Novel pearly-luster ABS material and processing method

A technology of ABS materials and processing methods, which is applied in the field of new pearlescent ABS materials and processing, can solve problems such as poor compatibility, decreased mechanical properties of ABS, and high shearing force, so as to reduce the difficulty of dispersion, improve mechanical properties, and strong The effect of mechanical strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

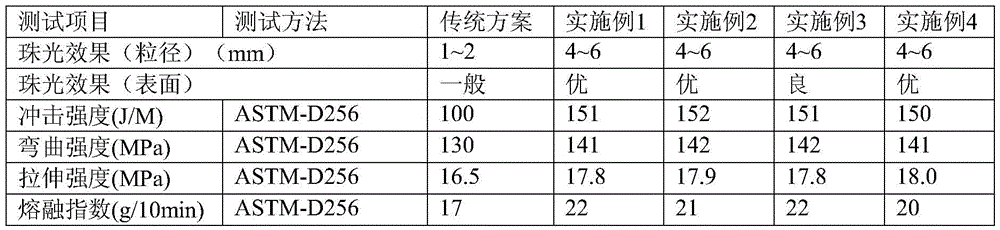

Examples

Embodiment 1

[0023] A new pearlescent ABS material is composed of the following components in weight percentage: ABS resin is acrylonitrile-butadiene-styrene terpolymer, 85%; pearlescent pigment particles are flaky mica-coated pearlescent pigments, 6%; compatibilizer is white mineral oil, 6%; lubricant is zinc stearate, 0.8%; antioxidant is pentaerythritol ester 0.4%; toughening agent is styrene-butadiene-styrene copolymer, 1.8%;

[0024] The specific processing method includes the following steps:

[0025] (1) Take each raw material by formula ratio;

[0026] (2) Put the pearlescent pigment granules into a high-speed mixer and stir, the temperature of the high-speed mixer is 80-100°C, and stir at a speed of 400-500 rpm for 10-15 minutes to remove excess water in the pearlescent pigment granules;

[0027] (3) After removing the water in step (2), add the weighed compatibilizer and pearlescent pigment particles into the high-speed mixer, and stir the high-speed mixer at a speed of 900-110...

Embodiment 2

[0031] A new pearlescent ABS material is composed of the following components in weight percentage: ABS resin is acrylonitrile-butadiene-styrene terpolymer, 82%; pearlescent pigment particles are flaky mica-coated pearlescent pigments, 7.5%; compatibilizer is white mineral oil, 7.5%; lubricant is zinc stearate, 0.7%; antioxidant is pentaerythritol ester 0.5%; toughening agent is styrene-butadiene-styrene copolymer, 1.8%;

[0032] The specific preparation method is the same as Example 1 of the present invention.

Embodiment 3

[0034] A new pearlescent ABS material is composed of the following components in weight percentage: ABS resin is acrylonitrile-butadiene-styrene terpolymer, 80%; pearlescent pigment particles are flaky mica-coated pearlescent pigments, 9%; compatibilizer is white mineral oil, 9%; lubricant is zinc stearate, 0.8%; antioxidant is pentaerythritol ester 0.5%; toughening agent is styrene-butadiene-styrene copolymer, 1.7%;

[0035] The specific preparation method is the same as Example 1 of the present invention.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com