Method for preparing ultralow-temperature lithium ion battery anode slurry

A lithium-ion battery and negative electrode slurry technology, which is applied to battery electrodes, secondary batteries, circuits, etc., can solve problems such as poor low temperature resistance and abnormal operation of batteries, and achieve reduced dispersion difficulty, good wetting effect, and improved flow sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

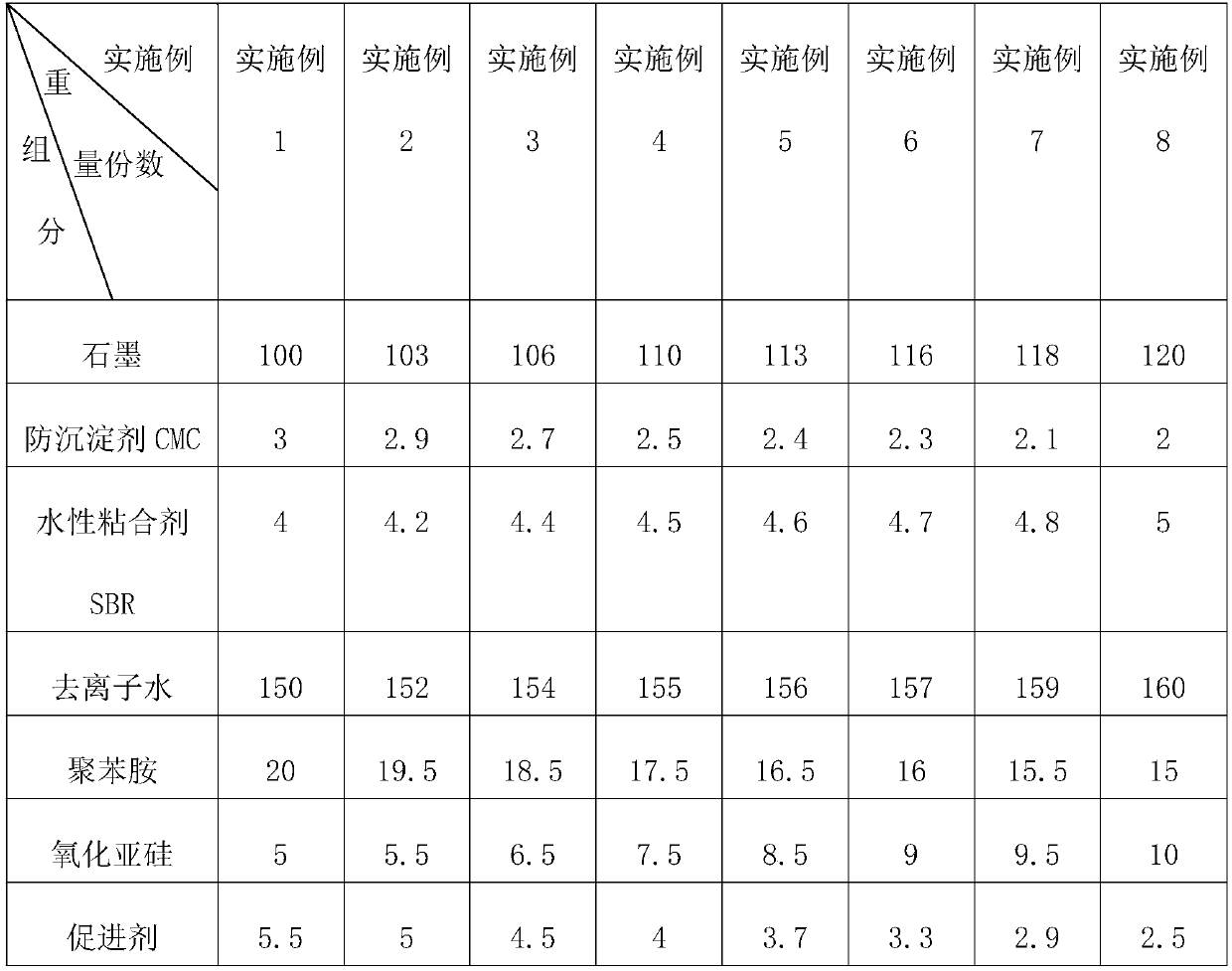

Embodiment 1-8

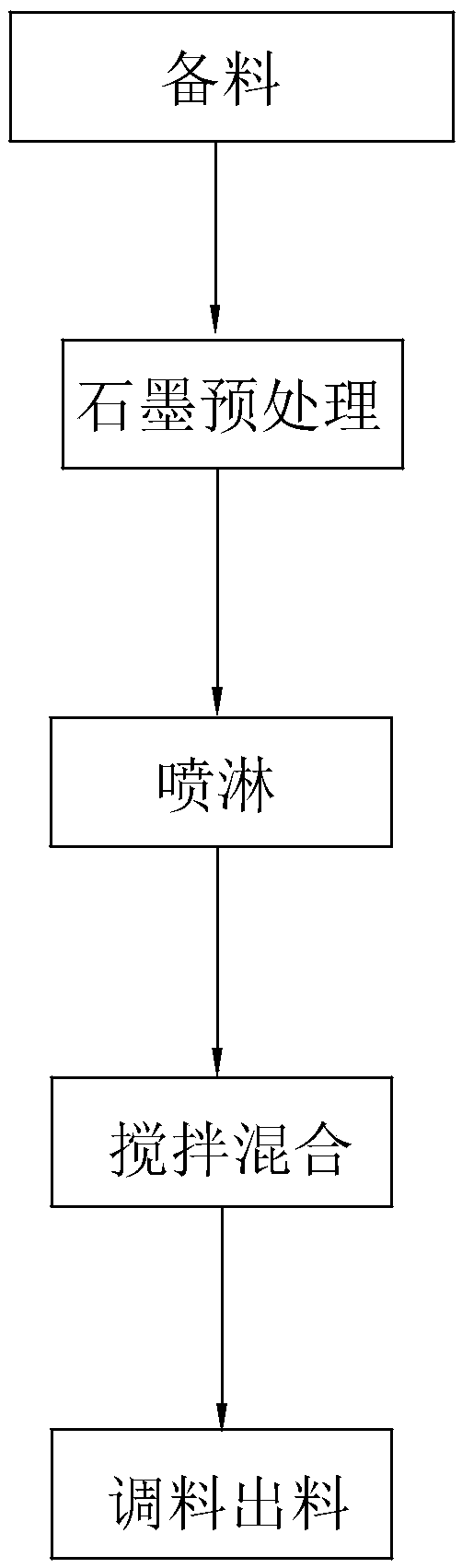

[0039] Embodiment 1-8: a kind of method of ultra-low temperature lithium-ion battery negative electrode slurry batching, comprises the following steps:

[0040] Step 1, prepare materials, weigh graphite, anti-precipitation agent CMC, water-based adhesive SBR, deionized water, polyaniline, silicon oxide, accelerator in proportion with an electronic balance;

[0041] Step 2, graphite pretreatment, the graphite is placed in a high temperature reaction furnace under normal pressure for high temperature baking at a temperature of 350°C for 1 hour, and after cooling, passes through a 100-mesh sieve to obtain pretreated graphite;

[0042] Step 3, spraying, spray the accelerator on the surface of the graphite through the nozzle, then put it into a vacuum mixing tank, then add the anti-precipitation agent CMC, polyaniline, and silicon oxide for preliminary mixing, the stirring speed is 120rpm, and the time is 5min ;

[0043] Step 4: Stir and mix. Gradually add deionized water to the v...

Embodiment 9

[0048] Embodiment 9: A kind of method of ultra-low temperature lithium-ion battery negative electrode slurry batching, the difference with embodiment 1 is that accelerator mainly is made up of ethanol and isopropanol, and the weight and number ratio of ethanol and isopropanol is 1:1.5.

Embodiment 10

[0049] Embodiment 10: A kind of method of ultra-low temperature lithium-ion battery negative electrode slurry batching, the difference with embodiment 1 is that the accelerator is mainly composed of ethanol and isopropanol, and the weight and number ratio of ethanol and isopropanol is 1:1.8.

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com