Patents

Literature

45results about How to "Improve overlay effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

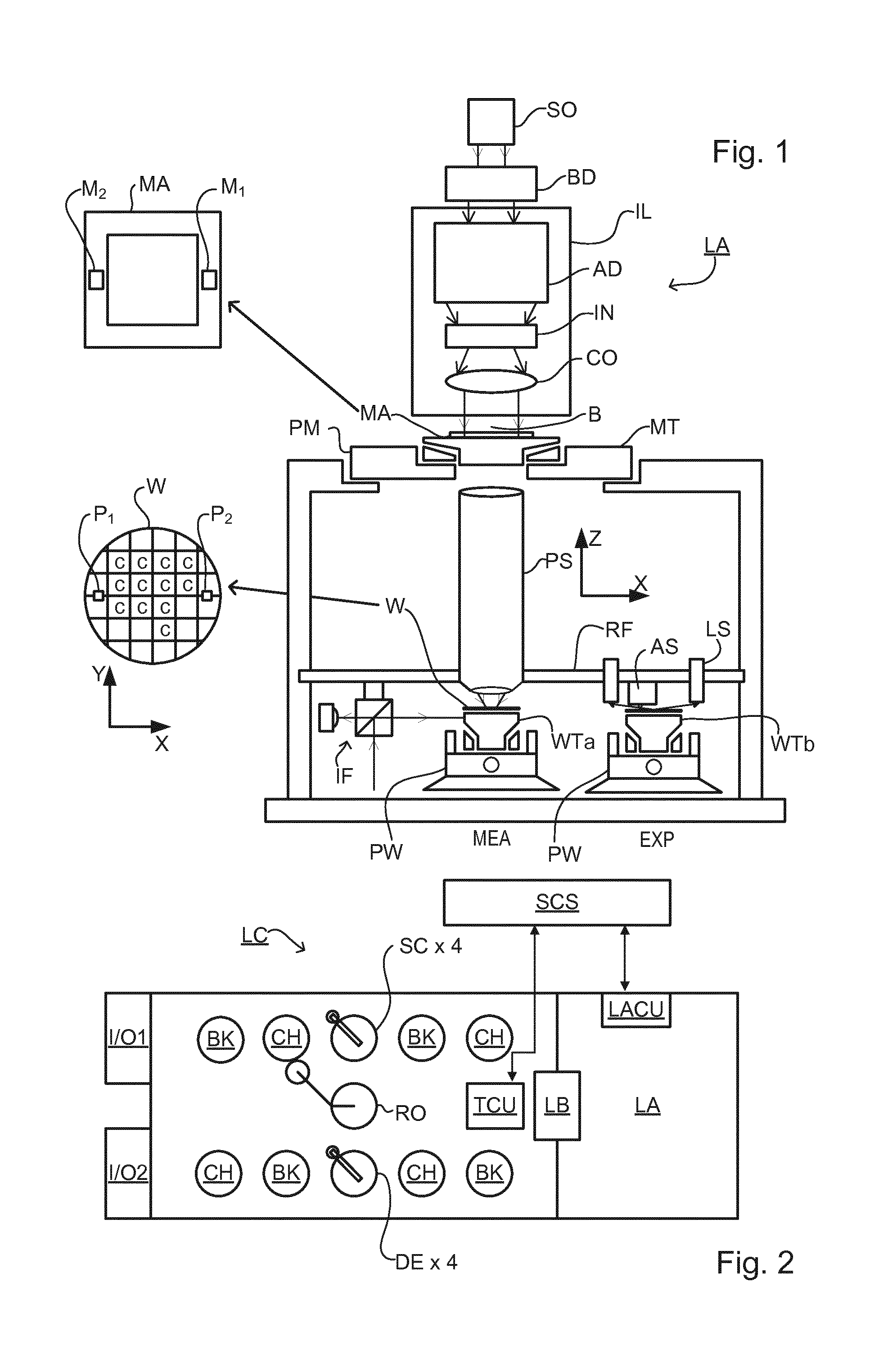

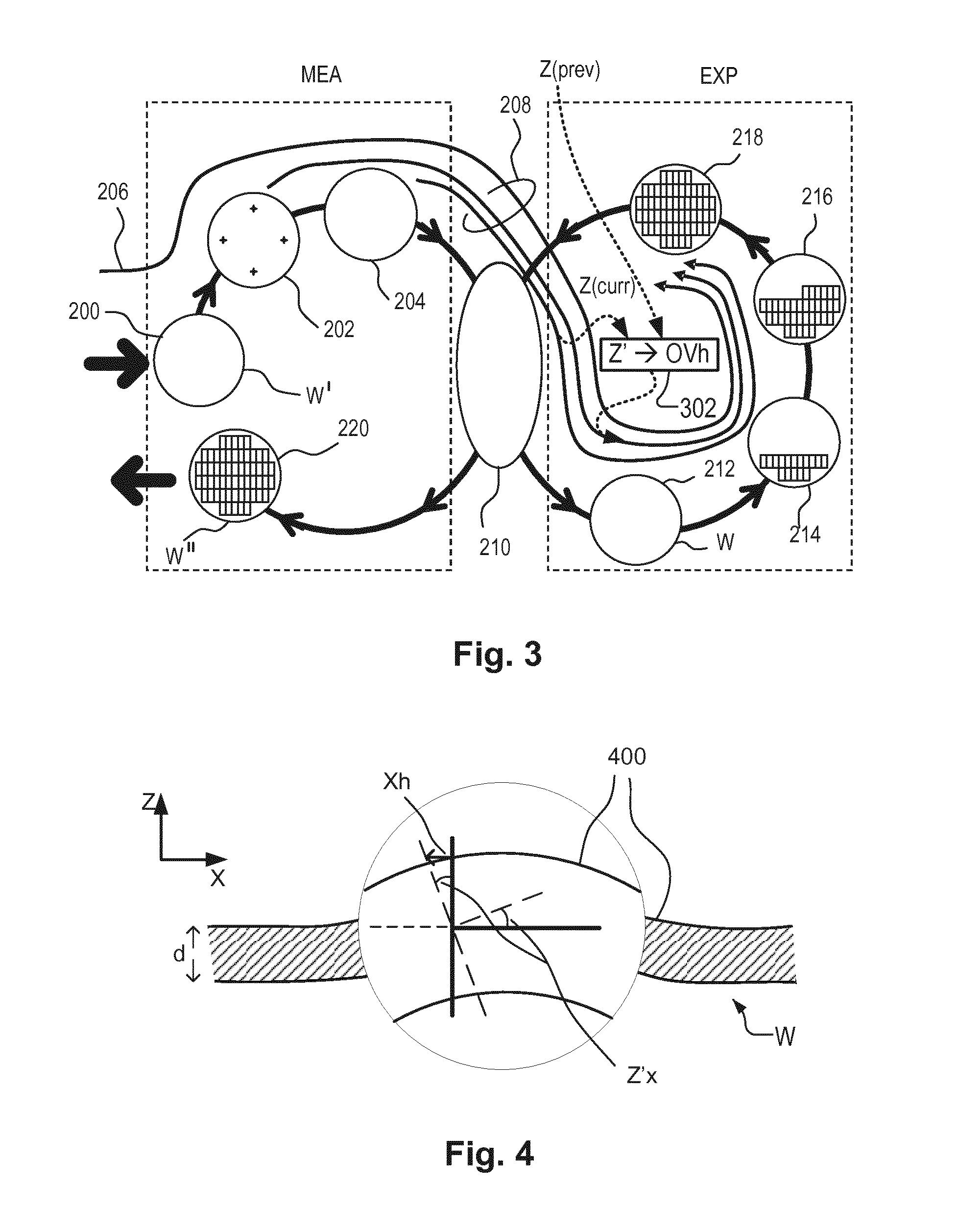

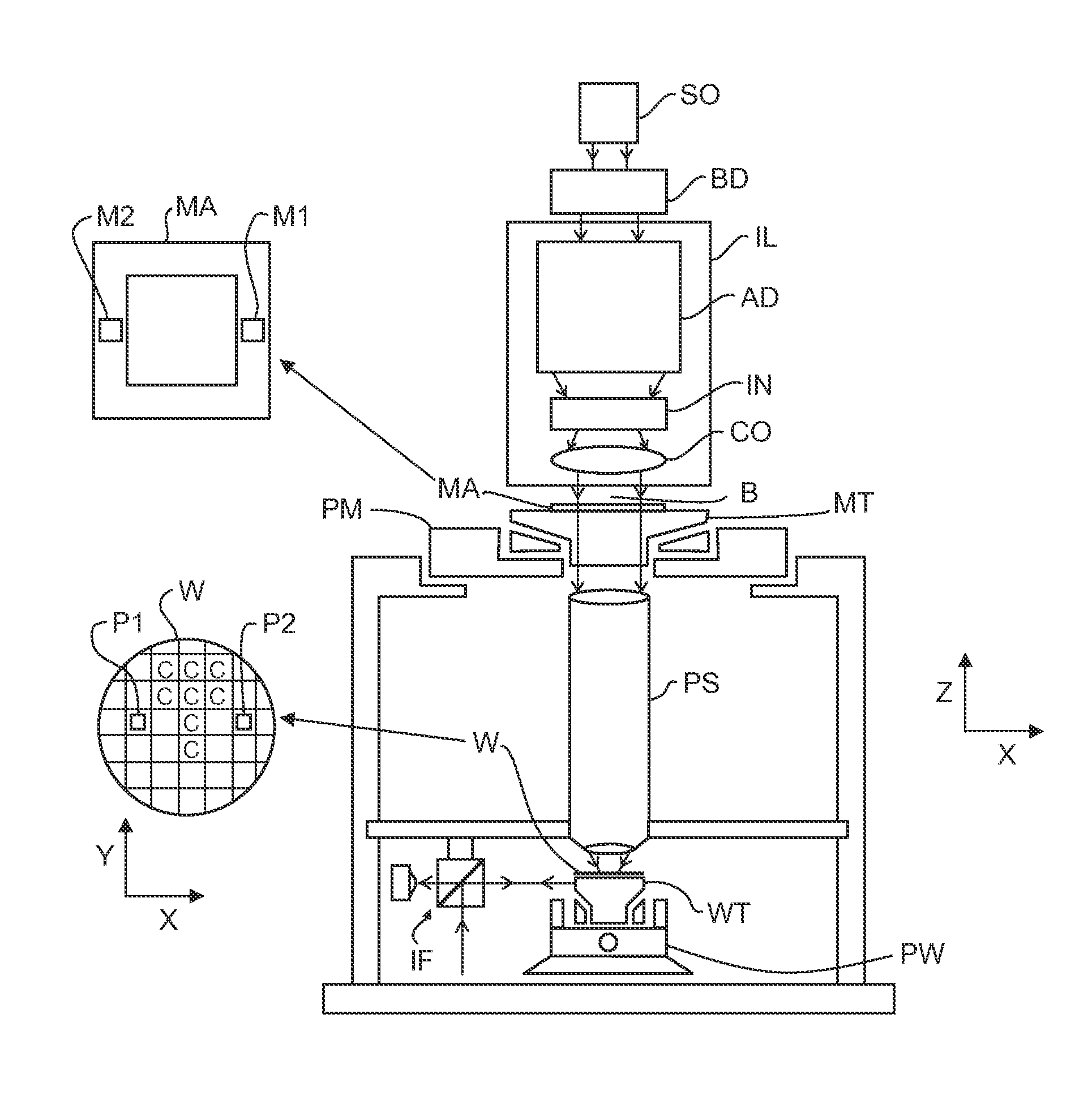

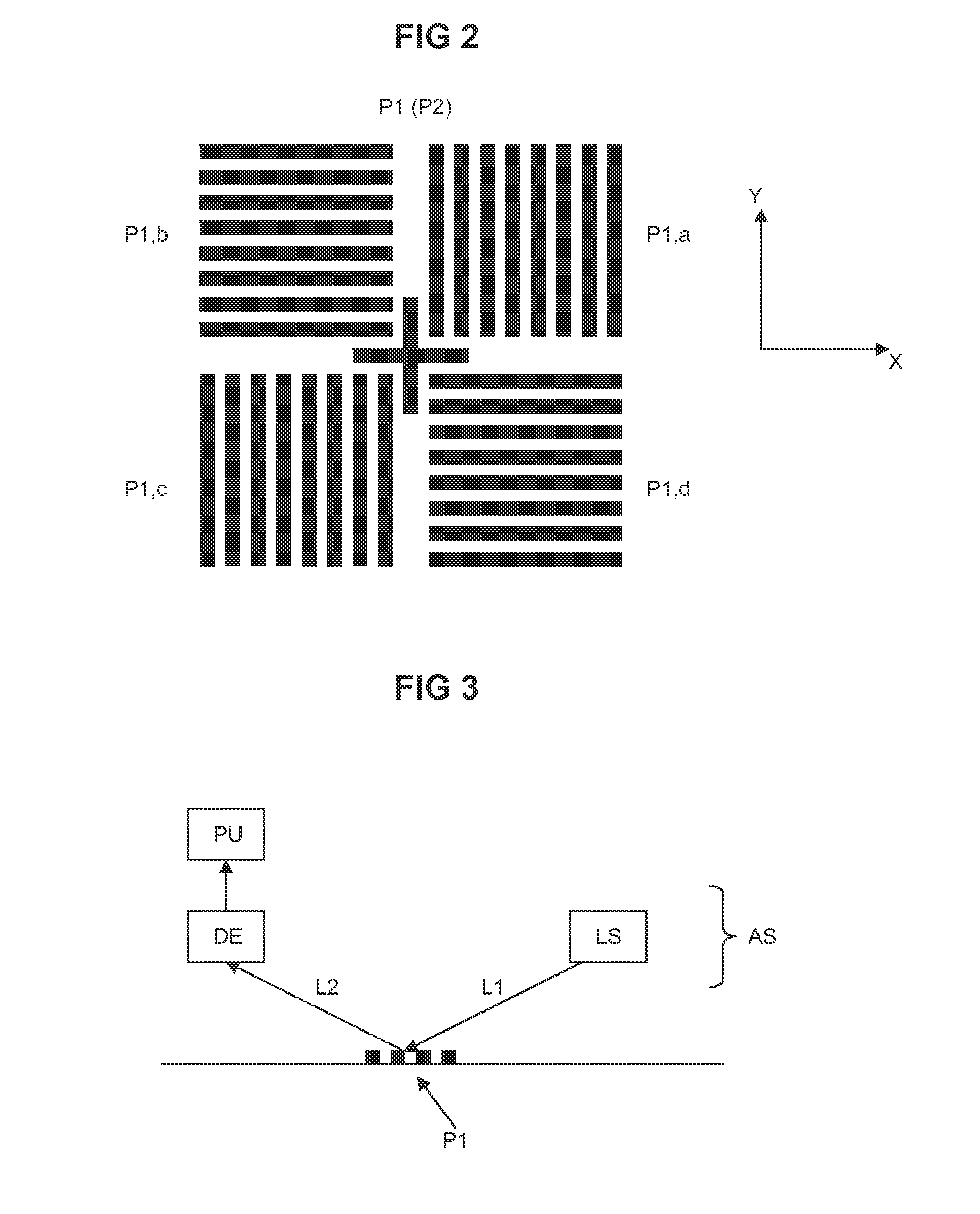

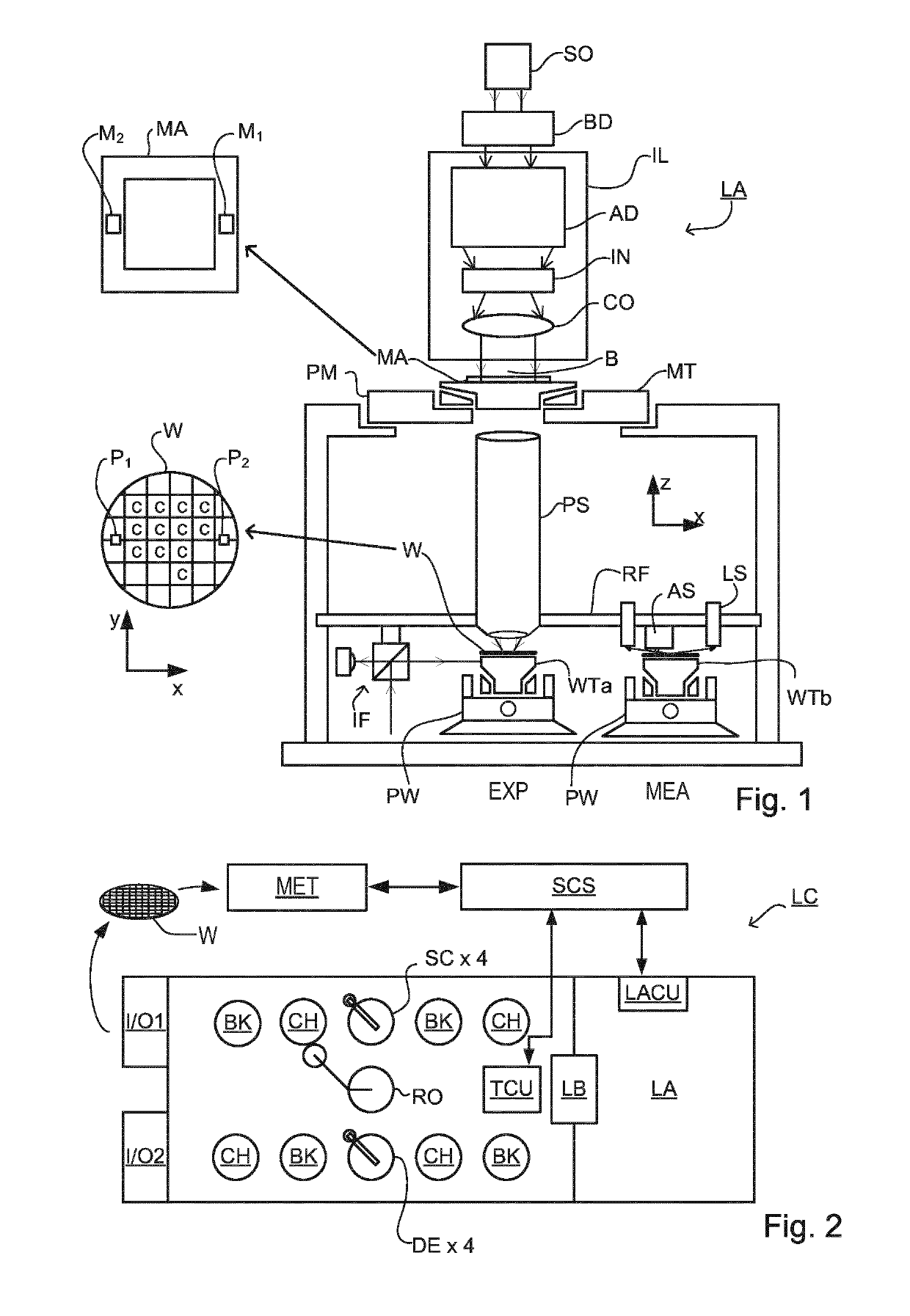

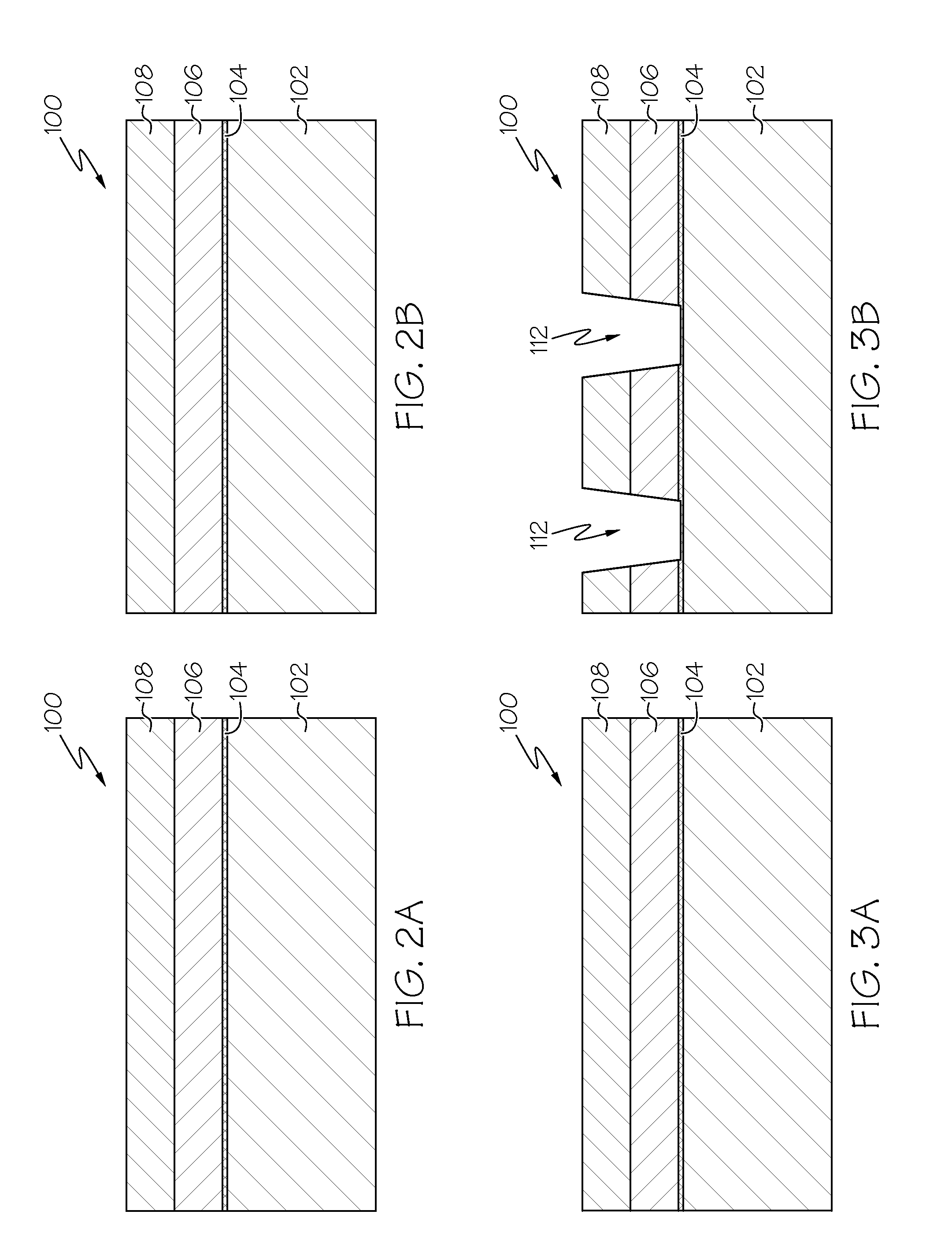

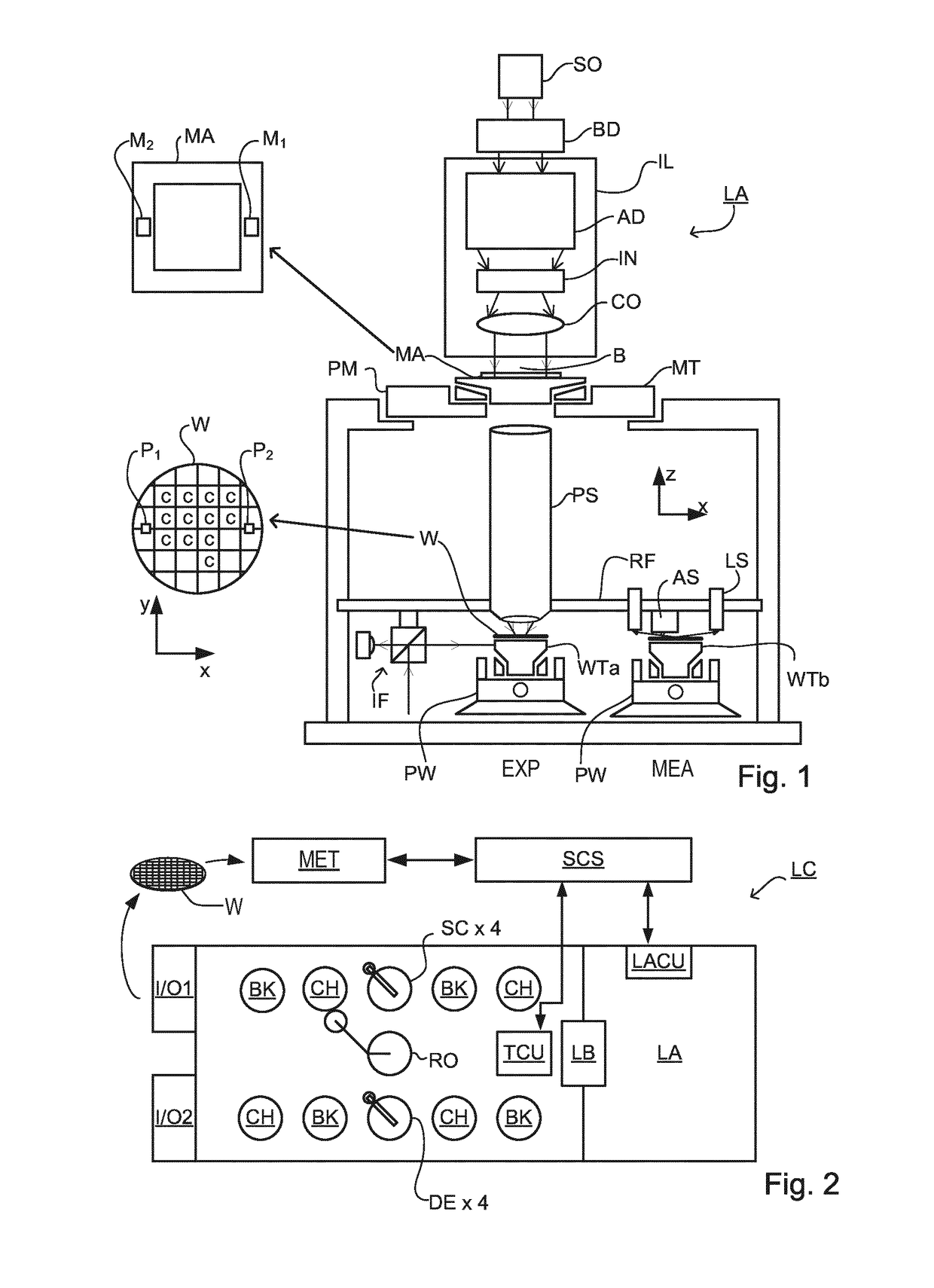

Lithographic apparatus, device manufacturing method and associated data processing apparatus and computer program product

ActiveUS20160334712A1Improve overlay effectAdversely impacting throughputPhotomechanical exposure apparatusMicrolithography exposure apparatusLevel sensorEngineering

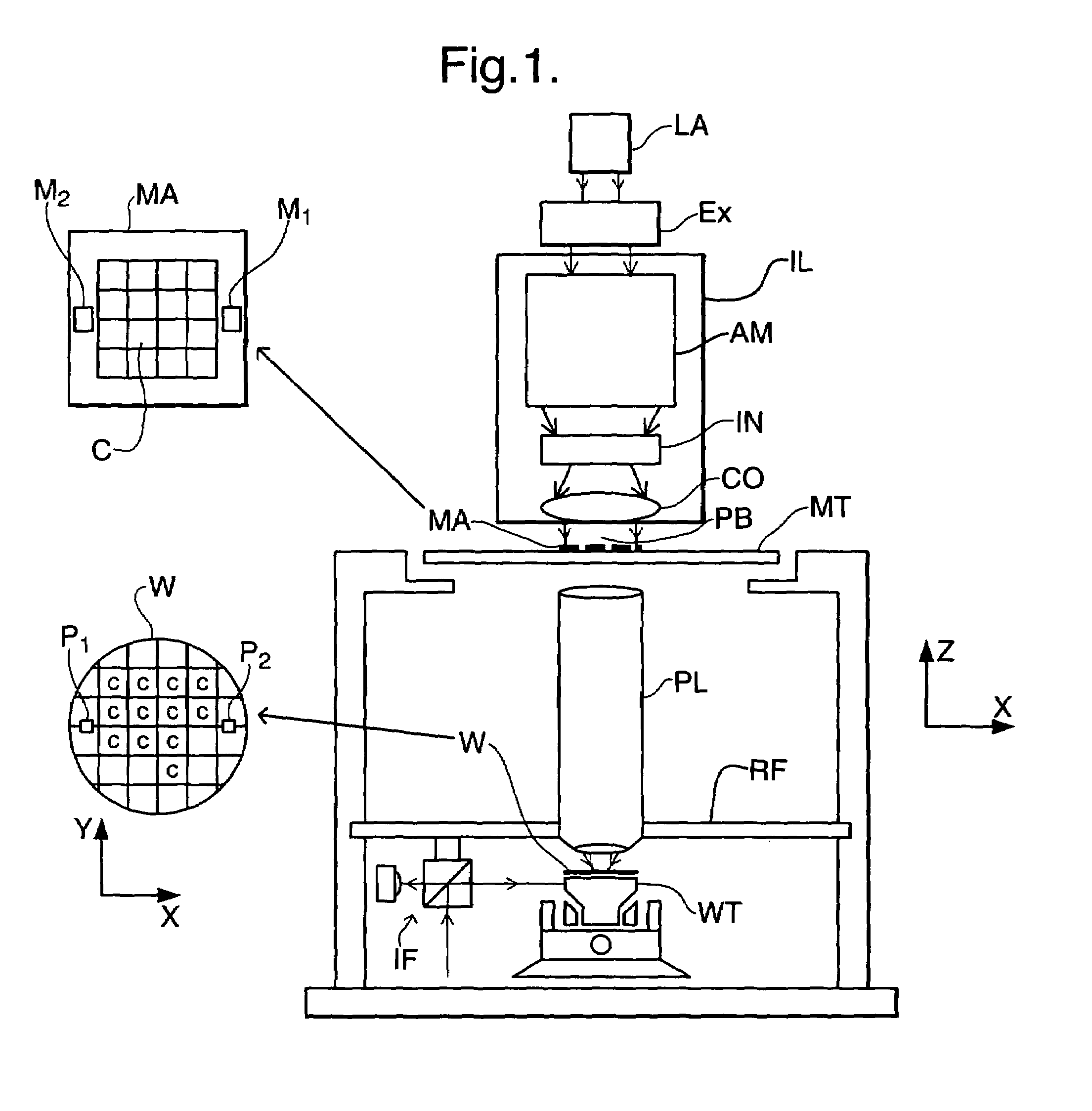

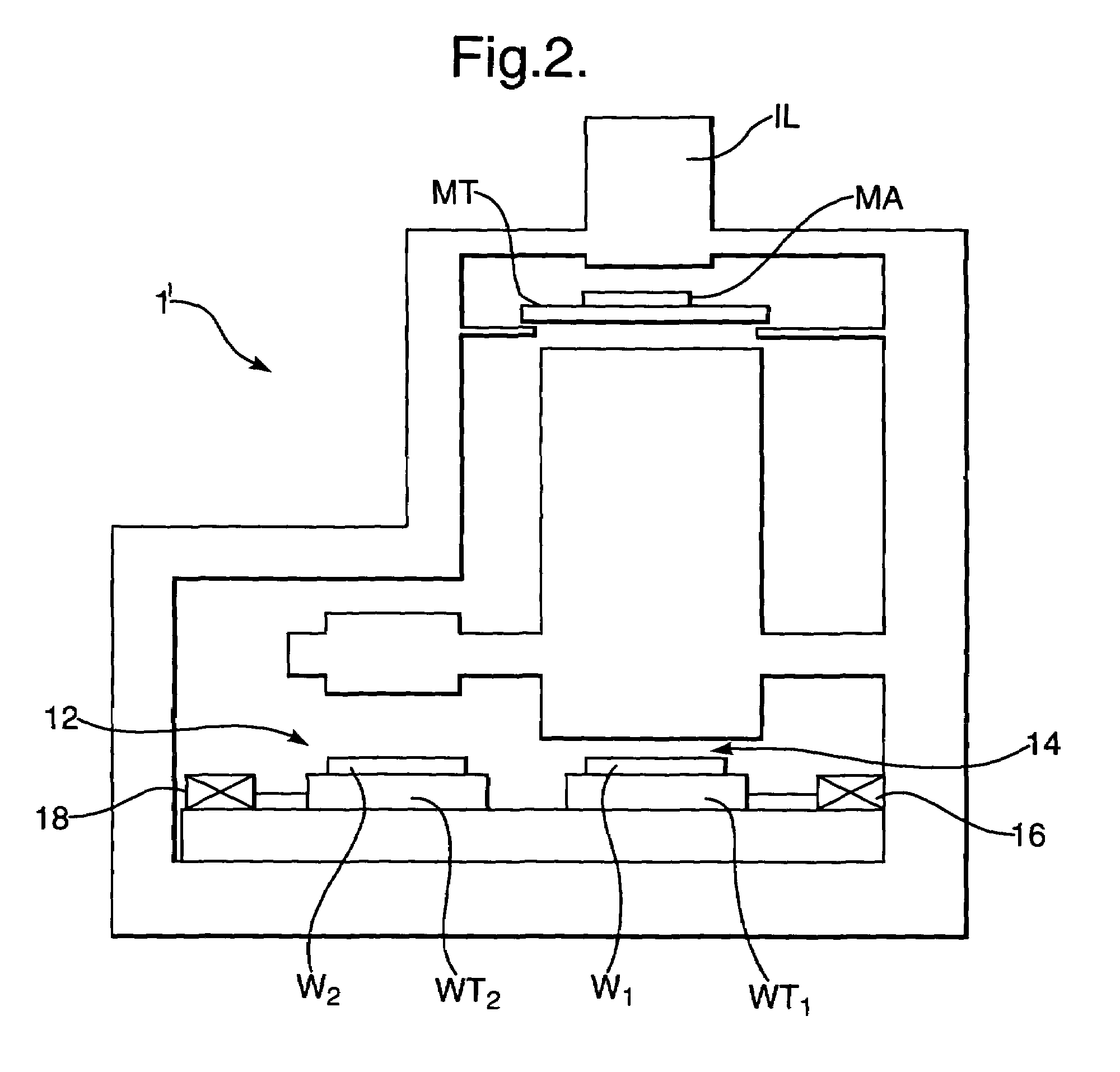

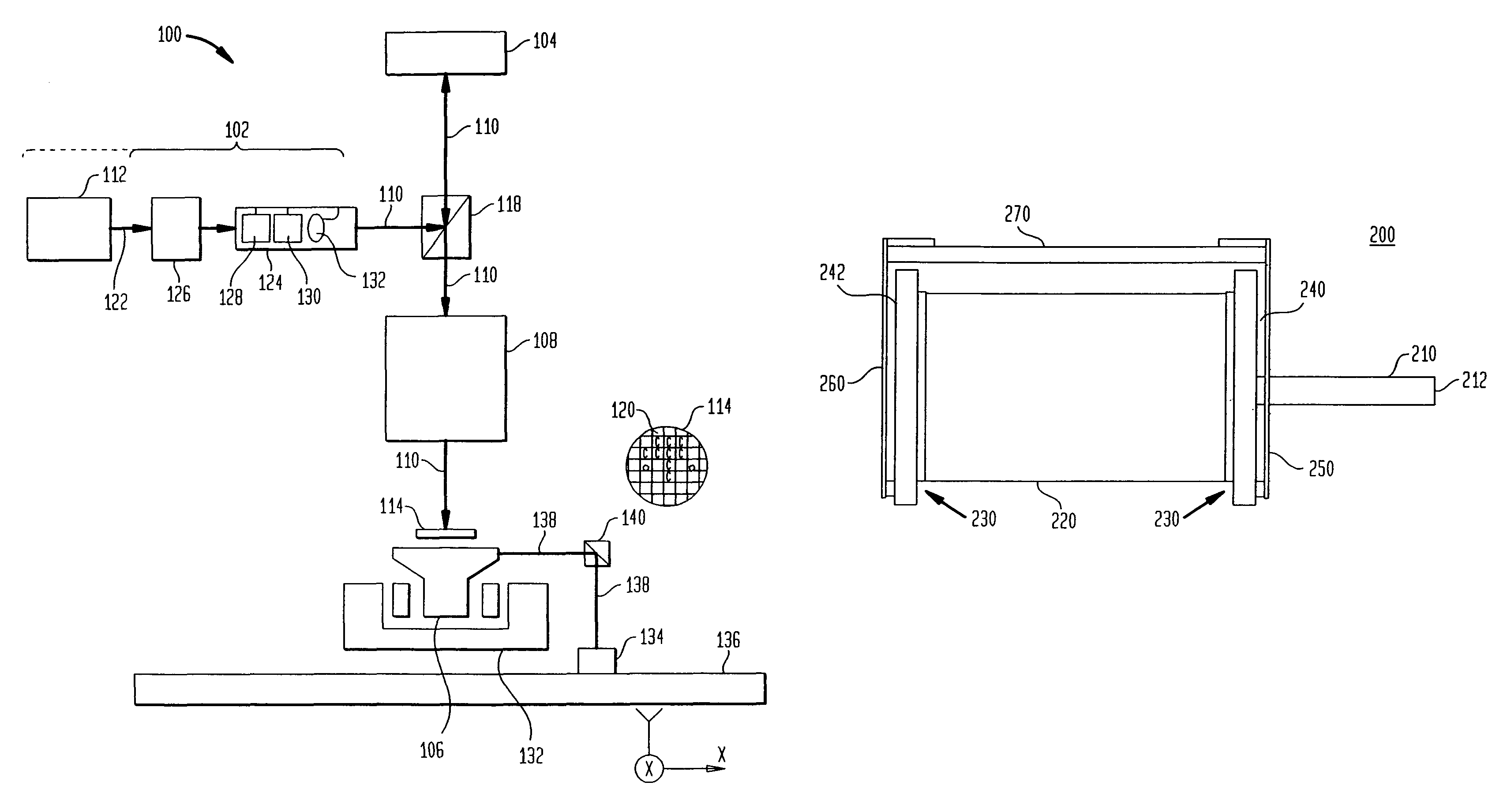

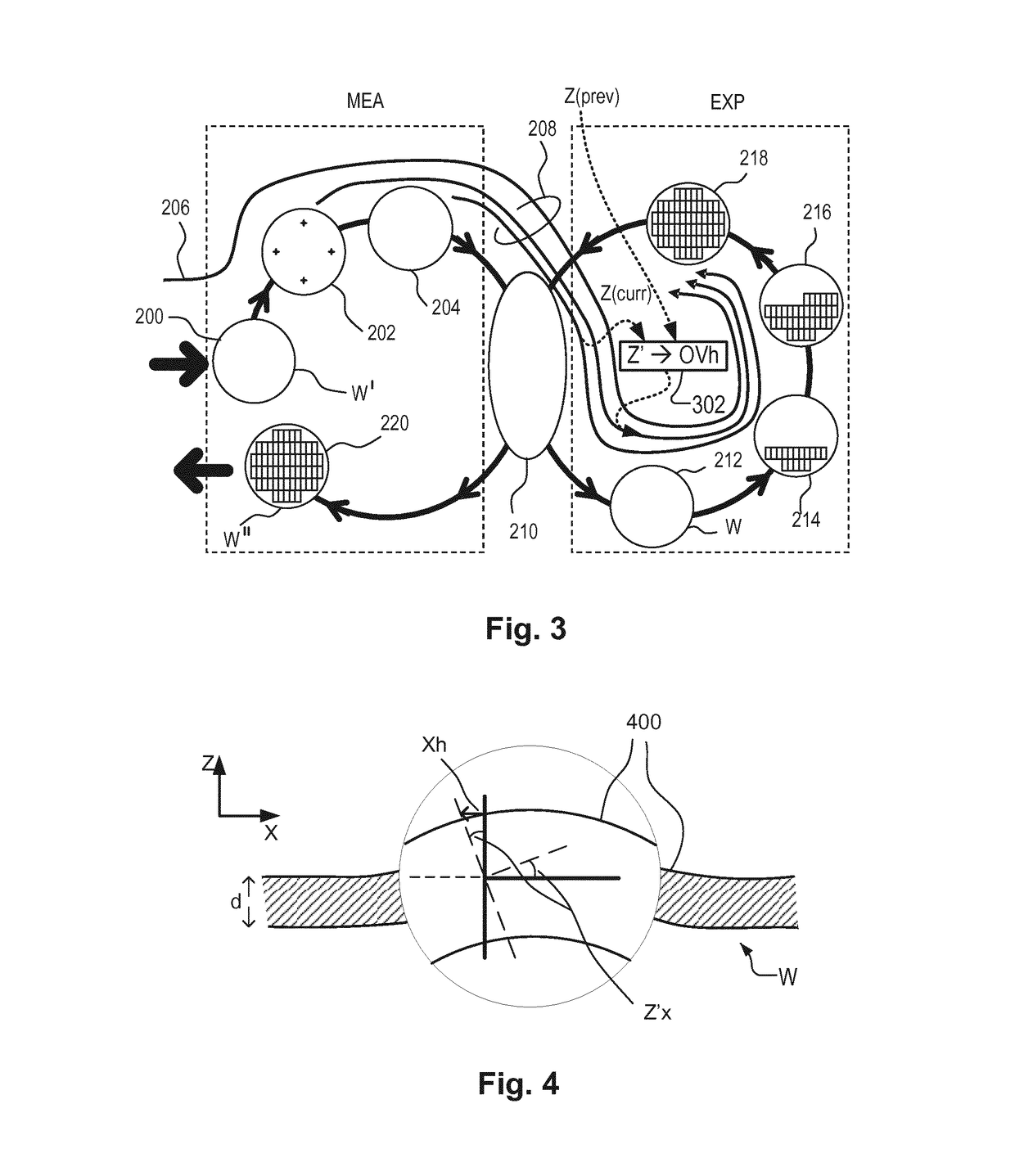

A lithographic apparatus applies a pattern repeatedly to target portions across a substrate. Prior to applying the pattern an alignment sensor measures positions of marks in the plane of the substrate and a level sensor measures height deviations in a direction normal to the plane of the substrate. The apparatus applies the pattern to the substrate while positioning the applied pattern using the positions measured by the alignment sensor and using the height deviations measured by the level sensor. The apparatus is further arranged to calculate and apply corrections in the positioning of the applied pattern, based on derivatives of the measured height deviations. The corrections may be calculated on an intrafield and / or interfield basis. The corrections may be based on changes between the observed height deviations and height deviations measured previously on the same substrate.

Owner:ASML NETHERLANDS BV

Optical element damping systems

ActiveUS20070153348A1Increase dampingDamp motionPhotomechanical apparatusMountingsLithographic artistAudio power amplifier

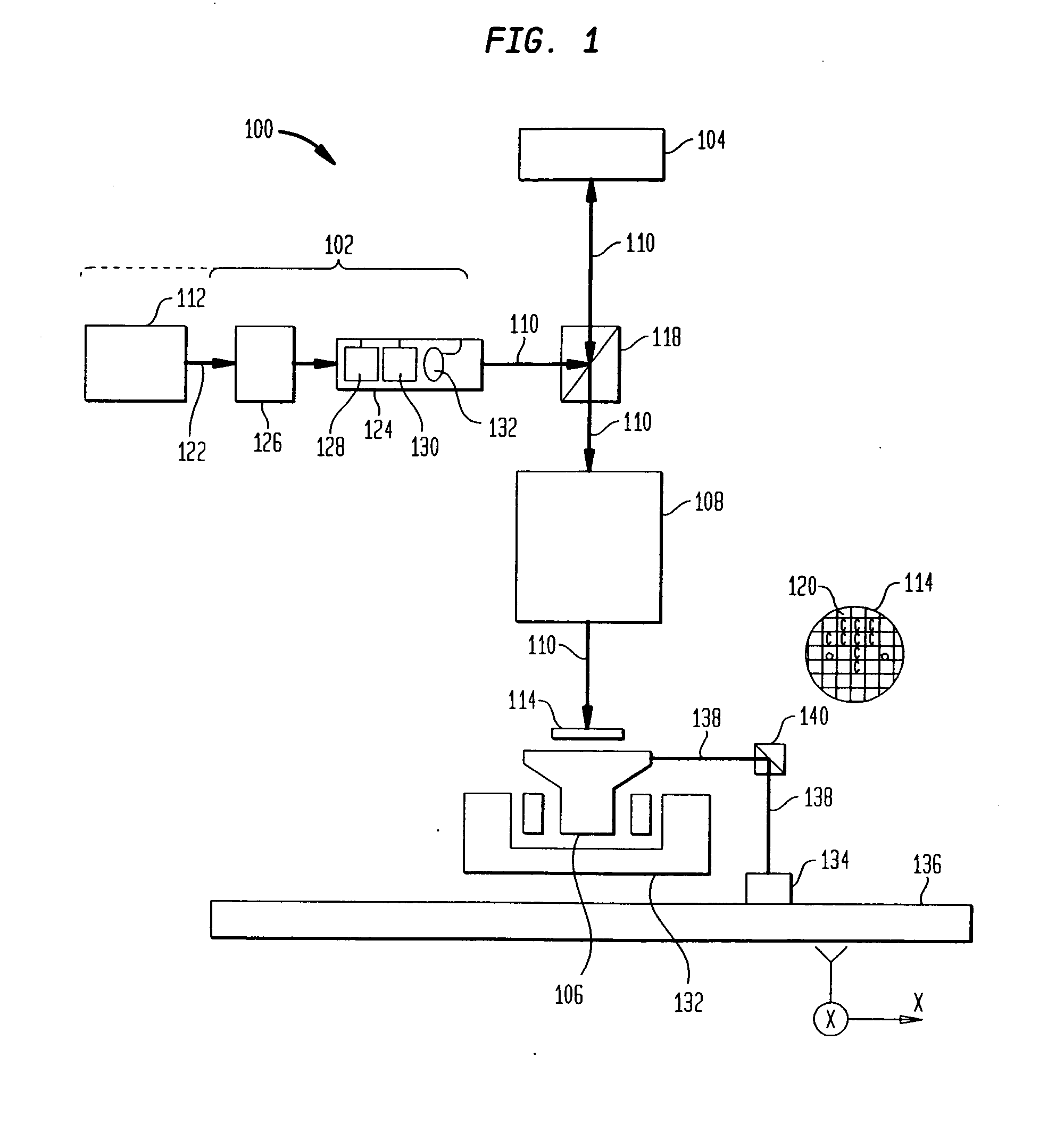

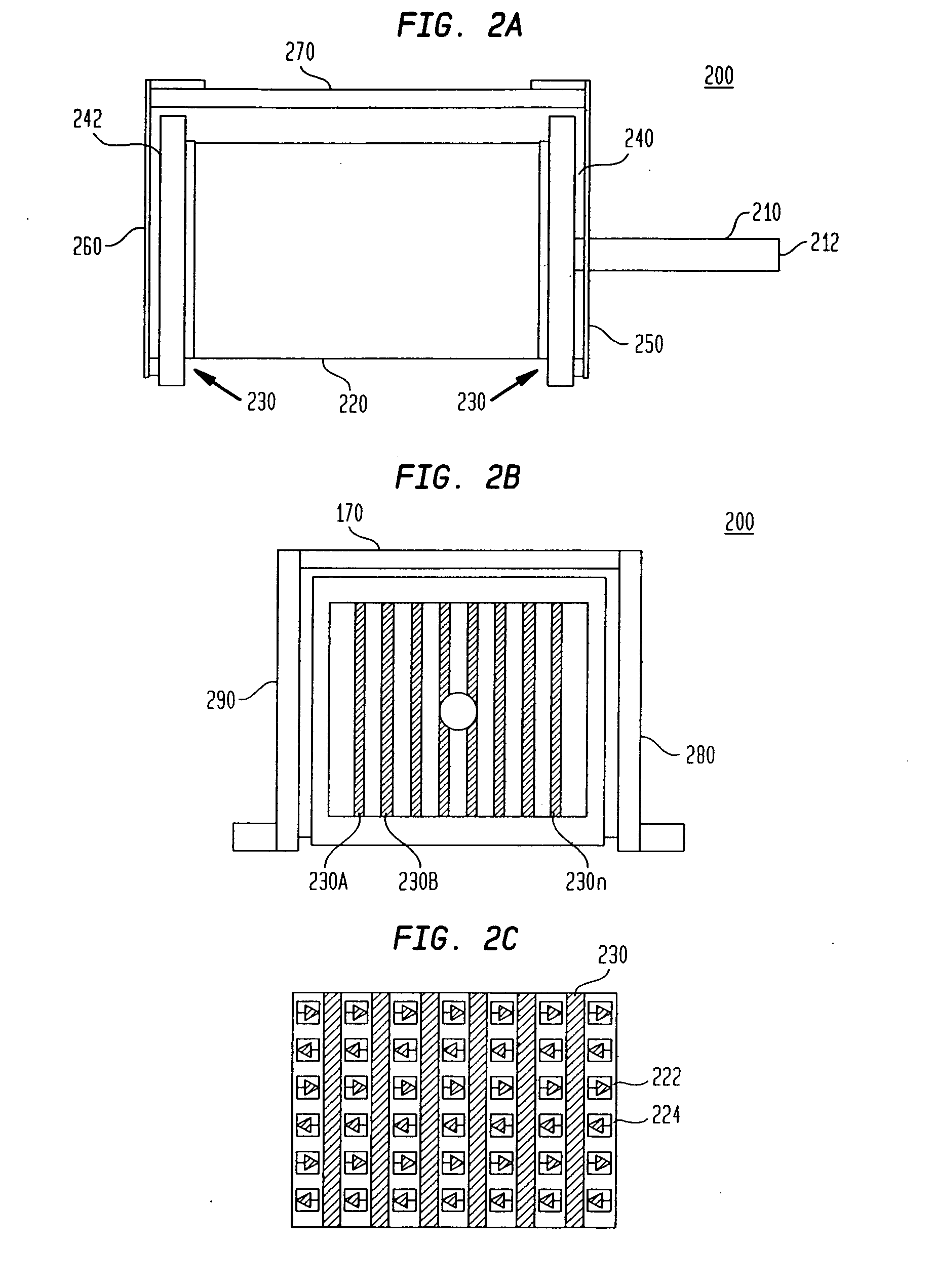

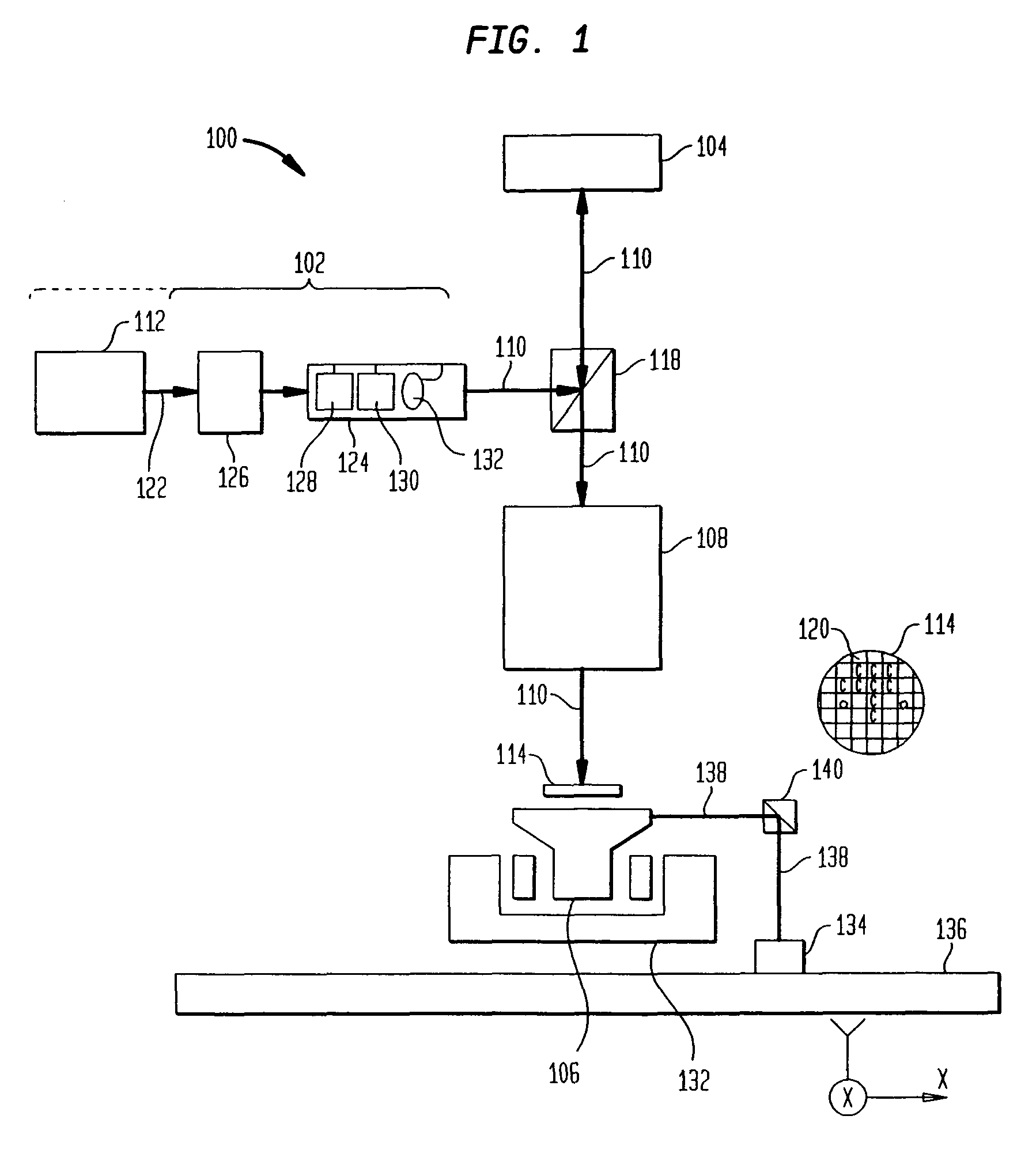

The present invention is directed to optical element damping systems. In particular, an eddy current damper is disclosed. The eddy current damper includes a rod, a series of conducting plates coupled to the rod, and layers of magnets. The alternating layers have alternating magnetic fields. When an optical element moves, the optical element will exert a force on the rod. The rod causes the conducting plates to move relative to the alternating layers of magnets to generate eddy currents within each of the conducting plates, such that the eddy currents damp the motion of an optical element. In an alternative embodiment, an eddy current damper motion amplifier is used to provide additional mechanical advantage that significantly increases the damping provided by the eddy current damper. Eddy current dampers are provided within conventional scanning lithography devices and optical maskless lithography devices to improve performance by stabilizing optical element motion.

Owner:ASML HLDG NV

Lithographic apparatus, device manufacturing method, and device manufactured thereby

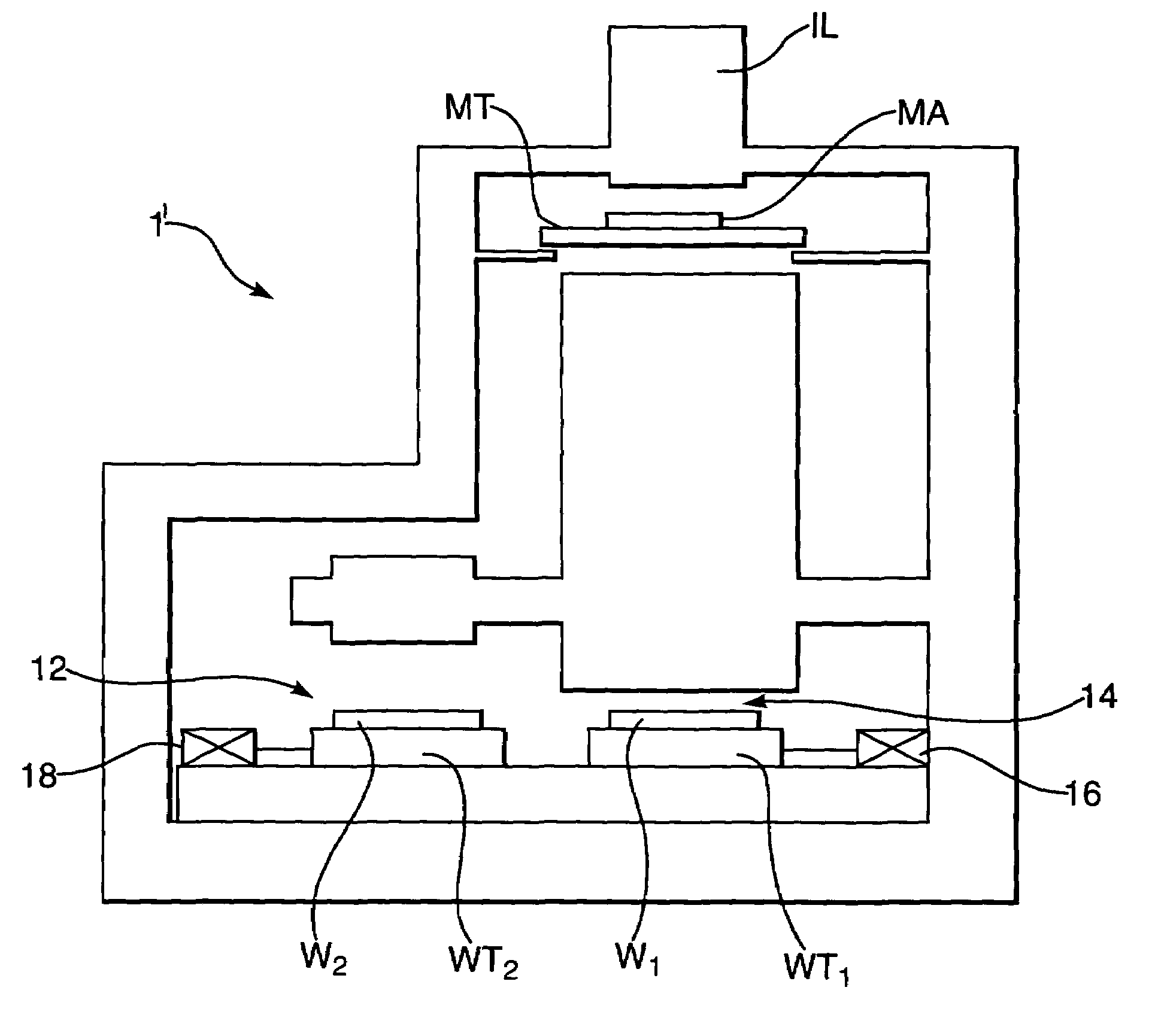

InactiveUS7046331B2Improve imaging effectEffect of differenceNon-fibrous pulp additionLayered productsEngineeringPhotolithography

A lithographic projection apparatus having at least two substrate holders is controlled to reduce effects of differences in images caused by differences between the two substrate holders. The apparatus includes an internal or external detector that identifies a substrate and associates it with a respective one of the substrate holders. A controller ensures that either the substrate is processed on the appropriate holder or that correction is applied to the imaging. In an alternate embodiment, the substrate is associated with a respective one of the substrate holders and is consistently processed using that substrate holder without further identification steps.

Owner:ASML NETHERLANDS BV

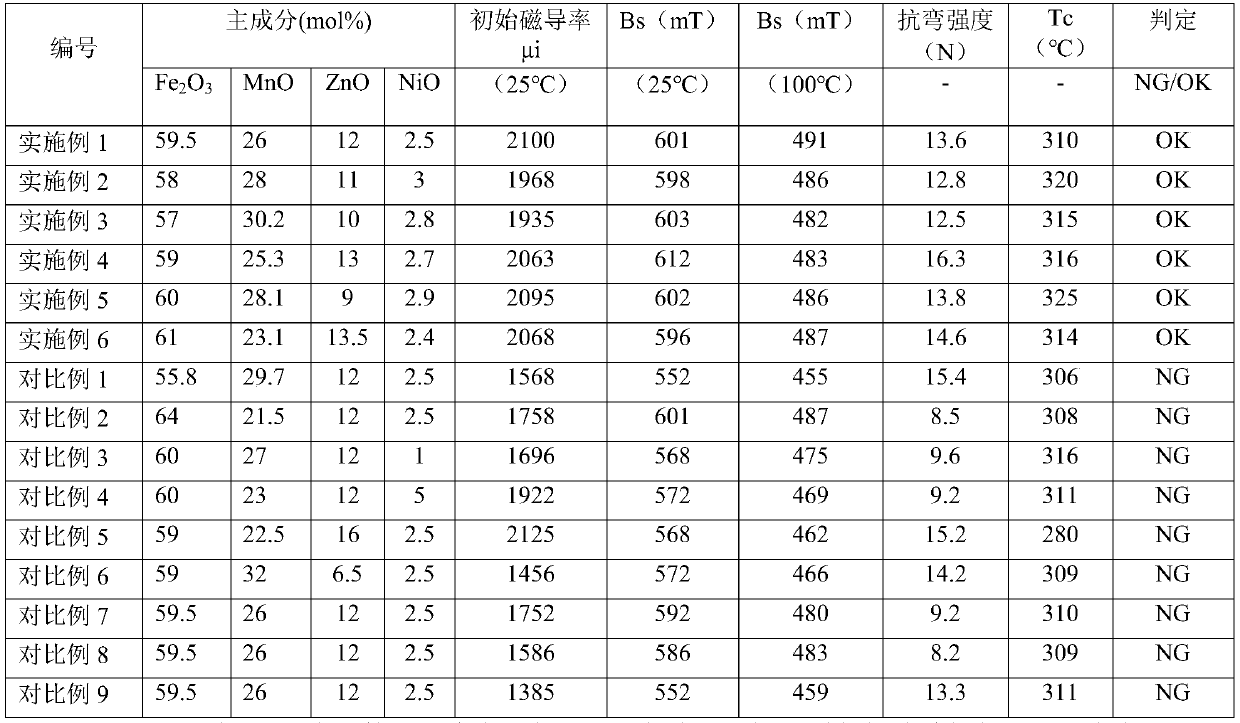

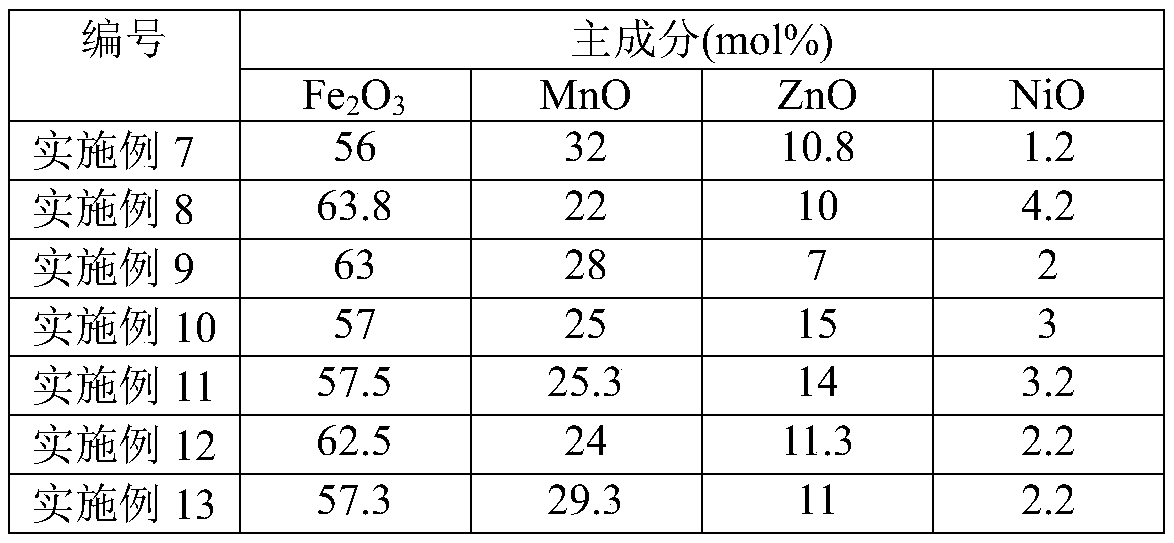

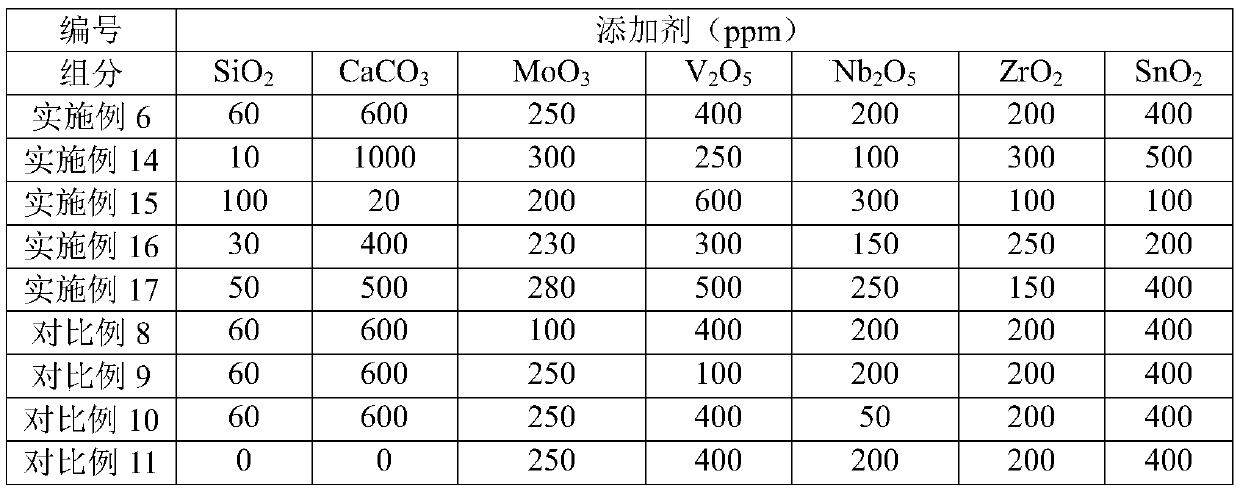

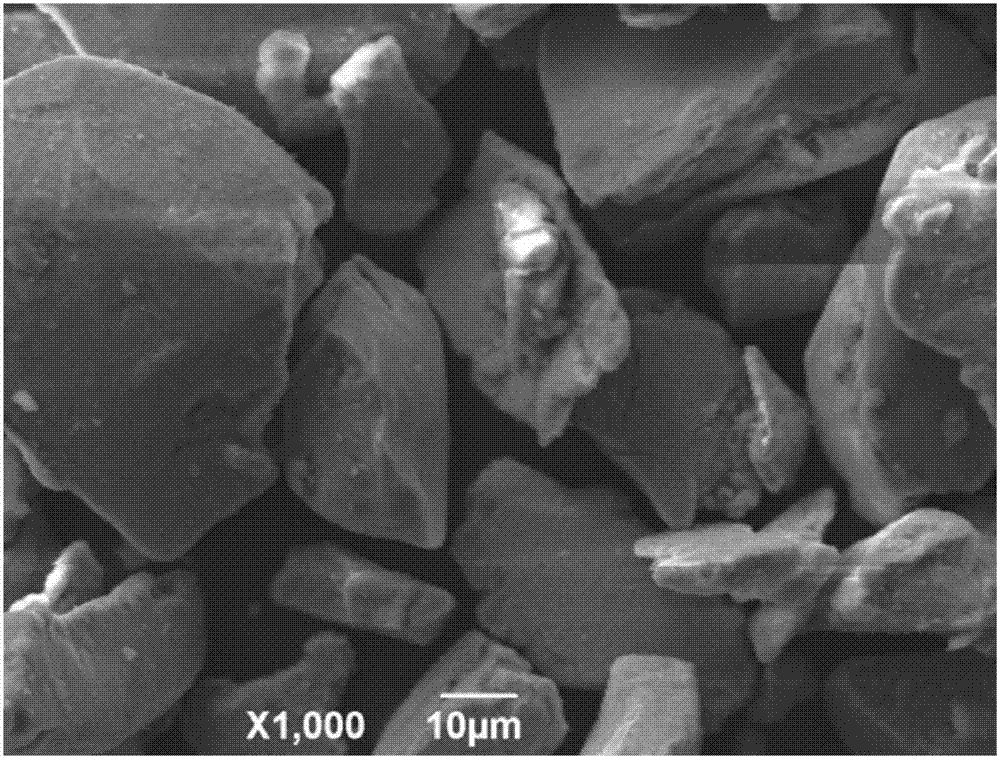

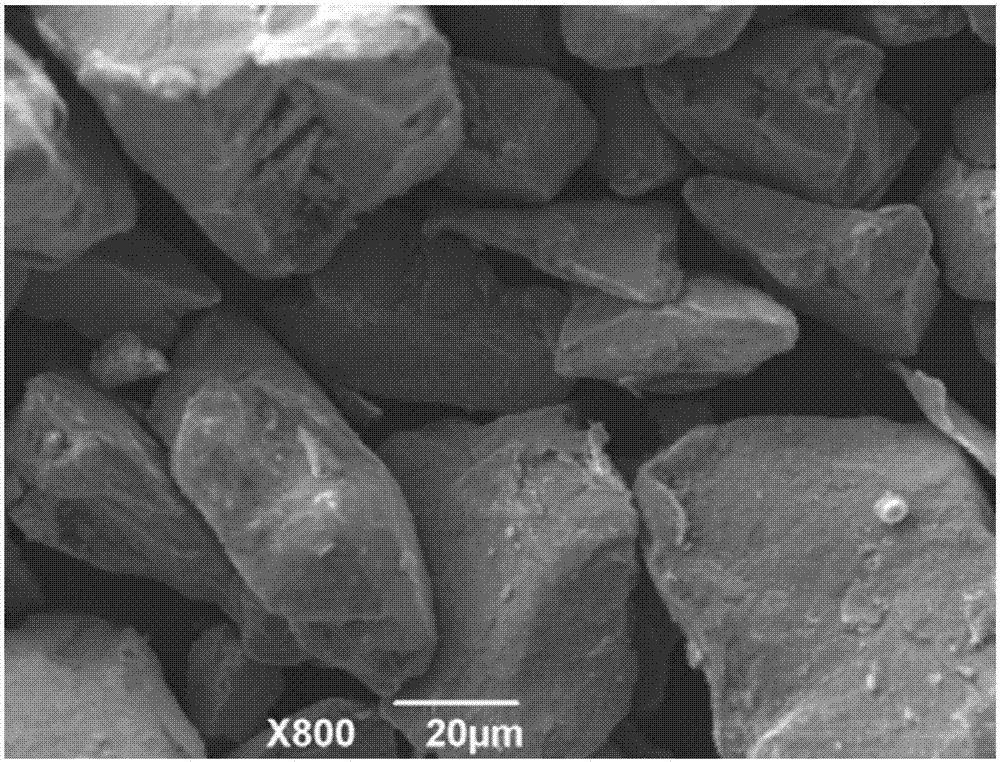

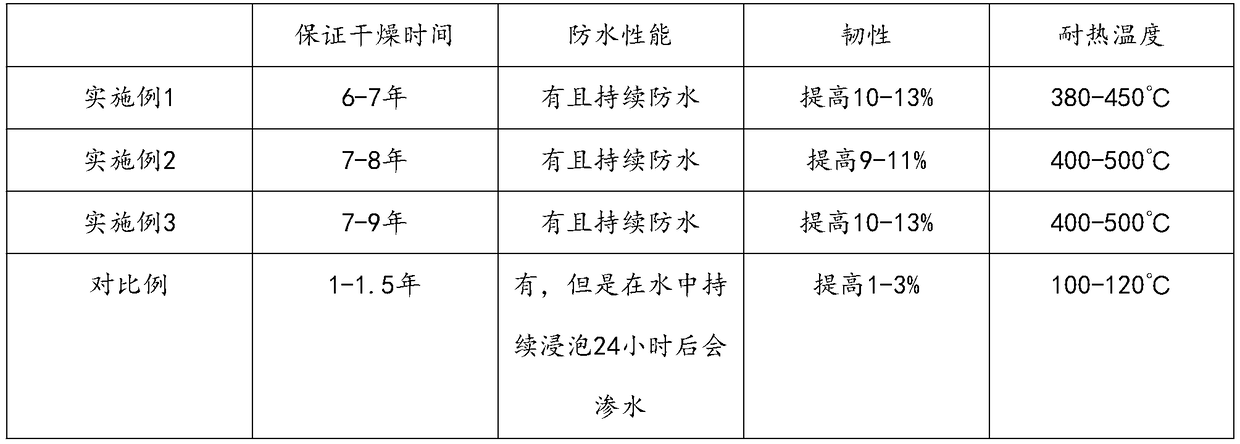

High-Bs high-strength manganese-zinc ferrite material and preparation method thereof

The invention relates to the technical field of magnetic materials, and provides a high-Bs high-strength manganese-zinc ferrite material in order to solve the problems that a traditional manganese-zinc ferrite material is low in magnetic strength, high in magnetic conductivity and low in Curie temperature after loading current. The material is composed of a main component and additives; the main component comprises, by mole percent, 56-63.8% of Fe2O3, 22-32% of MnO, 7-15% of ZnO and 1.2-4.2% of NiO; according to the total quantity of the main component, the additives comprise 10-100 ppm SiO2,200-1000 ppm CaCO3, 200-300 ppm MoO3, 250-600 ppm V2O5, 100-300 ppm Nb2O5, 100-300 ppm ZrO2 and 100-500 ppm SnO2. In the formula of the MnZn ferrite material, an iron-rich formula with the molar ratioof Fe2O3 higher than 55% is designed so that high-Bs can be greatly improved, and the superposition performance of the high-Bs can be further improved. Through synergistic interaction and mutual effects of the additives, the grain growth is uniform, the mechanical strength can be improved, the grain resistivity can be increased, and the loss of the MnZn ferrite material can be reduced.

Owner:HENGDIAN GRP DMEGC MAGNETICS CO LTD

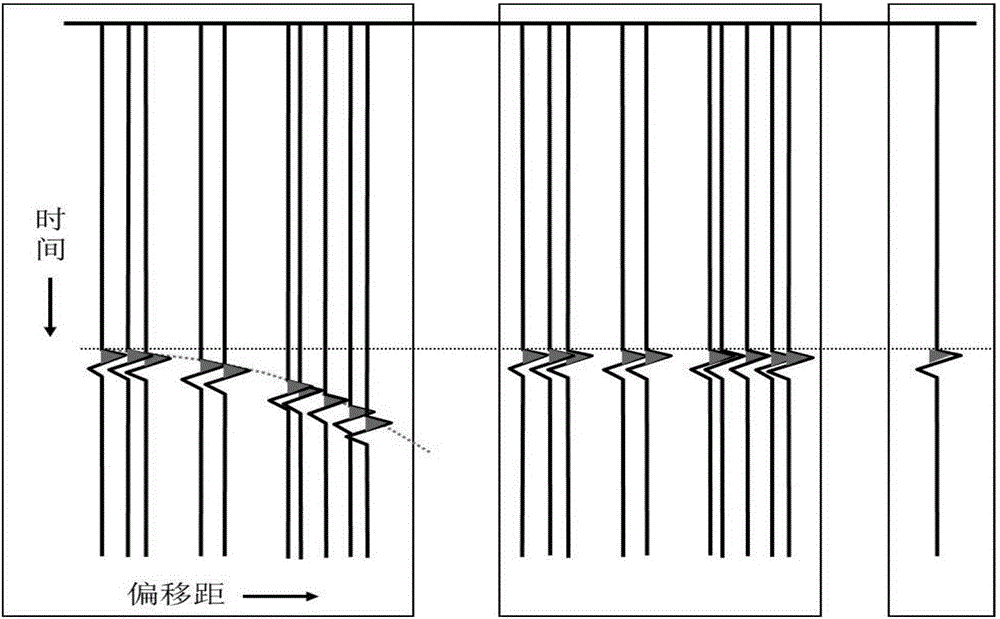

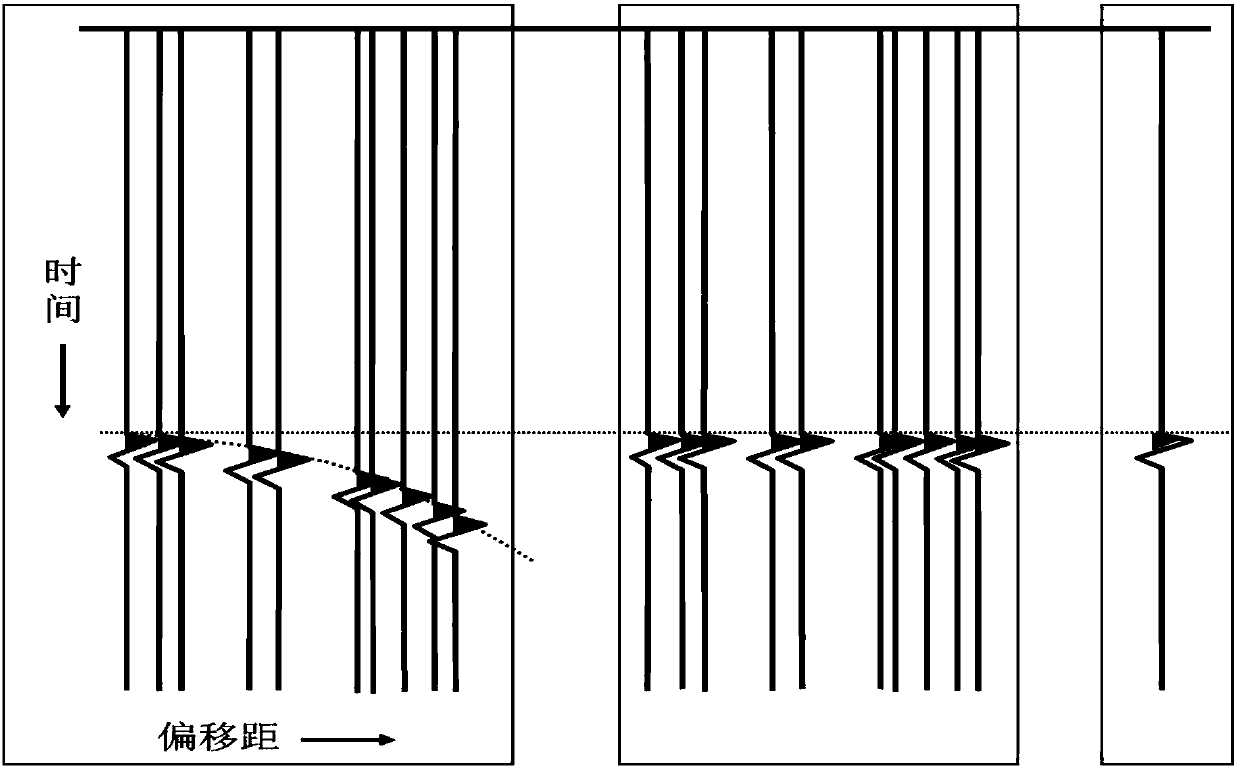

Dynamic-matching dynamic-correction method

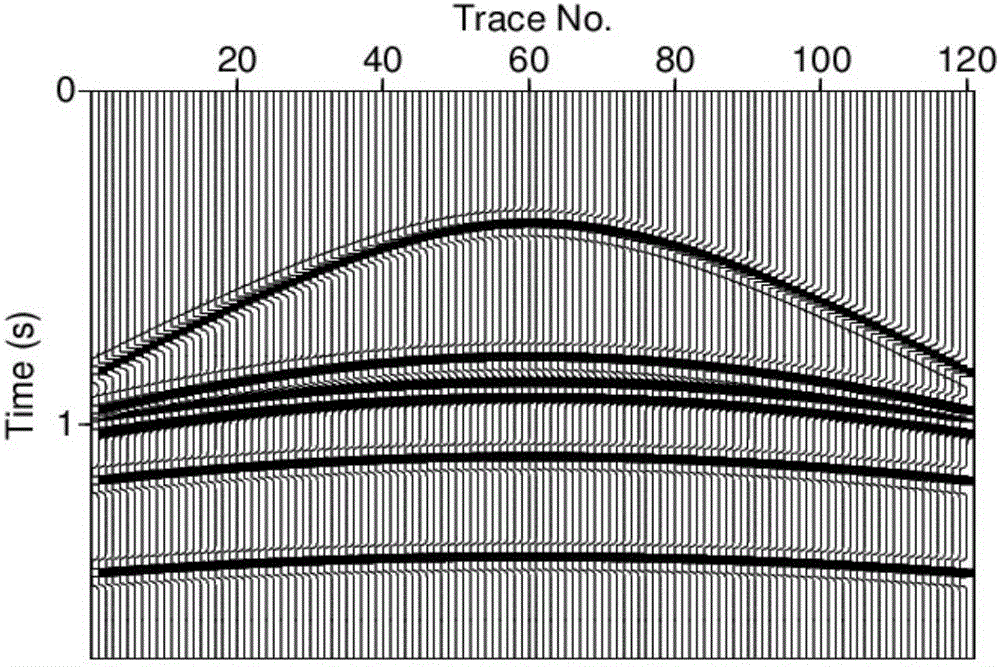

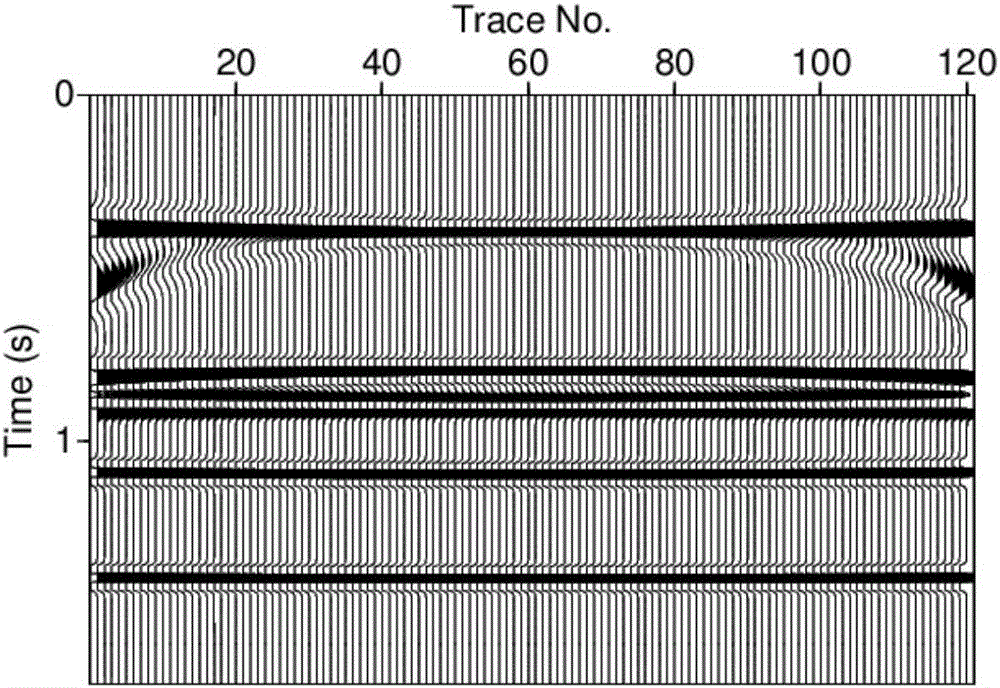

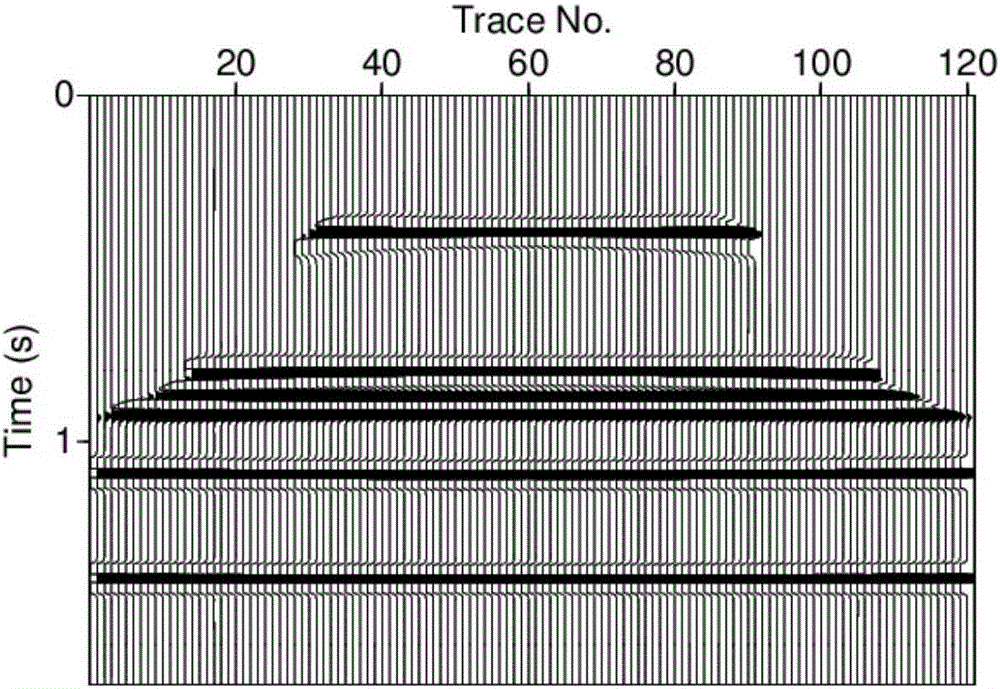

ActiveCN105182420AEliminate wavelet stretching effectsImprove overlay effectSeismic signal processingOffset distanceCorrection method

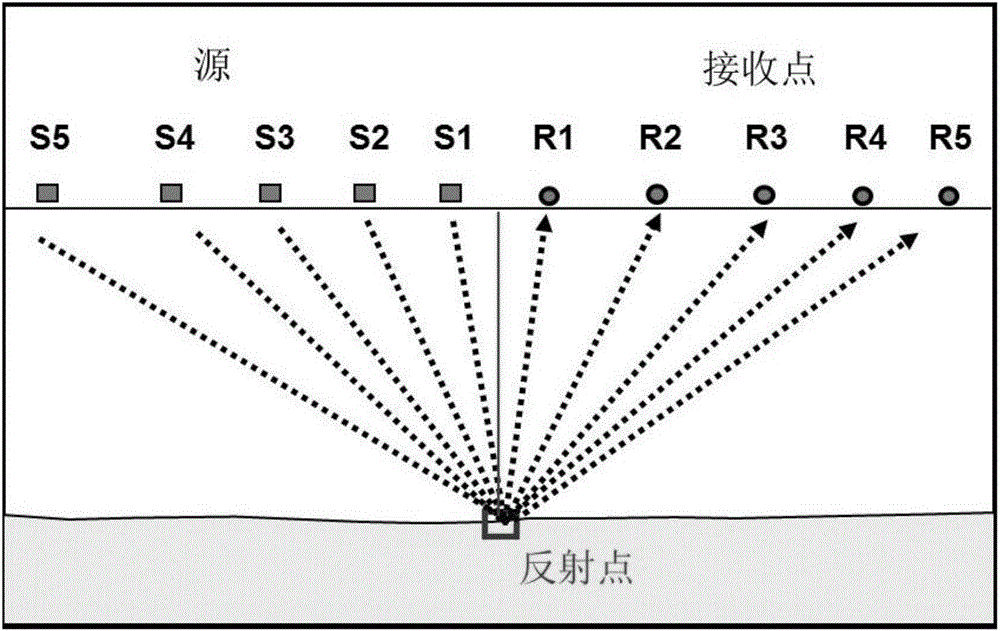

The invention discloses a dynamic-matching dynamic-correction method, and the method comprises the steps: obtaining raw seismic data of CMP or CIP seismic channels of N sampling points of each of M seismic channels, and selecting the seismic channel with a zero offset distance; calculating and obtaining a forward error of a channel direction and a reverse error of the channel direction; carrying out the smoothening of the channel direction, and calculating and obtaining a smoothening error of the channel direction of M seismic channels; enabling the smoothening error of the channel direction to serve as new seismic data which has M seismic channels, wherein each seismic channel has N sampling points, carrying out transposition, and calculating a direction smoothening error of the sampling points; enabling the direction smoothening error of the sampling points to serve as seismic data, carrying out transposition, and obtaining the forward error of the channel direction after the smoothening of raw seismic data; calculating and obtaining time difference between the zero offset distance seismic channel of the raw seismic data and each of M seismic channels, and correcting the time differences of all channels in the raw seismic channel through the time difference, obtaining a time difference field, and carrying out dynamic correction through the time difference field.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

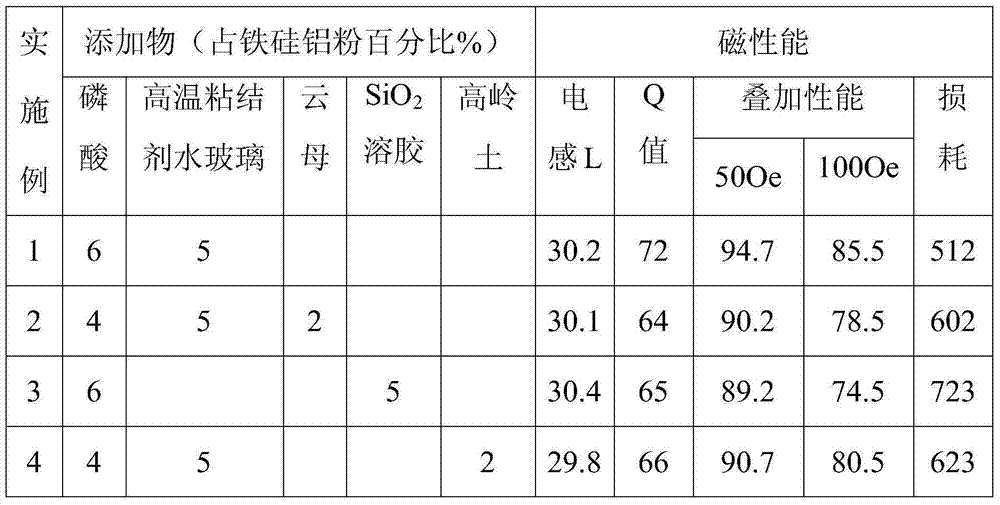

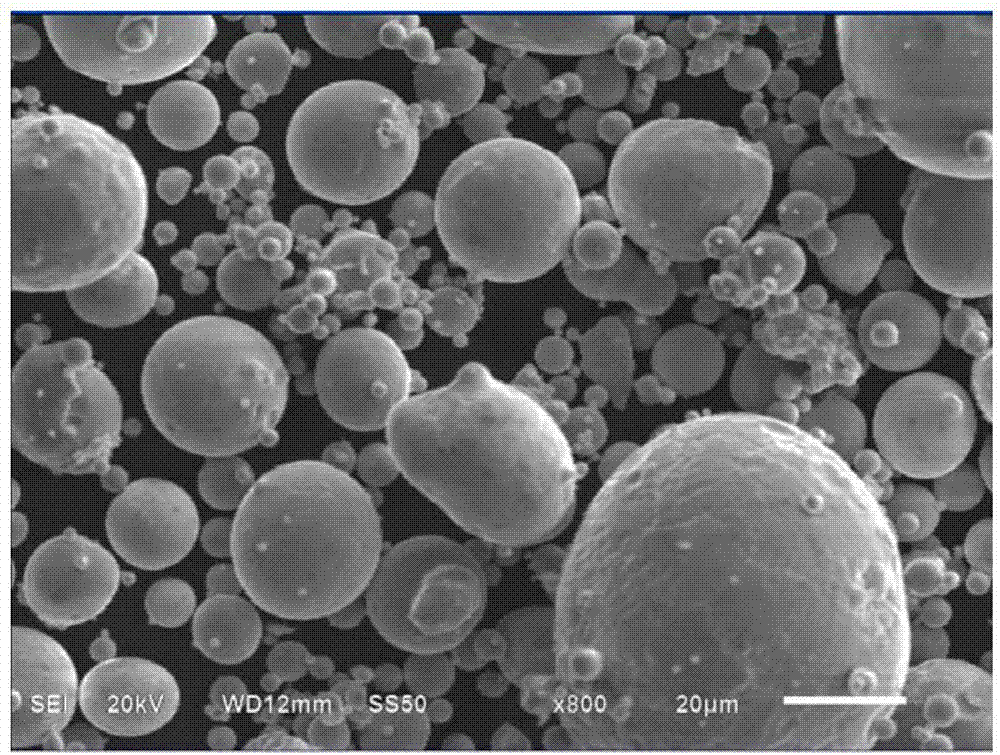

Preparation method of low-loss high-superposition sendust material with magnetic conductivity mu equal to 26

InactiveCN104505208AReduce lossImprove overlay effectInductances/transformers/magnets manufactureMagnetic materialsCompression moldingSendust

The invention discloses a preparation method of a low-loss high-superposition sendust material with magnetic conductivity mu equal to 26. The method comprises the steps of performing batching, phosphatization and primary annealing, adding an appropriate high-temperature resistant insulating material, performing compression molding and secondary annealing, and then performing appropriate insulating coating. According to the method, the loss of a magnetic core prepared from the sendust material with the magnetic conductivity mu equal to 26 is 500mW / cm3 at 100K / 100mT; and the superposition property is 100Oe:85% and 50Oe:95%. The method has the benefits that the loss of the sendust material is reduced by 100-300mW / cm3 compared with that of other sendust materials of the same kind; and the superposition property is improved by 10% compared with that of the sendust materials of the same kind, reaches an iron silicon level and is approximate to the level of high-flux iron nickel.

Owner:HENGDIAN GRP DMEGC MAGNETICS CO LTD

Smelting method for high-strength thick and large ductile iron

InactiveCN105950954AAvoid burnsQuality improvementProcess efficiency improvementMedium frequencyDuctile iron

The invention relates to a smelting method for high-strength thick and large ductile iron. Steel scrap is added into a medium-frequency induction electric furnace to be smelted, then foundry returns are added, heat preservation is performed for 5 min to 10 min when the temperature of molten iron in the furnace reaches 1500 DEG C to 1520 DEG C, meanwhile, quenching and tempering treatment is performed, and base iron is formed; a spheroidizing agent is added into a spheroidizing reaction pit of a spheroidizing tundish, then the spheroidizing agent is covered with an inoculant, and finally the inoculant is covered with a 0 silicon steel sheet; when the temperature of the base iron reaches 1430 DEG C to 1460 DEG C, the base iron is discharged out of the furnace to enter the spheroidizing tundish, when a spheroidizing reaction breaks out and begins, the inoculant is added into the spheroidizing tundish again, and after spheroidizing, final molten iron is formed; and after spheroidizing ends, the final molten iron is subjected to pouring and casting at the temperature of 1320 DEG C to 1340 DEG C within 10 min, meanwhile, a third-time inoculant is added, after pouring, when a casting is cooled to 830 DEG C to 880 DEG C, a box is opened for air cooling, and a ductile iron pearlite is obtained. The smelting method has the beneficial effects that the smelting method can prevent burning losses of crystallizing nucleation in molten iron, the molten iron quality is improved, and strength can also be substantially improved.

Owner:江苏力源金河铸造有限公司

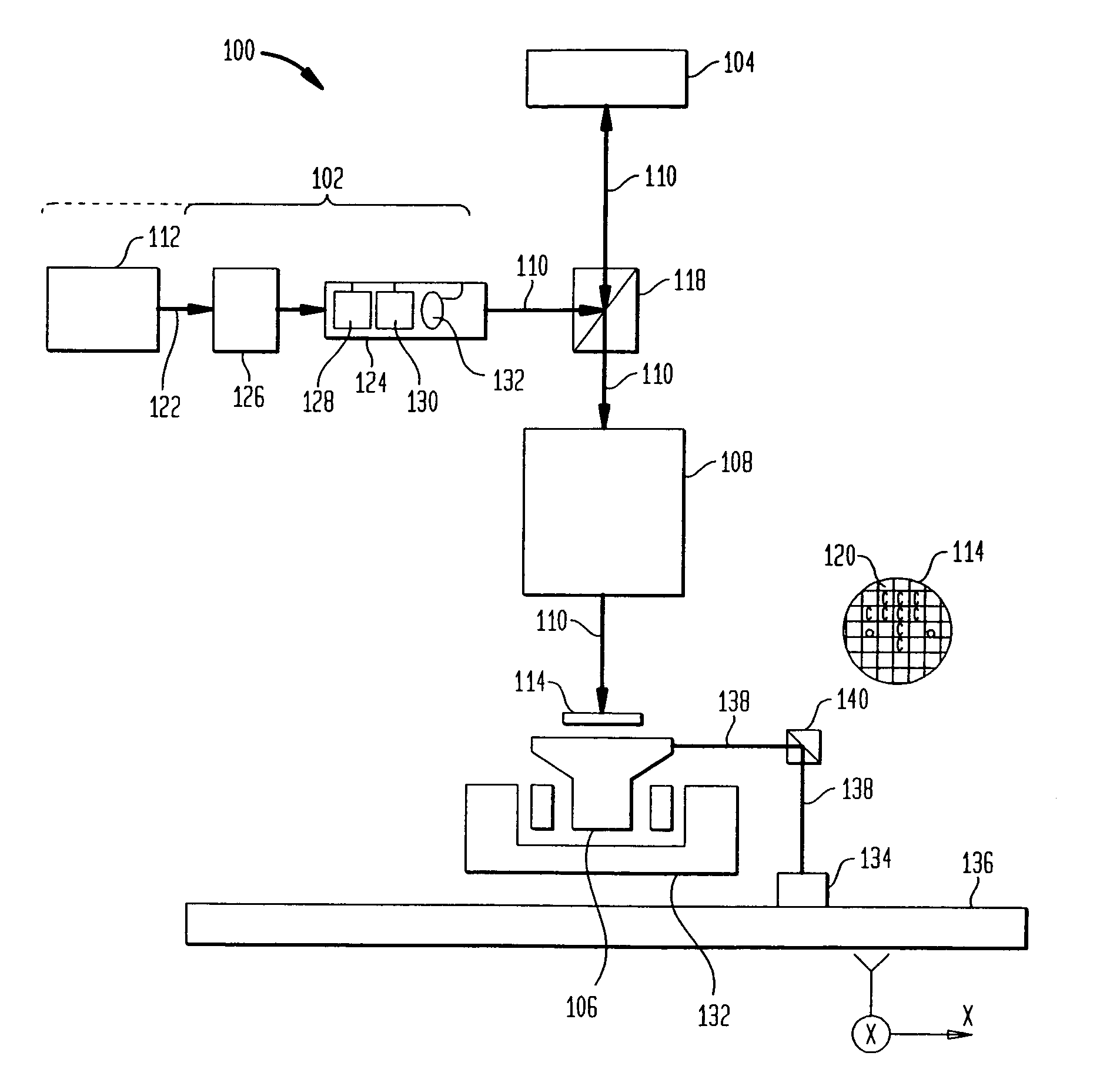

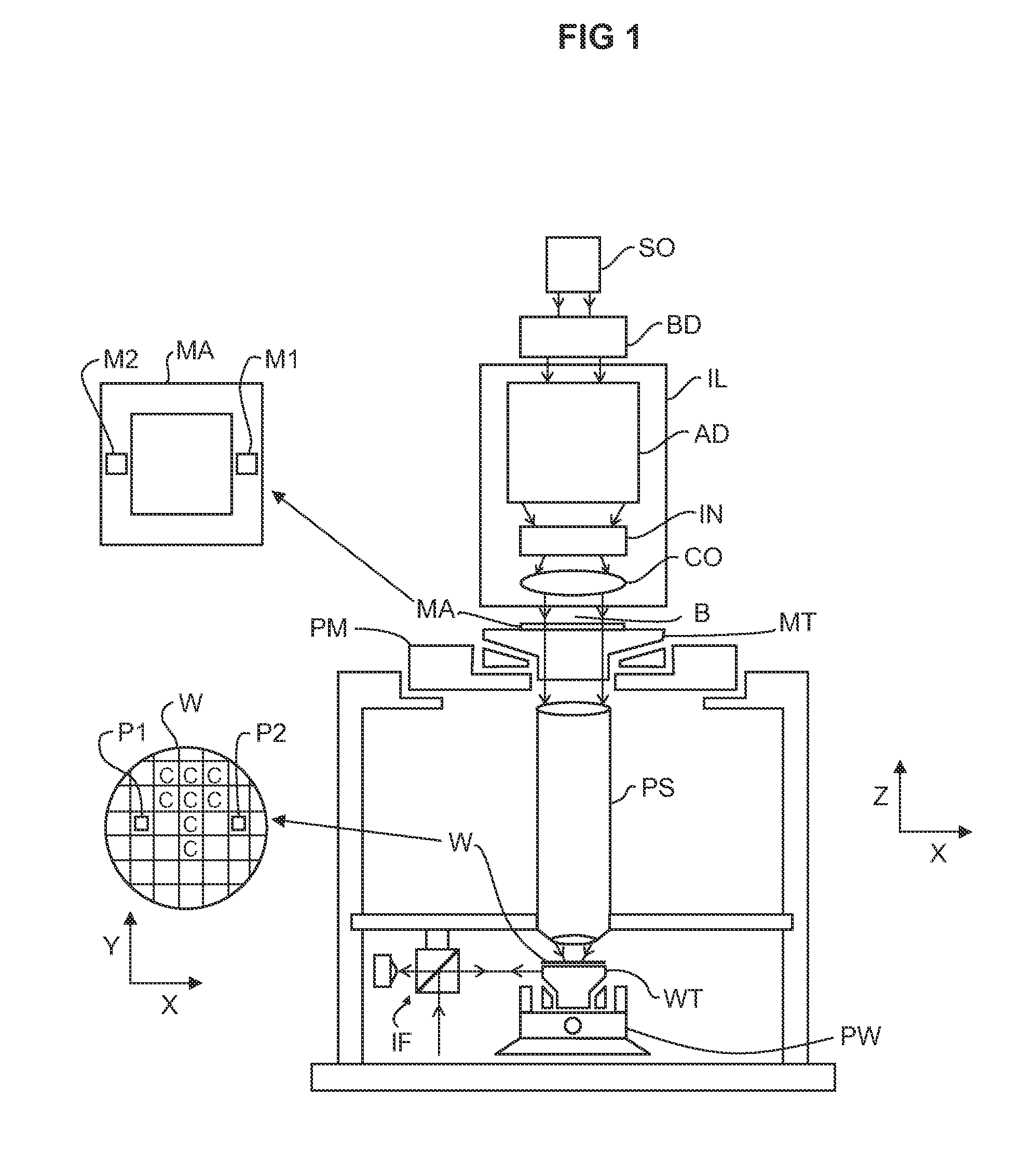

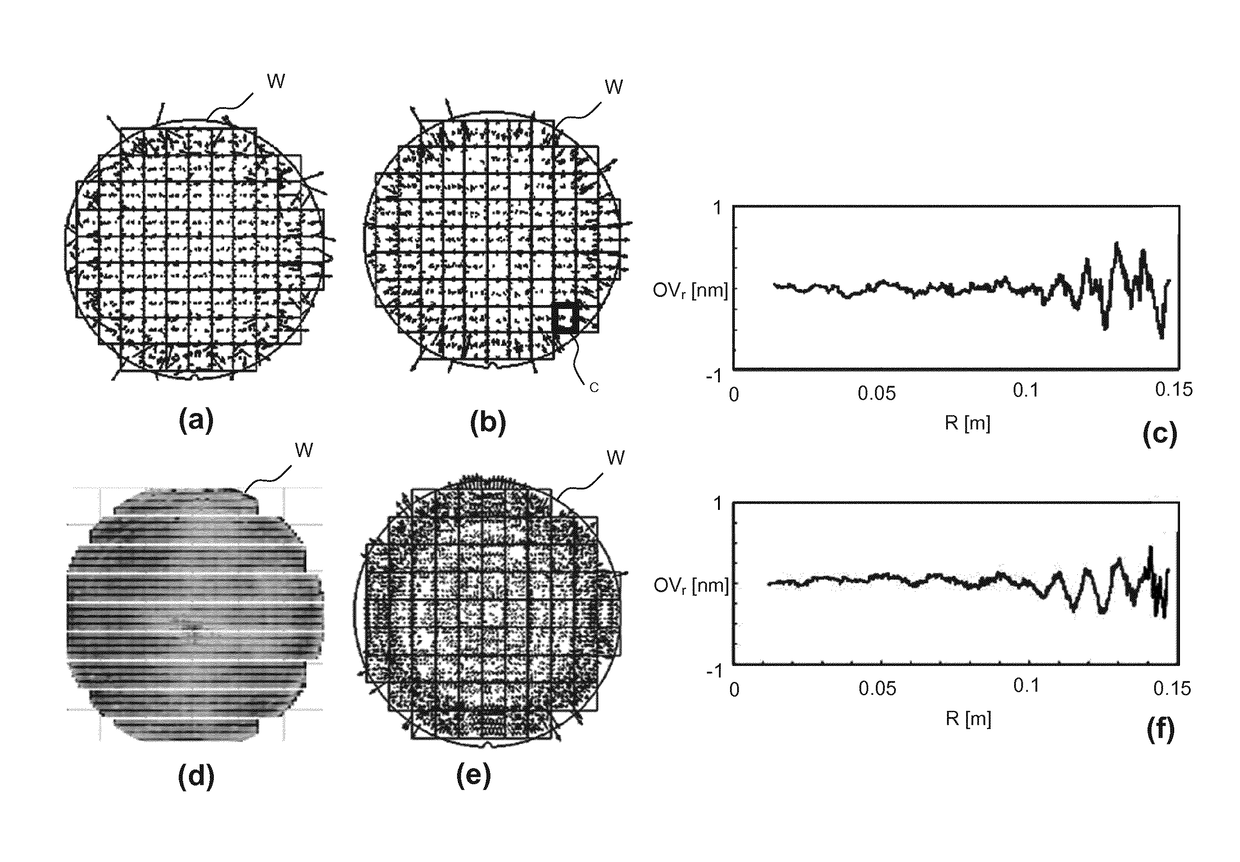

Alignment mark deformation estimating method, substrate position predicting method, alignment system and lithographic apparatus

InactiveUS8982347B2Improve overlay effectPointing accuratelyPhotomechanical treatmentUsing optical meansSensor systemPhotolithography

Owner:ASML NETHERLANDS BV

Insulation covering agent of Fe-based soft-magnetic alloyed powder

ActiveCN108010603AImprove overlay effectReduce magnetic lossInorganic material magnetismInorganic insulatorsThioureaHexamethylenetetramine

The invention discloses an insulation covering agent of Fe-based soft-magnetic metallic magnetic powder, and belongs to the technical field of preparation of magnetic materials. The insulation covering agent is formed by phosphoric acid, polyphosphate, dihydric phosphate and an additive, the insulation covering agent comprises following components: 10-50 wt% of phosphoric acid, 30-60 wt% of dihydric phosphate, 10-30 wt% of polyphosphate, and 1-5 wt% of the additive, the additive is one of sodium molybdate, thiourea, and hexamethylenetetramine, the dihydric phosphate is one or two of manganesedihydrogen phosphate, zinc dihydrogen phosphate, and aluminum dihydrogen phosphate; and the polyphosphate is sodium tripolyphosphate or sodium pyrophosphate. The Fe-based soft-magnetic metallic magnetic powder is covered by employing the insulation covering agent, a covering layer is uniform, tight and insulated, and a magnetic powder core with excellent magnetic performance can be obtained.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY

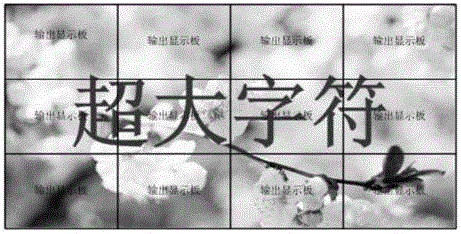

System and method for character superimposition processing of splicing wall

ActiveCN105049758AImprove overlay effectGuaranteed peer-to-peer displayTelevision system detailsColor television detailsImage resolutionComputer graphics (images)

The invention discloses a method character superimposition processing of a splicing wall, and includes: generating a character image having a resolution ratio equal to that of the splicing wall; segmenting the character image according to the row and column number of the splicing wall, so as to obtain a plurality of character subimages; performing denoising on the segmented character subimages, and storing the character subimages after denoising; when a display image sent by a front end signal source is received, segmenting the display image according to the row and column number of the splicing wall, so as to obtain a plurality of display subimages; and performing superimposition processing on the display subimages and the character subimages after denoising, and controlling a display unit to display an image after superimposition processing. The invention also discloses a system for character superimposition processing of the splicing wall. A character superimposition effect is improved, and hardware cost of the system does not need to be additionally increased.

Owner:SHENZHEN CREATEK ELECTRONICS

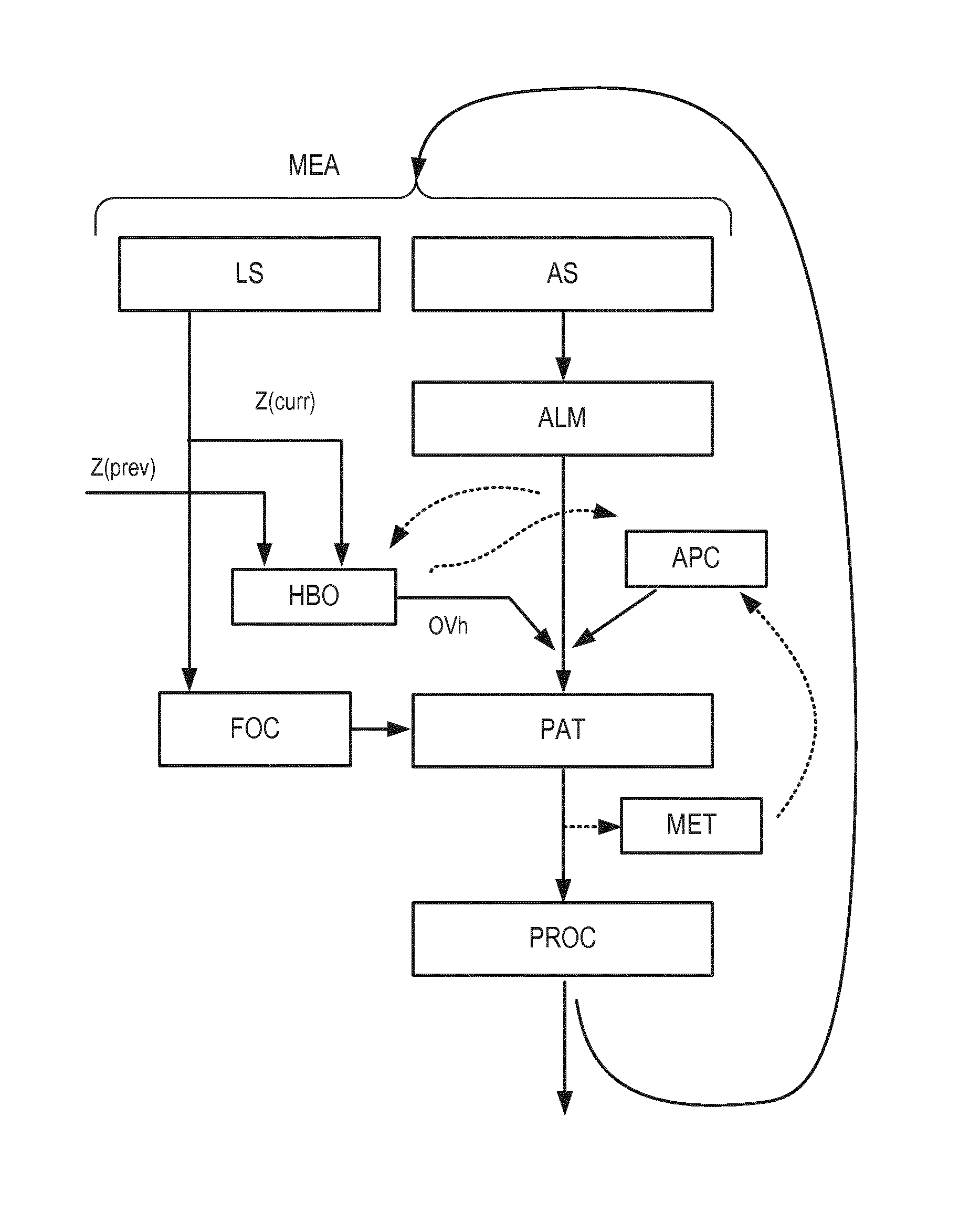

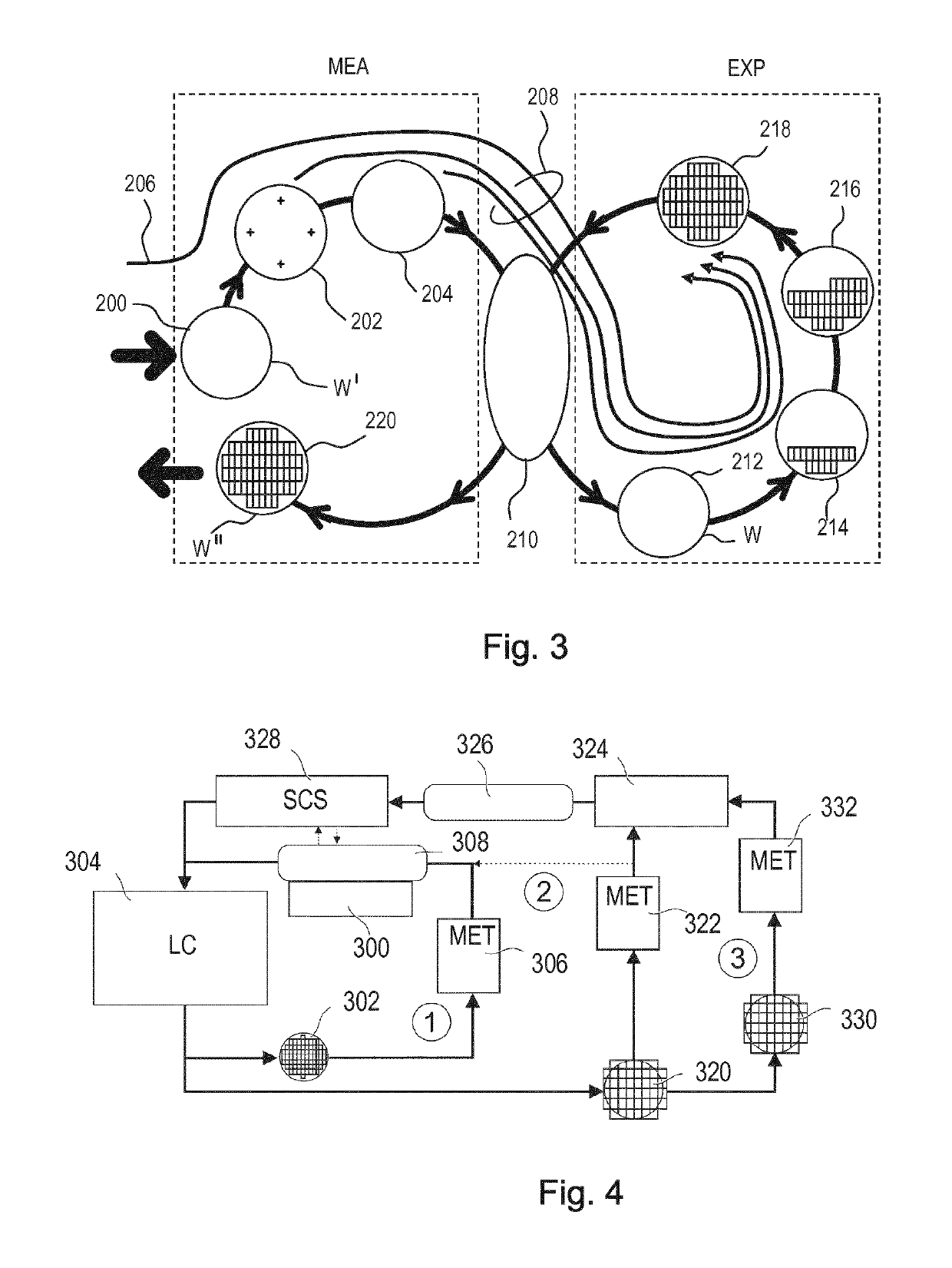

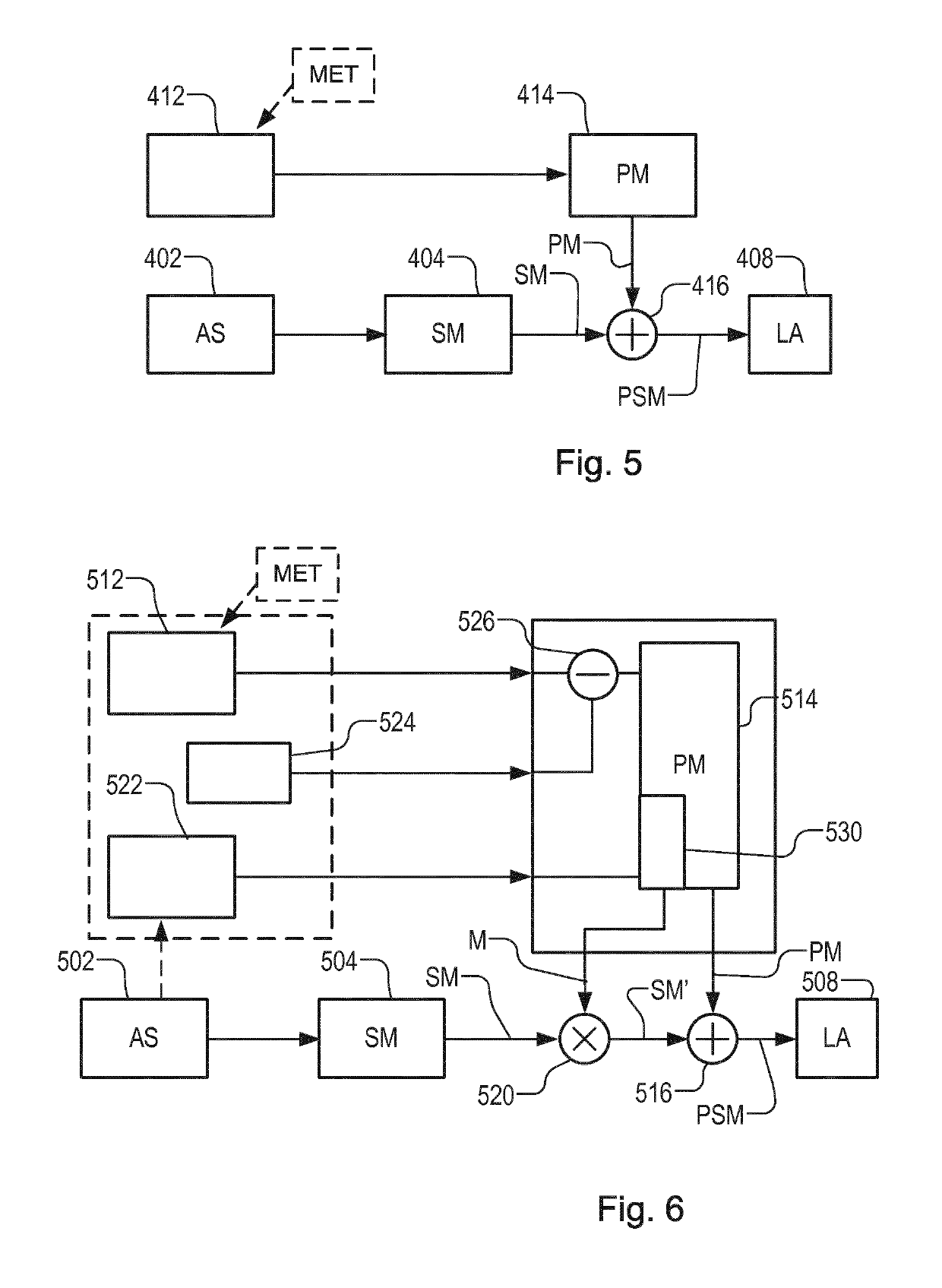

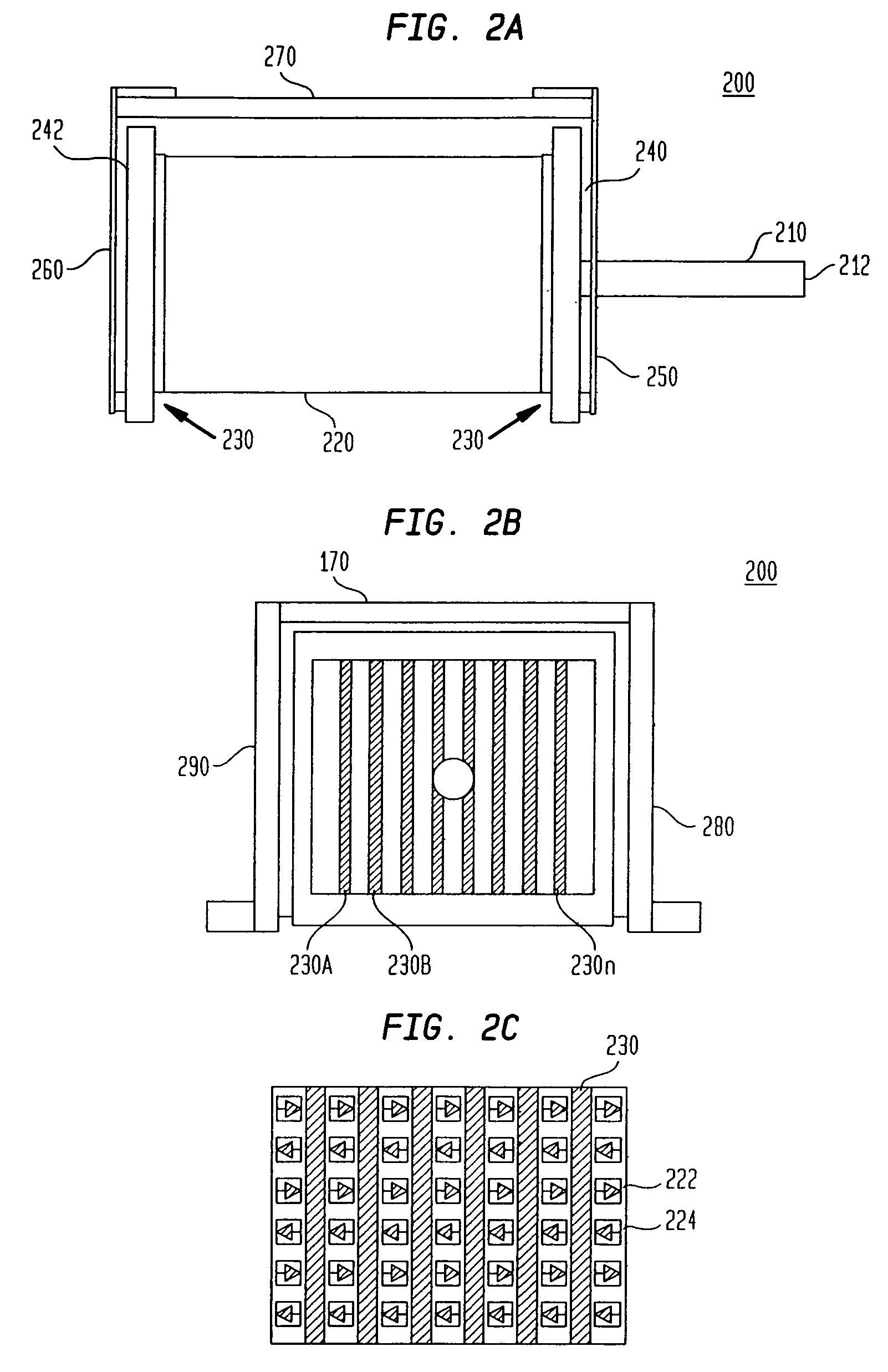

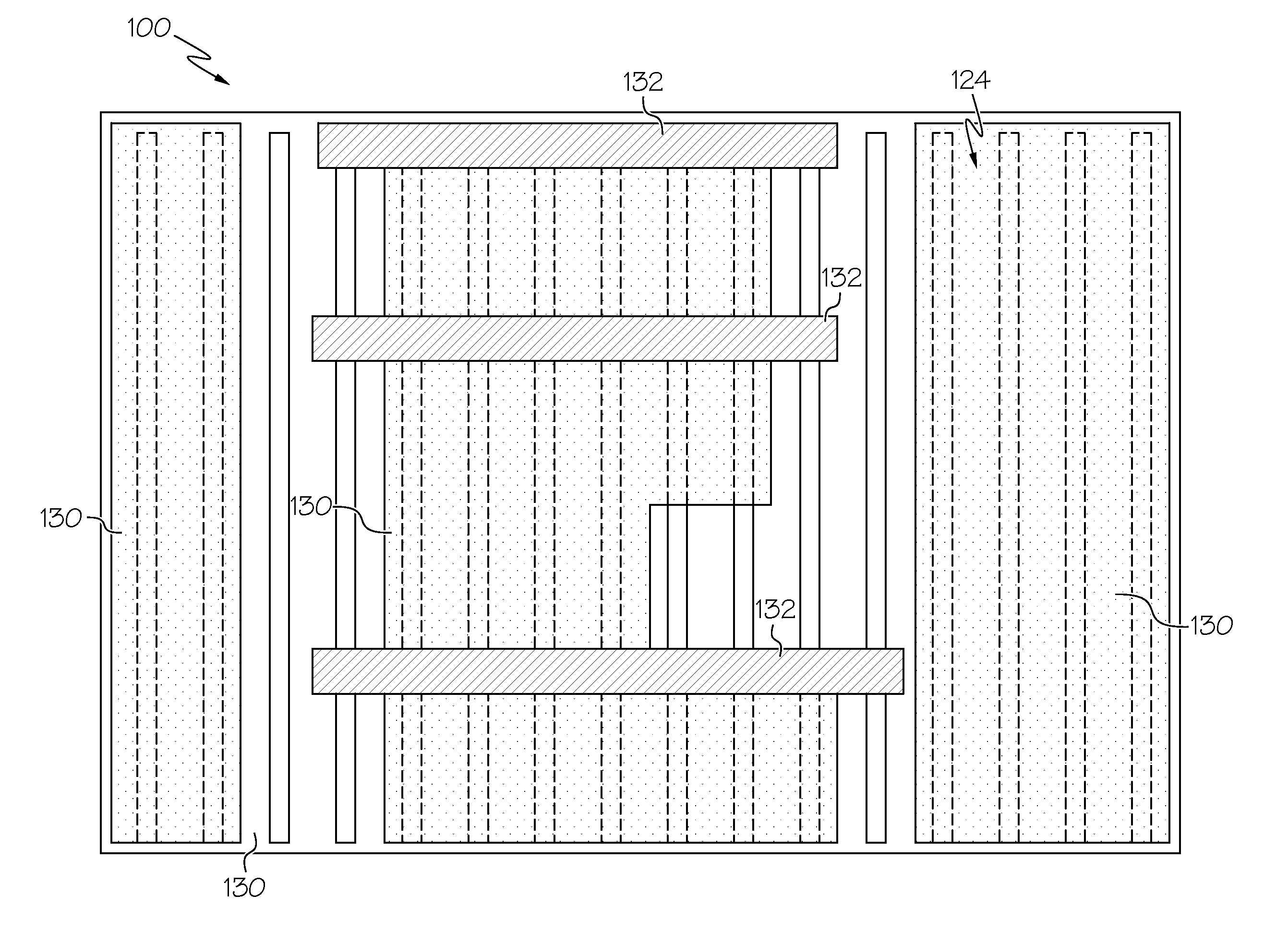

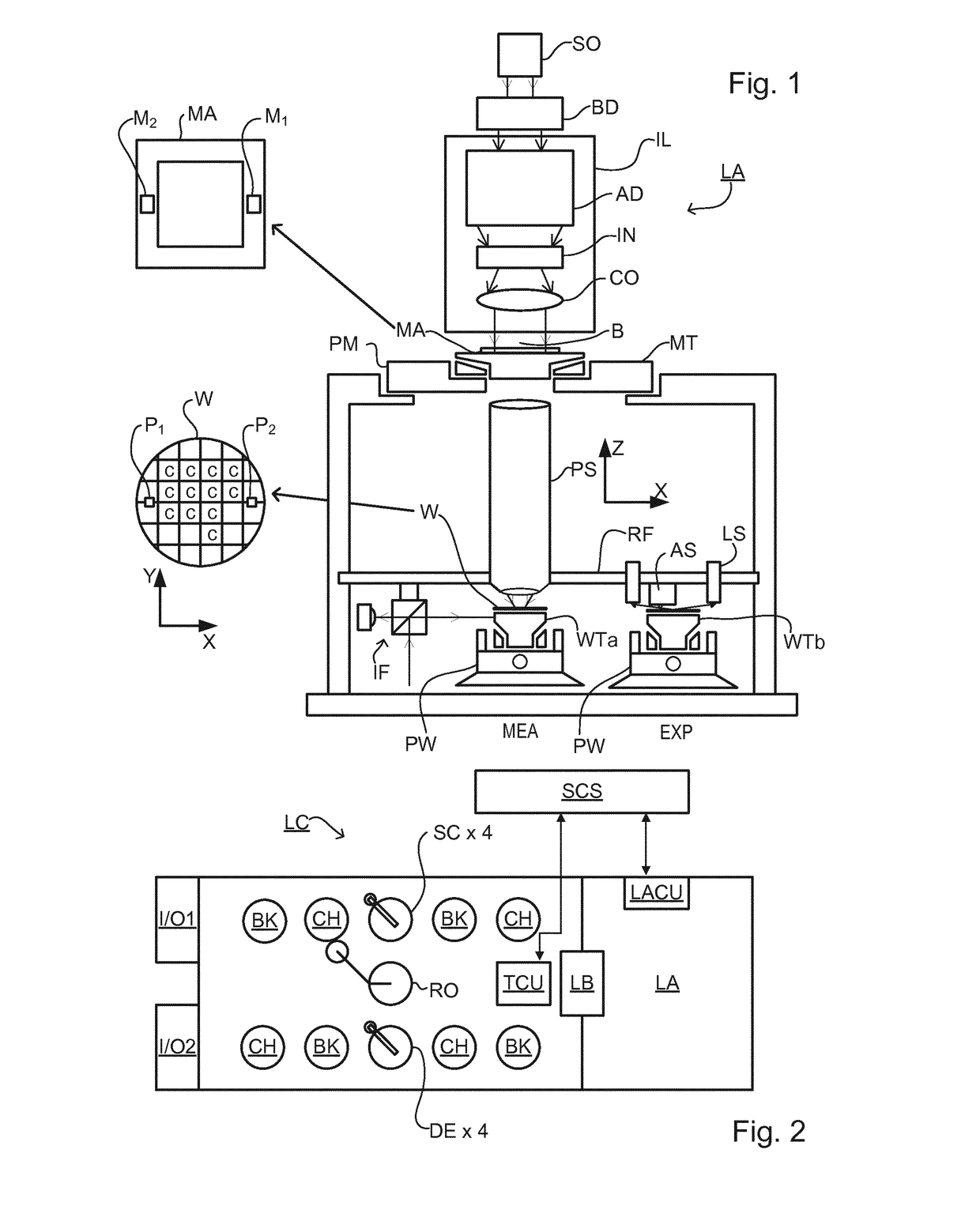

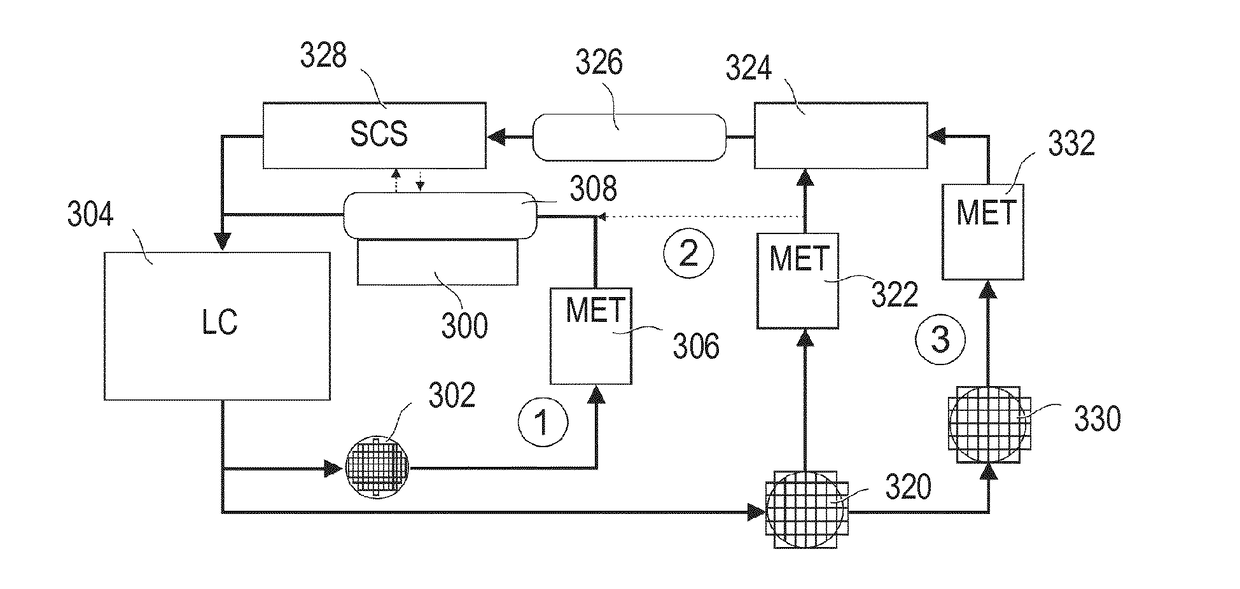

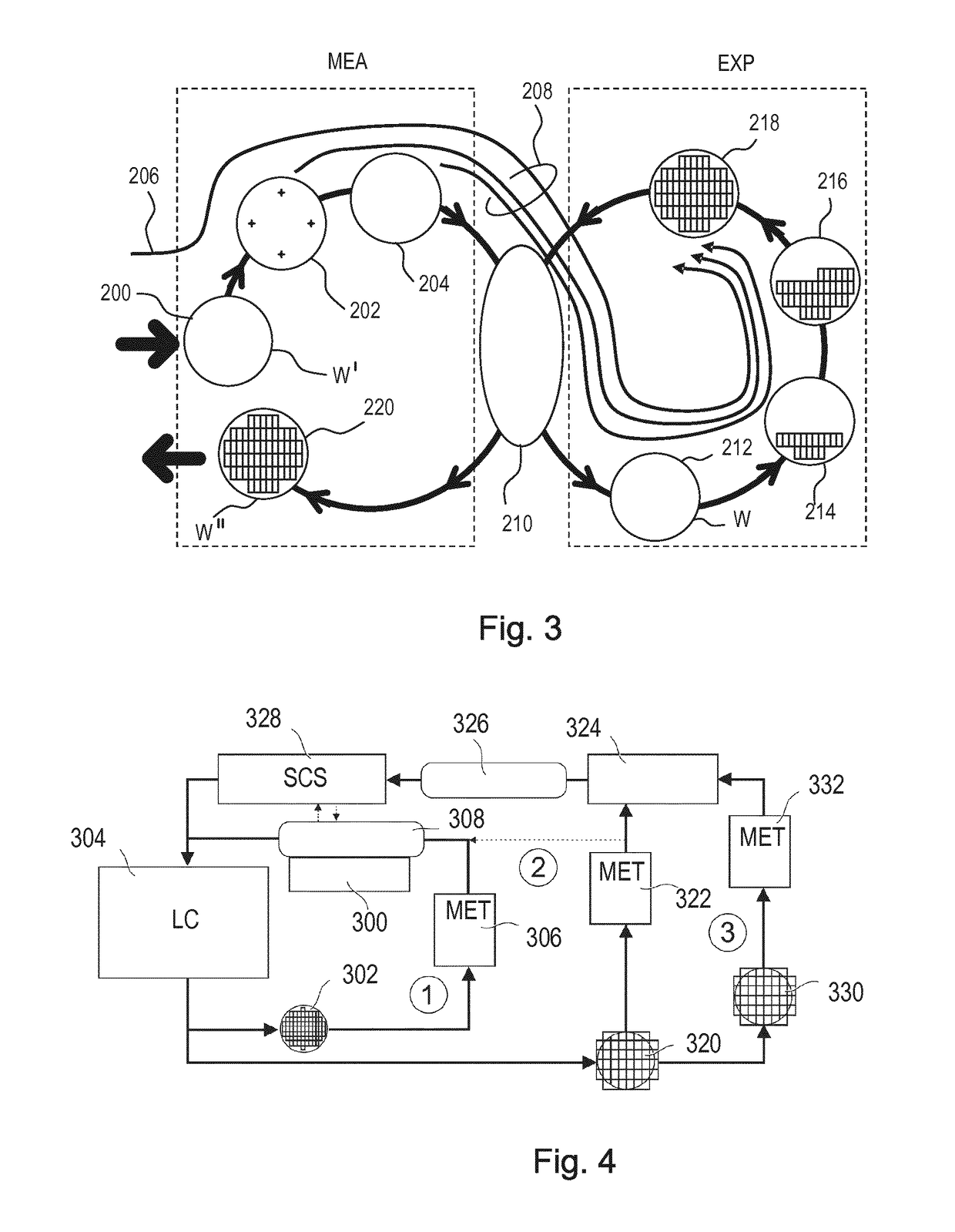

Method of controlling a lithographic apparatus and device manufacturing method, control system for a lithographic apparatus and lithographic apparatus

ActiveUS10331040B2Improve overlay effectEliminate and reducePhotomechanical exposure apparatusMicrolithography exposure apparatusControl systemEngineering

In a method of controlling a lithographic apparatus, historical performance measurements are used to calculate a process model relating to a lithographic process. Current positions of a plurality of alignment marks provided on a current substrate are measured and used to calculate a substrate model relating to a current substrate. Additionally, historical position measurements obtained at the time of processing the prior substrates are used with the historical performance measurements to calculate a model mapping. The model mapping is applied to modify the substrate model. The lithographic apparatus is controlled using the process model and the modified substrate model together. Overlay performance is improved by avoiding over- or under-correction of correlated components of the process model and the substrate model. The model mapping may be a subspace mapping, and dimensionality of the model mapping may be reduced, before it is used.

Owner:ASML NETHERLANDS BV

Optical element damping systems

ActiveUS7751130B2Increase dampingDamp motionPhotomechanical apparatusMountingsLithographic artistAudio power amplifier

The present invention is directed to optical element damping systems. In particular, an eddy current damper is disclosed. The eddy current damper includes a rod, a series of conducting plates coupled to the rod, and layers of magnets. The alternating layers have alternating magnetic fields. When an optical element moves, the optical element will exert a force on the rod. The rod causes the conducting plates to move relative to the alternating layers of magnets to generate eddy currents within each of the conducting plates, such that the eddy currents damp the motion of an optical element. In an alternative embodiment, an eddy current damper motion amplifier is used to provide additional mechanical advantage that significantly increases the damping provided by the eddy current damper. Eddy current dampers are provided within conventional scanning lithography devices and optical maskless lithography devices to improve performance by stabilizing optical element motion.

Owner:ASML HLDG NV

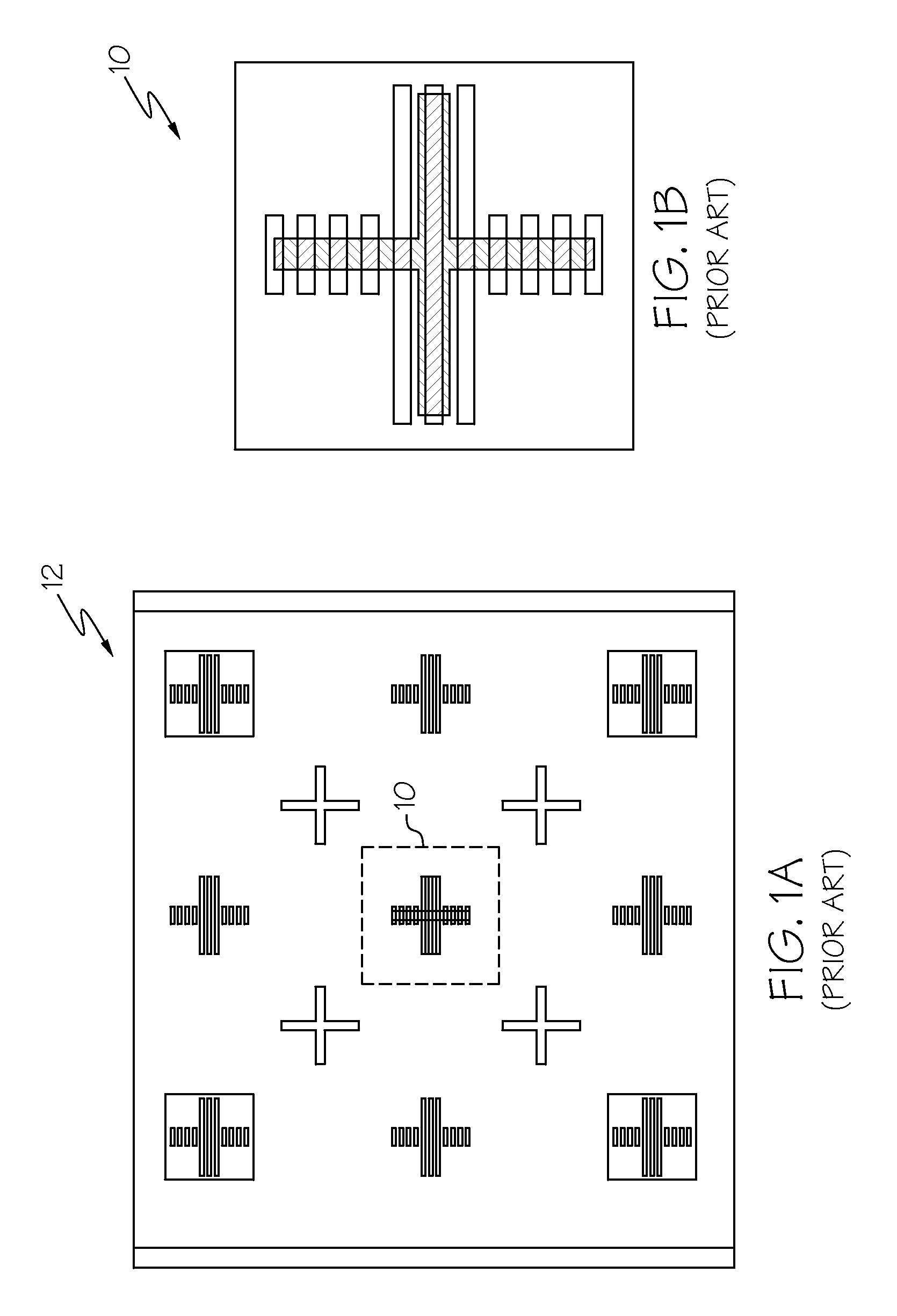

Overlay performance for a fin field effect transistor device

InactiveUS9219002B2Improve overlay effectAvoids finificationSemiconductor/solid-state device detailsSolid-state devicesEngineeringField-effect transistor

Approaches for improving overlay performance for an integrated circuit (IC) device are provided. Specifically, the IC device (e.g., a fin field effect transistor (FinFET)) is provided with an oxide layer and a pad layer formed over a substrate, wherein the oxide layer comprises an alignment and overlay mark, an oxide deposited in a set of openings formed through the pad layer and into the substrate, a mandrel layer deposited over the oxide material and the pad layer, and a set of fins patterned in the IC device without etching the alignment and overlay mark. With this approach, the alignment and overlay mark is provided with the fin cut (FC) layer and, therefore, avoids finification.

Owner:ALSEPHINA INNOVATIONS INC

Lithographic apparatus, device manufacturing method and associated data processing apparatus and computer program product

ActiveUS10025193B2Adversely impacting throughputImprove overlay effectPhotomechanical exposure apparatusMicrolithography exposure apparatusLevel sensorEngineering

A lithographic apparatus applies a pattern repeatedly to target portions across a substrate. Prior to applying the pattern an alignment sensor measures positions of marks in the plane of the substrate and a level sensor measures height deviations in a direction normal to the plane of the substrate. The apparatus applies the pattern to the substrate while positioning the applied pattern using the positions measured by the alignment sensor and using the height deviations measured by the level sensor. The apparatus is further arranged to calculate and apply corrections in the positioning of the applied pattern, based on derivatives of the measured height deviations. The corrections may be calculated on an intrafield and / or interfield basis. The corrections may be based on changes between the observed height deviations and height deviations measured previously on the same substrate.

Owner:ASML NETHERLANDS BV

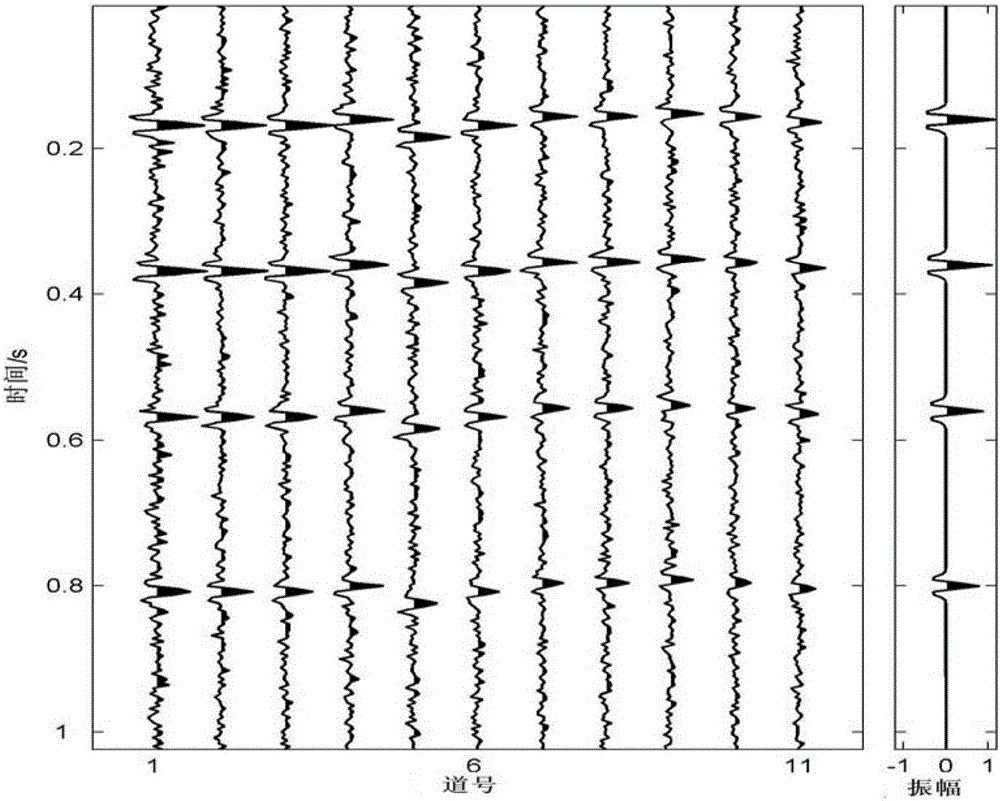

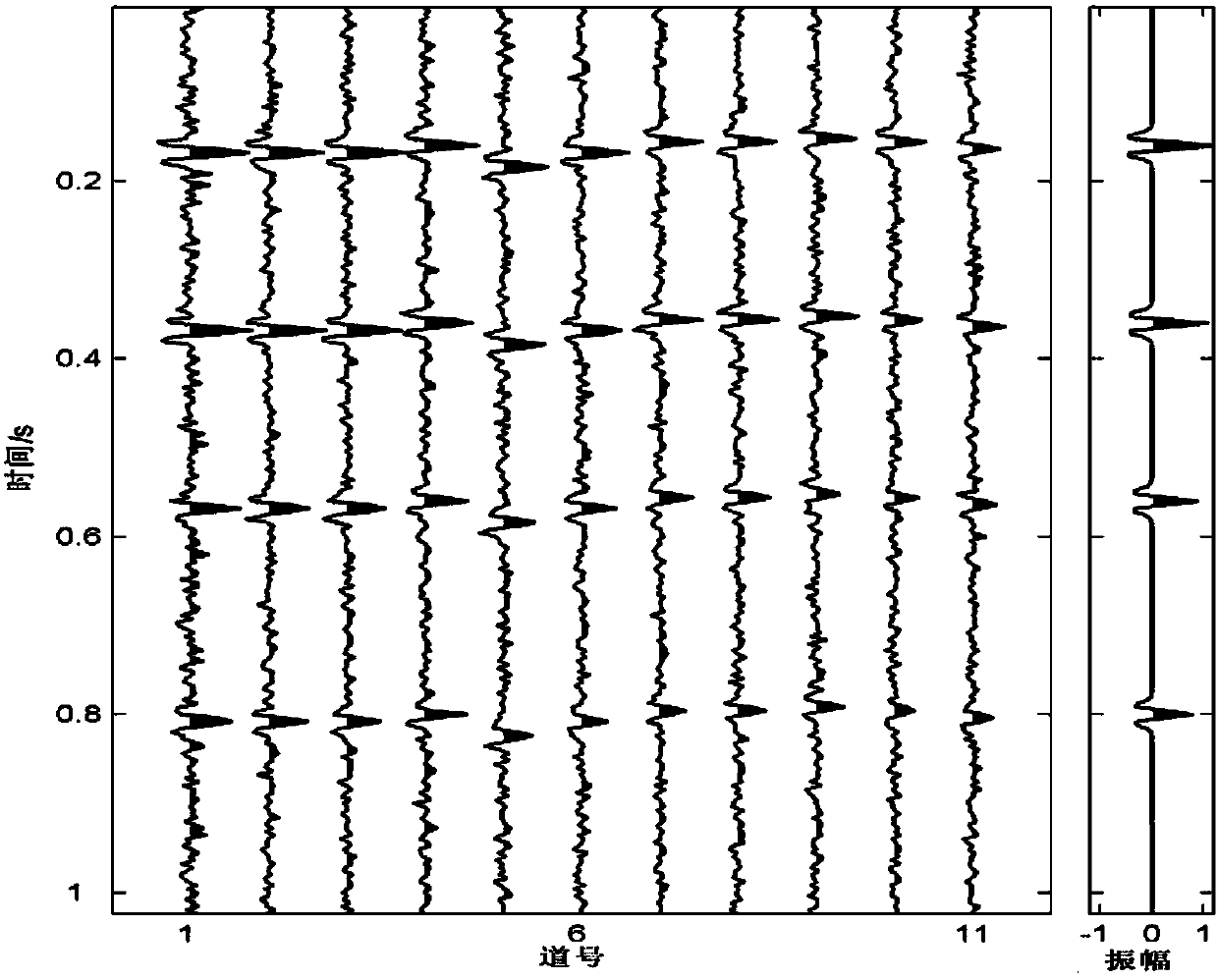

Time-frequency domain seismic data processing method based on weighted stacking

ActiveCN105954799AImprove overlay effectReduce noise interferenceSeismic signal processingS transformStack effect

The invention provides a time-frequency domain seismic data processing method based on weighted stacking, and the method comprises the following steps: 1) an original seismic to-be-stacked signal is converted in a time-frequency transform domain which is formed by S transform, and a instantaneous phase in the time-frequency transform domain is extracted; 2) a stacking weight is constructed; 3) the stacking weight is applied to obtain a final stacking result, and the stacking of the seismic signal is completed. According to the invention, a weight formed by the instantaneous phase is introduced to a weight stacking process, the noise interference is attenuated, and a weak energy effective signal is enhanced, and the stacking effect of the seismic data is further improved on weak amplitude effective signal energy maintenance, random disturbance suppression and residual moveout correction.

Owner:PETROCHINA CO LTD

Chlorine-free ammonia-free antifreezing agent used for concrete and preparation method of antifreezing agent

The invention discloses a chlorine-free ammonia-free antifreezing agent used for concrete and a preparation method of the antifreezing agent, belongs to the technical field of building materials, andrelates to the technical field of concrete external additives. The antifreezing agent used for the concrete includes glycerin, ethanol and water; the antifreezing agent also includes the following components: 10-20 parts of a naphthalene-based-polycarboxylate composite water-reducing agent, 10-15 parts of triterpenoid saponin, 5-10 parts of glucose ester, 0.5-1 part of alkylbenzene sulfonate, 8-15parts of methyl silicone oil, 5-12 parts of an inorganic salt compound, and 0.3-0.8 part of isoamyl alcohol polyoxyethylene ether; and the antifreezing agent is prepared by adopting the preparation method of a combination of ultrasonic treatment and homogenization treatment. The method disclosed by the invention adopts the ethanol, the glycerin and the water as a mother liquor of the antifreezingagent, and the water reducing agent and an air entraining agent are added as low-heat phase-change heat-storage materials; and the preparation method is simple, and the obtained product is stable, has strong workability with the concrete, improves a bleeding phenomenon of the concrete under the negative-temperature condition, improves antifreezing performance of the concrete, has no chlorine, noammonia, and is environmentally-friendly and pollution-free.

Owner:WUHU YANGZHAN NEW MATERIAL TECH SERVICE CO LTD

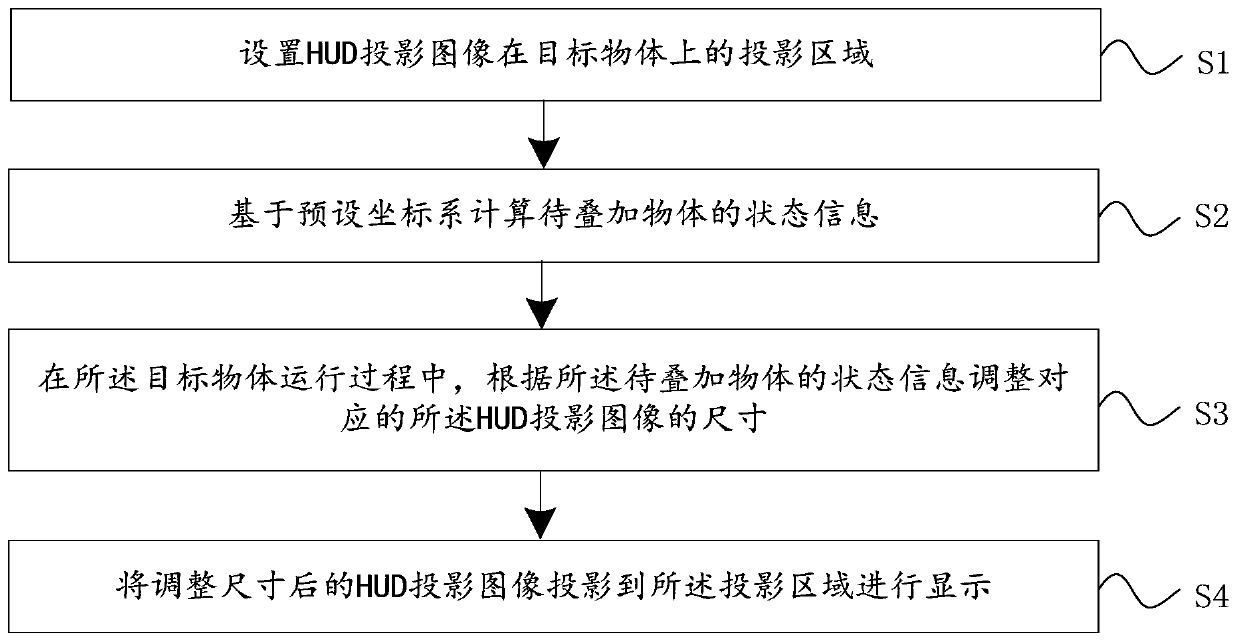

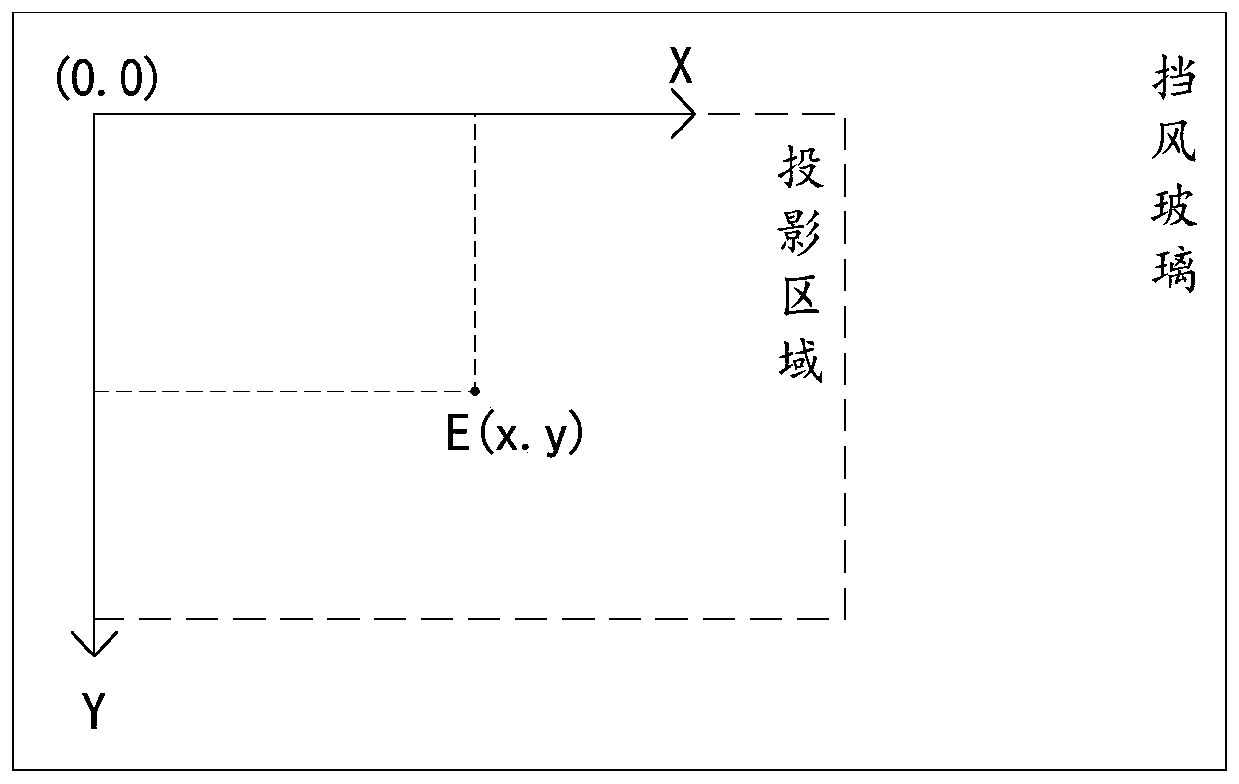

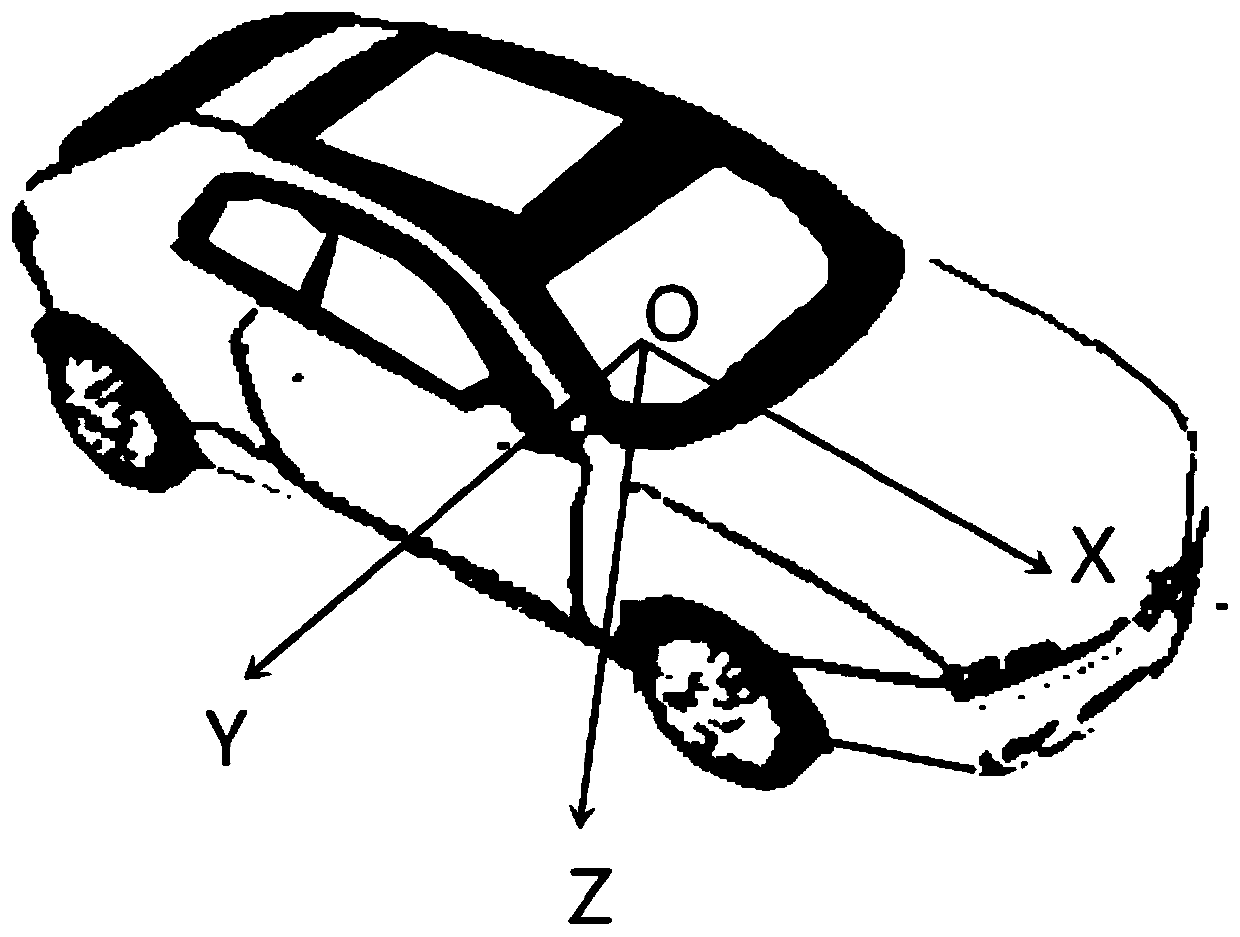

HUD projection image display method and device

InactiveCN111107332AReal-time size adjustmentImprove overlay effectPicture reproducers using projection devicesComputer graphics (images)Projection image

The invention discloses an HUD projection image display method. The method comprises the following steps: setting a projection area of an HUD projection image on a target object; calculating state information of the to-be-superposed object based on a preset coordinate system; wherein the to-be-superposed object is an object in a road condition where the target object is located, and the state information comprises at least one of a coverage area, covered by the projection area, of an area formed by coordinate points of the to-be-superposed object and a distance between the to-be-superposed object and the target object; in the operation process of the target object, adjusting the size of the corresponding HUD projection image according to the state information of the to-be-superposed object; and projecting the HUD projection image of which the size is adjusted to the projection area for display. The invention further discloses an HUD projection image display device, by adopting the embodiment of the invention, the size of the HUD projection image can be adjusted in real time according to the change of the road condition, and the visual experience of a user is improved.

Owner:HUMAN HORIZONS (SHANGHAI) CLOUD COMPUTING TECH CO LTD

Method of controlling a lithographic apparatus and device manufacturing method, control system for a lithographic apparatus and lithographic apparatus

ActiveUS20180284621A1Improve overlay effectEliminate and reducePhotomechanical exposure apparatusMicrolithography exposure apparatusControl systemComputational model

In a method of controlling a lithographic apparatus, historical performance measurements are used to calculate a process model relating to a lithographic process. Current positions of a plurality of alignment marks provided on a current substrate are measured and used to calculate a substrate model relating to a current substrate. Additionally, historical position measurements obtained at the time of processing the prior substrates are used with the historical performance measurements to calculate a model mapping. The model mapping is applied to modify the substrate model. The lithographic apparatus is controlled using the process model and the modified substrate model together. Overlay performance is improved by avoiding over- or under-correction of correlated components of the process model and the substrate model. The model mapping may be a subspace mapping, and dimensionality of the model mapping may be reduced, before it is used.

Owner:ASML NETHERLANDS BV

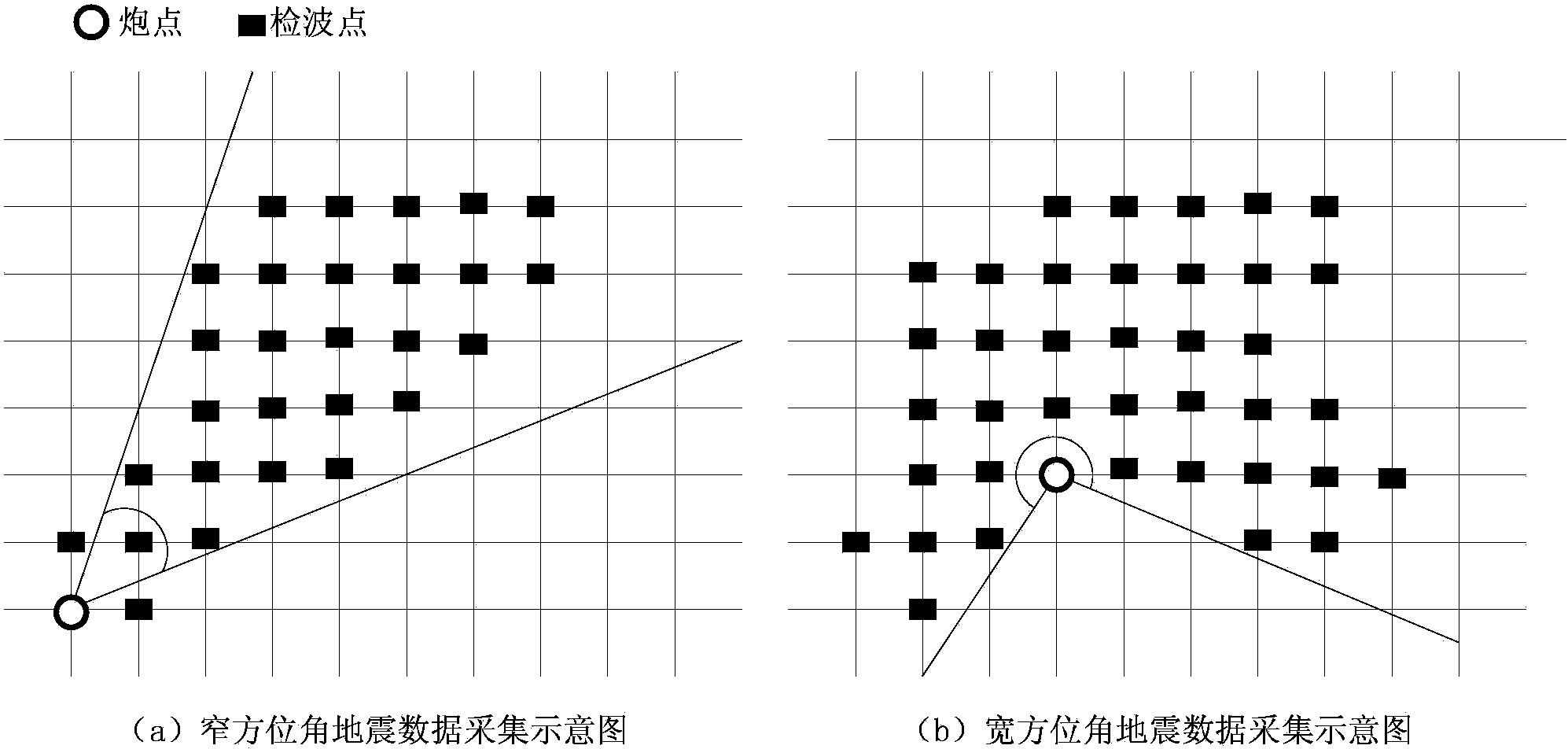

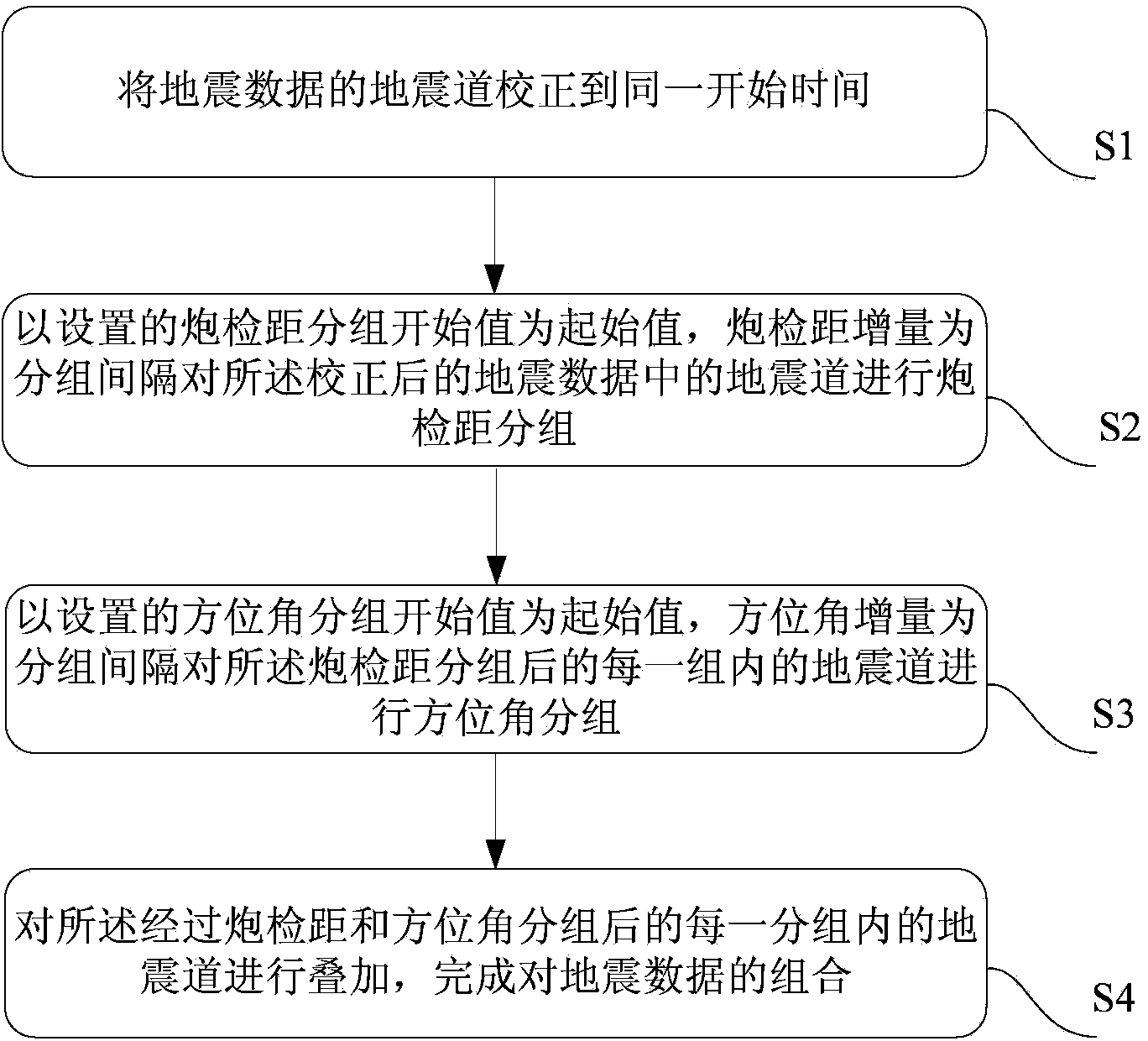

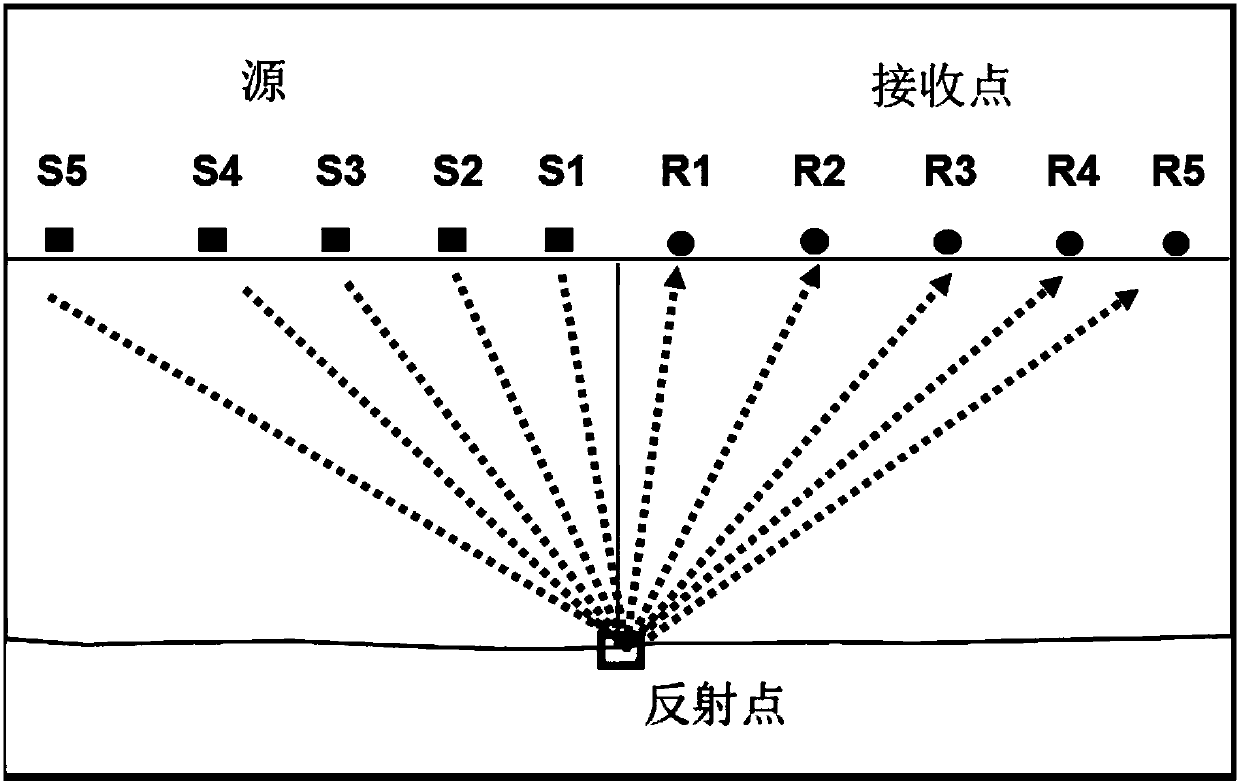

Earthquake data combination method, apparatus and system

ActiveCN104166160AImprove overlay effectReduce raw data impactSeismic signal processingCombined methodSignal-to-noise ratio (imaging)

The invention provides an earthquake data combination method, apparatus and system. The method comprises: correcting seismic channels of earthquake data to the same starting time; carrying out offset distance grouping and azimuth grouping on the earthquake data after correction; and performing superposition on the seismic channels in each group after the offset distance grouping and azimuth grouping are performed, and finishing combination of the earthquake data. By using each embodiment of the invention, at the time when the earthquake data is compressed, the influence on original data is reduced, and the spatial distribution characteristic and the effective information of the original data are well maintained. According to the invention, at the time when the earthquake data with wide azimuth angles is compressed, the signal-to-noise ratio of the earthquake data after compression can also be improved, and convenience is provided for subsequent earthquake data processing and interpretation.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

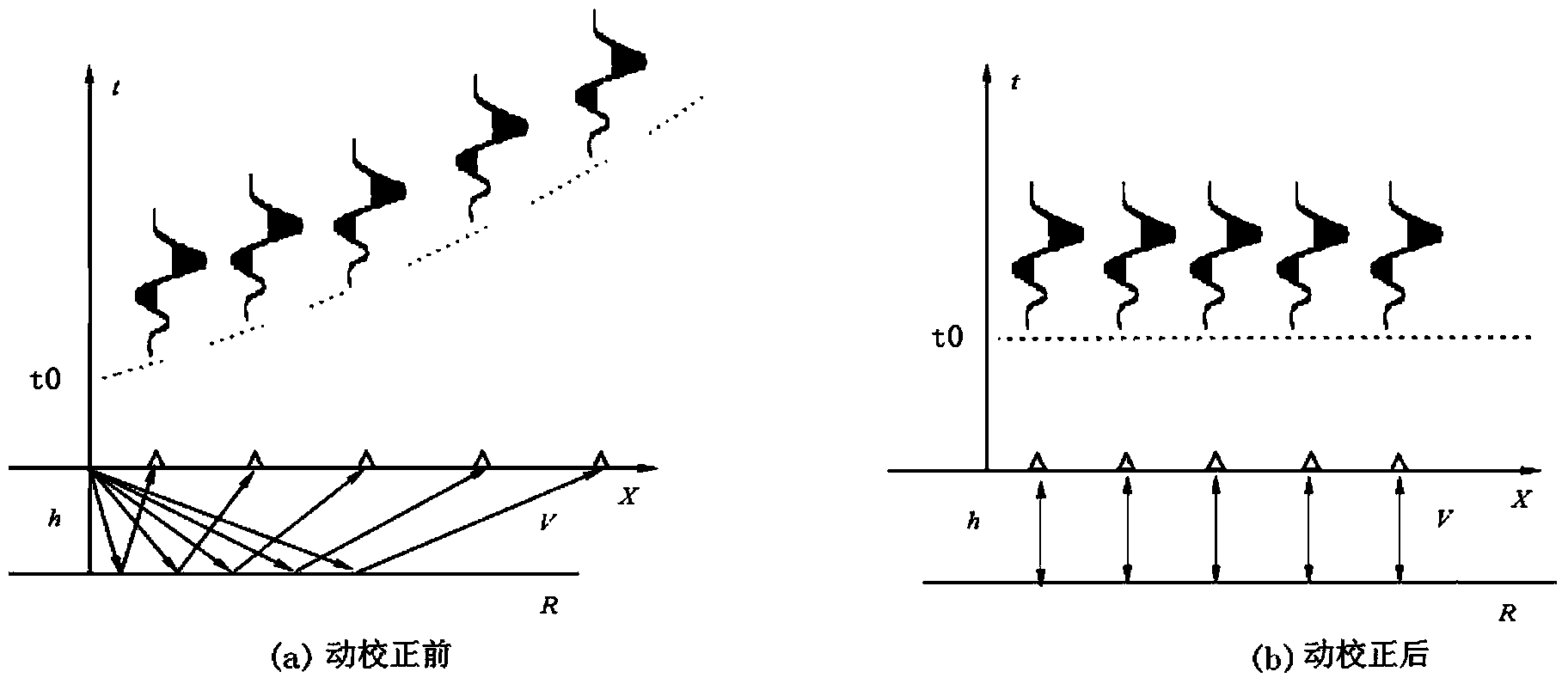

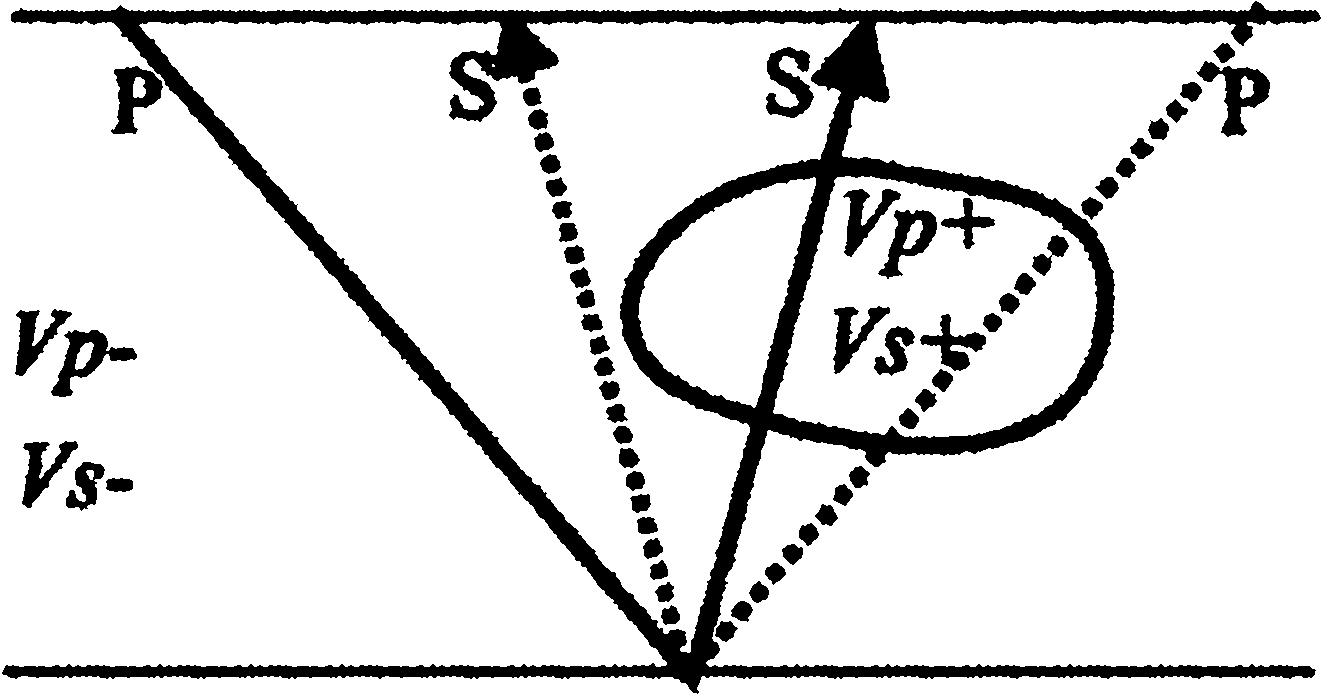

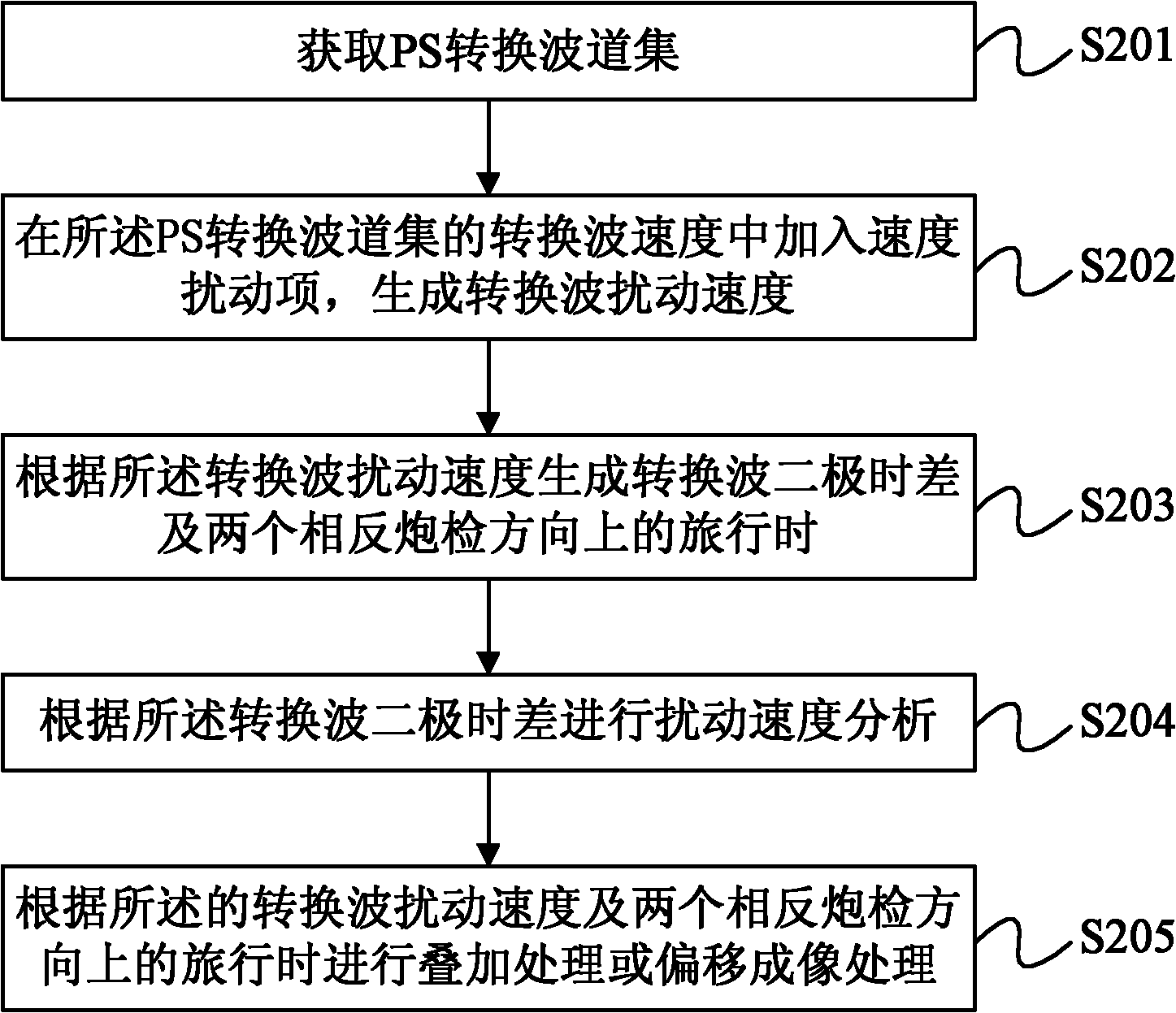

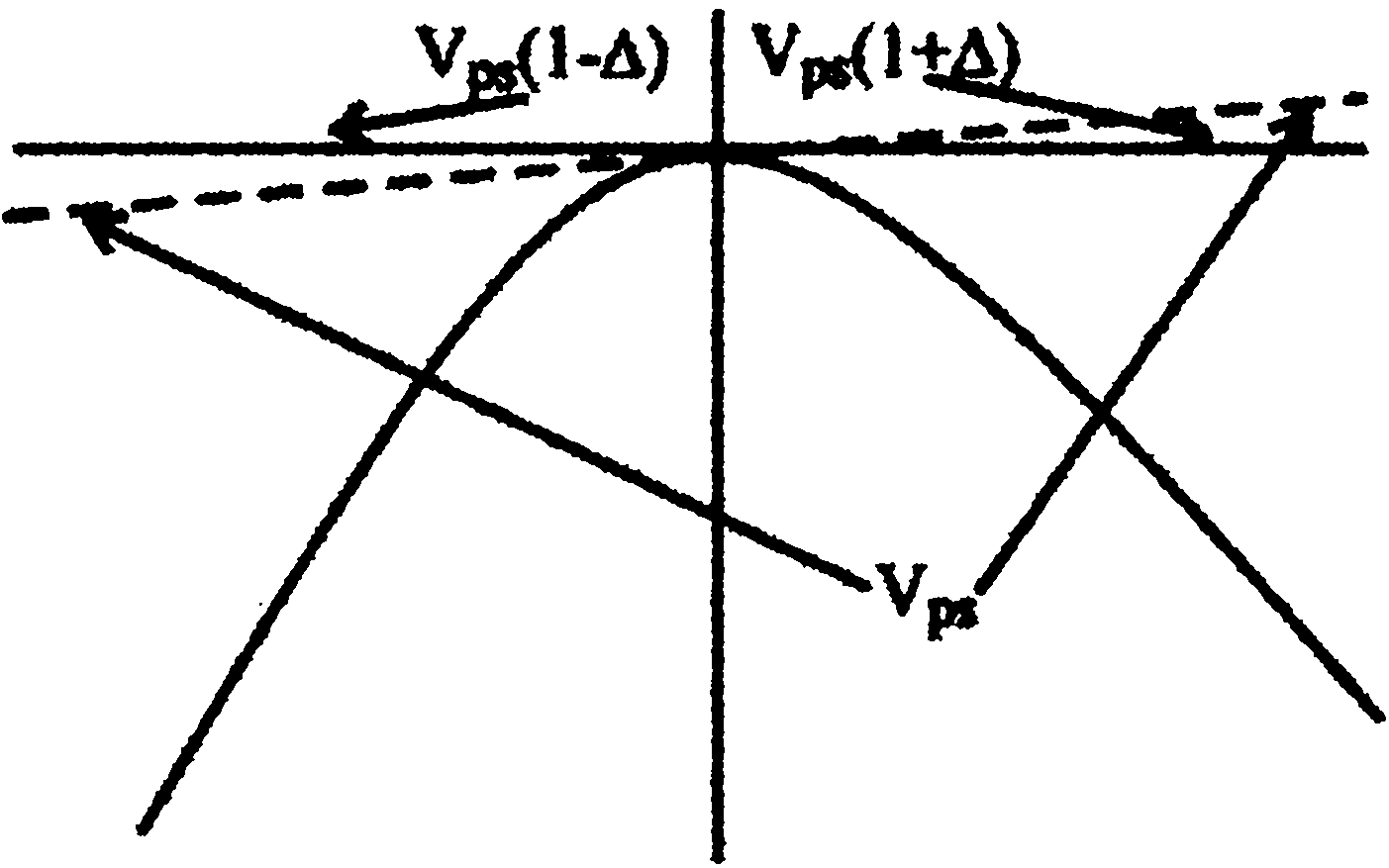

Converted wave secondary response compensation method

InactiveCN102466820AImprove overlay effect and offset imaging qualityImprove overlay effectSeismic signal processingTime differenceClassical mechanics

The invention provides a converted wave secondary response compensation method. The method comprises steps of: obtaining a PS (Primary-Secondary) converted wave gather; adding a velocity disturbance term in the velocity of the converted wave in the PS converted wave gather to generate a converted wave disturbance velocity; generating converted wave secondary time difference and travel time in two opposite offset directions according to the converted wave disturbance velocity; analyzing the disturbance velocity according to the converted wave secondary time difference; performing stacking treatment or migration imaging treatment according to the converted wave disturbance velocity and the travel time in two opposite offset directions. According to the converted wave secondary response compensation method provided by the invention, the secondary response of the PS converted wave can be compensated, the events of the PS converted wave are aligned, and the stacking effect and the migration imaging quality of the PS converted wave are improved.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

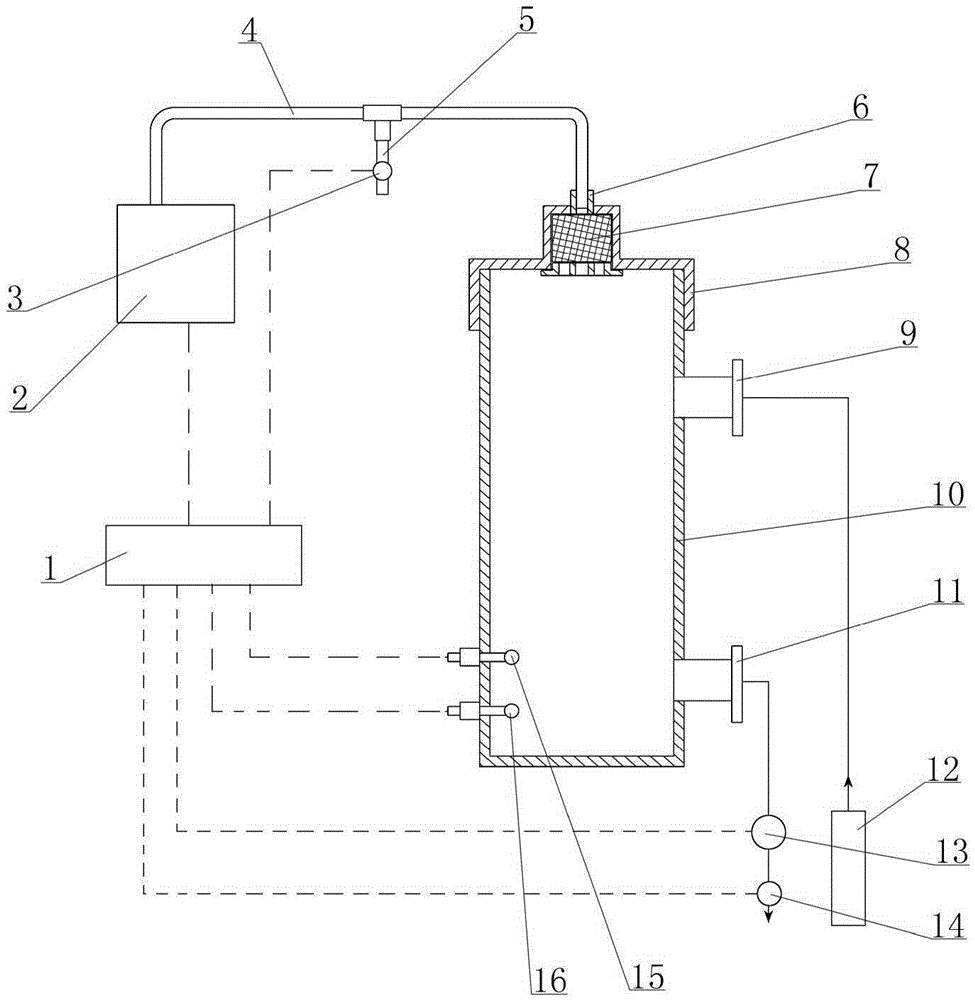

Full-time pressure-superposed non-negative-pressure water supply device

InactiveCN106592708AImprove overlay effectImprove energy saving performanceService pipe systemsWater mainsEngineeringLiquid level sensor

The invention discloses a full-time pressure-superposed non-negative-pressure water supply device including a current stabilizing compensator. The current stabilizing compensator includes a tank body. A water outlet, a liquid level sensor, a pressure sensor and a water inlet are arranged in the side wall of the tank body. A top cover is arranged at the upper end of the tank body. An air port is arranged in the top cover. The air port is connected with an air pump. An air conveying pipe is connected with an electromagnetic air exhaust valve through a tee joint and an exhaust pipeline. The water inlet is connected with a municipal pipe. The water outlet is connected with a secondary pressure pump unit. An output pipeline of the secondary pressure pump unit is provided with an output pressure meter. An output pressure meter, a water pressure sensor and a water level sensor send collected data to a controller. Working states of the secondary pressure pump unit, the air pump and the electromagnetic air exhaust valve are controlled by the controller. Constant pressure in the tank body can be ensured all the time during the working process of the current stabilizing compensator, so that the secondary pressurizing is performed based on prior pressure of the municipal pipeline; the pressure-superposing effect of the current stabilizing compensator is improved substantially and the energy saving performance of the non-negative-pressure water supply device is improved.

Owner:SHANDONG HUALI WATER SUPPLY EQUIP CO LTD

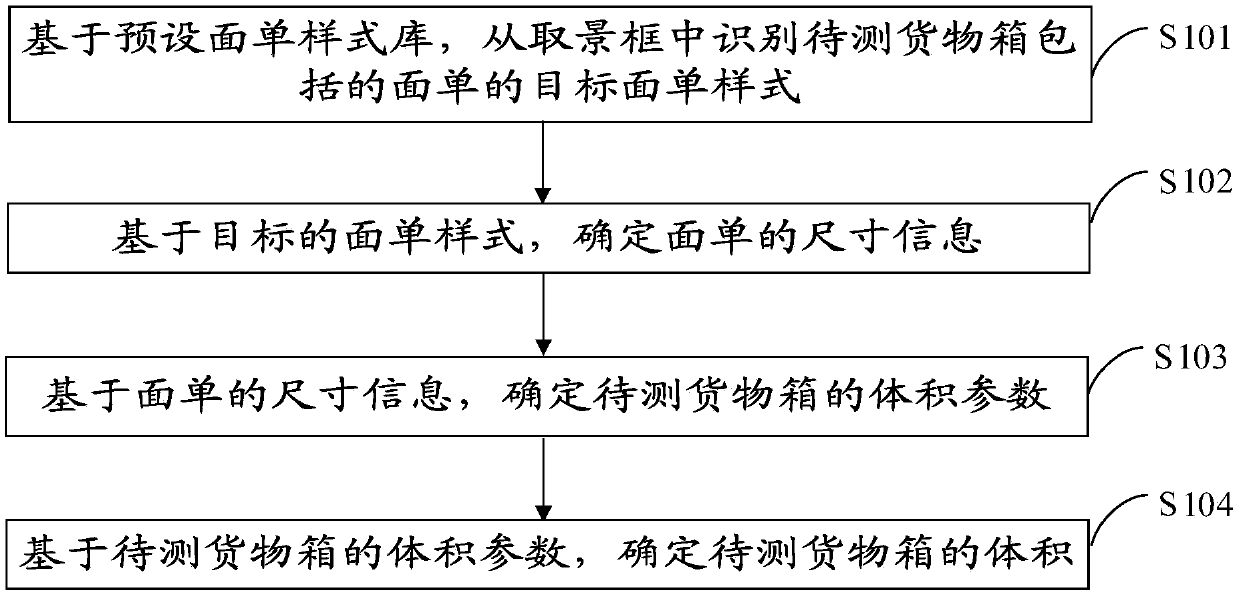

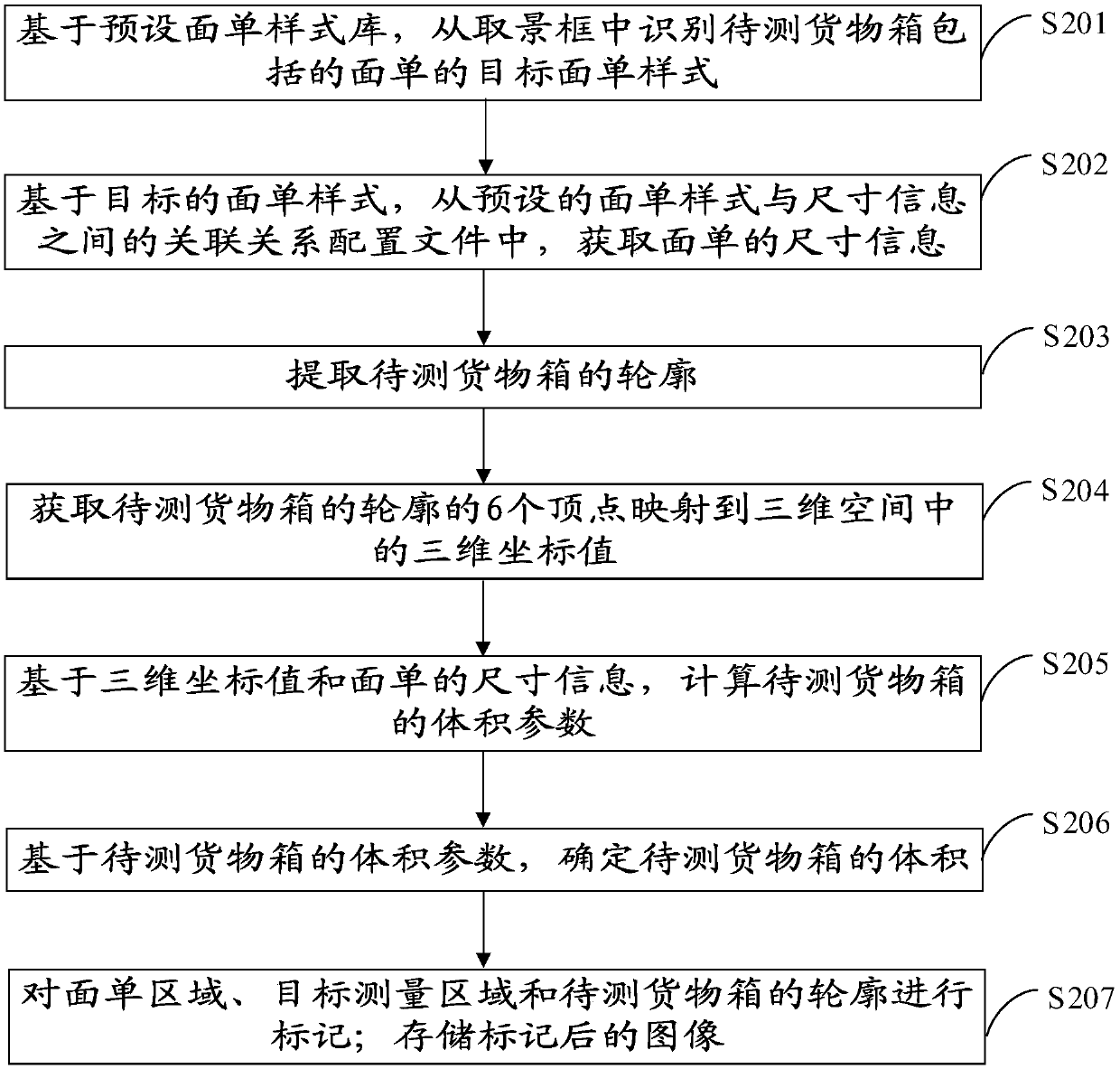

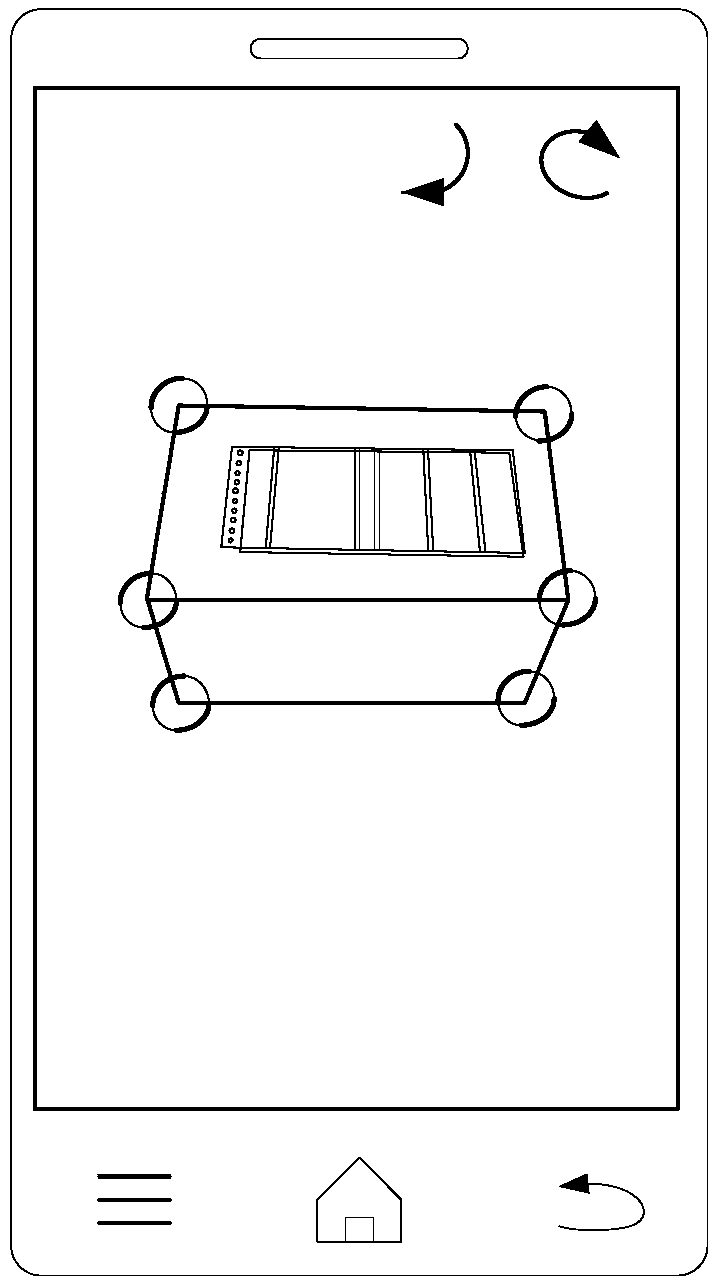

Cargo box size measuring method and device

InactiveCN109540002AImprove overlay effectImprove efficiencyUsing optical meansContainer/cavity capacity measurementLogistics managementSize measurement

The invention provides a cargo box size measuring method and device, and relates to the technical field of logistics transportation. The method comprises the following steps: based on a preset expresssheet style library, a target express sheet style of an express sheet of a to-be-measured cargo box is recognized from a viewing frame; on the basis of the recognized target express sheet style, sizeinformation of the express sheet is determined; and then by determining a size ratio of the express sheet to the to-be-measured cargo box, volume parameters of the to-be-measured cargo box are determined, and then the volume of the to-be-measured cargo box is determined. That is, the efficiency and accuracy of measuring the volume of the to-be-detected cargo box are improved in an automatic measuring mode.

Owner:上海德启信息科技有限公司

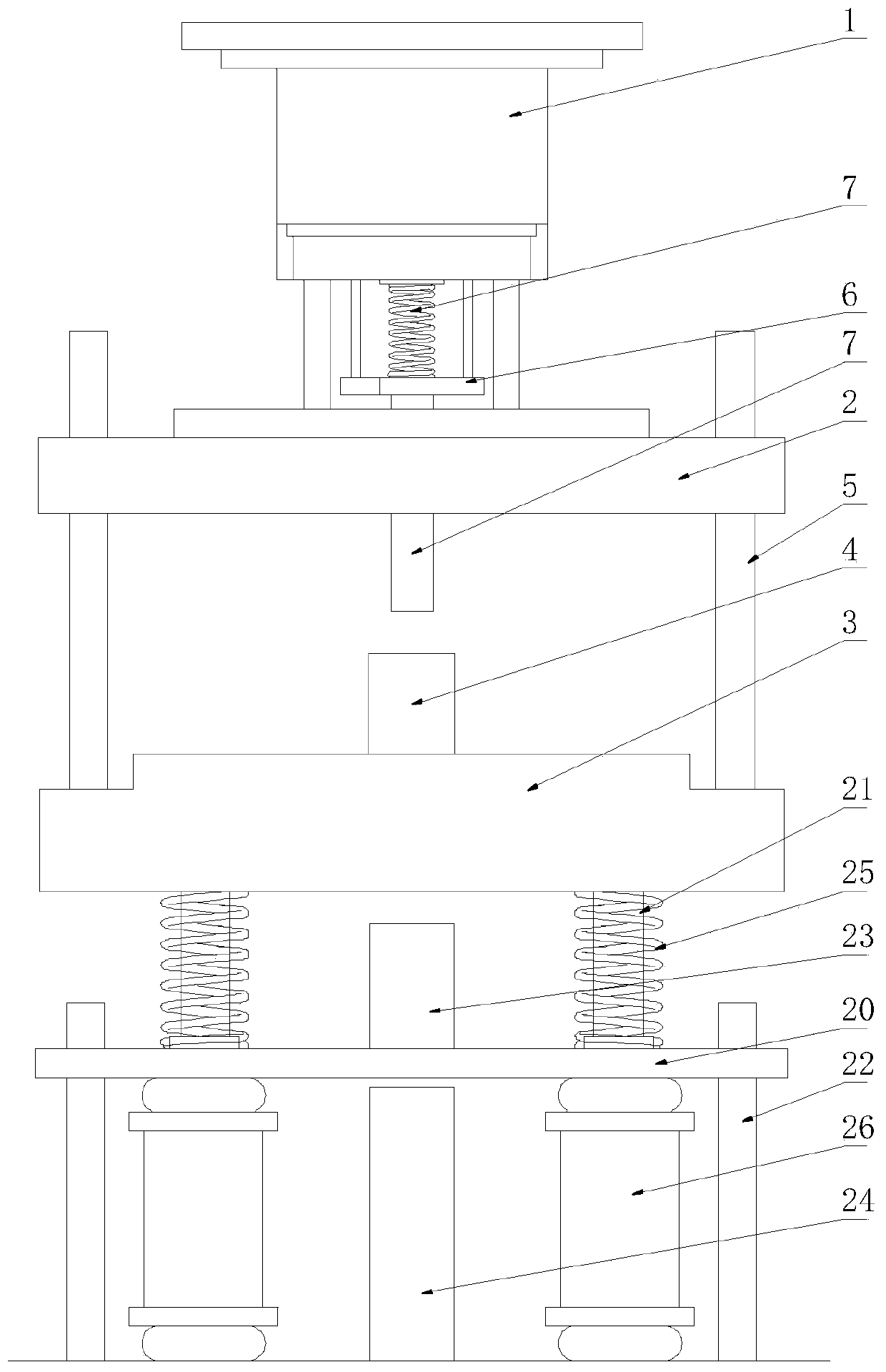

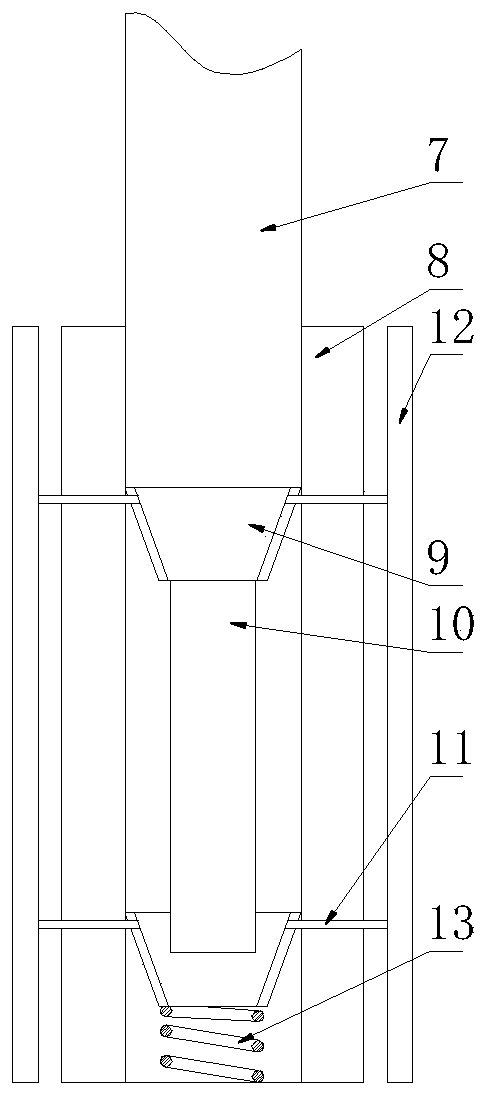

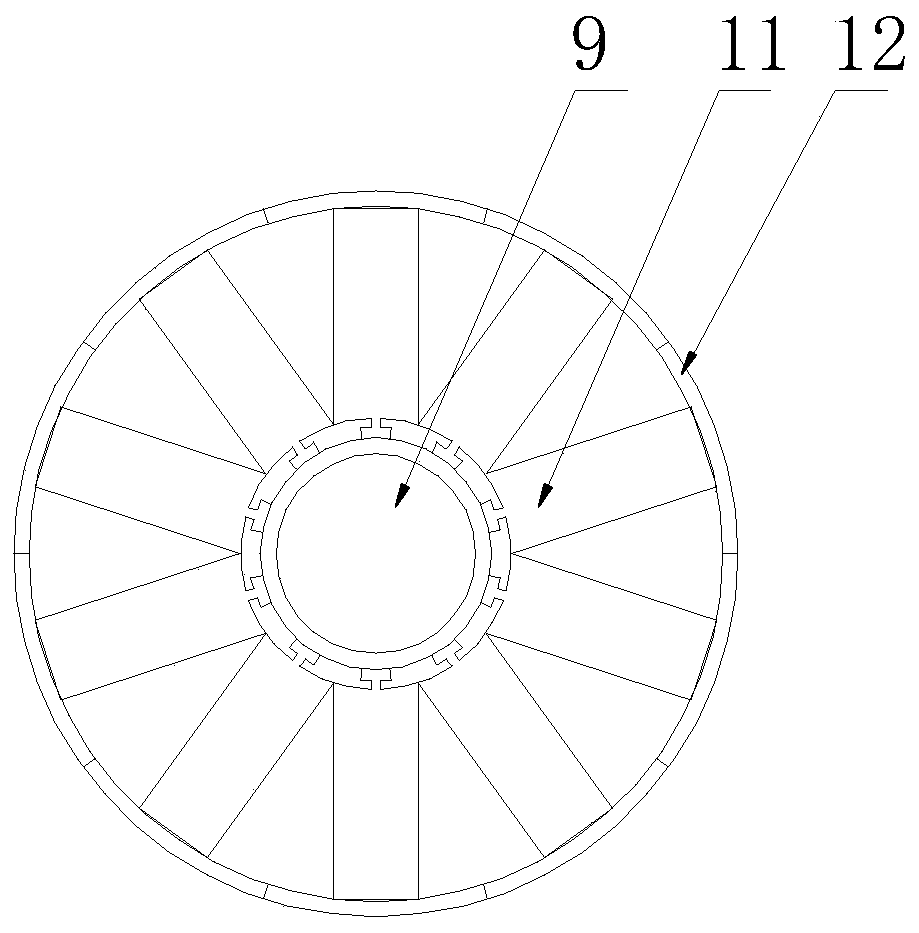

Lamination buffering device for permanent magnet rotor of neodymium-iron-boron permanent magnet synchronous motor

PendingCN110429773ALimit offsetLimit inner wall deformationManufacturing stator/rotor bodiesElectric machinesPermanent magnet rotorStress process

A lamination buffering device for a permanent magnet rotor of a neodymium-iron-boron permanent magnet synchronous motor comprises a pressure head, an upper sliding base, a lower sliding base, an external expansion mechanism and a second-stage buffer mechanism. The pressure head is arranged on the top of the upper sliding base; the lower sliding base is arranged under the upper sliding base; and the top center of the lower sliding base is provided with the external expansion mechanism. The external expansion mechanism comprises a cylindrical body, conical heads, a pressure rod, push pieces, external expansion pieces and a reset spring. The second-stage buffer mechanism comprises a buffer base, a first-stage buffer guide rod, a second-stage buffer guide rod, a first-stage limit column, a second-stage limit column, a buffer spring and a buffer rubber column. Through cooperation of a punch rod and the external expansion mechanism, limit of multilayer silicon steel sheets during laminationof the rotor silicon steel sheets is realized to prevent deviation and inner wall deformation; through the second-stage buffer mechanism, the pressure on the silicon steel sheets is changed slowly, and the stress process is prolonged, so that the deviation is further reduced, and the lamination effect is improved; and the lamination buffering device is worth wide promoting.

Owner:JIANGXI SENYANG TECH

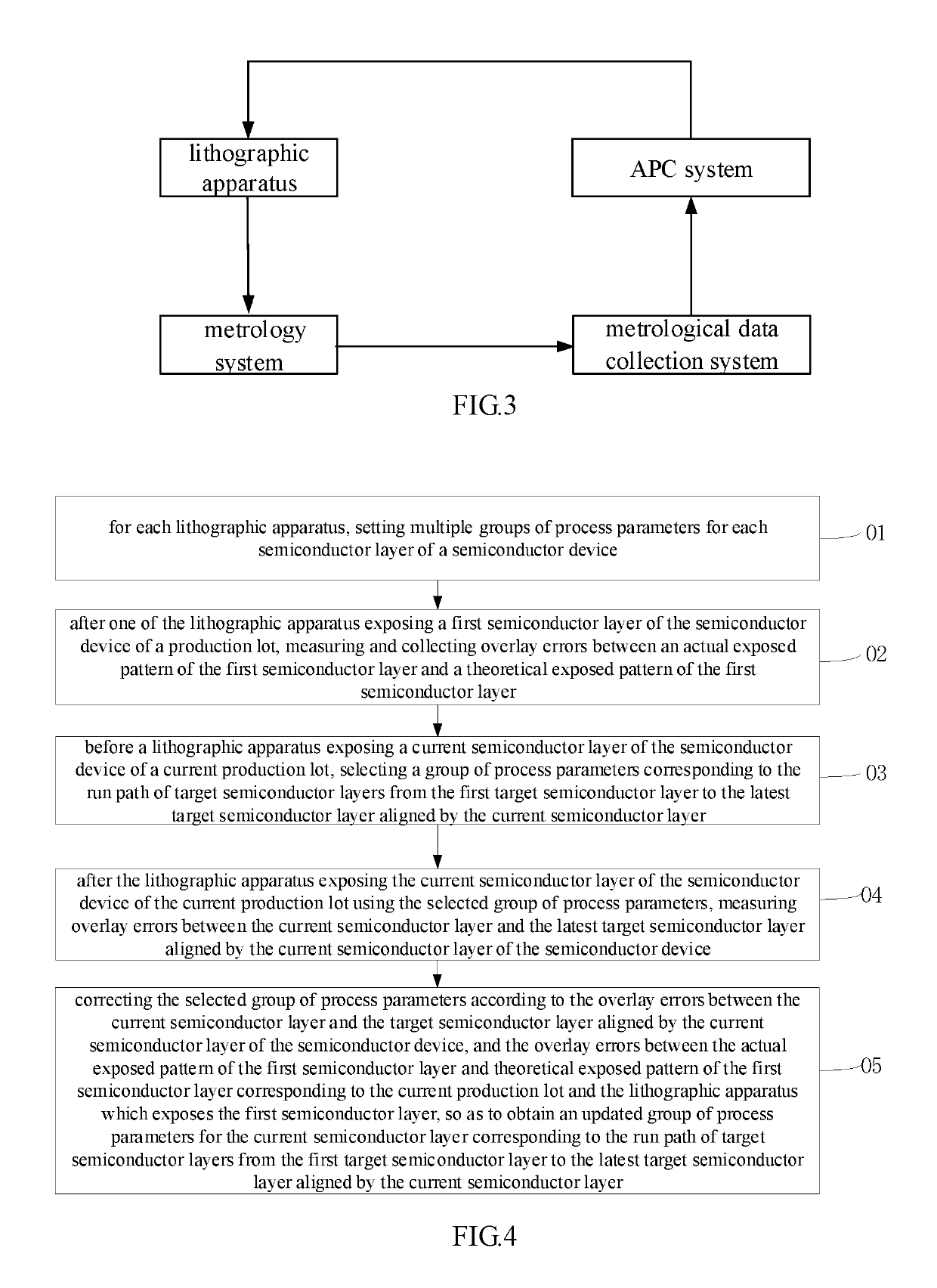

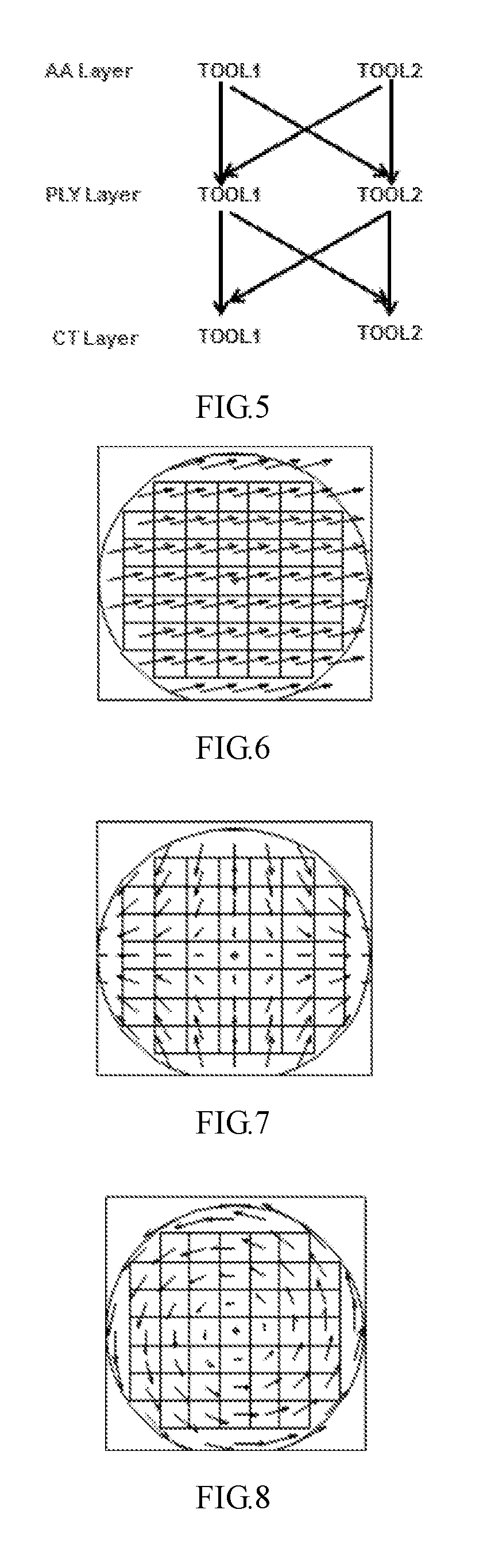

Optimization method and system for overlay error compensation

ActiveUS10261426B2Reduce rework rateResidue reductionSemiconductor/solid-state device testing/measurementSemiconductor/solid-state device manufacturingSemiconductor packageEngineering

An optimization method for overlay error compensation is disclosed. The method comprises setting process parameters for each semiconductor layer of a semiconductor device corresponding to a run path formed by different lithographic apparatus which sequentially process target semiconductor layers from a first target layer to a latest target layer; measuring overlay errors between an actual and a theoretical exposed patterns of the first semiconductor layer; selecting a group of process parameters corresponding to the run path from the first target layer to the latest target layer aligned by the current semiconductor layer; after exposing the current semiconductor layer using the selected process parameters, measuring overlay errors between the current semiconductor layer and its target layer; and correcting the selected process parameters according to the overlay errors between the current semiconductor layer and its target layer, and the overlay errors between the actual and theoretical exposed patterns of the first semiconductor layer.

Owner:SHANGHAI HUALI MICROELECTRONICS CORP

Wear-resistant coating material for a wooden tea table surface plates

The invention relates to a wear-resistant coating material for a wooden tea table surface plates, and relates to the technical field of tea table processing and production, wherein the wear-resistantcoating material is prepared from the following materials by weight: 10-15 parts of a resin, 4-9 parts of a silane coupling agent KH-550, 4-8 parts of modified perlite, 5-9 parts of an adhesion aid, 1-5 parts of N,N-methylenebisacrylamide, 4-9 parts of n-dodecyltrichlorosilane, 1-5 parts of polydicyclopentadiene, 1-6 parts of 2-(heptadecenyl)-4,5-dihydro-1H-imidazole-1-ethanol, 1-3 parts of dioctyl epoxy tetrahydrophthalate, 2-7 parts of nanometer titanium dioxide, 4-8 parts of an anti-aging agent A, 4-9 parts of a filler, and 16-22 parts of deionized water. According to the present invention,the method is reasonable, the operation is convenient, and the wear-resistant coating material has characteristics of wear resistance and high temperature resistance.

Owner:聚宝实木家私

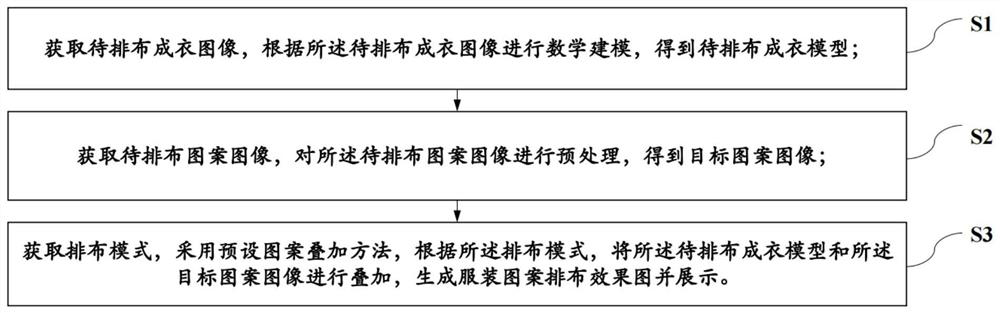

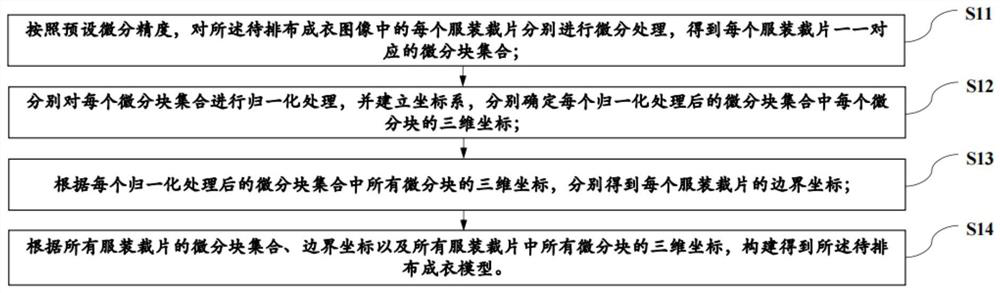

Internet-based garment pattern arrangement method and system and storage medium

PendingCN113111403AImprove layout efficiencyQuality improvementCAD customisation/personalisationGeometric CADSoftware engineeringThe Internet

The invention relates to an internet-based garment pattern arrangement method and system and a storage medium, and the method comprises the steps: obtaining a to-be-arranged garment image, carrying out mathematical modeling according to the to-be-arranged garment image, and obtaining a to-be-arranged garment model; obtaining a to-be-arranged pattern image, and preprocessing the to-be-arranged pattern image to obtain a target pattern image; and obtaining an arrangement mode, superposing the to-be-arranged garment model and the target pattern image according to the arrangement mode by adopting a preset pattern superposition method, and generating and displaying a garment pattern arrangement effect picture. Customized clothing pattern design can be carried out based on the Internet technology, the garment pattern arrangement effect picture most conforming to expectation is generated and displayed to the user, repeated communication and modification are not needed, the customization efficiency is improved, the rework rate is low, the intelligent degree is high, and the user experience feeling is high.

Owner:虞健 +1

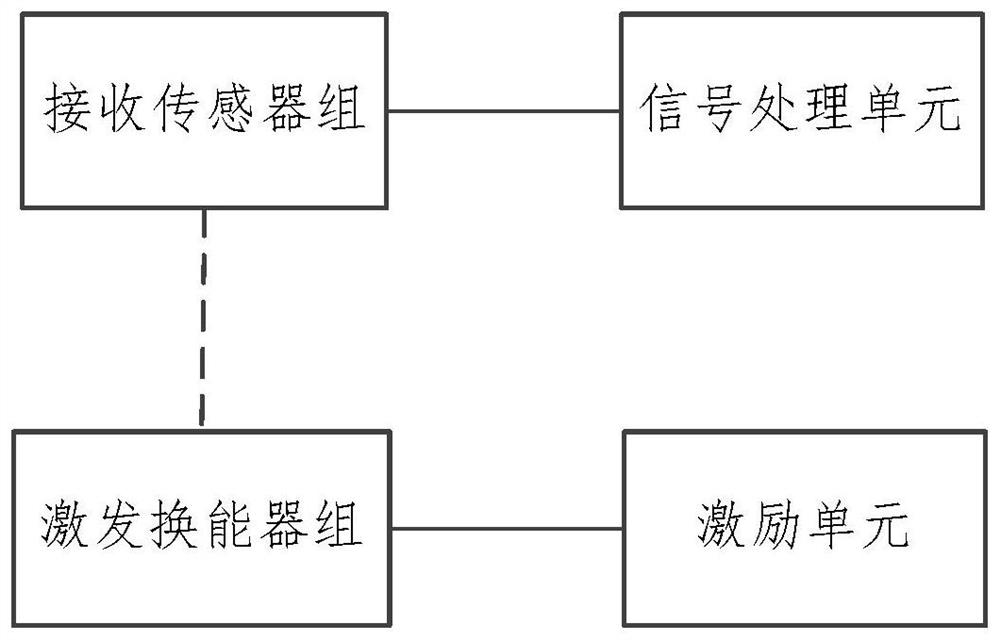

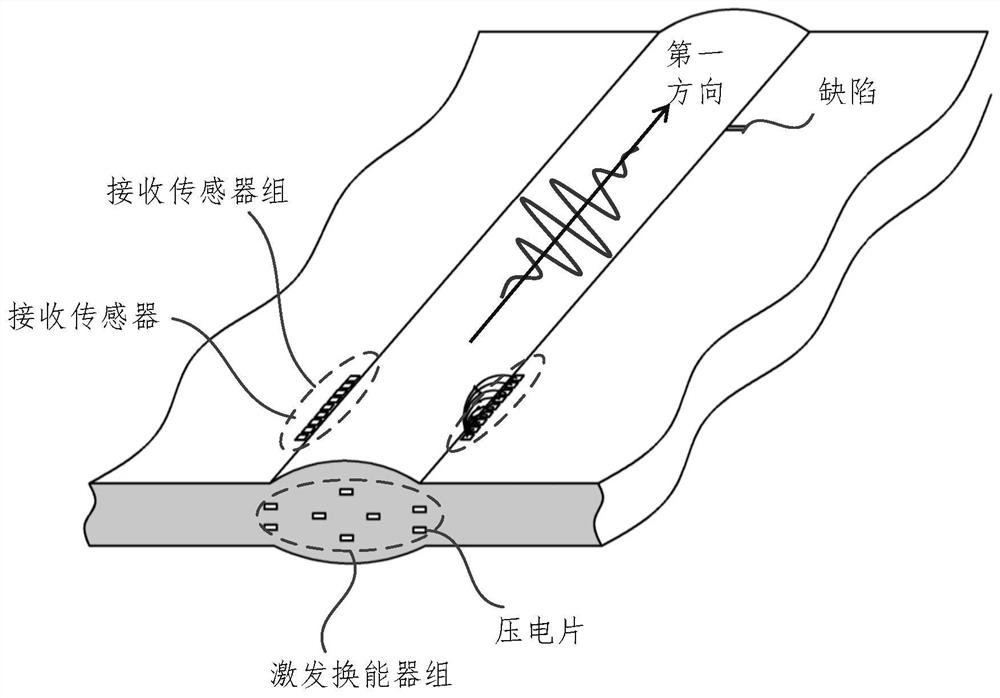

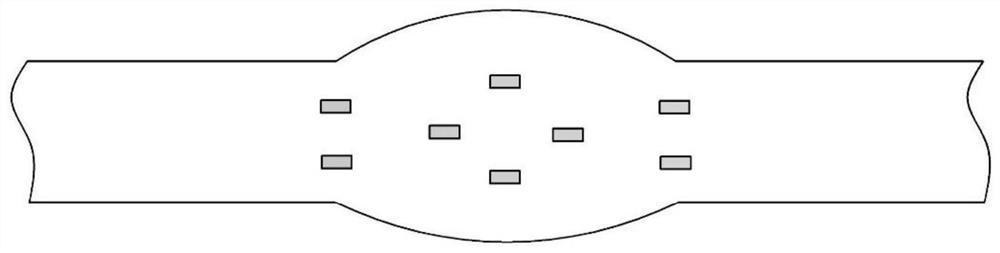

Weld defect detection method and device, electronic equipment and storage medium

ActiveCN113466336ANo dead angle detectionImprove efficiencyAnalysing solids using sonic/ultrasonic/infrasonic wavesWeld seamEngineering

The invention relates to a weld defect detection method and device, electronic equipment and a storage medium. The method comprises the steps of determining a first vibration signal corresponding to a target sensor based on a detection signal of the target sensor; determining a first vibration signal corresponding to each non-target sensor based on the detection signal of each non-target sensor; based on the first vibration signals corresponding to the non-target sensors, determining second vibration signals of reference waves corresponding to the non-target sensors at target sensor setting positions; superposing the first vibration signal corresponding to the target sensor and the second vibration signal of each reference wave at the setting position of the target sensor to obtain a superposed third vibration signal; and determining weld defect data in the to-be-detected component based on the superposed third vibration signal. The device can be used for detecting local defects in a long welding seam structure with high transverse resolution capability and high axial positioning precision, and can realize remote in-service quality monitoring.

Owner:BEIHANG UNIV

Polyimide label material for power system fault identification and preparation method thereof

ActiveCN111785155BUniform coatingPlay a stabilizing roleStampsLuminescent paintsPolyurethane adhesivePhosphoric acid

The invention provides a polyimide label material for power system fault identification and a preparation method thereof. The polyimide label material comprises from top to bottom: a color-changing layer for identification, a black polyimide film, an acrylic glue layer, and a transparent PET Silicone oil release film; the logo color-changing layer includes: dispersion liquid, coating liquid, coating liquid curing agent; the dispersion liquid includes: ammonium manganese phosphate powder, dioxane and dimethylacetamide, by adding three These are mixed and then ground to ammonium manganese phosphate powder particle size of 3-7 μm; the coating solution includes: polyurethane glue, white luminous powder, titanium dioxide.

Owner:SHENZHEN LICHANGSHI ADHESIVE PROD

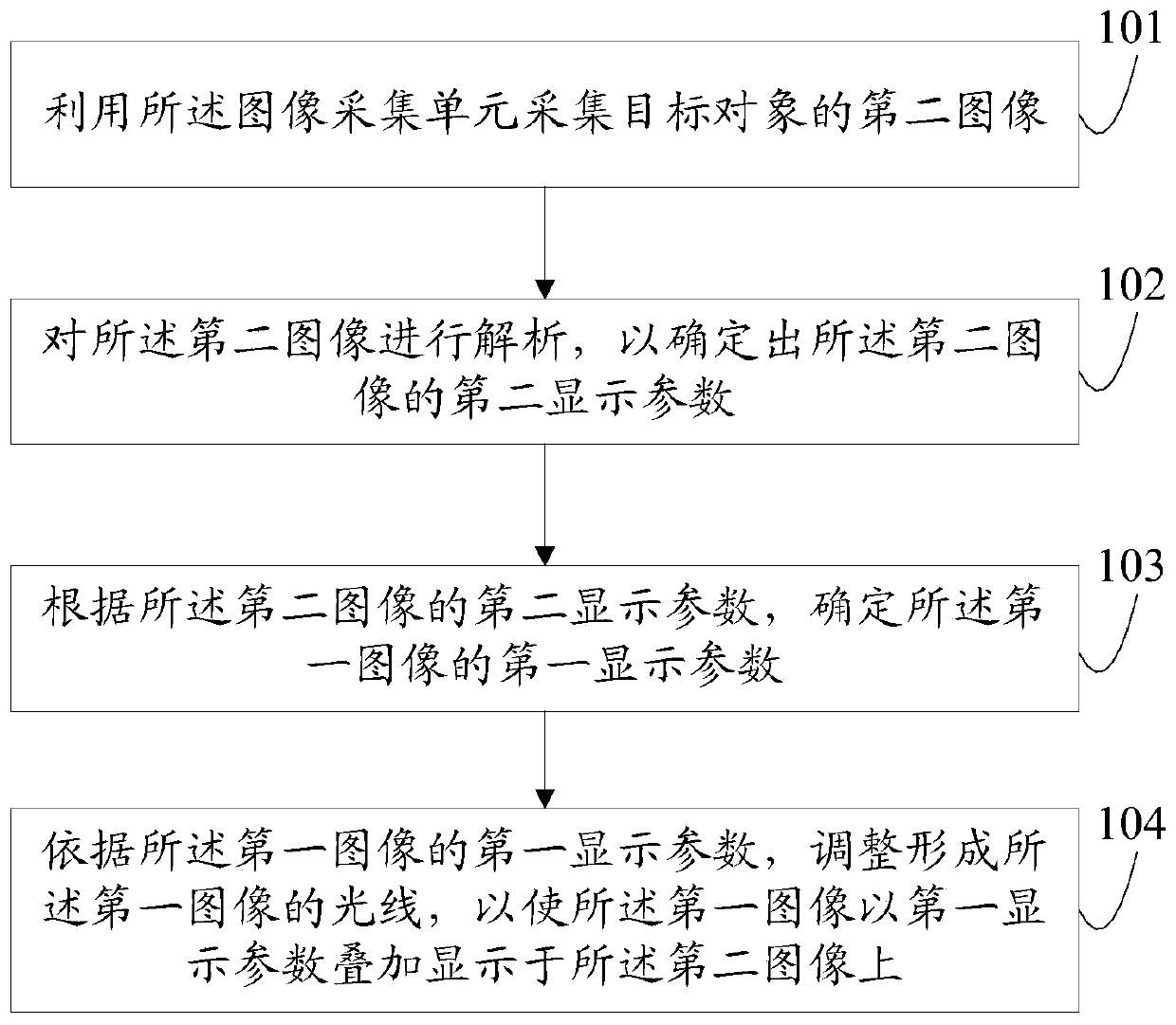

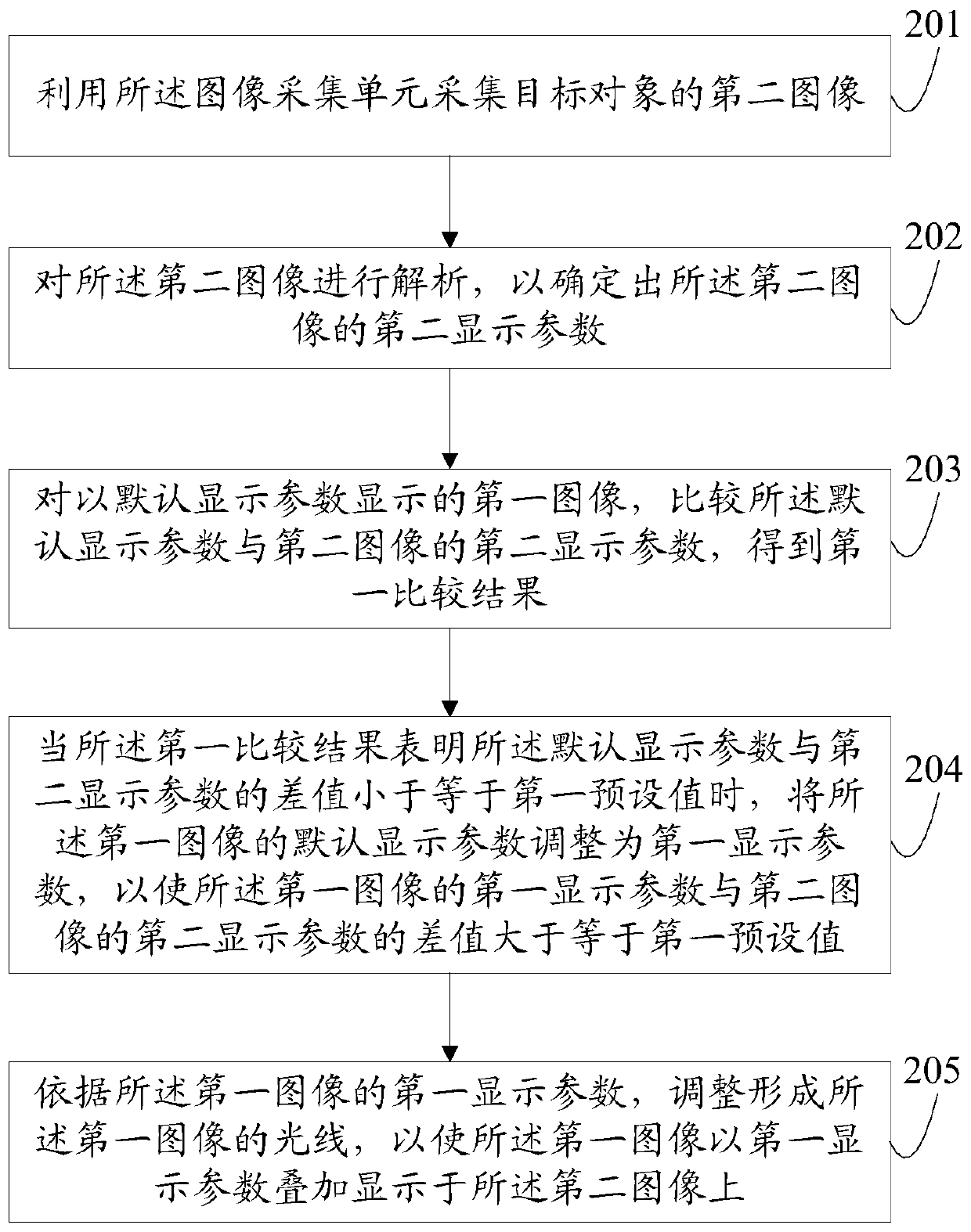

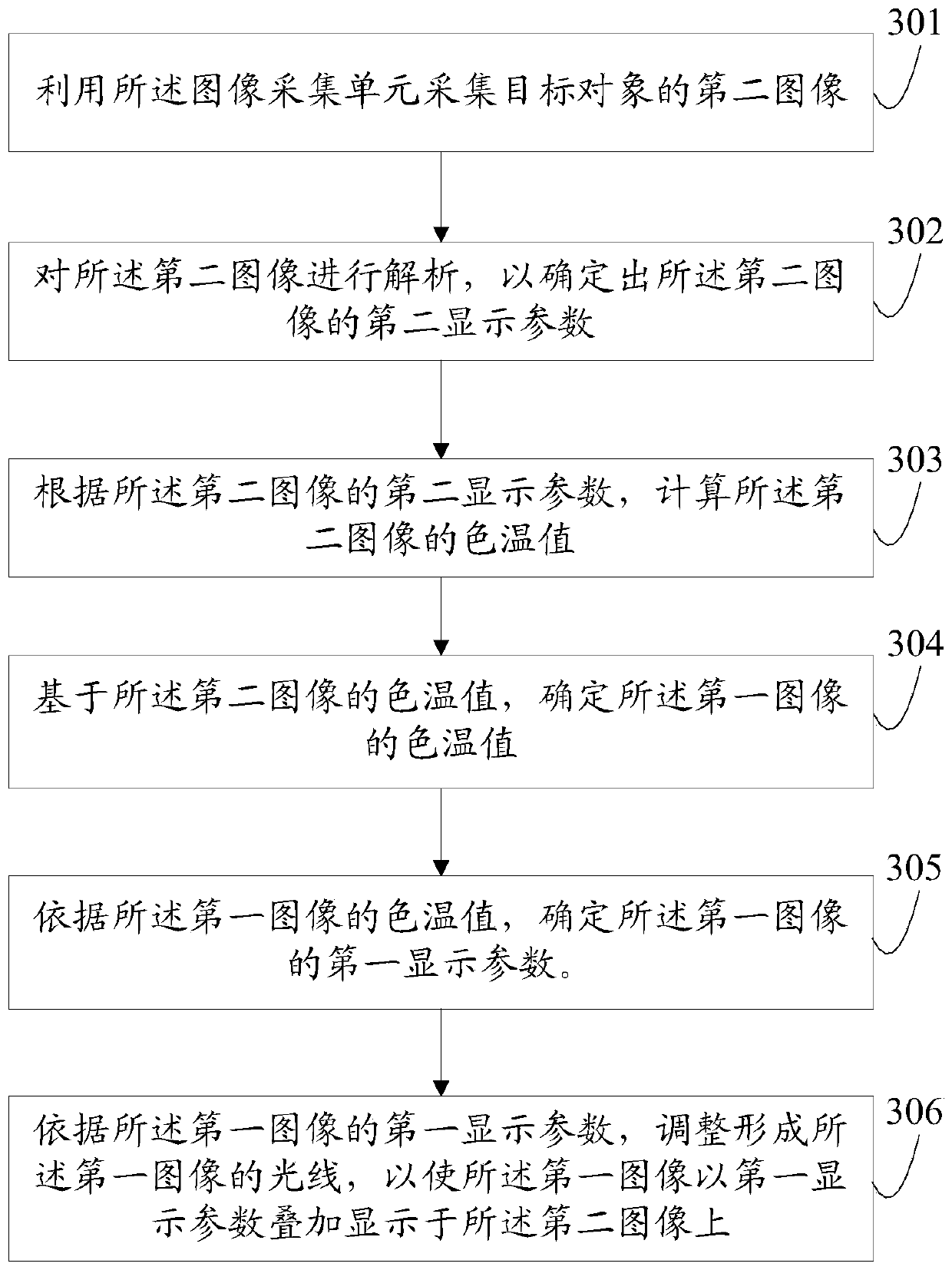

An information processing method and portable electronic device

ActiveCN105468250BEasy to distinguishImprove experienceInput/output processes for data processingOptical elementsInformation processingLens plate

The present invention discloses an information processing method and a portable electronic device. The electronic device can emit a light used for forming a first image from a projecting source of a projection unit, and project the light to eyes of a user of the electronic device by a lens unit of a lens module, so that the user can see the first image at a visual focus position through the lens module. The information processing method comprises: acquiring a second image of a target object by using an image acquisition unit; performing analysis on the second image so as to determine a second display parameter of the second image; according to the second display parameter of the second image, determining a first display parameter of the first image; and according to the first display parameter of the first image, adjusting the light that forms the first image, so that the first image are displayed on the second image in an overlapping way by the first display parameter.

Owner:LENOVO (BEIJING) LTD

A Time-Frequency Domain Seismic Data Processing Method Based on Weighted Stacking

ActiveCN105954799BImprove overlay effectReduce noise interferenceSeismic signal processingDifferential space timeS transform

The invention provides a time-frequency domain seismic data processing method based on weighted stacking, and the method comprises the following steps: 1) an original seismic to-be-stacked signal is converted in a time-frequency transform domain which is formed by S transform, and a instantaneous phase in the time-frequency transform domain is extracted; 2) a stacking weight is constructed; 3) the stacking weight is applied to obtain a final stacking result, and the stacking of the seismic signal is completed. According to the invention, a weight formed by the instantaneous phase is introduced to a weight stacking process, the noise interference is attenuated, and a weak energy effective signal is enhanced, and the stacking effect of the seismic data is further improved on weak amplitude effective signal energy maintenance, random disturbance suppression and residual moveout correction.

Owner:PETROCHINA CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com