Preparation method of low-loss high-superposition sendust material with magnetic conductivity mu equal to 26

A technology of sendust and low loss, which is applied in the field of preparation of low loss and high stacked sendust materials, and can solve the problem of low DC superposition performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Select 1 kg of 200-mesh sendust powder to a temperature-controllable stirring pot, add 200 ml of 30% phosphoric acid aqueous solution, the amount of phosphoric acid added accounts for 6% of the sendust powder by weight, and after stirring continuously for 1 hour, the temperature of the stirring pot rises to 120 ° C. Roast until dry; after sieving, put the powder into an annealing furnace protected by nitrogen and anneal at high temperature for 2 hours; then add 50g of high-temperature binder water glass (that is, account for 5% of the sendust powder by weight), and continue stirring until dry ; Add 3g of zinc stearate lubricating powder, stir evenly, and mix the powder with 18T / cm 3 Pressure pressed into standard magnetic rings of OD27.0, ID14.8, HT11.0; annealing treatment is carried out under the protection of nitrogen at 720±5°C, the oxygen content is controlled at 20ppm during annealing treatment, and the heat treatment time is 180 minutes; Resin paint spraying.

...

Embodiment 2

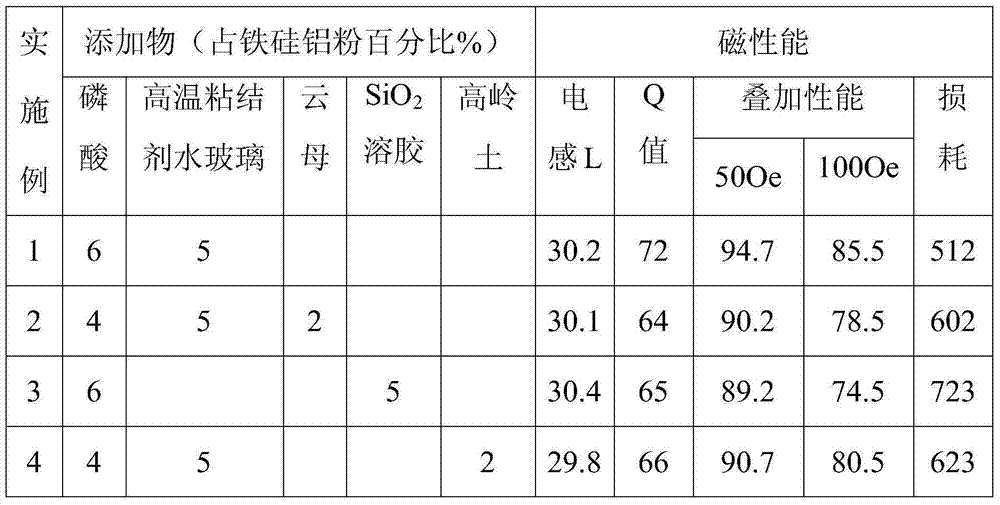

[0031] The preparation process of the magnetic core is the same as in Example 1, except that the amount of phosphoric acid in the formula is reduced to 4% by weight of sendust powder, and 2% of mica powder is added. In order to achieve the median value of inductance, the secondary annealing temperature after compression molding needs to be increased , the test results are shown in Table 1. It can be seen from Table 1 that the loss value of power loss at 100kHz and 100mT is 602mW / cm3; the superposition performance is 100Oe: 78.5%; 50Oe: 90.2%.

Embodiment 3

[0033] The preparation process of the magnetic core is the same as in Example 1, except that 5% high-temperature binder water glass is changed to 5% SiO in the formula 2 sol, the test results are shown in Table 1. It can be seen from Table 1 that the loss value of power loss at 100kHz and 100mT is 723mW / cm3; the superposition performance is 100Oe: 74.5%; 50Oe: 89.2%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| loss value | aaaaa | aaaaa |

| loss value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com