Lithium titanate negative electrode material and preparation method thereof

A negative electrode material, lithium titanate technology, applied in nanotechnology for materials and surface science, battery electrodes, electrical components, etc., can solve the problems that affect the electrochemical performance of lithium titanate negative electrode materials, high battery internal resistance, contact resistance, etc. Large and other problems, to achieve the effect of eliminating negative effects, increasing solid content, and reducing internal resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

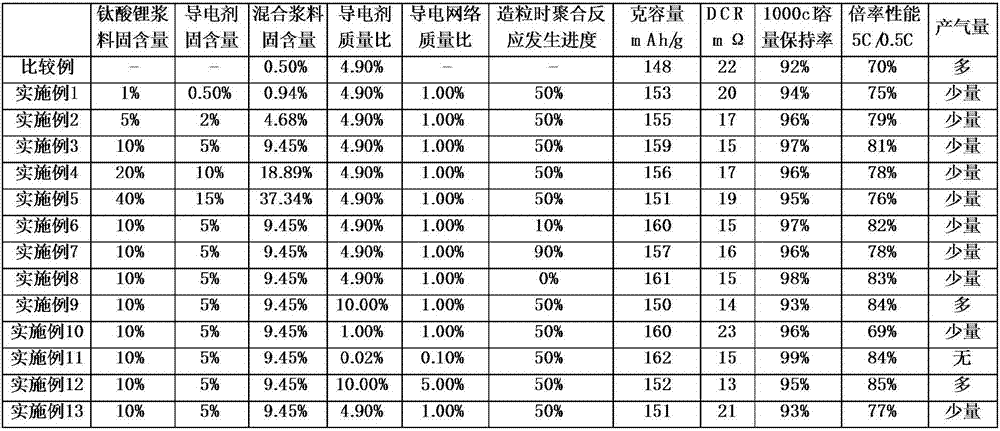

Examples

Embodiment 1

[0037] Embodiment 1, differs from comparative example in that this embodiment comprises the following steps:

[0038] Step 1, kneading: Lithium titanate, methyl methacrylate, sodium lauryl sulfate (mass ratio: lithium titanate: methyl methacrylate: sodium lauryl sulfate=93 :1:1), NMP (solid content is 1%) mixed and then kneaded, the revolution is 60 turns / min, and the rotation is 500 turns / min; Kneading 2h obtains mixture 1; Conductive carbon black, polyvinylpyrrolidone (mass ratio is Conductive carbon black: polyvinylpyrrolidone=4.9:0.1) and NMP (solid content is 0.5%) are mixed and kneaded, the revolution is 60 revolutions / min, and the rotation is 500 revolutions / min; Kneading 2h obtains mixture 2; Mixture 1, mixture 2 (mass ratio is lithium titanate: conductive carbon black=93:4.9) mixed together, continue kneading, revolution is 20 revolutions / min, rotation is 300 revolutions / min; After kneading 2h, obtain polymer monomer, nano titanic acid Mixed slurry with uniform dispe...

Embodiment 2

[0043] Embodiment 2 is different from Embodiment 1 in that this embodiment includes the following steps:

[0044] Step 1, kneading: Lithium titanate, methyl methacrylate, sodium lauryl sulfate (mass ratio: lithium titanate: methyl methacrylate: sodium lauryl sulfate=93 :1:1), NMP (solid content is 5%) are mixed and then kneaded, the revolution is 20 turns / min, and the rotation is 300 turns / min; Kneading 2h obtains mixture 1; Conductive carbon black, polyvinylpyrrolidone (mass ratio is Conductive carbon black: polyvinylpyrrolidone=4.9:0.1) and NMP (solid content is 2%) are mixed and kneaded, the revolution is 20 revolutions / min, and the rotation is 300 revolutions / min; Kneading 2h obtains mixture 2; Mixture 1, mixture 2 (mass ratio is lithium titanate: conductive carbon black=93:4.9) mixed together, continue kneading, revolution is 20 revolutions / min, rotation is 300 revolutions / min; After kneading 2h, obtain polymer monomer, nano titanic acid Mixed slurry with uniform dispers...

Embodiment 3

[0048] Embodiment 3 is different from Embodiment 1 in that this embodiment includes the following steps:

[0049] Step 1, kneading: Lithium titanate, methyl methacrylate, sodium lauryl sulfate (mass ratio: lithium titanate: methyl methacrylate: sodium lauryl sulfate=93 :1:1), NMP (solid content is 10%) mixed and kneaded, the revolution is 10 turns / min, and the rotation is 100 turns / min; Kneading 4h obtains mixture 1; Conductive carbon black, polyvinylpyrrolidone (mass ratio is Conductive carbon black: polyvinylpyrrolidone=4.9:0.1) and NMP (solid content is 5%) are mixed and kneaded, the revolution is 10 revolutions / min, and the rotation is 100 revolutions / min; kneading 4h obtains mixture 2; Mixture 1, mixture 2 (mass ratio is lithium titanate: conductive carbon black = 93:4.9) mixed together, continue to knead, the revolution is 10 revolutions / min, and the rotation is 100 revolutions / min; after kneading for 4 hours, polymer monomer and nano titanic acid Mixed slurry with unif...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com