Hydrolysis unit for glucosamine hydrochloride production

A technology of glucosamine hydrochloride and hydrolysis device, which is applied in the direction of amino sugar, sugar derivatives, sugar derivatives, etc., which can solve the problems of slow hydrolysis speed and affecting hydrolysis efficiency, and achieve the effect of increasing speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

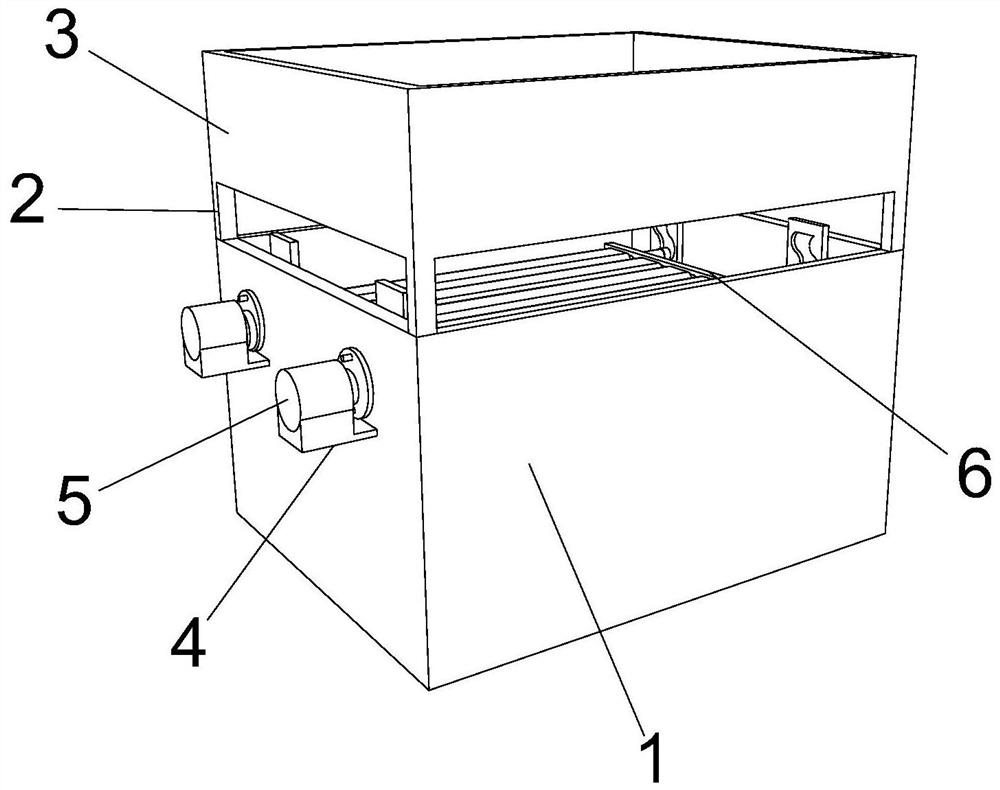

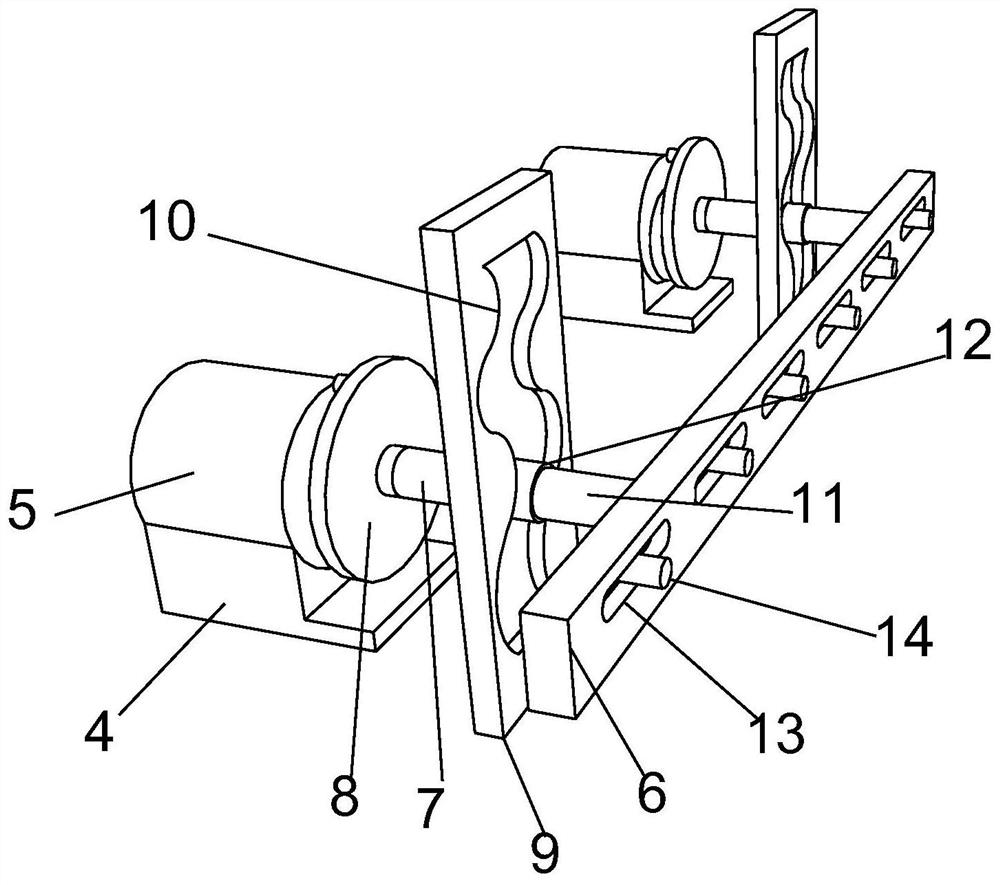

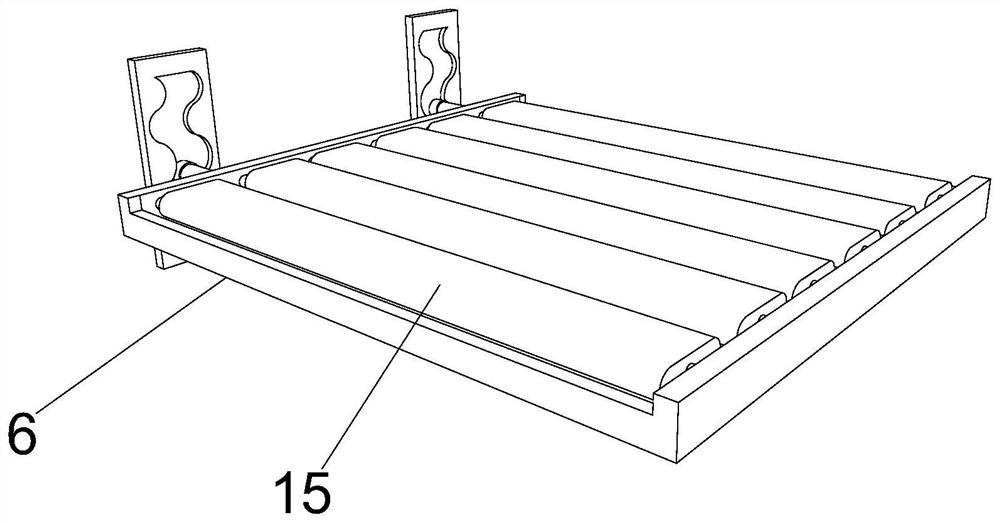

[0029] Embodiment: Glucosamine hydrochloride production hydrolysis device, such as Figure 1-Figure 7As shown, it includes a hydrolysis box 1, the hydrolysis box 1 is a rectangular hollow box and the upper end of the hydrolysis box 1 is hollowed out, and the four corners of the upper end of the hydrolysis box 1 are fixed vertically upward with support rods 2, and the support rods 2 are rectangular Long rods, the upper ends of the four sets of support rods 2 are fixed with a storage box 3, the storage box 3 is a rectangular box, and a row of leaking grooves 301 are horizontally provided at the inner lower end of the storage box 3, and the leaking grooves 301 are rectangular grooves and leaking materials The groove 301 runs through the bottom inner wall of the storage box 3 up and down, and the inside of the leaking material tank 301 is movably installed with a turning plate 302 through a rotating shaft. The inside of the storage box 3 is loaded with hydrochloride that needs to ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| specific rotation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com