Permanent antistatic polycarbonate composite and preparation method thereof

A technology of polycarbonate and composition, which is applied in the field of permanent antistatic transparent polycarbonate composition and its preparation, and can solve the problem that polycarbonate molding temperature cannot be used to prepare transparent PC materials, the surface is easy to accumulate static charges, and the material is destroyed Process and other issues, to achieve the effect of easy automatic control, improved melt fluidity, and high transparency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment example 1

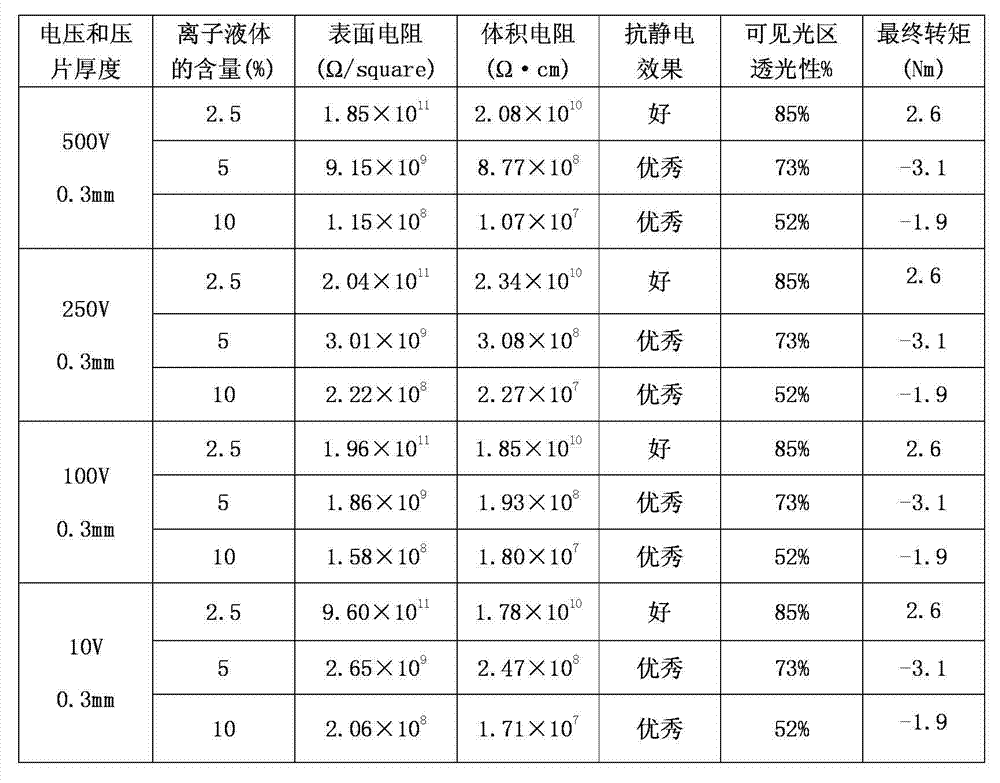

[0028] Add 191g of polycarbonate, 1g of polyvinylidene fluoride, 3g of other additives, and 5g of tri-n-butylmethylamine bis(trifluoromethanesulfonyl)imide salt into a Haake rheometer at 260°C for 15 minutes and then extrude through a twin-screw It is extruded, cut into pellets and dried before packaging. The temperature of each zone of the twin-screw extruder is set at 240°C-270°C. The prepared composition was thermocompressed at 250° C., and its surface resistance, volume resistance and light transmittance were measured.

Embodiment example 2

[0030] Add 186g of polycarbonate, 1g of polyvinylidene fluoride, 3g of other additives, and 10g of tri-n-butylmethylamine bis(trifluoromethanesulfonyl)imide salt into a Haake rheometer at 260°C for 15 minutes and then extrude through a twin-screw It is extruded, cut into pellets and dried before packaging. The temperature of each zone of the twin-screw extruder is set at 240°C-270°C. The prepared composition was thermocompressed at 250° C., and its surface resistance, volume resistance and light transmittance were measured.

Embodiment example 3

[0032] Add 176g of polycarbonate, 1g of polyvinylidene fluoride, 3g of other additives, and 20g of tri-n-butylmethylamine bis(trifluoromethanesulfonyl)imide salt into a Haake rheometer at 260°C for 15 minutes and then extrude through a twin-screw It is extruded, cut into pellets and dried before packaging. The temperature of each zone of the twin-screw extruder is set at 240°C-270°C. The prepared composition was thermocompressed at 250° C., and its surface resistance, volume resistance and light transmittance were measured.

[0033] Table 1 Surface resistance, volume resistance and light transmittance test results of implementation cases 1-3

[0034]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com