Acid dye and preparation method thereof

An acid dye and dye technology, applied in the direction of dyeing, textile and paper making, etc., can solve the problems of fur's aesthetic effect, no pearl effect, easy damage to animal fur, etc., and achieves good pearl effect, good levelness, dispersion good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

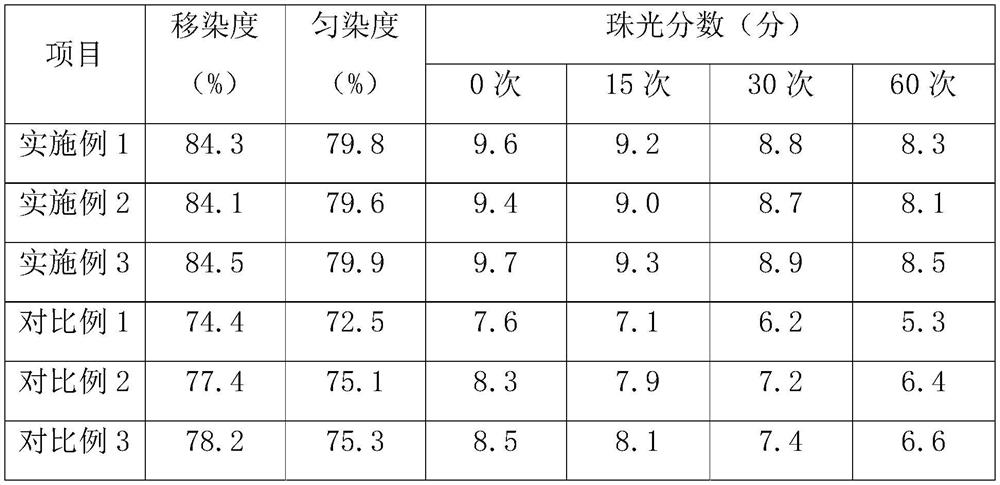

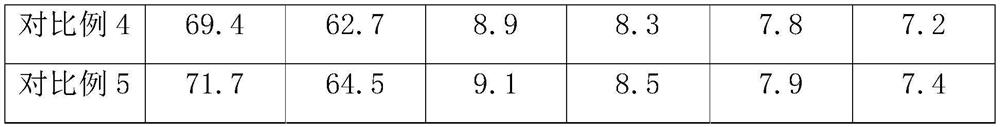

Examples

preparation example 1

[0047] Preparation example 1: The core material is prepared by the following method:

[0048] S331. Weigh 5kg of mica powder and 35kg of deionized water, place the mica powder in deionized water and stir at a speed of 300r / min for 10min to obtain a suspension; transfer the suspension into a stirring tank and heat up to 92 degrees Celsius , then add 1.3kg of urea, stir at a speed of 310r / min for 14min, then add 1.3kg of urea, and continue stirring for 14min to obtain a stirring solution;

[0049] S332. Adjust the stirred solution prepared in S331 to a pH value of 2.1, and stir at a speed of 310 r / min for 1.2 h; then add 9.5 kg of a 10% titanium tetrachloride solution by mass fraction, and continue the reaction for 32 min; naturally cool to room temperature, After suction filtration and washing to neutrality, dry at 110°C for 1.6h to obtain a dry powder;

[0050] S333. Transfer the dry powder to a muffle furnace for calcination at 820 degrees centigrade for 35 minutes, and natu...

preparation example 2

[0052] S331. Weigh 5kg of mica powder and 35kg of deionized water, place the mica powder in deionized water and stir at a speed of 300r / min for 10min to obtain a suspension; transfer the suspension into a stirring tank and heat up to 85 degrees Celsius , then add 1.2kg of urea, stir at a speed of 200r / min for 10min, then add 1.2kg of urea, and continue stirring for 10min to obtain a stirring solution;

[0053] S332. Adjust the stirred solution prepared in S331 to a pH value of 1.7, and stir at a speed of 200 r / min for 1 h; then add 9 kg of titanium tetrachloride solution with a mass fraction of 10%, and continue the reaction for 25 min; naturally cool to room temperature, and After filtering and washing to neutrality, dry at 110°C for 1 hour to obtain a dry powder;

[0054] S333. Transfer the dry powder to a muffle furnace for calcination at 700 degrees centigrade for 20 minutes, and naturally cool to room temperature to obtain a modified mica sheet, which is a core material, ...

preparation example 3

[0056] S331. Weigh 5kg of mica powder and 35kg of deionized water, place the mica powder in deionized water and stir at a speed of 300r / min for 10min to obtain a suspension; transfer the suspension into a stirring tank and heat up to 95 degrees Celsius , then add 1.5kg of urea, stir at a speed of 350r / min for 19min, then add 1.5kg of urea, and continue stirring for 19min to obtain a stirring solution;

[0057] S332. Adjust the stirred solution prepared in S331 to a pH value of 2.5, and stir at a speed of 350 r / min for 1.5 h; then add 10 kg of titanium tetrachloride solution with a mass fraction of 10%, and continue the reaction for 35 min; naturally cool to room temperature, and After suction filtration and washing to neutrality, dry at 110°C for 2 hours to obtain a dry powder;

[0058] S333. Transfer the dry powder to a muffle furnace for calcination at 900 degrees Celsius for 45 minutes, and naturally cool to room temperature to obtain a modified mica sheet, which is a core ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com