Low-smoke halogen-free flame-retardant polyolefin cable material and preparation method thereof

A technology of polyolefin cable material and ethylene, which is applied in the direction of circuits, electrical components, plastic/resin/wax insulators, etc., can solve the problems of difficult to obtain high oxygen index and high mechanical performance cable materials, and achieve large-scale industrial production, Avoid the effect of reducing mechanical properties and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

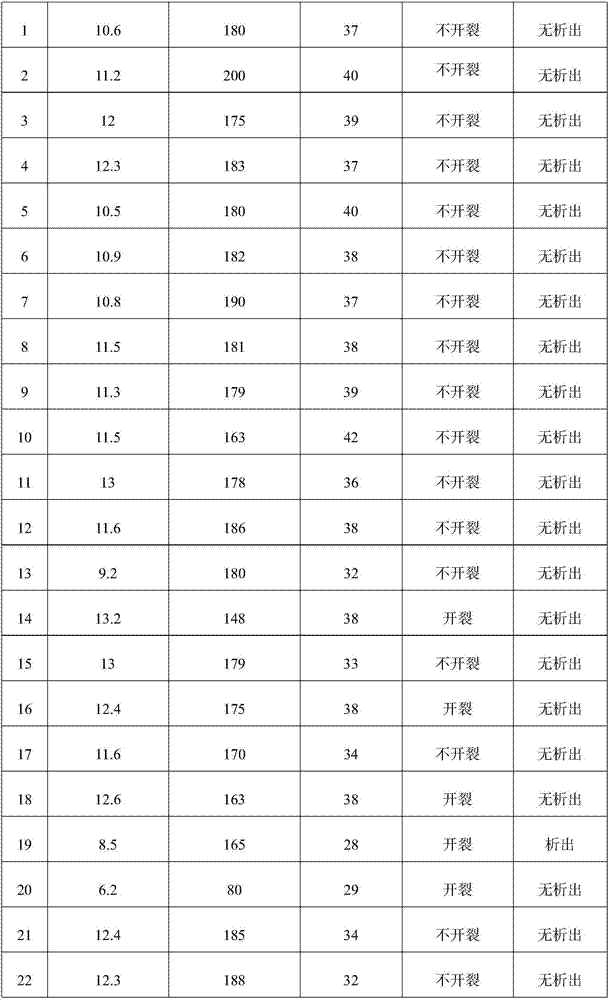

Examples

preparation example Construction

[0018] A preparation method of a low-smoke halogen-free flame-retardant polyolefin cable material comprises: (1) mixing ethylene-vinyl acetate copolymer, elastomer, magnesium hydroxide, polyphosphazene, PPE-MAH and processing aids in parts by weight Specific mixing, mechanical stirring to obtain the mixture; wherein, preferably, a high-speed mixer is used for mixing, the speed of the high-speed mixer is 700-900rpm, and the stirring time is at least 3min to achieve better mixing effect;

[0019] (2) Extrude and pelletize the mixture to obtain a low-smoke, halogen-free, flame-retardant polyolefin cable compound; preferably, a twin-screw extruder is used to extrude the mixture, in order to achieve a better extrusion effect and further improve the mechanical properties of the product Performance, preferably, the diameter of the twin-screw extruder is less than 200mm; the aspect ratio is 36-44:1; the rotation speed of the main engine is 250-1800rpm; the temperature of the barrel is ...

Embodiment 1

[0022] This example provides a low-smoke, halogen-free, flame-retardant polyolefin cable material. The raw materials include: 34 parts of ethylene-vinyl acetate copolymer, 5 parts of polyolefin elastomer, 55 parts of magnesium hydroxide, polyphosphorus 5 parts of nitrile, 0.5 part of PPE-MAH, 0.25 part of antioxidant 1010 and 0.25 part of calcium stearate.

[0023] The present embodiment provides a kind of preparation method of low-smoke halogen-free flame-retardant polyolefin cable material, comprising: (1) ethylene-vinyl acetate copolymer, elastomer, magnesium hydroxide, polyphosphazene, PPE-MAH and processing The additives are mixed according to the above weight ratio, and the high-speed mixer with a rotation speed of 700-900rpm is used for mixing for at least 3 minutes; (2) The mixture is extruded by a twin-screw extruder, and the diameter of the twin-screw extruder is less than 200mm ;Length-to-diameter ratio is 36-44:1; main engine speed is 250-1800rpm; barrel temperatur...

Embodiment 2

[0025] This example provides a low-smoke, halogen-free, flame-retardant polyolefin cable material. The raw materials include, by weight fraction: 23 parts of ethylene-vinyl acetate copolymer, 10 parts of EPDM rubber, 61 parts of magnesium hydroxide, poly 5 parts of phosphazene, 0.5 part of PPE-MAH, 0.25 part of antioxidant 1010 and 0.25 part of calcium stearate.

[0026] This example provides a method for preparing a low-smoke, halogen-free, flame-retardant polyolefin cable material. Please refer to Example 1 for specific steps.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com