Lithium ion battery and positive electrode slurry stirring method therefor

A lithium-ion battery and cathode slurry technology, which is applied in battery electrodes, secondary batteries, mixer accessories, etc., can solve the problems of large particle size of cathode slurry, the capacity and service life of lithium batteries need to be improved, and the dispersion performance is poor. Achieve the effect of improving dispersibility, convenient operability, economical and practical value, and improving production qualification rate and consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

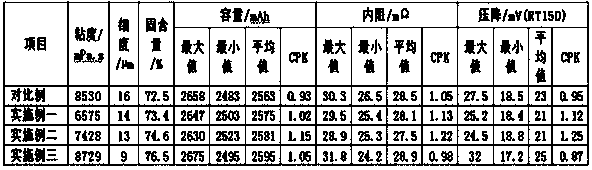

Embodiment 1

[0028] Preparation of positive electrode slurry and positive electrode sheet of lithium battery: the positive electrode active material is used as the positive electrode active material with a mass ratio of nickel-cobalt lithium manganese oxide: lithium iron phosphate: lithium manganate, and its weight content is 96.4%; Ethylene (PVDF molecular weight 1.3 million) is used as the binder, and its weight content is 1.6%; carbon black and carbon nanotubes are used as the conductive agent, and its weight content is 1% and 1% respectively. Dry mix the above materials with a stirring speed of 30HZ, disperse at 200rpm, stir for 2 hours evenly, add the solvent methyl pyrrolidone (NMP), turn on the mixer and set the circulating water constant temperature system to 45-55°C, and use a stirring speed of 40HZ , Disperse and stir at 2000rpm for 4 hours to make positive electrode slurry evenly, and lower to normal temperature to test the solid content, viscosity and fineness of the slurry. Th...

Embodiment 2

[0034] Preparation of positive electrode slurry and positive electrode sheet of lithium battery: the positive electrode active material is used as the positive electrode active material with a mass ratio of nickel-cobalt lithium manganese oxide: lithium iron phosphate: lithium manganate, and its weight content is 96.4%; Ethylene (PVDF molecular weight 1.3 million) is used as the binder, and its weight content is 1.6%; superconducting carbon black and carbon nanotubes are used as the conductive agent, and its weight content is 1% and 1% respectively. The above materials are mixed by dry mixing at a stirring speed of 30HZ, dispersed at 200rpm, stirred for 1.5 hours, and the solvent methyl pyrrolidone (NMP) is added, and the circulating water constant temperature system of the mixer is set to 55-65°C, and the stirring speed is 40HZ, Disperse and stir at 2000rpm for 3.0 hours to uniformly make positive electrode slurry, and lower to room temperature to test the solid content, visco...

Embodiment 3

[0040] Preparation of positive electrode slurry and positive electrode sheet of lithium battery: the positive electrode active material is used as the positive electrode active material with a mass ratio of nickel-cobalt lithium manganate: lithium iron phosphate: lithium manganate, and its weight content is 96.4%; Ethylene (PVDF molecular weight 1.3 million) is used as the binder, and its weight content is 1.6%; carbon black and carbon nanotubes are used as the conductive agent, and its weight content is 1% and 1% respectively. Dry mix the above materials with a stirring speed of 30HZ, disperse at 200rpm, stir for 1.5 hours evenly, add the solvent methyl pyrrolidone (NMP), turn on the mixer and set the circulating water constant temperature system to 65-75°C, and use a stirring speed of 40HZ , Disperse at 2000rpm and stir for 2.5 hours to evenly make positive electrode slurry, and lower to normal temperature to test the solid content, viscosity and fineness of the slurry. The ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fineness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com