A kind of low-shrinkage, high-strength concrete and its preparation method

A high-strength, low-shrinkage technology, applied in clay preparation devices, chemical instruments and methods, manufacturing tools, etc., can solve the problems of large shrinkage, large shrinkage of ultra-high-strength concrete, and low concrete strength, and achieve uniform dispersion promotion and low dosage , Improve the effect of shrinkage resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

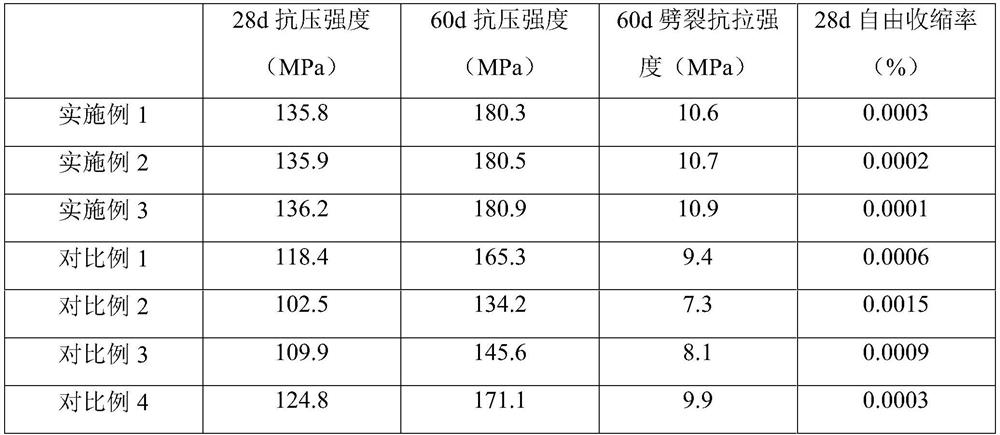

Examples

Embodiment 1

[0041]A preparation method of low-shrinkage, high-strength concrete, the specific steps are as follows:

[0042] (1) First mix 1kg cement, 1.5kg river sand and 0.3kg petroleum coke powder evenly to obtain mixed dry material;

[0043] (2) Then 0.3kg vermiculite powder and 0.6kg mineral powder are added in 0.8kg water, activated, and ball milled to obtain the premix;

[0044] (3) Then pour the mixed dry material into the premix, stir and mix, then add 0.2kg of fiber gel composite material, 1.8kg of light aggregate and 0.01kg of admixture, and stir to obtain a slurry;

[0045] (4) Finally, inject the slurry into the mold, vibrate and form it, and then maintain it to obtain a low-shrinkage, high-strength concrete;

[0046] Wherein, the fiber gel composite material is prepared from glucono δ-lactone, allylamine and acrylamide through polymerization reaction, and polyethersulfone-polyamide fiber and polyamide fiber are added during the polymerization reaction. Acrylonitrile fibers...

Embodiment 2

[0064] A preparation method of low-shrinkage, high-strength concrete, the specific steps are as follows:

[0065] (1) First mix 1kg cement, 2kg river sand and 0.2kg petroleum coke powder evenly to obtain mixed dry material;

[0066] (2) Then add 0.5kg vermiculite powder and 0.4kg mineral powder into 1kg water, activate, and ball mill to obtain the premix;

[0067] (3) Then pour the mixed dry material into the premix, stir and mix, then add 0.1kg of fiber gel composite material, 2.2kg of light aggregate and 0.008kg of admixture, and stir to obtain a slurry;

[0068] (4) Finally, inject the slurry into the mold, vibrate and form it, and then maintain it to obtain a low-shrinkage, high-strength concrete;

[0069] Wherein, the fiber gel composite material is prepared from glucono δ-lactone, allylamine and acrylamide through polymerization reaction, and polyethersulfone-polyamide fiber and polyamide fiber are added during the polymerization reaction. Acrylonitrile fibers to form ...

Embodiment 3

[0087] A preparation method of low-shrinkage, high-strength concrete, the specific steps are as follows:

[0088] (1) First mix 1kg cement, 1.8kg river sand and 0.25kg petroleum coke powder evenly to obtain mixed dry material;

[0089] (2) Then 0.4kg vermiculite powder and 0.5kg mineral powder are added in 0.9kg water, activated, and ball milled to obtain the premix;

[0090] (3) Then pour the mixed dry material into the premix, stir and mix, then add 0.15kg of fiber gel composite material, 2kg of light aggregate and 0.009kg of admixture, and stir to obtain a slurry;

[0091] (4) Finally, inject the slurry into the mold, vibrate and form it, and then maintain it to obtain a low-shrinkage, high-strength concrete;

[0092] Wherein, the fiber gel composite material is prepared from glucono δ-lactone, allylamine and acrylamide through polymerization reaction, and polyethersulfone-polyamide fiber and polyamide fiber are added during the polymerization reaction. Acrylonitrile fibe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com