Hot working method for improving mechanical properties of medium carbon steel

A hot working, carbon steel technology, applied in the field of metal material science, can solve the problems of low strength of medium carbon steel, strict control of process system, insufficient dispersion strengthening effect of granular carbides, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] The experimental material is 35 medium carbon steel, and the medium carbon steel includes the following elements in mass percentage: C 0.36%, Mn 0.56%, Si 0.32%, P 0.027%, S 0.025%, and the balance is iron.

[0033] A medium-carbon steel sample with a size of Φ8×10mm is subjected to high-temperature and high-pressure heat treatment on a CS-ΙΙB six-sided top press, with a pressure of 6GPa, a temperature of 900°C, and a holding time of 10 minutes; to room temperature to obtain pretreated medium carbon steel;

[0034] The pretreated medium carbon steel was heated up to 500°C at a rate of 50°C / min under a pressure of 6GPa, and after holding the temperature for 30 minutes, the power was turned off and the pressure was maintained and cooled to room temperature with the furnace.

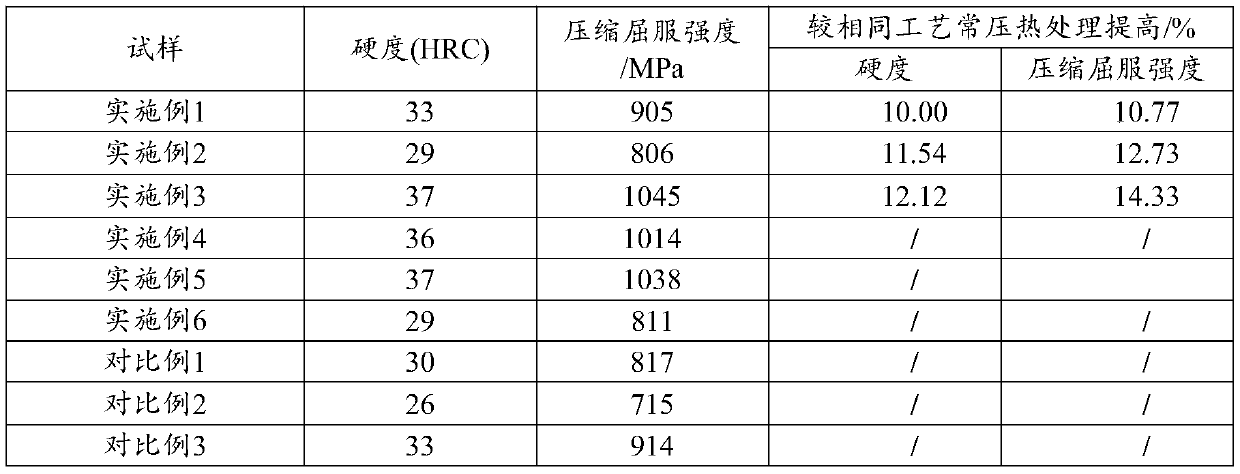

[0035] The mechanical properties of medium carbon steel obtained by high temperature and high pressure heat treatment and low temperature and high pressure heat treatment are shown in Table 1.

Embodiment 2

[0037] The experimental material is 45 medium carbon steel, and the medium carbon steel includes the following elements in mass percentage: C 0.46%, Mn 0.51%, Si 0.28%, P 0.031%, S 0.028%, and iron in the balance.

[0038] The size of the sample and the experimental equipment are the same as in Example 1. The pressure of the high-temperature and high-pressure heat treatment is 2GPa, the temperature is 860°C, and the holding time is 15min. Then, the power is turned off and the pressure is kept and the furnace is cooled to room temperature to obtain a pretreated medium carbon steel;

[0039] The pretreated medium carbon steel was heated up to 600°C at a rate of 50°C / min under a pressure of 2GPa, and after 60min of heat preservation, the power was turned off and the pressure was maintained to cool down to room temperature with the furnace.

[0040] The mechanical properties of medium carbon steel obtained by high temperature and high pressure heat treatment and low temperature and...

Embodiment 3

[0042] The experimental materials, sample size and experimental equipment are the same as in Example 2. The pressure of high temperature and high pressure heat treatment is 4GPa, the temperature is 900°C, and the holding time is 10min. ;

[0043]The medium-carbon steel was heated up to 500°C at a rate of 50°C / min under a pressure of 4GPa, and after holding for 40 minutes, the power was turned off and the pressure was maintained to cool down to room temperature with the furnace.

[0044] The mechanical properties of medium carbon steel obtained by high temperature and high pressure heat treatment and low temperature and high pressure heat treatment are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com