A preparation method of lithium titanate negative electrode material and lithium titanate negative electrode material prepared by the method

A negative electrode material, lithium titanate technology, applied in the direction of battery electrodes, structural parts, electrical components, etc., can solve the problems of small contact area, affecting the electrochemical performance of lithium titanate negative electrode materials, large gas production, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

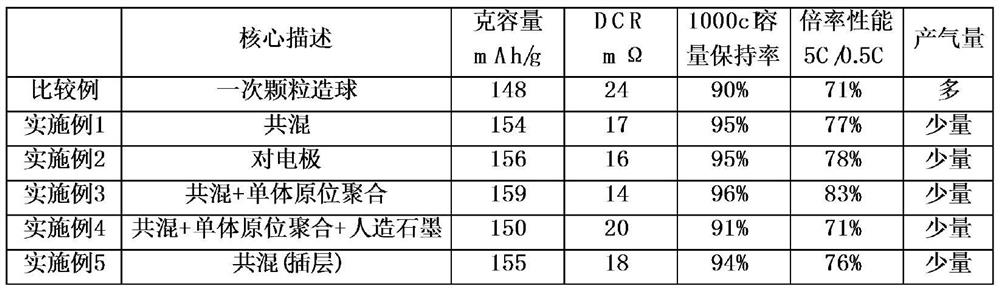

Examples

Embodiment 1

[0038] Embodiment 1, differs from comparative example in that this embodiment comprises the following steps:

[0039] Step 1, dry-mix lithium metal powder, lithium titanate with a diameter of 100 nm, and graphite particles with a particle size of 6 μm until uniform;

[0040] Step 2, select the electrolyte solution with lithium hexafluorophosphate as the salt and PC as the solvent, add it to the above mixture and continue stirring. At this time, under the action of metal lithium powder, PC will peel off the graphite particles to form an open structure, and at the same time, the lithium titanate particles will filling into the inlet structure;

[0041] Step 3, after the filling is completed, the electrolyte components are removed, coated and carbonized to obtain the lithium titanate negative electrode material.

[0042] The rest are the same as the comparative example and will not be repeated here.

Embodiment 2

[0043] Embodiment 2 is different from the comparative example in that the present embodiment comprises the following steps:

[0044] Step 1, mixing and kneading lithium titanate with a diameter of 100 nm, graphite particles with a particle size of 6 μm, and lithium hexafluorophosphate as the salt and PC as the solvent until uniform;

[0045] Step 2, assemble the counter electrode with lithium iron phosphate as the power source material, and then form the counter electrode with the material obtained in step 1, connect the external circuit, charge with a current of 1A, peel off the graphite particles, and form a graphite sheet opening structure; After that, the nano-lithium titanate particles will be continuously filled into the opening structure of the graphite sheet;

[0046] Step 3, after the filling is completed, the electrolyte components are removed, coated and carbonized to obtain the lithium titanate negative electrode material.

[0047] The rest are the same as the com...

Embodiment 3

[0048] Embodiment 3 is different from Embodiment 1 in that this embodiment includes the following steps:

[0049] Step 1, dry mixing and kneading lithium metal powder, lithium titanate with a diameter of 100 nm, methyl methacrylate, sodium lauryl sulfate, and graphite particles with a particle size of 6 μm until uniform;

[0050] Step 2, select the electrolyte solution with lithium hexafluorophosphate as the salt and PC as the solvent, add it to the above mixture and continue stirring. At this time, under the action of metal lithium powder, PC will peel off the graphite particles to form an open structure, and at the same time, the lithium titanate particles will filling into the open structure;

[0051] Step 3, dissolving tert-butyl peroxybenzoate in PC to form an initiator solution, after the filling described in step 3 is completed, add the initiator solution, increase the temperature, and impel the polymerization reaction of the polymer monomer, in titanic acid A polymer ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com