Polyaniline epoxy anti-corrosive paint and preparation method thereof

A polyaniline epoxy and anti-corrosion coating technology, applied in the coating field, can solve the problems affecting the appearance and anti-corrosion performance of the coating, the solvent volatilization speed is not easy to control, the coating leveling is poor, etc. time, easy to disperse effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

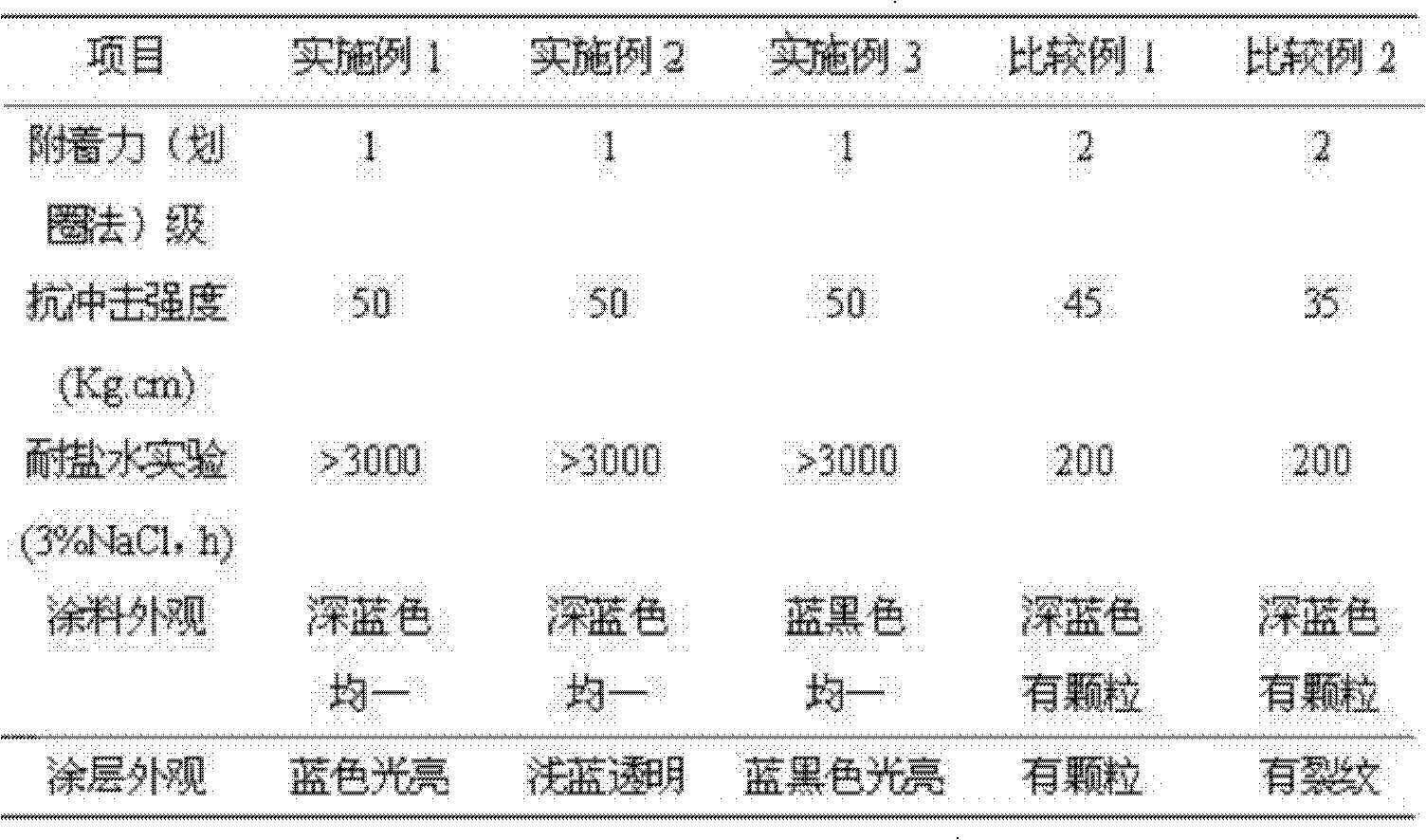

Examples

Embodiment 1

[0020] Polyaniline epoxy anticorrosion coating is prepared according to the following steps:

[0021] 1. Preparation of mixed solvent: Mix 42.5 g of xylene and 57.5 g of n-butanol, and stir evenly to obtain a mixed solvent.

[0022] 2. Preparation of component A: Add 37.5 g of intrinsic polyaniline / attapulgite nanocomposite filter cake with a solid content of 30% to 100 g of mixed solvent, heat while stirring, and distill the The moisture is removed, and the polyaniline / attapulgite composite material organic dispersion that obtains solid content is 20%; To 50g solid content, add 50g epoxy resin ( E-44), stir until the epoxy resin is fully dissolved to obtain component A.

[0023] 3. Preparation of component B: Add 45 g of polyamide (molecular weight 650) to 55 g of absolute ethanol, mix and stir until the polyamide is fully dissolved to obtain component B.

[0024] 4. Part A and Part B can be divided into packages first. When using, mix 100g of Part A and 100g of Part B and ...

Embodiment 2

[0026] Polyaniline epoxy anticorrosion coating is prepared according to the following steps:

[0027] 1. Preparation of mixed solvent: Mix 25 g of toluene and 75 g of isobutanol, and stir evenly to obtain a mixed solvent.

[0028] 2. Preparation of component A: Add 25 g of intrinsic polyaniline / attapulgite nanocomposite filter cake with a solid content of 20% to 100 g of mixed solvent, heat while stirring, and distill the Moisture is removed, and the polyaniline / attapulgite composite material organic dispersion that obtains solid content is 12.5%; To 60g solid content, add 40g epoxy resin (E -44), stirring until the epoxy resin is fully dissolved to obtain component A.

[0029] 3. Preparation of component B: Add 30 g of polyamide (molecular weight: 650) to 70 g of absolute ethanol, mix and stir until the polyamide is fully dissolved to obtain component B.

[0030] 4. Part A and Part B can be divided into packages first. When using, mix 50g of Part A and 60g of Part B and sti...

Embodiment 3

[0032] Polyaniline epoxy anticorrosion coating is prepared according to the following steps:

[0033] 1. Preparation of mixed solvent: Mix 60 g of xylene and 40 g of tert-butanol, and stir evenly to obtain a mixed solvent.

[0034] 2. Preparation of component A: Add 50 g of doped polyaniline / attapulgite nanocomposite filter cake with a solid content of 40% to 100 g of mixed solvent (the dopant is phosphoric acid), heat while stirring, and pass The method of distillation removes the moisture in the system, obtains the polyaniline / attapulgite composite material organic dispersion that solid content is 25%; Add 60g of epoxy resin (E-44) and stir until the epoxy resin is fully dissolved to obtain component A.

[0035] 3. Preparation of component B: Add 60 g of polyamide (molecular weight: 650) to 40 g of absolute ethanol, mix and stir until the polyamide is fully dissolved to obtain component B.

[0036] 4. Part A and Part B can be divided into packages first. When using, mix 10...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com