Wear-resistant coating material for a wooden tea table surface plates

A wear-resistant paint and coffee table technology, applied in the field of wear-resistant paint, can solve the problems of poor bearing capacity, high temperature resistance, wood damage, etc., and achieve the effects of convenient operation, increased service life, and increased waterproof performance and wear resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

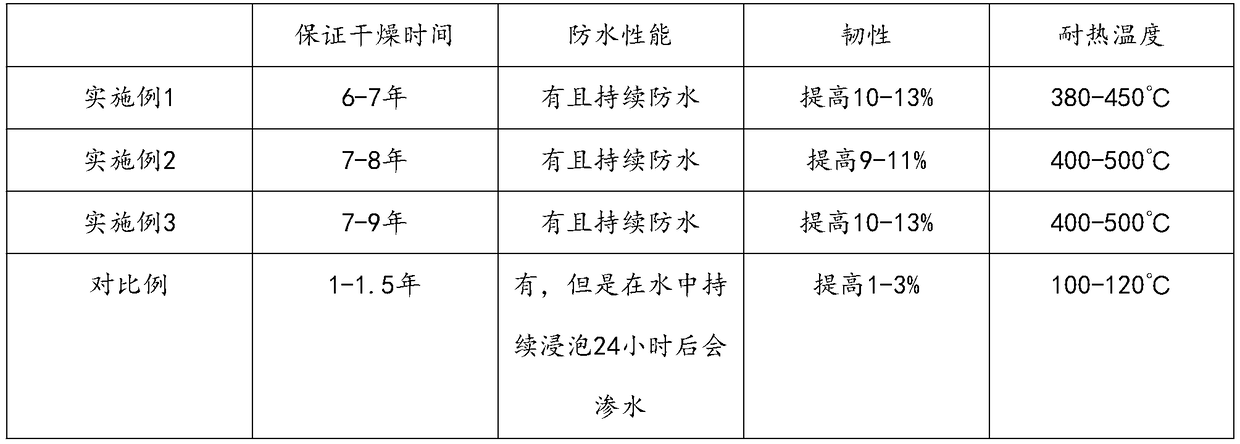

Examples

Embodiment 1

[0030] A wear-resistant coating for wooden tea table panels, characterized in that: it is made of the following materials by weight,

[0031] 10-15 parts of resin, 9 parts of silane coupling agent KH-5504, 4-8 parts of modified perlite, 1-5 parts of N, N-methylenebisacrylamide, 4 parts of n-dodecyl trichlorosilane -9 parts, 1-5 parts of polydicyclopentadiene, 1-6 parts of 1-hydroxyethyl-2-oleyl imidazoline, 1-3 parts of epoxy tetrahydrophthalate dioctyl, nano-titanium dioxide 2 -7 parts, 4-8 parts of antioxidant A, 4-9 parts of filler, 16-22 parts of deionized water;

[0032] The resin comprises one of polyvinyl chloride resin, epoxy resin, furan resin, amino resin, and silicone resin;

[0033] The preparation method of the modified perlite is as follows: grind the perlite and pass through a 300-400 mesh sieve, then put it into the reaction kettle and add deionized water equal to the weight of the perlite to raise the temperature to 85-95°C, and then keep the temperature cons...

Embodiment 2

[0046] A wear-resistant coating for wooden tea table panels, characterized in that: it is made of the following materials by weight,

[0047] 10-15 parts of resin, 9 parts of silane coupling agent KH-5504, 4-8 parts of modified perlite, 5-9 parts of bonding agent, 1-5 parts of N, N-methylenebisacrylamide, 4-9 parts of n-dodecyltrichlorosilane, 1-5 parts of polydicyclopentadiene, 1-6 parts of 1-hydroxyethyl-2-oleyl imidazoline, dioctyl epoxy tetrahydrophthalate 1-3 parts of ester, 2-7 parts of nano titanium dioxide, 4-8 parts of anti-aging agent A, 16-22 parts of deionized water;

[0048] The resin comprises one of polyvinyl chloride resin, epoxy resin, furan resin, amino resin, and silicone resin;

[0049]The preparation method of the modified perlite is as follows: grind the perlite and pass through a 300-400 mesh sieve, then put it into the reaction kettle and add deionized water equal to the weight of the perlite to raise the temperature to 85-95°C, and then keep the tempe...

Embodiment 3

[0060] A wear-resistant coating for wooden tea table panels, characterized in that: it is made of the following materials by weight,

[0061] 10-15 parts of resin, 9 parts of silane coupling agent KH-5504, 4-8 parts of modified perlite, 5-9 parts of bonding agent, 1-5 parts of N, N-methylenebisacrylamide, 4-9 parts of n-dodecyltrichlorosilane, 1-5 parts of polydicyclopentadiene, 1-6 parts of 1-hydroxyethyl-2-oleyl imidazoline, dioctyl epoxy tetrahydrophthalate 1-3 parts of ester, 2-7 parts of nano titanium dioxide, 4-8 parts of anti-aging agent A, 4-9 parts of filler, 16-22 parts of deionized water;

[0062] The resin comprises one of polyvinyl chloride resin, epoxy resin, furan resin, amino resin, and silicone resin;

[0063] The preparation method of the modified perlite is as follows: grind the perlite and pass through a 300-400 mesh sieve, then put it into the reaction kettle and add deionized water equal to the weight of the perlite to raise the temperature to 85-95°C, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com