High-Bs high-strength manganese-zinc ferrite material and preparation method thereof

A manganese-zinc ferrite, high-strength technology, applied in the field of magnetic materials, can solve the problems of large changes in magnetic permeability, low Curie temperature, low magnet strength, etc., to reduce loss, increase high Bs, and improve superposition performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] (1) Batching: take main component raw material and additive according to following proportioning ratio, and main component is made up of the raw material of the molar percentage shown in table 1: Fe 2 o 3 59.5mol%, MnO 26mol%, ZnO 12mol%, NiO 2.5mol%; based on the total amount of main components, the additive is composed of raw materials with the following content: SiO 2 60ppm, CaCO 3 600ppm, MoO 3 250ppm, V 2 o 5 400ppm, Nb 2 o 5 200ppm, ZrO 2 200ppm, SnO 2 400ppm; add deionized water to the sand mill for the main component raw materials to circulate, mix and crush, and spray dry to get the spray material;

[0042] (2) Pre-burning: Put the spray material into the pre-burning furnace of the rotary kiln and carry out pre-burning at 800°C for 5 hours, and the feed rate is 250kg / h to obtain the pre-burning material;

[0043] (3) Sanding: After adding additives to the pre-fired material, add deionized water for sanding to obtain sanding abrasives; the feed ...

Embodiment 2-6

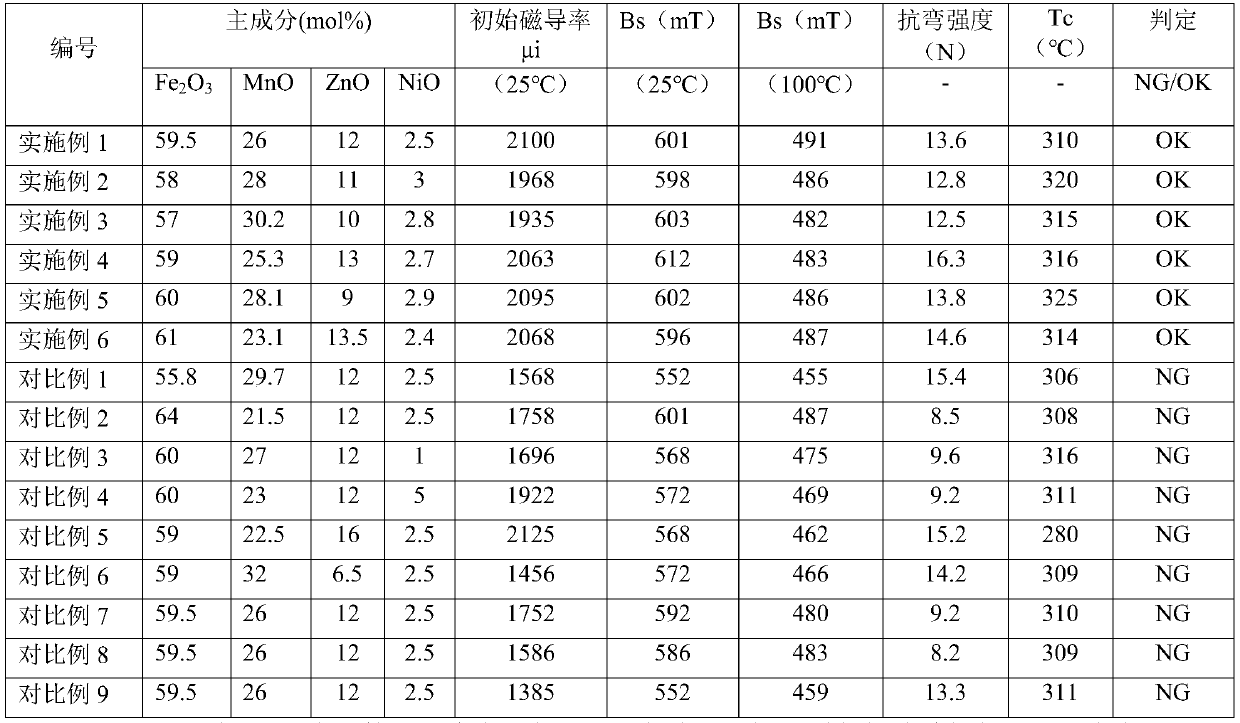

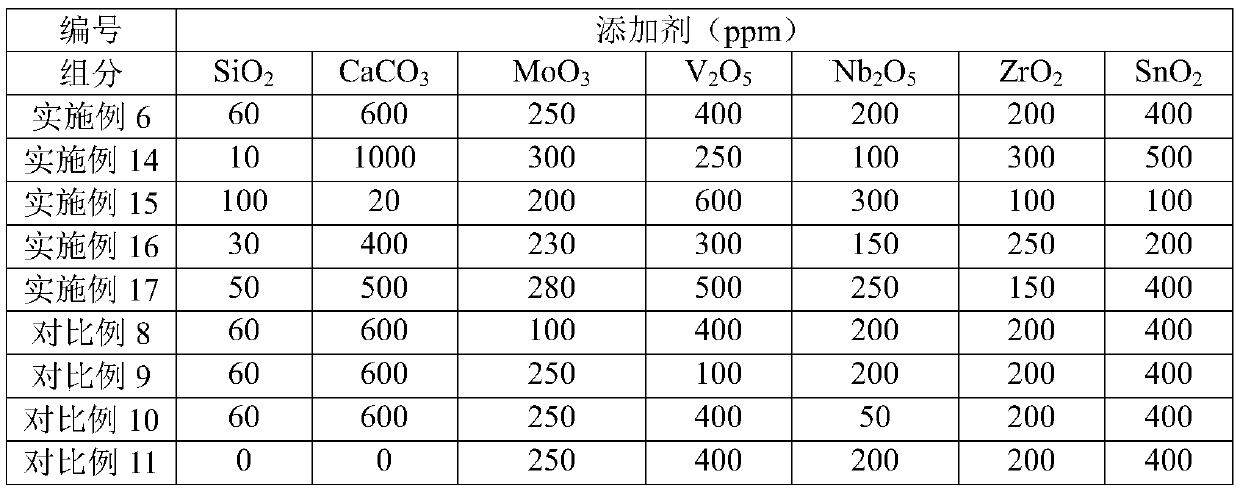

[0051] The difference between Examples 2-6 and Example 1 is that the formulations of the main components are different, see Table 1, and the rest of the process conditions are identical.

[0052] The difference between Comparative Examples 1-6 and Example 1 is that the formulations of the main components are different, see Table 1, and the rest of the process conditions are identical.

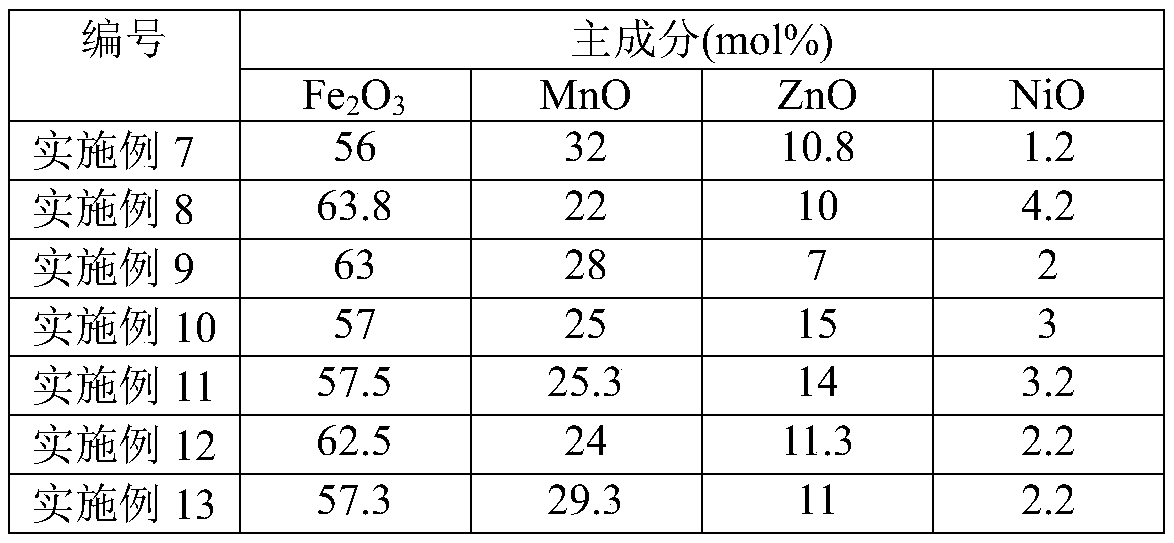

Embodiment 7

[0067] (1) Batching: take main component raw material and additive according to following proportioning ratio, and main component is made up of the raw material of the molar percentage shown in table 2: Fe 2 o 3 56mol%, MnO 32mol%, ZnO 10.8mol%, NiO 1.2mol%; based on the total amount of main components, the additive is composed of raw materials with the following content: SiO2 60ppm, CaCO 3 600ppm, MoO 3 250ppm, V 2 o 5 400ppm, Nb 2 o 5 200ppm, ZrO 2 200ppm, SnO 2 400ppm; add deionized water to the sand mill for the main component raw materials to circulate, mix and crush, and spray dry to get the spray material;

[0068] (2) Pre-burning: put the spray material into the rotary kiln pre-burning furnace and carry out pre-burning at 750°C for 6 hours, and the feed rate is 240kg / h to obtain the pre-burning material;

[0069] (3) Sanding: After adding additives to the calcined material, add deionized water for sanding to obtain sanding abrasives; the feed rate is 22...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com