A kind of scratch-coating type mid-coat automotive coating based on thermoplastic acrylic resin and preparation method thereof

A thermoplastic acrylic and resin technology, applied in the direction of coating, can solve problems such as heavy workload, and achieve the effect of improving adhesion, reducing cracking of topcoat, and excellent smoothness of topcoat

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

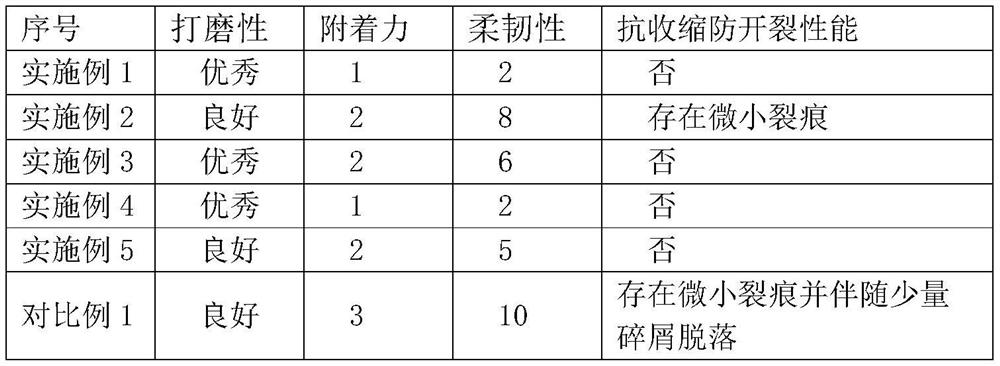

Examples

Embodiment 1

[0031] A kind of preparation method based on thermoplastic acrylic resin scraping type intermediate coating automobile paint, comprises the steps:

[0032] Step 1: Mix 39kg of thermoplastic acrylic resin NeoCryl B-735 with 37kg of xylene for 15 minutes, and add 800g of wetting and dispersing agent BYK-W966 after mixing evenly; the dispersion temperature is 60°C, which should be controlled during the entire reaction process;

[0033] Step 2: Add 4kg of calcium carbonate and 16kg of quartz powder to the mixture in step 1 under high-speed stirring; the powder should be added gradually so that the powder can be evenly dispersed into the system, and the dispersion time is 35min.

[0034] Step 3: Add 200g of pigment dispersant BYK-163 and 3kg of titanium dioxide to the reaction system in step 2, stir at high speed for 6 minutes, and then stir at low speed and discharge after stirring evenly.

Embodiment 2

[0036] A kind of preparation method based on thermoplastic acrylic resin scraping type intermediate coating automobile paint, comprises the steps:

[0037] Step 1: Mix 44kg of thermoplastic acrylic resin NeoCryl B-735 with 24.7kg of xylene for 15 minutes, add 1kg of wetting and dispersing agent BYK-W966 after mixing evenly; the dispersion temperature is 65°C, and should be controlled at this temperature during the entire reaction process ;

[0038] Step 2: Add 5kg of quartz powder and 20kg of calcium carbonate to the mixture in step 1 under high-speed stirring; the powder should be added gradually so that the powder can be evenly dispersed into the system, and the dispersion time is 40min.

[0039] Step 3: Add 300g of pigment dispersant BYK-163 and 5kg of titanium dioxide to the reaction system in step 2 and stir at a high speed for 6 minutes, then stir at a low speed and discharge after stirring evenly.

Embodiment 3

[0041] A kind of preparation method based on thermoplastic acrylic resin scraping type intermediate coating automobile paint, comprises the steps:

[0042] Step 1: Mix 38kg of thermoplastic acrylic resin NeoCryl B-735 with 36.3kg of xylene for 15 minutes, and add 0.6kg of wetting and dispersing agent BYK-W966 after mixing evenly; the dispersion temperature is 60°C, which should be controlled during the entire reaction process temperature;

[0043] Step 2: Add 10kg of calcium carbonate and 10kg of quartz powder to the mixture in step 1 under high-speed stirring; the powder should be added gradually so that the powder can be evenly dispersed into the system, and the dispersion time is 30min.

[0044] Step 3: Add 100g of pigment dispersant BYK-163 and 2kg of titanium dioxide to the reaction system in step 2, stir at high speed for 10min, and then stir at low speed and discharge after stirring evenly.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com