High-strength electroplating PC/ABS alloy material and preparation method thereof

An alloy material and high-strength technology, which is applied in the field of electroplating PC/ABS alloy materials and preparation, can solve the problems of low strength of electroplating PC/ABS alloys, and achieve good impact strength, improved bending strength, and improved impact strength.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

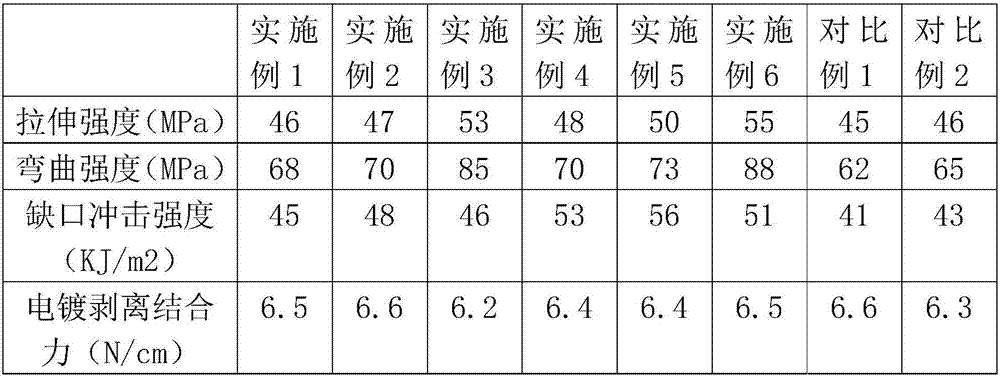

Examples

Embodiment 1

[0062] High-strength electroplated PC / ABS alloy material is prepared from the following raw materials in parts by weight: 45 parts of PC, 50 parts of ABS, 5 parts of ABS-g-MAH compatibilizer, 3 parts of GMA toughening agent, 0.5 parts of nano Calcium carbonate, 0.2 parts of antioxidant 168, 0.2 parts of lubricant.

[0063] The GMA toughening agent is a PTW toughening agent, and the lubricant is a PETS lubricant.

[0064] The preparation method of high-strength electroplating PC / ABS alloy material is as follows: weigh each component by weight, stir at a temperature of 25°C at a speed of 100r / min for 10 minutes to obtain a mixture, and place the mixture in a twin-screw extruder Extruded in a medium, then cut into 1cm×1cm×1cm particles, cooled to 25°C to obtain a high-strength electroplated PC / ABS alloy; the twin-screw extruder used is divided into 9 sections, and the set temperatures are 170°C, 200°C, 220°C, 230°C, 235°C, 240°C, 245°C, 250°C, 240°C, the feeding screw speed is 1...

Embodiment 2

[0066] High-strength electroplated PC / ABS alloy material is prepared from the following raw materials in parts by weight: 45 parts of PC, 50 parts of ABS, 5 parts of ABS-g-MAH compatibilizer, 5 parts of GMA toughening agent, 0.5 parts of nano Calcium carbonate, 0.2 parts of antioxidant 168, 0.2 parts of lubricant.

[0067] The GMA toughening agent is a PTW toughening agent, and the lubricant is a PETS lubricant.

[0068] The preparation method of high-strength electroplating PC / ABS alloy material is as follows: weigh each component by weight, stir at a temperature of 25°C at a speed of 100r / min for 10 minutes to obtain a mixture, and place the mixture in a twin-screw extruder Extruded in a medium, then cut into 1cm×1cm×1cm particles, cooled to 25°C to obtain a high-strength electroplated PC / ABS alloy; the twin-screw extruder used is divided into 9 sections, and the set temperatures are 170°C, 200°C, 220°C, 230°C, 235°C, 240°C, 245°C, 250°C, 240°C, the feeding screw speed is 1...

Embodiment 3

[0070] High-strength electroplated PC / ABS alloy material is prepared from the following raw materials in parts by weight: 45 parts of PC, 50 parts of ABS, 5 parts of ABS-g-MAH compatibilizer, 5 parts of GMA toughening agent, 1 part of nano Calcium carbonate, 0.2 parts of antioxidant 168, 0.2 parts of lubricant.

[0071] The GMA toughening agent is a PTW toughening agent, and the lubricant is a PETS lubricant.

[0072] The preparation method of high-strength electroplating PC / ABS alloy material is as follows: weigh each component by weight, stir at a temperature of 25°C at a speed of 100r / min for 10 minutes to obtain a mixture, and place the mixture in a twin-screw extruder Extruded in a medium, then cut into 1cm×1cm×1cm particles, cooled to 25°C to obtain a high-strength electroplated PC / ABS alloy; the twin-screw extruder used is divided into 9 sections, and the set temperatures are 170°C, 200°C, 220°C, 230°C, 235°C, 240°C, 245°C, 250°C, 240°C, the feeding screw speed is 10r / ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com