Dispersion method of nano material

A nanomaterial and dispersion technology, applied in mixing methods, chemical instruments and methods, dissolution, etc., can solve the problems of uneven dispersion, insignificant dispersion effect of carbon nanomaterials, and backward dispersion equipment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

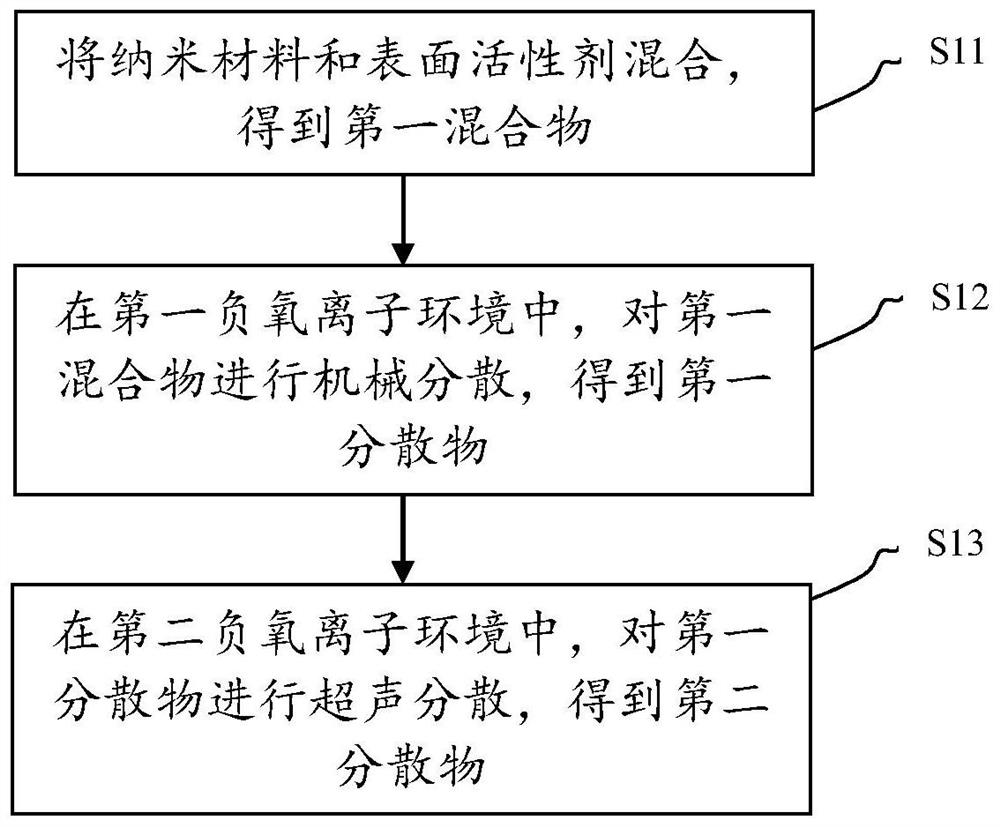

Method used

Image

Examples

Embodiment 1

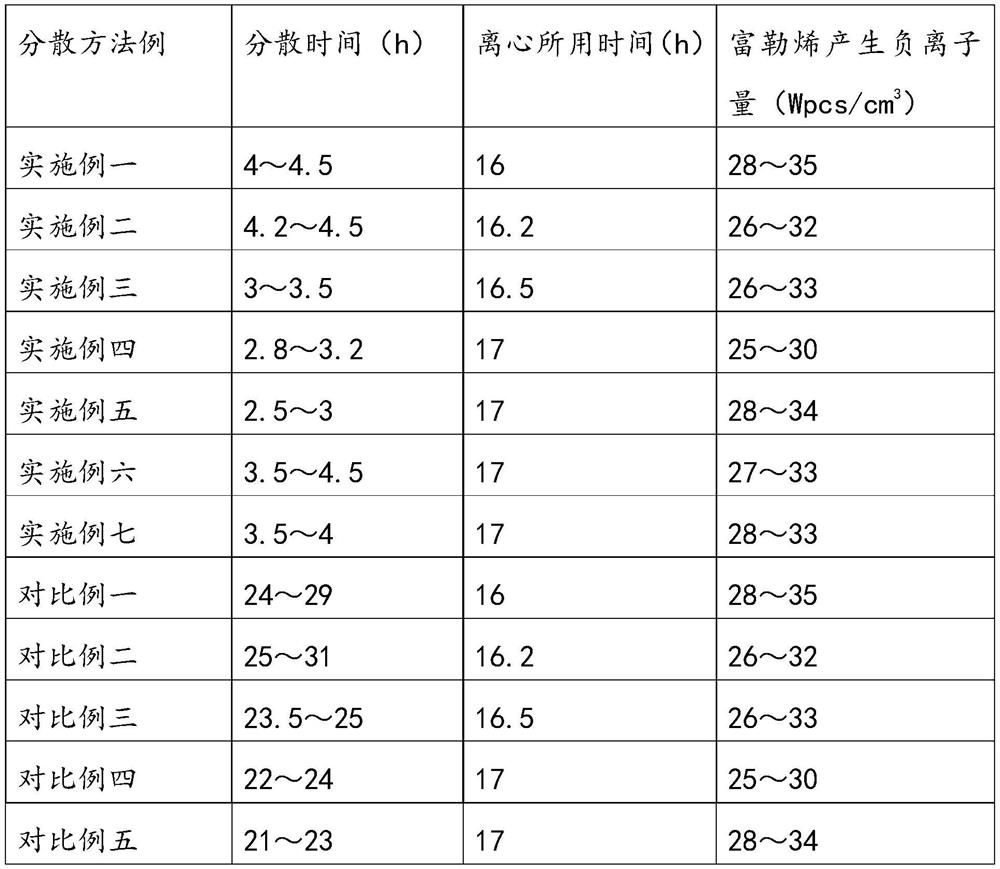

[0041] Weigh fullerene and carbon nanotubes according to the mass ratio of 1:0.1, add polyvinylpyrrolidone and chloroform mixed solution, the mass ratio of the mixed solution to the total mass of fullerene and carbon nanotubes is 60 : 1, where the mass fraction of polyvinylpyrrolidone is 2% based on the quality of the mixed solution of polyvinylpyrrolidone and chloroform, and the first mixture is obtained;

[0042] The negative oxygen ions generated by the negative oxygen ion air purifier are directly passed into the closed environment where the mechanical dispersion is located through the collection tube, creating the first negative oxygen ion environment. Based on the volume of the closed space where the mechanical dispersion process is located, pass into The concentration of negative oxygen ions is: 1 thousand / cm 3 ;

[0043] In the first negative oxygen ion environment, use a grinder to grind the first mixture, and then use a magnetic stirrer to stir to obtain a dispersio...

Embodiment 2

[0048] Weigh the fullerene and the carbon nanotube according to the mass ratio of 1:0.5, add the mixed solution of polyvinylpyrrolidone and chloroform to mix, the mass ratio of the mixed solution to the total mass of the fullerene and the carbon nanotube is 80 : 1, based on the quality of the mixed solution of polyvinylpyrrolidone and chloroform, the mass fraction of polyvinylpyrrolidone is 2%, and the first mixture is obtained;

[0049] The negative oxygen ions generated by the negative oxygen ion air purifier are directly passed into the closed environment where the mechanical dispersion is located through the collection tube, creating the first negative oxygen ion environment. Based on the volume of the closed space where the mechanical dispersion process is located, pass into The concentration of negative oxygen ions is: 1 thousand / cm 3 ;

[0050] In the first negative oxygen ion environment, use a grinder to grind the first mixture, and then use a magnetic stirrer to sti...

Embodiment 3

[0055] Weigh the fullerene and the nanowire at a mass ratio of 1:0.5, add a mixed solution of polyvinylpyrrolidone and chloroform to mix, and the mass ratio of the mixed solution to the total mass of the fullerene and the nanowire is 100: 1. Based on the quality of the mixed solution of polyvinylpyrrolidone and chloroform, the mass fraction of polyvinylpyrrolidone is 3%, and the first mixture is obtained;

[0056] The negative oxygen ions generated by the negative oxygen ion air purifier are directly passed into the closed environment where the mechanical dispersion is located through the collection tube, creating the first negative oxygen ion environment. Based on the volume of the closed space where the mechanical dispersion process is located, pass into The concentration of negative oxygen ions is: 5 thousand / cm 3 ;

[0057] In the first negative oxygen ion environment, the first mixture is ground with a grinder, and then stirred with a magnetic stirrer to obtain a dispers...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com