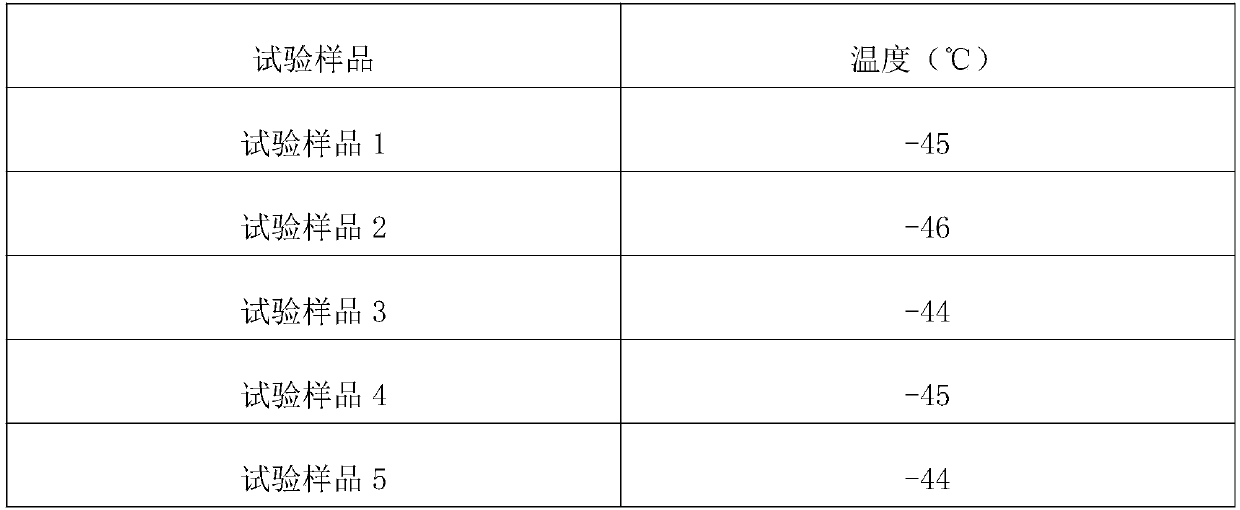

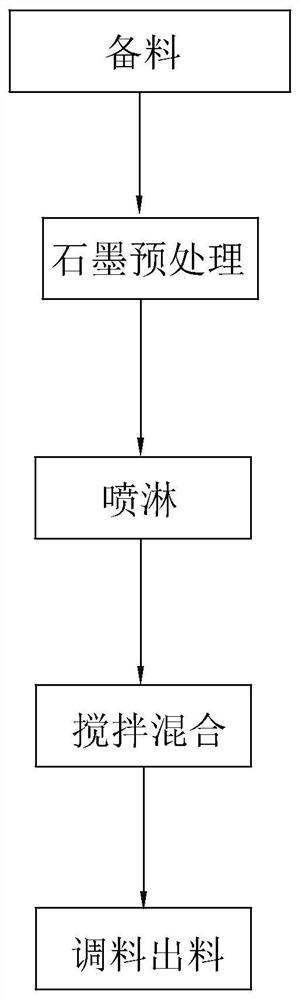

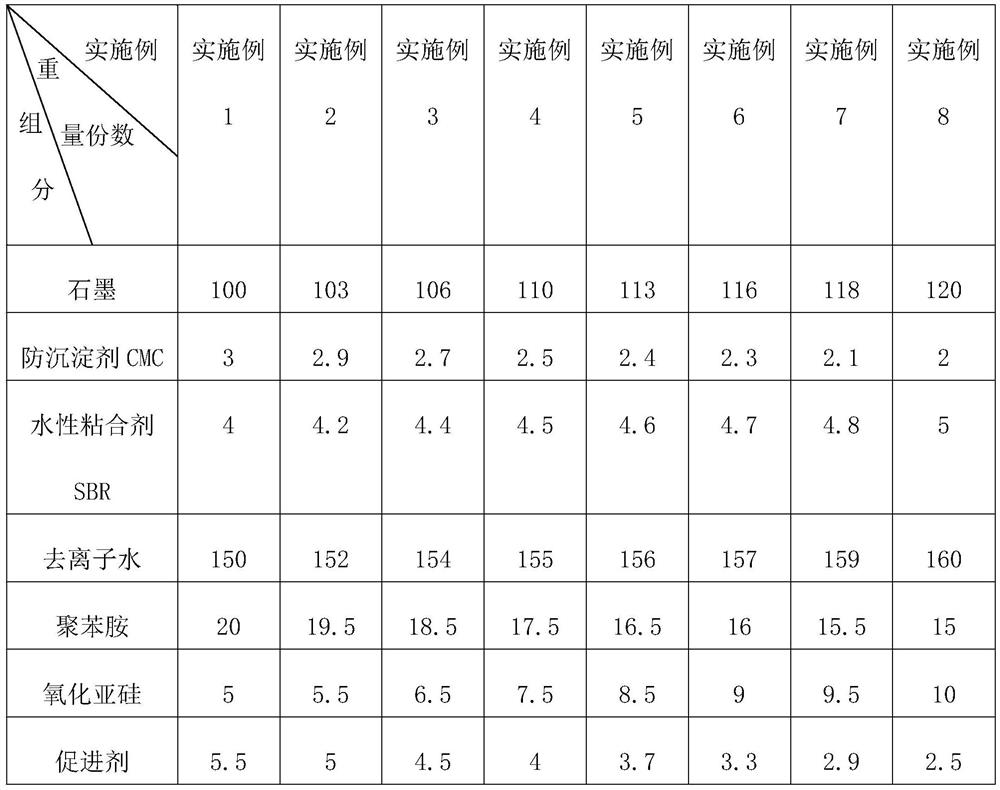

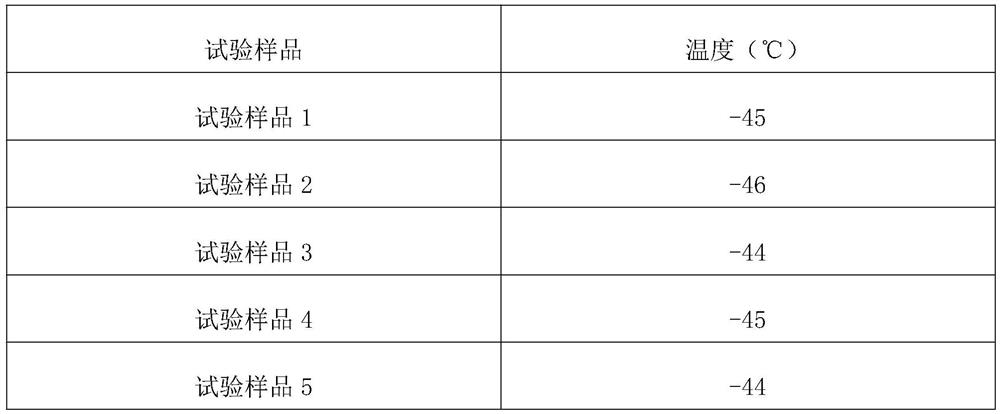

Method for preparing ultralow-temperature lithium ion battery anode slurry

ActiveCN111224072AImprove wettabilityUniform adhesionCell electrodesSecondary cellsPhysical chemistryGraphite

The invention discloses a method for preparing ultralow-temperature lithium ion battery anode slurry, relates to the technical field of lithium ion batteries, and solves the problem that the whole battery cannot normally operate in a low-temperature environment due to poor low-temperature resistance of a lithium ion battery anode. The process comprises the following steps: preparing materials, pretreating graphite, spraying, stirring and mixing, and discharging seasonings, wherein the raw materials mainly comprise graphite, an anti-settling agent CMC, a water-based adhesive SBR, deionized water, polyaniline, silicon monoxide and an accelerant. The ultralow-temperature lithium ion battery anode slurry prepared by the invention has good low-temperature resistance in the use process, and is beneficial to keeping the whole battery to normally operate.

Owner:深圳市三奇科技有限公司

Lithium titanate negative electrode material and preparation method thereof

ActiveCN107275598AEvenly dispersedReduce the difficulty of dispersionMaterial nanotechnologyCell electrodesNanoparticleEnergy storage

The invention belongs to the field of energy storage researches and in particular relates to a lithium titanate negative electrode material. The lithium titanate negative electrode material comprises a core structure and a shell structure, wherein the core structure has a secondary particle structure formed by uniformly dispersing primary nanoparticles into conducting agents and tightly stacking; the primary nanoparticles comprise lithium titanate nanoparticles; conducting networks are distributed among the lithium titanate nanoparticles, among the conducting agents and between the lithium titanate nanoparticles and the conducting agents; the conducting networks are tightly connected with the lithium titanate nanoparticles and the conducting agents, so that the lithium titanate negative electrode material has good electrochemical performance.

Owner:GUANGDONG ZHUGUANG NEW ENERGY TECH

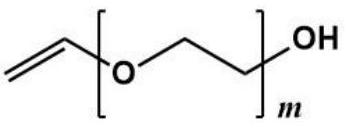

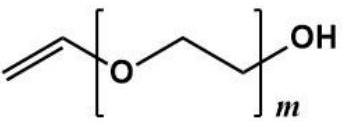

Preparation method of amphiphilic graphene type oil displacement material

ActiveCN113248669AReduce the difficulty of dispersionImprove stabilityDrilling compositionGraft reactionBis epoxide

The invention relates to a preparation method of an amphiphilic graphene type oil displacement material, and belongs to the technical field of oilfield chemistry. The preparation method comprises the following steps: carrying out asymmetric modification on nano graphene oxide by utilizing an interface reaction method to prepare a Janus amphiphilic nano graphene material; wherein the hydrophobic side modification is realized by utilizing reaction of long-chain organic amine and epoxy groups on the surface of the graphene oxide, and the hydrophilic side modification is realized by utilizing cerium salt as an initiator and a compound containing a polyoxyethylene chain segment as a monomer through a grafting reaction on the surface of the graphene oxide. The nano graphene oil displacement material has the advantages of small dispersion difficulty, good salt and temperature resistance, excellent long-term dispersion stability, small dosage, good oil displacement effect and the like, and can be used as a high-temperature and high-salt oil reservoir oil displacement agent.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

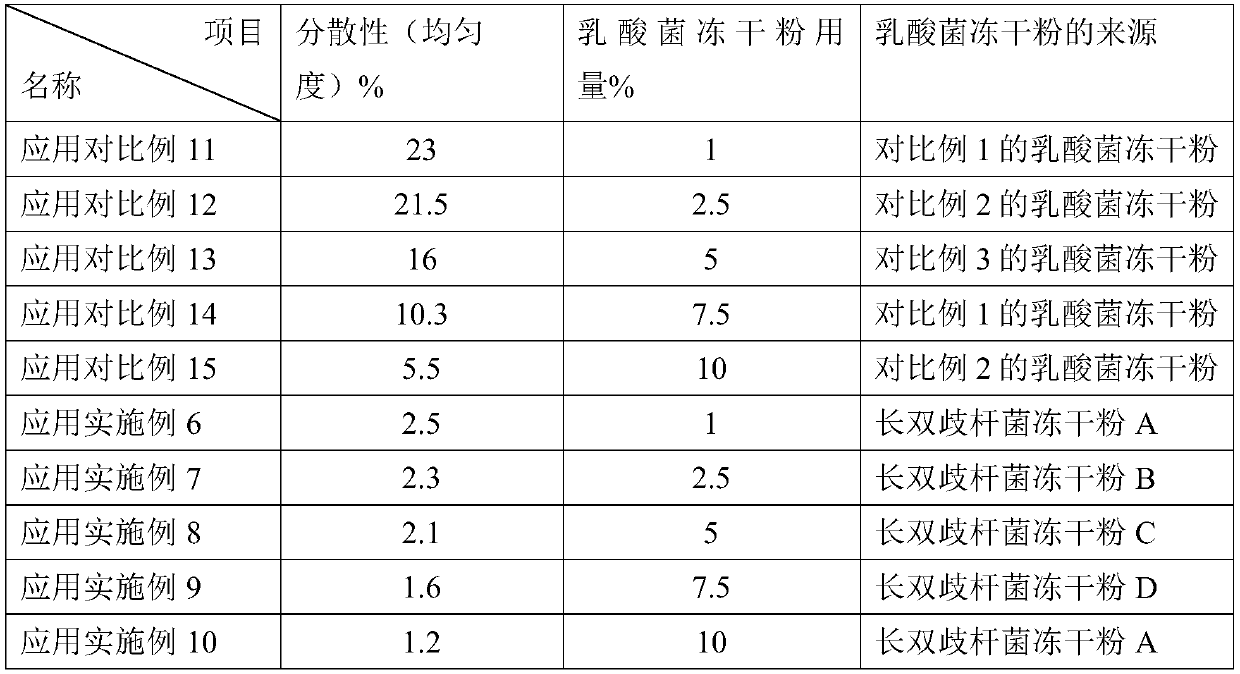

Bifidobacterium longum BL986, freeze-dried powder prepared from same and application of freeze-dried powder

InactiveCN111187734AHigh activityNo additional ingredientsFood freezingSugar food ingredientsBiotechnologyMicrobiological culture

The invention discloses a bifidobacterium longum BL986, freeze-dried powder prepared from the same and application of the freeze-dried powder. The bifidobacterium longum BL986 was submitted to the China General Microbiological Culture Collection Center (CGMCC) on October 28, 2019 for preservation with the preservation number CGMCC No.18743. When the bifidobacterium longum BL986 is used to preparelactic acid bacteria freeze-dried powder and the prepared lactic acid bacteria freeze-dried powder is used to prepare chocolate, the dispersibility is good, the uniformity is high, and the product quality is greatly improved.

Owner:SYNBIOTECH BIOTECHNOLOGY YANGZHOU CO LTD

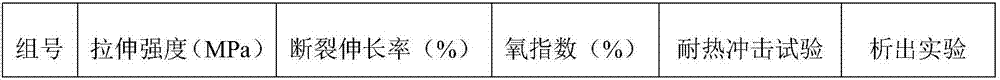

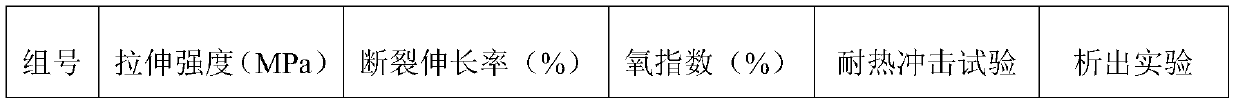

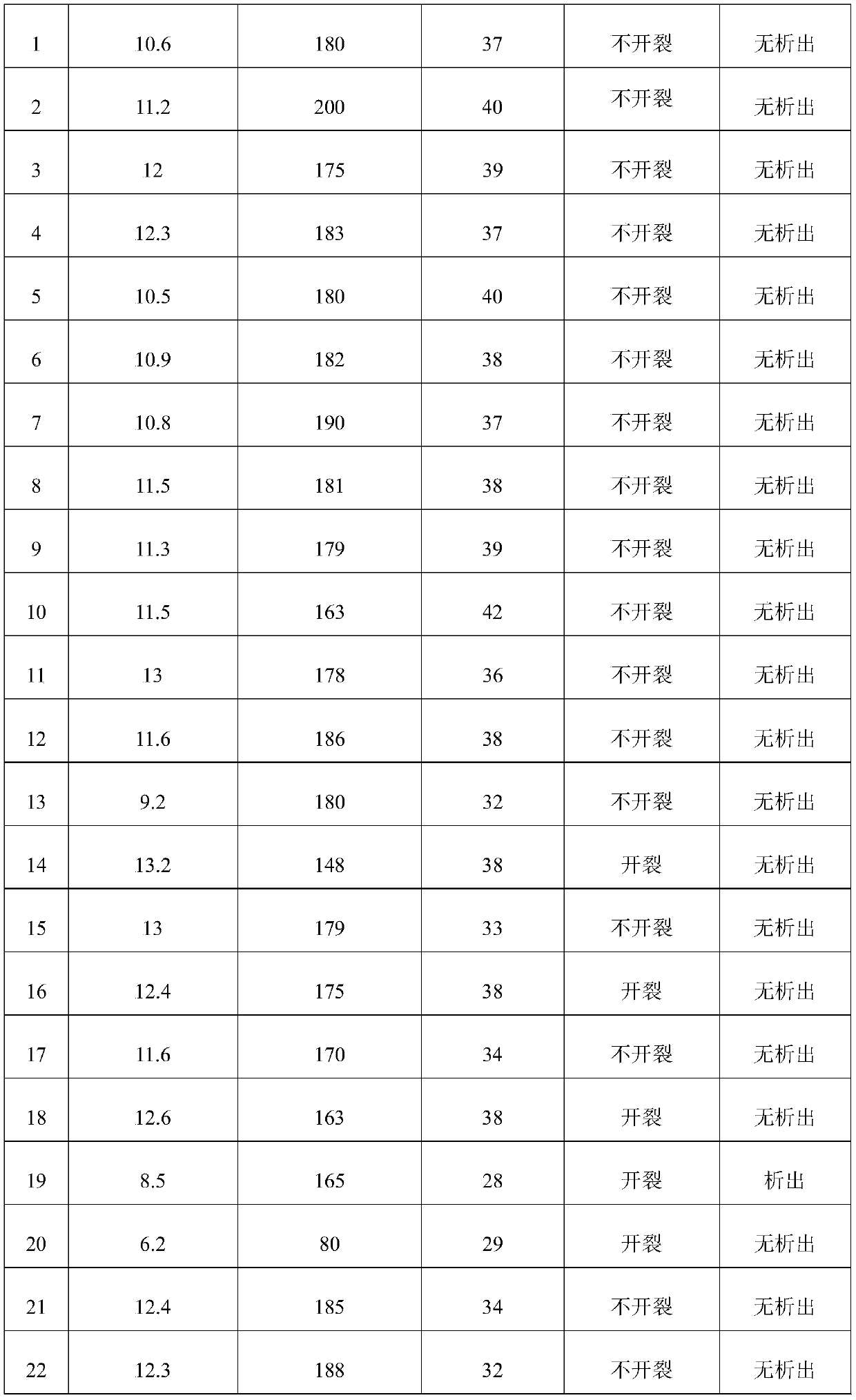

Low-smoke halogen-free flame-retardant polyolefin cable material and preparation method thereof

ActiveCN108003444AImprove flame retardant performanceImprove mechanical propertiesPlastic/resin/waxes insulatorsElastomerPolymer science

The invention belongs to the technical field of chemical materials, and provides a low-smoke halogen-free flame-retardant polyolefin cable material and a preparation method thereof. The cable materialis prepared from, by weight, 17-39 parts of ethylene-vinyl acetate copolymer, 5-10 parts of elastomer, 55-65 parts of magnesium hydroxide, 0.5-5 parts of polyphosphazene and 0.5-2 parts of maleic anhydride grafted polypheylene ether (PPE-MAH); the problem that in the prior art, the cable material with the high oxygen index and high mechanical property is difficult to obtain is solved. The preparation method comprises the steps that 1, the ethylene-vinyl acetate copolymer, the elastomer, the magnesium hydroxide, the polyphosphazene, the PPE-MAH and a processing agent are mixed according to theweight parts, mechanical stirring is conducted, and a mixture is obtained; 2, the mixture is extruded and diced, and the low-smoke halogen-free flame-retardant polyolefin cable material is obtained;the preparation method is scientific, reasonable and simple in design, easy to operate and capable of achieving large-scale industrial production.

Owner:SICHUAN UNFIRE POLYMER MATERIALS TECH

Polyaniline epoxy anti-corrosive paint and preparation method thereof

ActiveCN102101962BImprove mechanical propertiesImprove aging resistanceAnti-corrosive paintsEpoxy resin coatingsEpoxyIsobutanol

The invention discloses a polyaniline epoxy anti-corrosive paint and a preparation method thereof. The polyaniline epoxy anti-corrosive paint comprises a component A and a component B, wherein the component A comprises the following ingredients in percentage by mass: 40-60% of epoxy resin, 35-45% of mixed solvent and 5-15% of polyaniline / attapulgite nano composite material; and the component B comprises the following ingredients in percentage by mass: 30-60% of amine curing agent and 40-70% of anhydrous alcohol. The preparation method comprises the following steps: mixing phenylmethane or xylene with n-butyl alcohol, isobutanol or tert-butyl alcohol to obtain a mixed solvent, and mixing the component A and the component B in the weight ratio of 1:(0.5-1.2) for 0.5-1 hour. The mechanical properties, ageing resistance and corrosion resistance of the whole paint system are obviously enhanced, so that the metal surface is passivated to form a compact and stable oxide film, thereby preventing the metal from being further oxidized.

Owner:溧阳常大技术转移中心有限公司

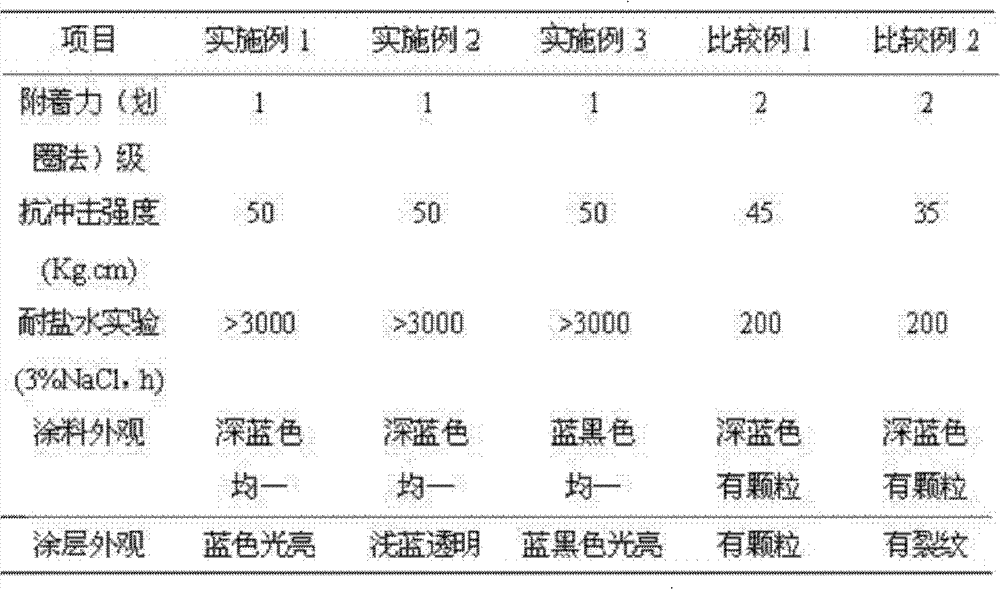

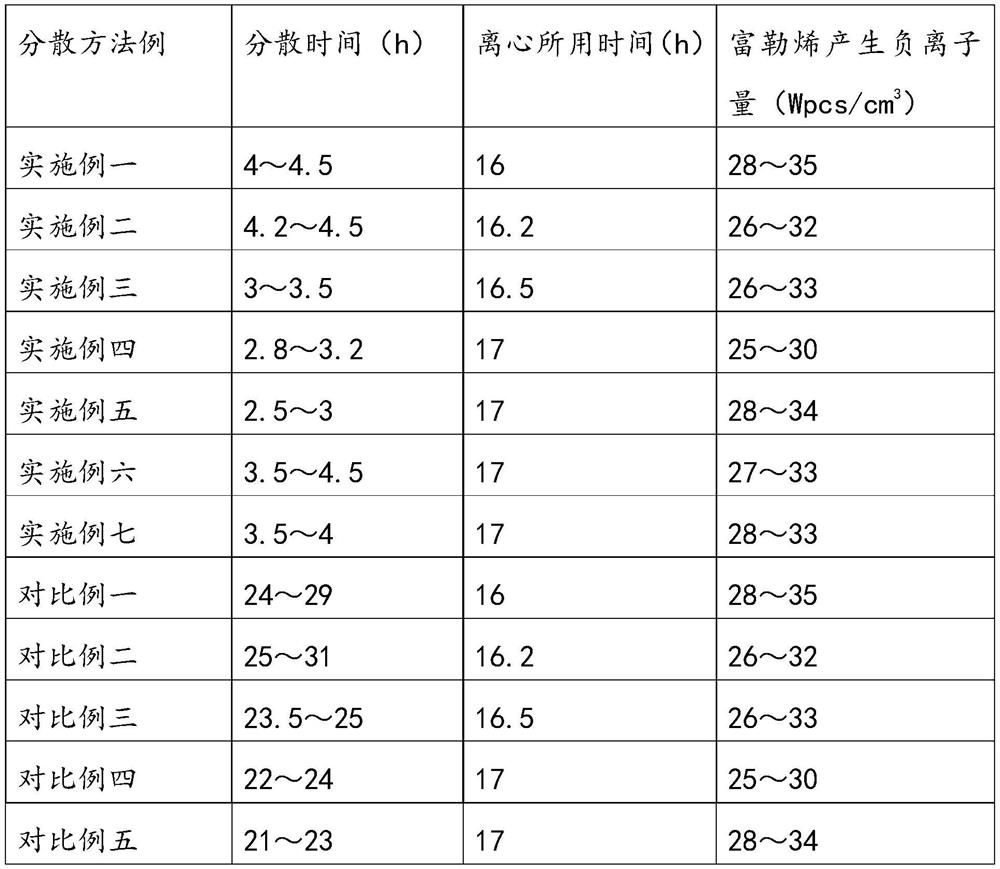

Dispersion method of nano material

PendingCN111821874AImprove dispersion efficiencyGood dispersionTransportation and packagingMixing methodsActive agentOxygen ions

The invention provides a dispersion method of a nano material. The method comprises the following steps: mixing a nano material with a surfactant to obtain a first mixture; mechanically dispersing thefirst mixture in a first negative oxygen ion environment to obtain a first dispersion; and in a second negative oxygen ion environment, carrying out ultrasonic dispersion on the first dispersion to obtain a second dispersion. According to the invention, the dispersion method belongs to a physical dispersion method, is rapid, safe and efficient, avoids the problem that other components are added in a chemical dispersion method to influence the nano material, and does not influence the function exertion of each component and the overall performance of the composite material; and mechanical dispersion and ultrasonic dispersion are adopted at the same time, and negative oxygen ions are added in different stages in a dispersion process to form a negative oxygen ion environment, so that the dispersion efficiency is improved, the dispersion difficulty is reduced, the dispersion effect is improved, and the preparation time cost is remarkably saved.

Owner:鸿翌科技有限公司

Preparation method of lithium titanate negative electrode material and lithium titanate negative electrode material prepared by employing method

ActiveCN107316993AImprove electrochemical performanceFully filledCell electrodesSecondary cellsCarbonizationGraphite particle

The invention belongs to the field of energy storage research, and particularly relates to a preparation method of a lithium titanate negative electrode material. The method mainly comprises the steps of 1, mixing a power source substance 1, nanometer lithium titanate particles and graphite particles until uniform mixing is achieved; 2, adding an electrolyte 1 and then continuing to mix to form ion passages, stripping the graphite particles under the effect of the power source substance at the moment to form an opening structure of a graphite sheet layer, and continuously filling the opening structure of the graphite sheet layer with the nanometer lithium titanate particles under a hybrid acting force; and 3, removing an electrolyte constituent after filling is completed, and performing coating and carbonization to obtain the lithium titanate negative electrode material. When the method is used for preparing a lithium titanate negative electrode, the opening of the graphite particle sheet layer and the filling of the lithium titanate particles can be simultaneously performed, so that the filling is smoother, and the lithium titanate negative electrode material is enabled to have favorable electrochemical performance.

Owner:GUANGDONG ZHUGUANG NEW ENERGY TECH

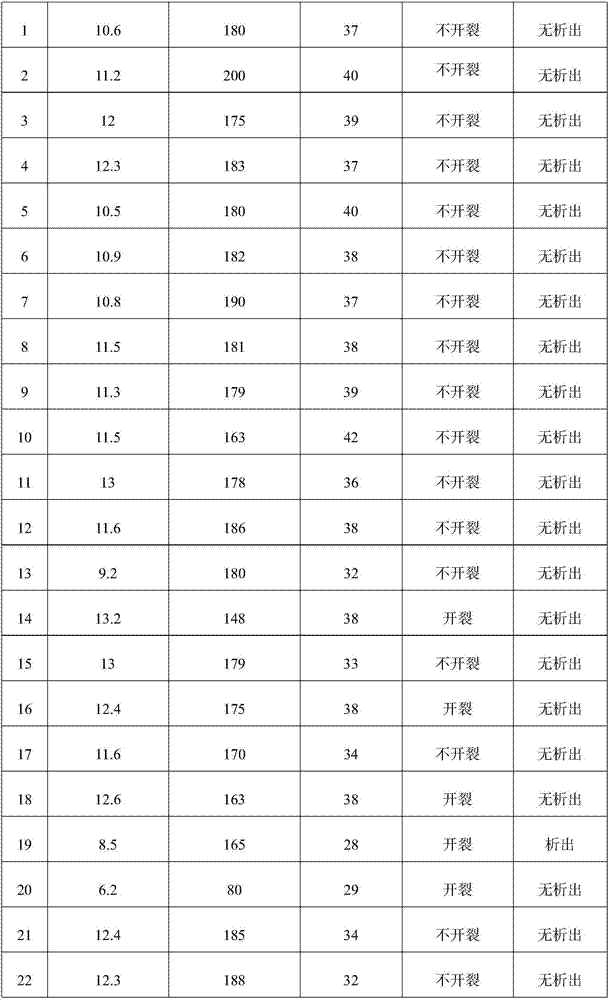

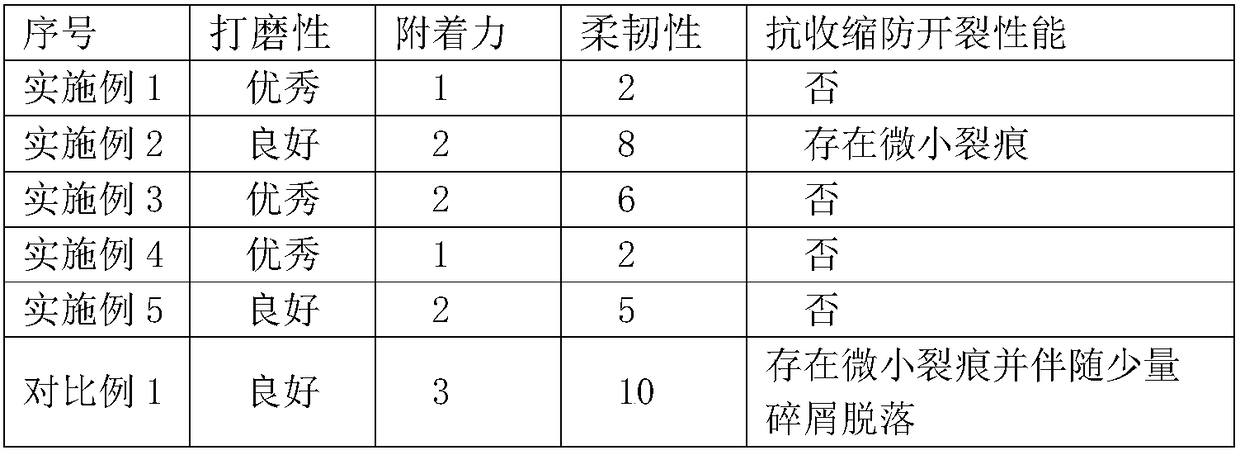

Scrape coating type under coat automobile paint based on thermoplastic acrylic resin and preparation method thereof

The invention discloses scrape coating type under coat automobile paint based on thermoplastic acrylic resin. The paint is prepared from the following ingredients in parts by weight: 38-44 parts of thermoplastic acrylic resin, 20-25 parts of powder, 0.5-1 part of a wetting dispersant BYK-W966, 2-8 parts of pigment and 0.1-0.3 part of a pigment dispersant; xylene is added until the total weight ofa system is 100 parts by weight; the thermoplastic acrylic resin is NeoCryl B-735 solid thermoplastic acrylic resin. The paint disclosed by the invention has the following excellent properties: 1, thescrape coating hand feeling is good; 2, the solid content is high, the viscosity is not high, and the VOC (volatile organic compounds) discharge is reduced; 3, the ductility is consistent with the ductility of finishing coat; 4, the adhesive force with the finishing coat is good; and 5, the viscosity is low in a high-temperature condition and high in a low-temperature condition.

Owner:清远永昌涂料有限公司

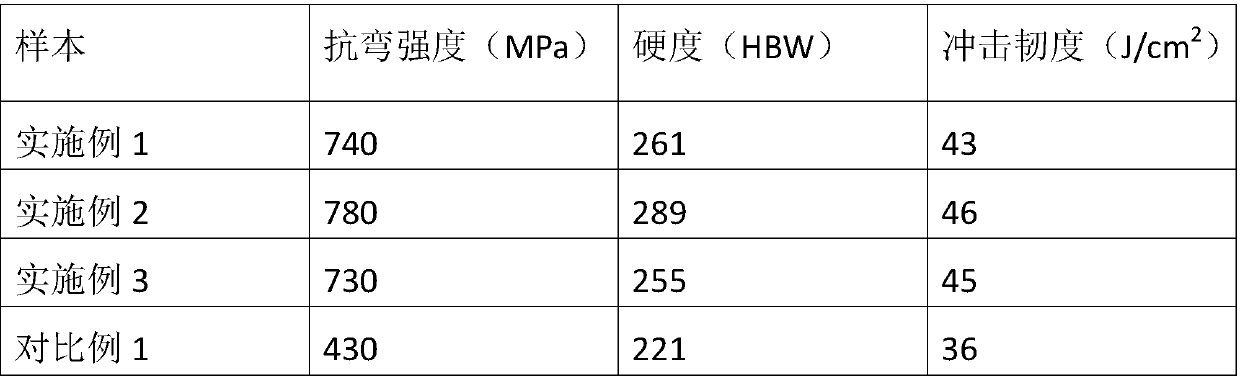

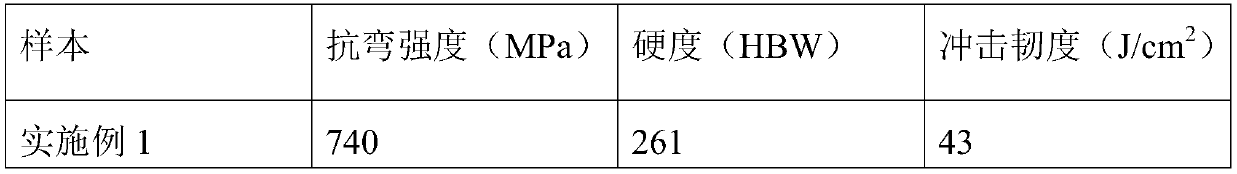

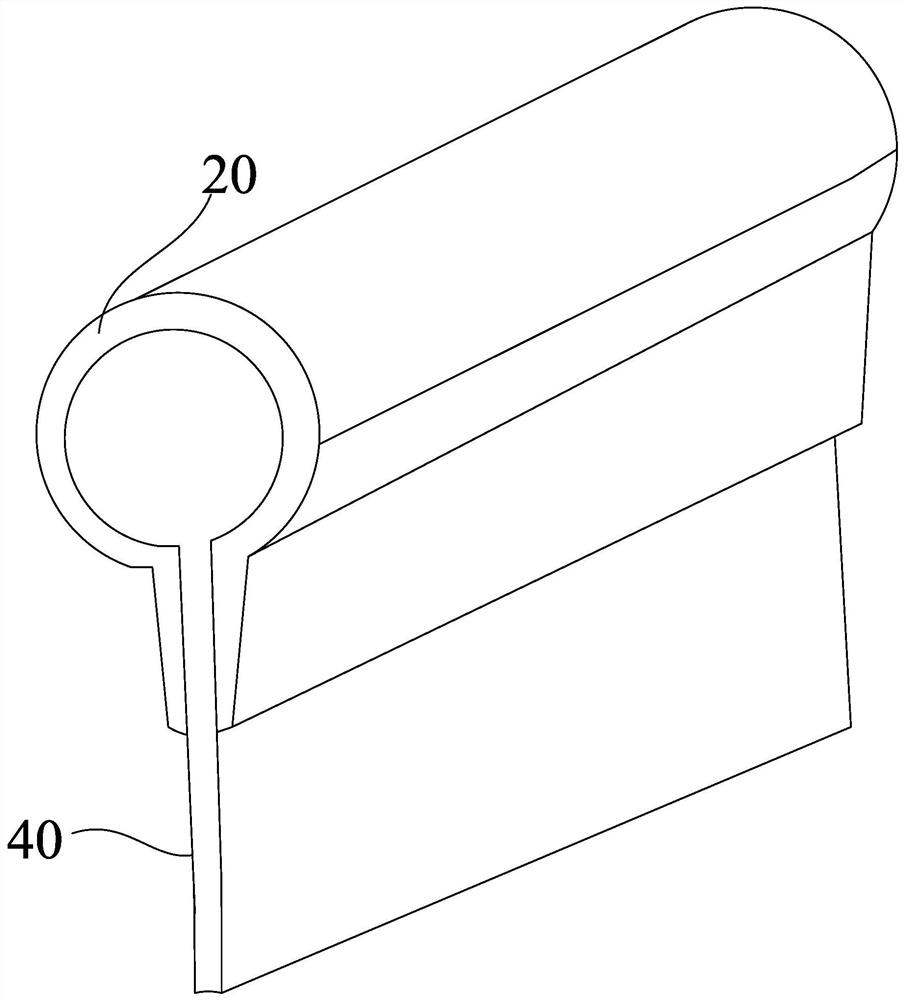

Graphene steel composite material, preparation method and applications thereof

ActiveCN110126378AEvenly distributedReduce the difficulty of dispersionLamination ancillary operationsLaminationPre treatmentCvd graphene

The present invention discloses a graphene steel composite material, which comprises steel layers and graphene layers, wherein the steel layers and the graphene layers are alternately stacked, the uppermost layer and the lowermost layer of the graphene steel composite material in a stacked direction are the steel layers, and the two adjacent steel layers are separated by one graphene layer. The invention further discloses a preparation method of the graphene steel composite material, wherein the preparation method comprises: providing a plurality of steel plates; providing a graphene dispersion liquid, wherein the graphene dispersion liquid comprises a graphene sheet dispersion agent and graphene sheets dispersed in the dispersion liquid; alternately stacking the steel plates and the graphene dispersion liquid to sandwich the graphene dispersion liquid between the two adjacent steel plates to form a sandwich structure, wherein the uppermost layer and the lowermost layer of the sandwichstructure are the steel plates; carrying out pressurizing pre-treatment on the sandwich structure; and sintering the pre-treated sandwich structure at a temperature of 900-1100 DEG C. The invention further discloses applications of the graphene steel composite material.

Owner:北京石墨烯技术研究院有限公司

Preparation method of lithium ion battery positive electrode material and lithium ion battery positive electrode material prepared by employing method

ActiveCN107316994AImprove electrochemical performanceFully filledCell electrodesSecondary cellsPower flowElectrical battery

The invention belongs to the field of energy storage research, and particularly relates to a preparation method of a lithium ion battery positive electrode material. The method mainly comprises the steps of 1, dry-mixing a power source substance 1, nanometer positive primary particles and graphite particles until uniform mixing is achieved; 2, adding an electrolyte 1 and then continuing to mix to form ion passages, stripping the graphite particles under the effect of the power source substance to form an opening structure of a graphite sheet layer, and continuously filling the opening structure of the graphite sheet layer with the nanometer positive primary particles; or 1', uniformly mixing the nanometer positive primary particles, the graphite particles and an electrolyte 2 for use; 2', assembling a power source substance 2 and the product obtained in the step 1' to form paired electrodes, applying a current between the two electrodes, stripping the graphite particles to form the opening structure of the graphite sheet layer, and continuously filling the opening structure of the graphite sheet layer with the nanometer positive primary particles; 3, removing an electrolyte constituent after filling is completed, and performing coating and carbonization to obtain the lithium ion battery positive electrode material. When the method is used for preparing a lithium ion battery positive electrode, the opening of the graphite particle sheet layer and the filling of the nanometer positive primary particles can be simultaneously performed, so that the filling is smoother, and the lithium ion battery positive electrode material is enabled to have favorable electrochemical performance.

Owner:GUANGDONG ZHUGUANG NEW ENERGY TECH

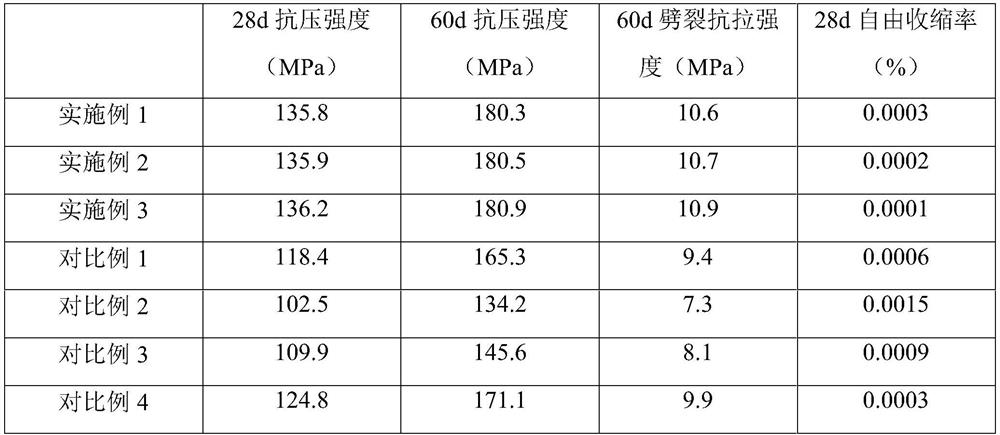

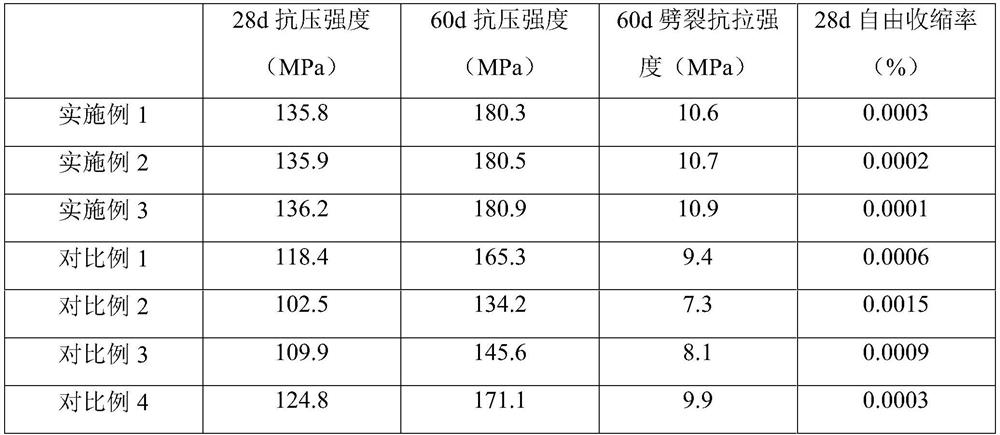

Low-shrinkage high-strength concrete and preparation method thereof

ActiveCN111943603ASmall shrinkageReduce intensityCeramic shaping apparatusConjugated synthetic polymer artificial filamentsFiberAggregate (composite)

The invention relates to low-shrinkage high-strength concrete and a preparation method thereof. The method comprises the following steps: uniformly mixing cement, river sand and petroleum coke powderto obtain a mixed dry material; adding vermiculite powder and mineral powder into water, activating and ball-milling to obtain a premix; pouring the mixed dry material into the premix, uniformly stirring and mixing, adding a fiber gel composite material, light aggregate and an additive, and uniformly stirring to obtain slurry; finally, injecting the slurry into a mold, vibrating, forming and curing to obtain the low-shrinkage high-strength concrete. The high strength and the low shrinkage of the product are guaranteed.

Owner:深圳市利建新材料有限公司

A kind of silicon carbon negative electrode material and preparation method thereof

ActiveCN107069016BEvenly dispersedReduce the difficulty of dispersionCell electrodesNano siliconNanotechnology

The invention belongs to the field of energy storage research, and particularly relates to a silicon-carbon negative electrode material. The silicon-carbon negative electrode material comprises a core structure and a shell structure; the core structure comprises a secondary granule structure which is formed by performing tight stacking after nanometer primary granules are uniformly dispersed in a conductive agent; the nanometer primary granules comprise nanometer silicon-based granules; a conductive network is distributed between the nanometer silicon-based granules, between the conductive agents, and between the nanometer silicon-based granules and the conductive agents; and the conductive network is tightly connected with the nanometer silicon-based granules and the conductive agents, thereby ensuring the excellent electrochemical performance of the silicon-carbon negative electrode material.

Owner:GUANGDONG ZHUGUANG NEW ENERGY TECH

A kind of method of batching negative electrode slurry of ultra-low temperature lithium ion battery

ActiveCN111224072BConducive to stable operationImprove low temperature resistanceCell electrodesSecondary cellsSilicon oxideGraphite

The invention discloses a method for batching ultra-low temperature lithium-ion battery negative electrode slurry, relates to the technical field of lithium-ion batteries, and solves the problem that the lithium-ion battery negative electrode has poor low temperature resistance and causes the whole battery to be in a low-temperature environment. Problems that don't work properly. The process steps include material preparation, graphite pretreatment, spraying, stirring and mixing, and seasoning and discharging. The raw materials mainly include graphite, anti-precipitation agent CMC, water-based binder SBR, deionized water, polyaniline, silicon oxide and accelerators. The ultra-low temperature lithium ion battery negative electrode slurry prepared by the invention has good low temperature resistance performance during use, and is beneficial to keep the battery as a whole in normal operation.

Owner:深圳市三奇科技有限公司

A kind of positive electrode material of lithium ion battery and preparation method thereof

ActiveCN107204461BEvenly dispersedReduce the difficulty of dispersionMaterial nanotechnologyCell electrodesManganeseManganate

The invention belongs to the field of energy storage research, and particularly relates to a positive electrode material for a lithium-ion battery. The positive electrode material for the lithium-ion battery comprises a core structure and a shell structure, wherein the core structure adopts a secondary particle structure formed by uniformly dispersing primary nanoparticles into conductive agents and then densely stacking; the primary nanoparticles comprise at least one of nanometer lithium cobaltate, nanometer lithium manganate, nanometer lithium iron phosphate, nanometer nickel cobalt manganese, nanometer nickel cobalt aluminum, nanometer lithium nickelate, nanometer lithium vanadium oxide and a nanometer lithium-enriched cathode material; in addition, conductive networks are distributed between the primary nanoparticles, between the conductive agents and between the primary nanoparticles and the conductive agents, and the conductive networks are tightly connected with the primary nanoparticles and the conductive agents so as to ensure that the positive electrode material for the lithium-ion battery has excellent electrochemical performance.

Owner:GUANGDONG ZHUGUANG NEW ENERGY TECH

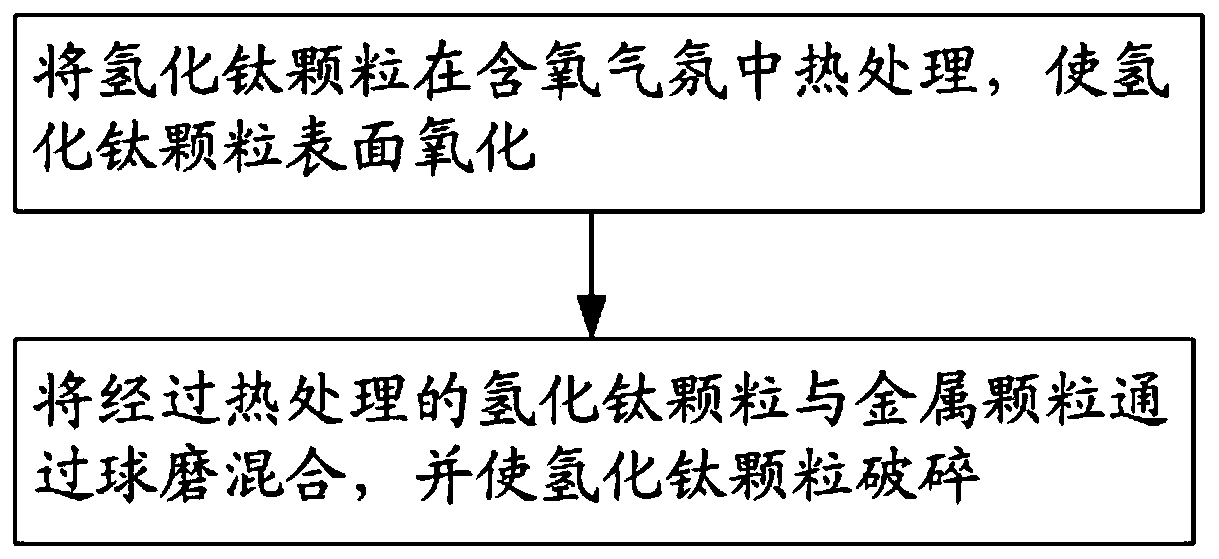

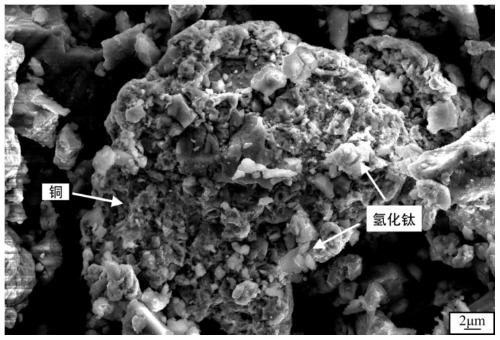

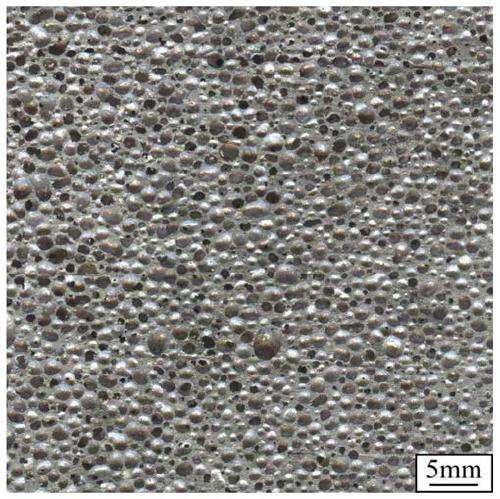

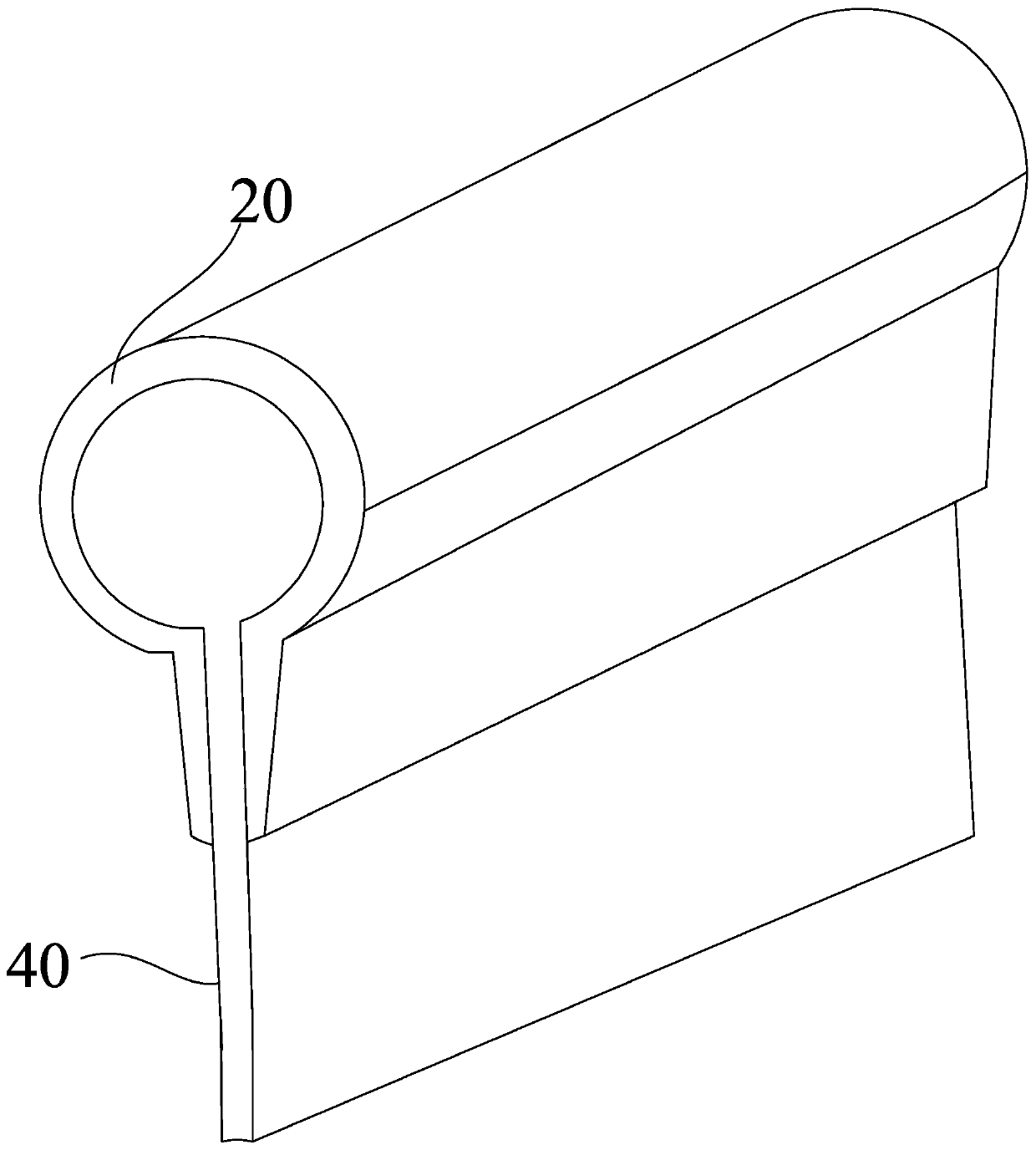

Foaming agent, preparation method thereof, and preparation method of aluminum foam

Owner:TSINGHUA UNIV

Preparation method of graphene ice skate bracket

The invention discloses an ice skate blade support. The ice skate blade support comprises a graphene steel composite sheet; the graphene steel composite sheet comprises steel layers and graphene layers which are alternately arranged in a stacked mode, the uppermost layer and the lowermost layer of the graphene steel composite sheet are steel layers, every two adjacent steel layers are spaced through one graphene layer, and the stacking direction is basically perpendicular to the length direction of the ice skate blade support. The invention further discloses a preparation method of the ice skate blade support. The preparation method comprises the following steps: providing a plurality of steel plates; providing a graphene dispersion liquid; stacking the steel plates and the graphene dispersion liquid alternately, so that the graphene dispersion liquid is clamped between every two adjacent steel plates to form a sandwich structure, and the uppermost layer and the lowermost layer of thesandwich structure are the steel plates; carrying out pressurization pretreatment on the sandwich structure; sintering the sandwich structure subjected to pressurization pretreatment at the temperature of 900-1100 DEG C to form the graphene steel composite sheet; and processing the graphene steel composite sheet into a predetermined shape of the ice skate blade support. The invention further discloses ice skates.

Owner:北京石墨烯技术研究院有限公司

A low-smoke halogen-free flame-retardant polyolefin cable material and its preparation method

ActiveCN108003444BImprove flame retardant performanceImprove mechanical propertiesPlastic/resin/waxes insulatorsElastomerPolymer science

The invention belongs to the technical field of chemical materials, and provides a low-smoke halogen-free flame-retardant polyolefin cable material and a preparation method thereof. The cable materialis prepared from, by weight, 17-39 parts of ethylene-vinyl acetate copolymer, 5-10 parts of elastomer, 55-65 parts of magnesium hydroxide, 0.5-5 parts of polyphosphazene and 0.5-2 parts of maleic anhydride grafted polypheylene ether (PPE-MAH); the problem that in the prior art, the cable material with the high oxygen index and high mechanical property is difficult to obtain is solved. The preparation method comprises the steps that 1, the ethylene-vinyl acetate copolymer, the elastomer, the magnesium hydroxide, the polyphosphazene, the PPE-MAH and a processing agent are mixed according to theweight parts, mechanical stirring is conducted, and a mixture is obtained; 2, the mixture is extruded and diced, and the low-smoke halogen-free flame-retardant polyolefin cable material is obtained;the preparation method is scientific, reasonable and simple in design, easy to operate and capable of achieving large-scale industrial production.

Owner:SICHUAN UNFIRE POLYMER MATERIALS TECH

A kind of scratch-coating type mid-coat automotive coating based on thermoplastic acrylic resin and preparation method thereof

Owner:清远永昌涂料有限公司

Graphene steel composite material, preparation method and application thereof

ActiveCN110126378BEvenly distributedReduce the difficulty of dispersionLamination ancillary operationsLaminationGraphene flakeGraphite

The present invention discloses a graphene steel composite material, which comprises steel layers and graphene layers, wherein the steel layers and the graphene layers are alternately stacked, the uppermost layer and the lowermost layer of the graphene steel composite material in a stacked direction are the steel layers, and the two adjacent steel layers are separated by one graphene layer. The invention further discloses a preparation method of the graphene steel composite material, wherein the preparation method comprises: providing a plurality of steel plates; providing a graphene dispersion liquid, wherein the graphene dispersion liquid comprises a graphene sheet dispersion agent and graphene sheets dispersed in the dispersion liquid; alternately stacking the steel plates and the graphene dispersion liquid to sandwich the graphene dispersion liquid between the two adjacent steel plates to form a sandwich structure, wherein the uppermost layer and the lowermost layer of the sandwichstructure are the steel plates; carrying out pressurizing pre-treatment on the sandwich structure; and sintering the pre-treated sandwich structure at a temperature of 900-1100 DEG C. The invention further discloses applications of the graphene steel composite material.

Owner:北京石墨烯技术研究院有限公司

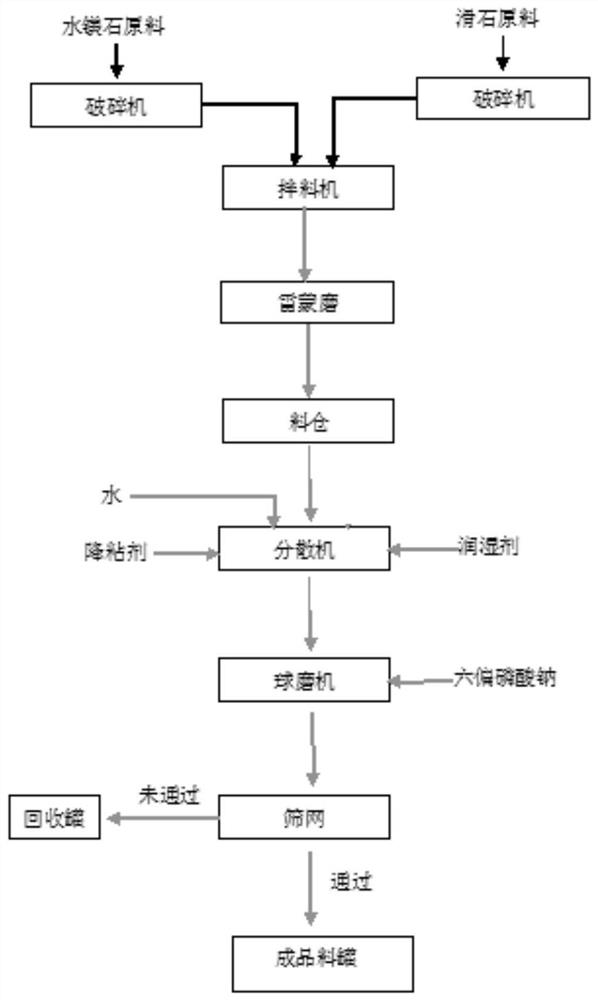

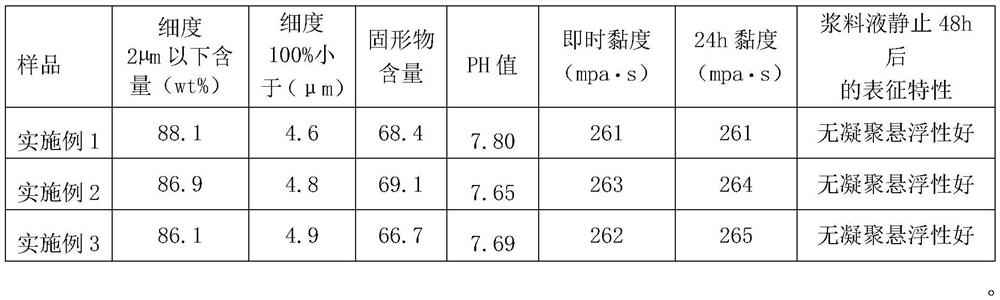

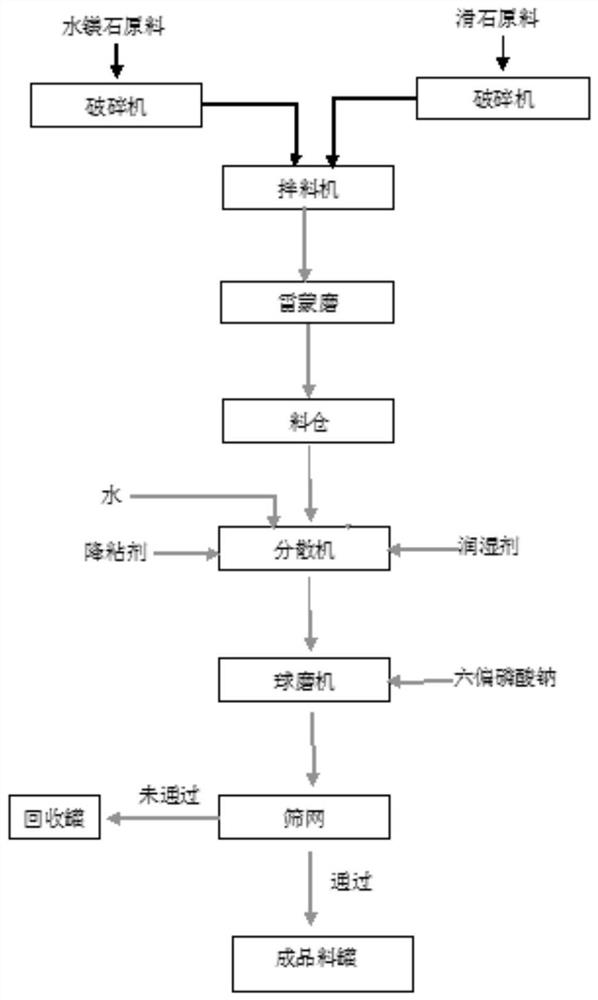

A kind of preparation method of wet papermaking coating slurry

ActiveCN111663364BExcellent peelabilityGood dispersionCoatings with pigmentsCoatingsSodium phosphatesPapermaking

A preparation method of wet papermaking coating slurry, the method uses talc and brucite composite powder as main raw materials, and the specific method includes: crushing talc and brucite block materials into slag below 20 mm, mixing After that, it is ground into 150-200 mesh coarse powder with a Raymond mill, and then a wetting agent, a viscosity reducer and water are added to the powder to prepare a slurry liquid, and then sent to a ball mill for grinding. During the grinding process, a grinding aid hexagonal is added. Sodium phosphate, after the grinding slurry is filtered through a screen, it is filled as a finished product and stored; the added amount of the grinding aid is 0.05wt%-0.08wt% of the composite powder of talc and brucite. The present invention adopts block brucite, which will become flake after grinding, and its properties are similar to talc, with good peelability, high aspect ratio, high whiteness and good dispersibility in water. These properties just make up for some of the deficiencies of talc used in paper coatings.

Owner:辽宁艾海滑石有限公司

A kind of preparation method of amphiphilic graphene type oil displacement material

ActiveCN113248669BReduce the difficulty of dispersionImprove stabilityDrilling compositionGraft reactionBis epoxide

The invention relates to a preparation method of an amphiphilic graphene-type oil displacement material, belonging to the technical field of oilfield chemistry. The Janus amphiphilic nano-graphene material was prepared by asymmetric modification of graphene oxide by interface reaction method; among them, the hydrophobic side modification was realized by the reaction between long-chain organic amines and epoxy groups on the surface of graphene oxide, and the hydrophilic side The modification is achieved by the grafting reaction on the surface of graphene oxide using cerium salts as initiators and compounds containing polyoxyethylene segments as monomers. This nano-graphene oil displacement material has the advantages of low dispersion difficulty, good salt and temperature resistance, excellent long-term dispersion stability, small dosage, and good oil displacement effect, and can be used as oil displacement agent for high temperature and high salt reservoirs.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

A kind of low-shrinkage, high-strength concrete and its preparation method

ActiveCN111943603BSmall shrinkageReduce intensityCeramic shaping apparatusConjugated synthetic polymer artificial filamentsFiberAggregate (composite)

The invention relates to a low-shrinkage, high-strength concrete and a preparation method thereof. Firstly, cement, river sand and petroleum coke powder are uniformly mixed to obtain a mixed dry material; then vermiculite powder and mineral powder are added to water, activated, and ball milled to obtain premixed Then pour the mixed dry material into the premix, stir and mix well, then add fiber gel composite material, light aggregate and admixture, and stir evenly to obtain a slurry; finally inject the slurry into the mold and vibrate to form, and maintain , that is, a low-shrinkage, high-strength concrete, while ensuring high strength and low shrinkage of the product.

Owner:深圳市利建新材料有限公司

A preparation method of lithium titanate negative electrode material and lithium titanate negative electrode material prepared by the method

ActiveCN107316993BElectrochemical stripping method is mildEasy to control the degree of peelingCell electrodesSecondary cellsElectrolytic agentGraphite particle

Owner:GUANGDONG ZHUGUANG NEW ENERGY TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com