Gradient porosity anode for solid oxide fuel cell and fuel cell

A solid oxide, fuel cell technology, used in fuel cells, battery electrodes, circuits, etc., to increase the activation specific surface area, improve overall performance, and improve thermal matching.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

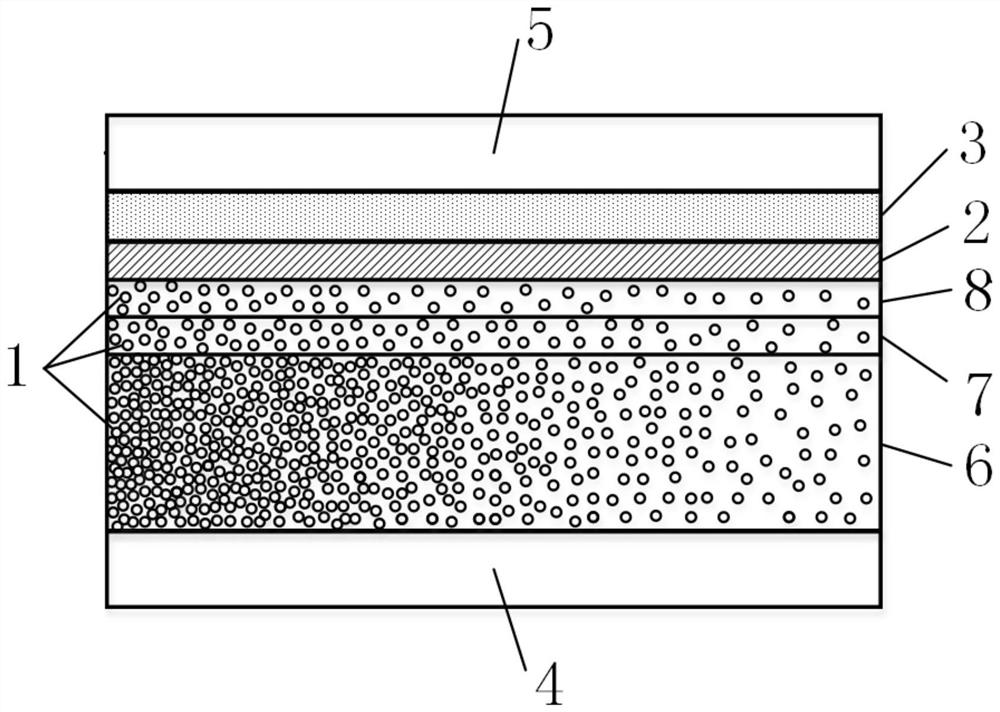

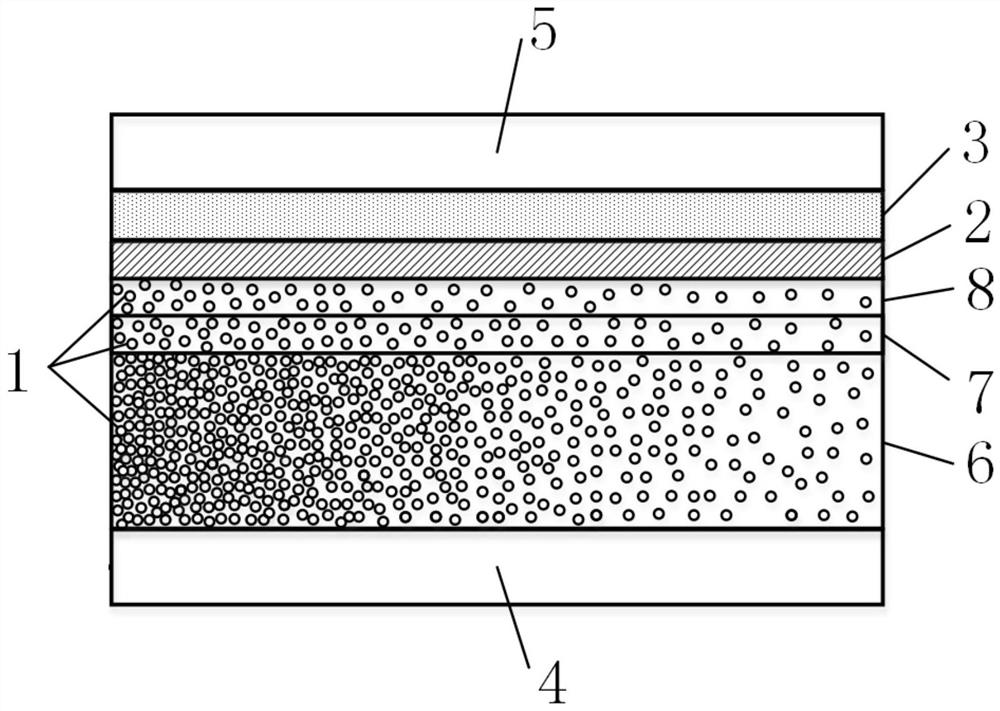

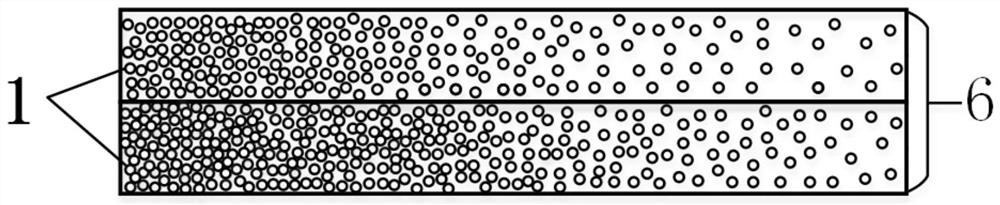

[0035] refer to figure 1 The solid oxide fuel cell gradient porosity anode is composed of an anode support layer 6, an anode transition layer 7 and an anode functional layer 8, wherein the thicknesses of the anode support layer 6, anode transition layer 7 and anode function layer 8 are 600 μm and 30 μm respectively and 30μm.

[0036] The solid oxide fuel cell gradient porosity anode is Ni-YSZ cermet, and it is prepared by casting or spraying. The specific preparation process is as follows:

[0037] First, the anode functional layer 8 is adjacent to the electrolyte layer 2, and the opening porosity of the anode functional layer 8 is linearly decreased from 0.3 to 0.1 along the horizontal direction of the electrode by controlling the content of the pore-forming agent. The electrochemical reaction mainly occurs in the anode functional layer 8, and the porosity of the anode functional layer 8 changes gradually along the horizontal direction, which is conducive to further increasing...

Embodiment 2

[0043] The difference between this embodiment and Embodiment 1 is that in the anode functional layer 8, by controlling the content of the pore-forming agent, the opening porosity of the anode functional layer 8 increases linearly from 0.1 to 0.1 along the horizontal direction of the electrode. 0.3; in the anode transition layer 7, by controlling the content of the pore former, the opening porosity of the anode transition layer 7 increases linearly from 0.3 to 0.5 along the horizontal direction of the electrode; in the anode support layer 6, by controlling The content of the pore-forming agent makes the opening porosity of the anode support layer 6 linearly increase from 0.5 to 0.7 along the horizontal direction, and its output power density is between Figure 5 shown.

Embodiment 3

[0045] In order to further enhance the strength of the solid oxide fuel cell, the anode support layer 6 has at least 2 layers, at most 60 layers, preferably 20-35 layers, and the opening porosity gradient of each anode support layer 6 increases progressively from top to bottom, which can be While ensuring the comprehensive electrical performance of the solid oxide fuel cell, the strength of the cell can be further improved.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com