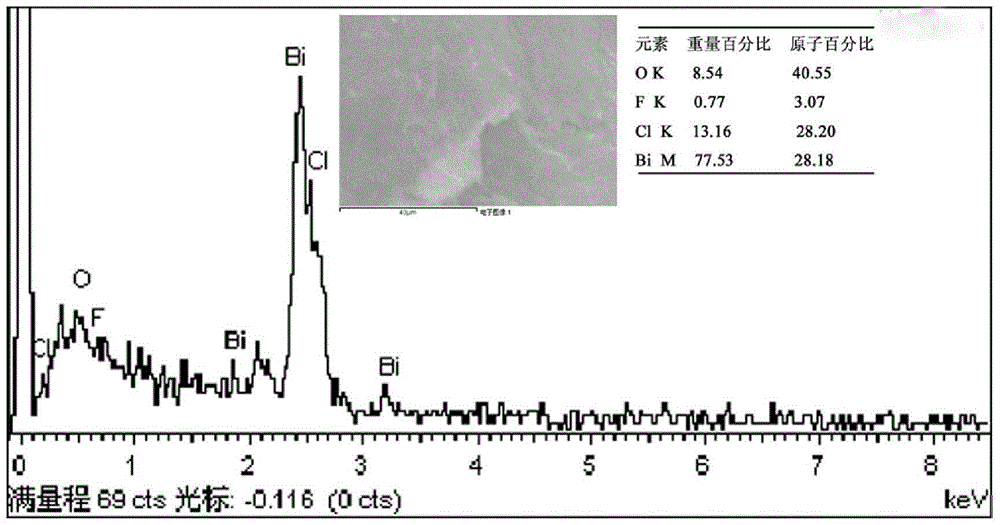

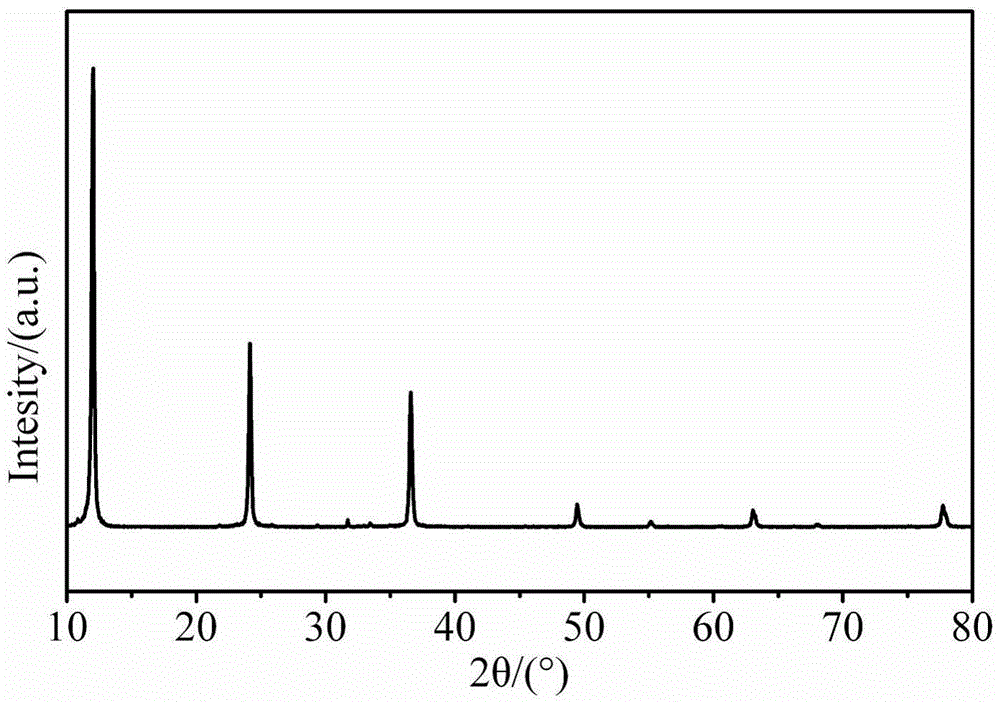

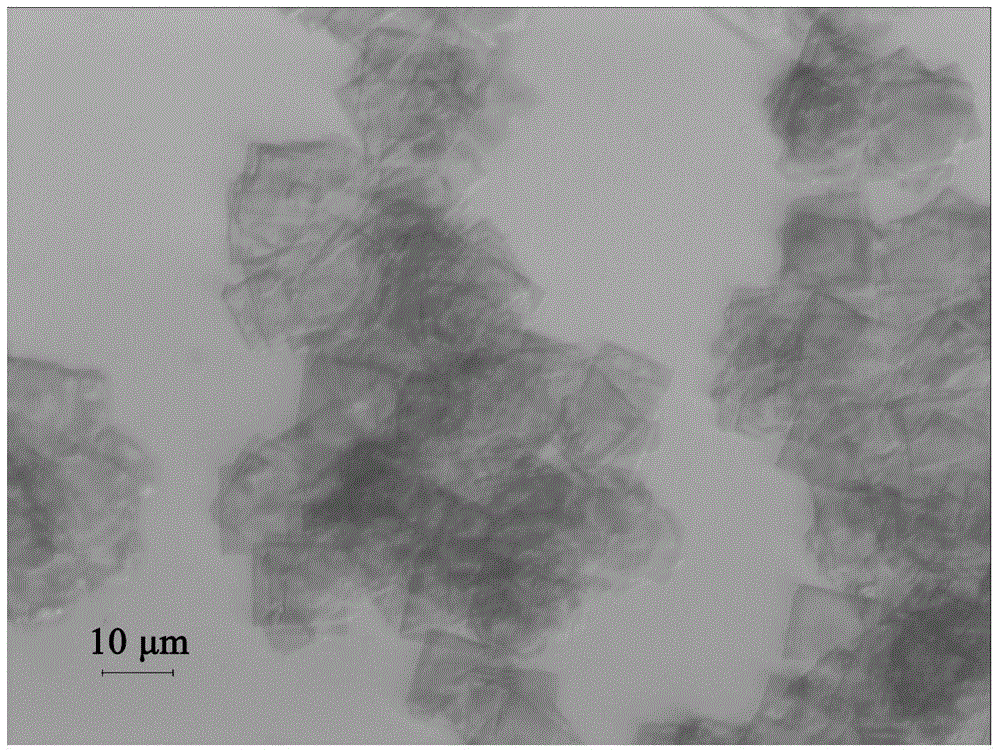

A kind of preparation method of novel fluorinated bismuth oxychloride

A technology of fluorinated bismuth oxychloride and bismuth oxychloride, which is applied in chemical instruments and methods, single crystal growth, polycrystalline material growth and other directions, can solve the problems of affecting brightness, high price, limited application fields, etc., and achieves improved coverage. The effect of strength, easy operation and strong weather resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035]a. Add 90 mL of 37.5 wt% concentrated hydrochloric acid and 4.2 g of octadecyltrimethylammonium chloride surfactant to 12 L of deionized water, mechanically stir at 600 rpm, and control the temperature of the reaction system within the range of 70 °C;

[0036] b. The ratio between bismuth chloride, bismuth nitrate and bismuth fluoride with a concentration of 0.7 moL / L is 0.4 : 0.5 : 0.1 and the concentration is 20 wt% sodium hydroxide solution respectively at a speed of 3.0 mL / min and a speed of 2.5mL / min were added to the reaction system at the same time;

[0037] c. After adding for 30 min, the ratio of 0.4: 0.5: 0.1 between bismuth chloride, bismuth nitrate and bismuth fluoride with a concentration of 0.7 moL / L was increased to 4.5 mL / min, Control the addition rate of 20 wt% sodium hydroxide solution to be 4.0 mL / min to maintain the pH value of the solution;

[0038] d. After adding the bismuth salt solution, quickly add 20 wt% sodium hydroxide solution to make t...

Embodiment 2

[0040] a. Add 200 mL of 37 wt% concentrated hydrochloric acid and 4.8 g of octadecyl dimethyl amine oxide surfactant to 12 L of deionized water, mechanically stir at 300 rpm, and control the temperature of the reaction system within the range of 80 °C;

[0041] b. The ratio between bismuth chloride, bismuth nitrate and bismuth fluoride with a concentration of 0.8 moL / L is 0.3 : 0.5 : 0.2 and the concentration is 20 wt% sodium hydroxide solution respectively at a speed of 3.0 mL / min and a speed of 2.5mL / min were added to the reaction system at the same time;

[0042] c. After adding for 30 min, the ratio of bismuth chloride, bismuth nitrate and bismuth fluoride with a concentration of 0.8 moL / L is 0.3: 0.5: 0.2. Control the addition rate of 20 wt% sodium hydroxide solution to be 4.0 mL / min to maintain the pH value of the solution;

[0043] d. After the bismuth salt solution is added, quickly add sodium hydroxide to make the pH value of the solution 10, remove the supernata...

Embodiment 3

[0045] a. Add 150 mL of 36 wt% concentrated hydrochloric acid and 6.0 g of tetradecyl dimethyl amine oxide surfactant to 12 L of deionized water, mechanically stir at 400 rpm, and control the temperature of the reaction system within the range of 75 °C;

[0046] b. The ratio between the bismuth chloride, bismuth nitrate and bismuth fluoride with a concentration of 0.8 moL / L is 0.1 : 0.5 : 0.4, and the concentration is 20 wt% sodium hydroxide solution respectively at a speed of 3.0 mL / min and a speed of 2.5mL / min were added to the reaction system at the same time;

[0047] c. After adding 30 min, the ratio between bismuth chloride, bismuth nitrate and bismuth fluoride of 0.8 mol / L is 0.1:0.5:0.4. The adding rate of wt% sodium hydroxide solution is 4.9 mL / min to keep the pH value of the solution;

[0048] d. After the bismuth salt solution has been added, quickly add sodium hydroxide to make the pH of the solution 10, remove the supernatant after standing for stratification...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com