Graphene steel composite material, preparation method and application thereof

A composite material and graphene technology, applied in chemical instruments and methods, skates, sports accessories, etc., can solve problems such as poor toughness, hardness, bending resistance and other mechanical properties, low structural precision, and short service life. , to achieve the effect of reducing the difficulty of dispersion, improving mechanical properties and improving performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0039] The embodiment of the present invention also provides a preparation method of a graphene steel composite material, comprising:

[0040] S10, provide multiple steel plates;

[0041] S20, providing a graphene dispersion liquid, comprising a graphene sheet dispersant and a graphene sheet dispersed in the dispersion liquid;

[0042] S30, stacking the steel plates and the graphene dispersion alternately, so that the graphene dispersion is sandwiched between two adjacent steel plates to form a sandwich structure, the uppermost layer and the lowermost layer of the sandwich structure is the steel plate;

[0043] S40, performing pressurized pretreatment on the sandwich structure; and

[0044] S50, sintering the sandwich structure after the pressure pretreatment at 900°C to 1100°C

[0045] In the preparation of the graphene-steel composite material of the present invention in the embodiment of the present invention, the graphene layer and the steel layer are combined by pressuri...

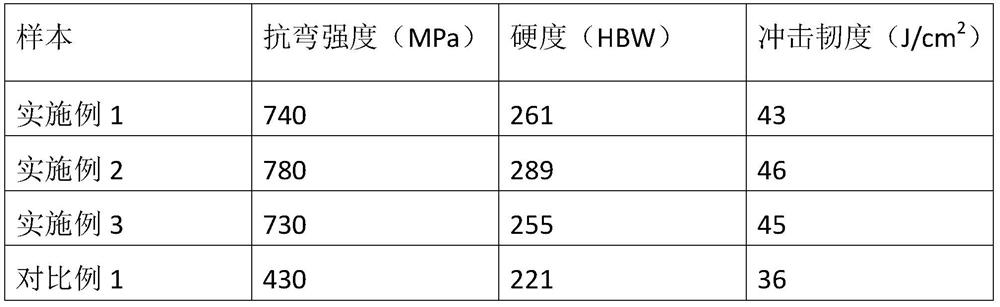

Embodiment 1

[0059] A steel plate with a thickness of 2-10 mm is rolled to a thickness of 0.4 mm, and subjected to stress relief annealing at 650-700° C., wherein the carbon content of the steel plate used is 0.5% carbon steel.

[0060] The annealed steel plate is mechanically ground to a thickness of 0.3mm, and the roughness is at Ra0.8.

[0061] Electrolytic polishing was carried out on the steel plate after mechanical grinding, the polishing temperature was 70°C, and the current density was 70A·dm -2 , electrolysis time 6min. The electrolyte composition is phosphoric acid 650ml / L, sulfuric acid 150ml / L, water 150ml / L, chromium trioxide 50g / L. After electropolishing, the steel plates were rinsed with deionized water.

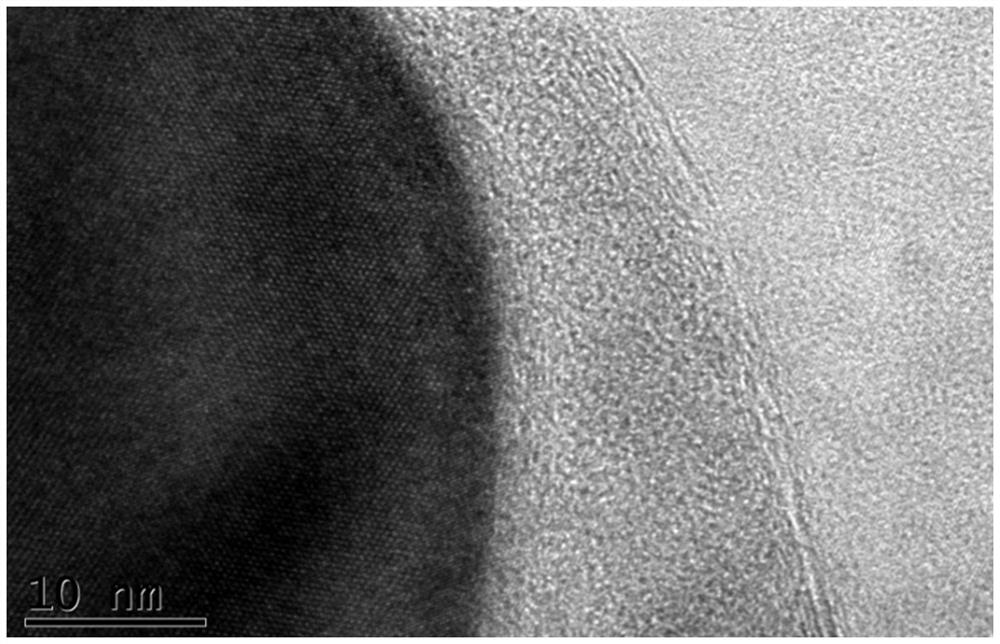

[0062] The mixed solution of graphene sheets, polyvinylpyrrolidone, and dimethylformamide was ultrasonicated for 80 minutes to obtain a graphene dispersion. The concentration of the graphene sheet in the graphene dispersion liquid is 7 mg / L, the diameter of the graphene...

Embodiment 2

[0068] Example 2 is basically the same as Example 1, except that the thickness of graphene dispersion coating or screen printing is 5 μm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com