Lower die of vacuum automatic coating die and vacuum automatic coating die

An automatic and vacuum technology, applied in the field of mold forming, can solve the problems of low efficiency, complex operation and high manufacturing cost, and achieve the effect of solving complex operation, high sealing efficiency and high cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

[0057] Specific embodiment 1 of the vacuum automatic skin-covering mold provided by the present invention, in this embodiment, the structure, manufacture and use method of the vacuum automatic skin-covering mold in the present invention are carried out by taking the production of polyurethane rigid foam interior parts as an example Introduction, as follows:

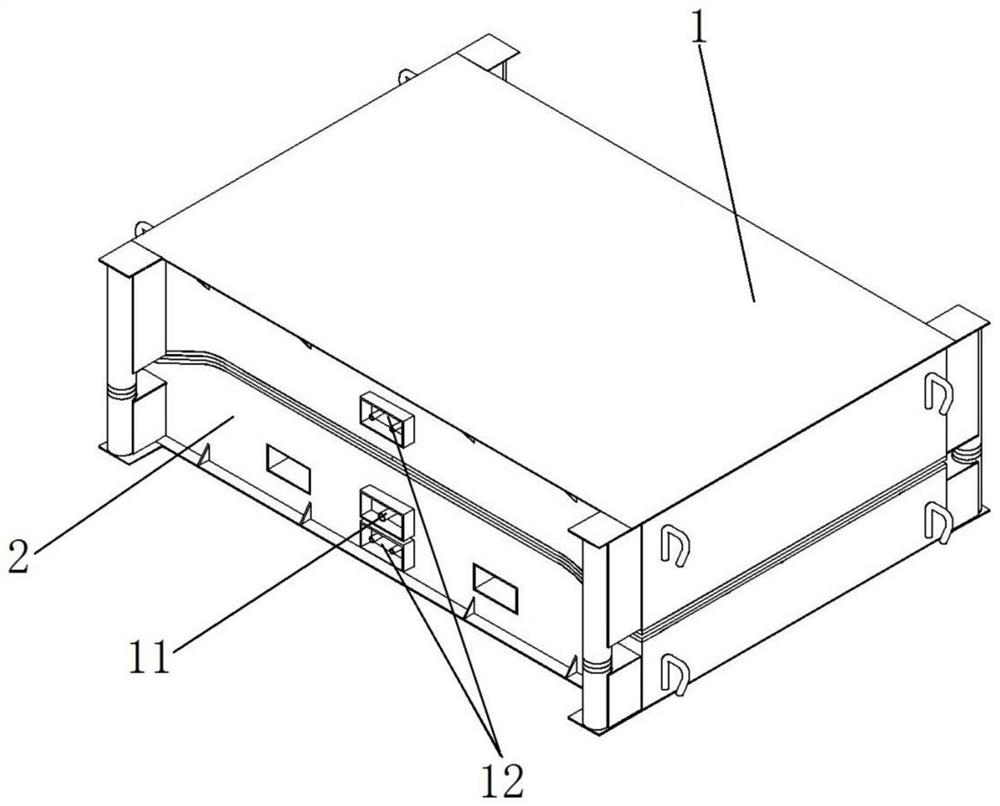

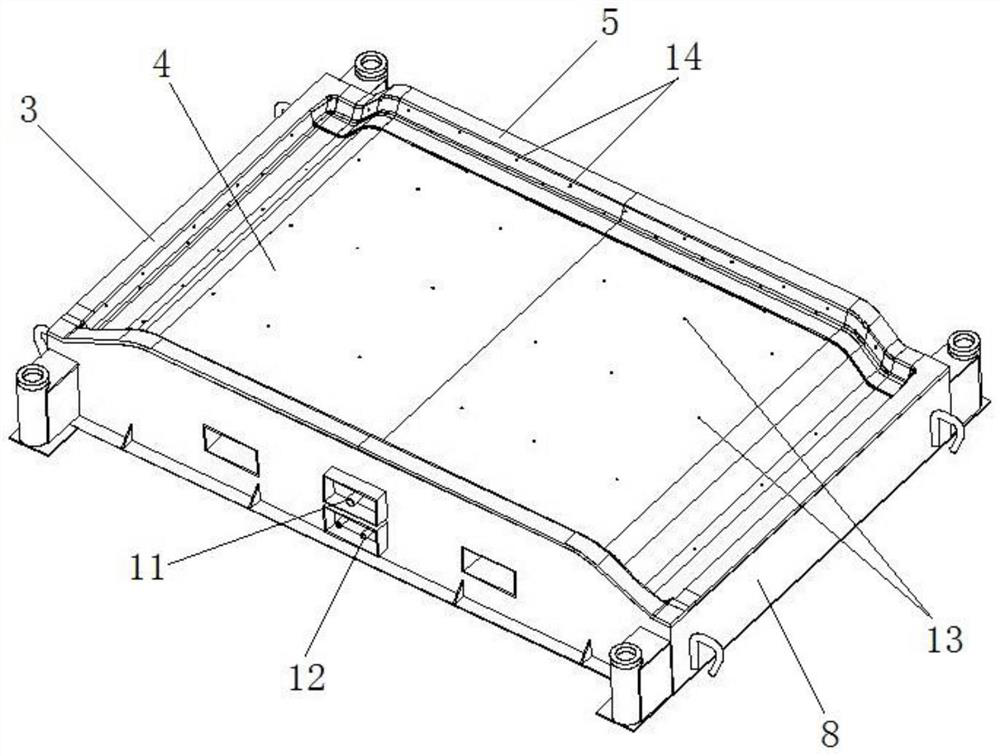

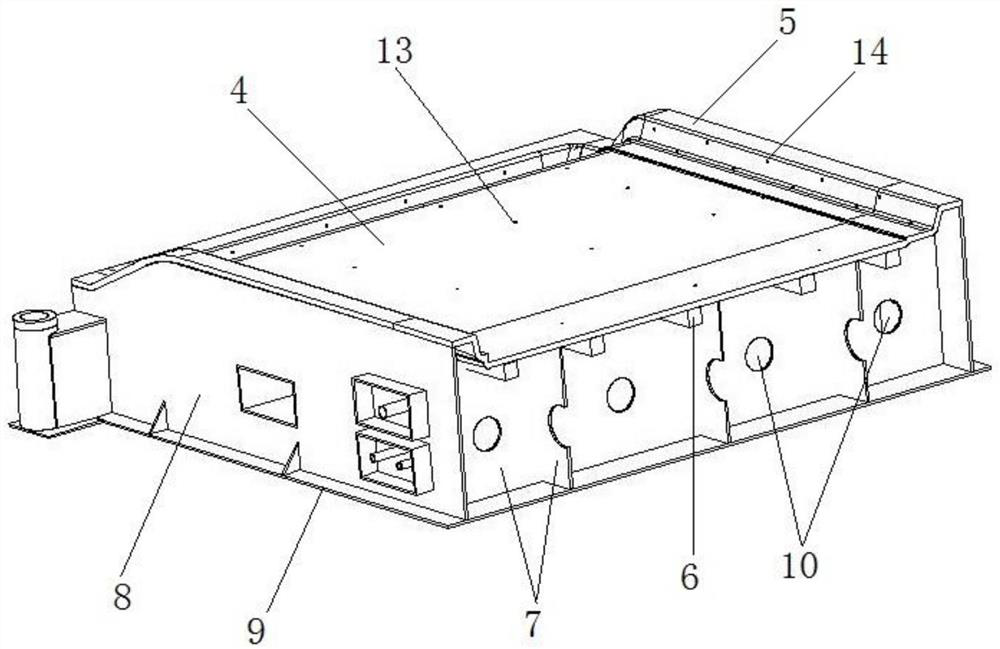

[0058] Such as figure 1 As shown, the vacuum automatic skinning mold includes an upper mold 1 and a lower mold 2. The upper mold 1 and the lower mold 2 have corresponding molding surfaces for molding products, and have a sealing structure on the periphery of the molding surface. Through the upper mold 1 and the lower mold The sealing structure of 2 and the molding surface cooperate to enclose the mold cavity. During specific production, based on the shape design of the product, it is necessary to lay a skin on the molding surface of the lower mold 2, and then fill the mold cavity with polyurethane hard foam to form the pr...

specific Embodiment 5

[0069] The specific embodiment 5 of the vacuum automatic skinning mold provided by the present invention mainly differs from the embodiment 1 in that the sealing structure in the embodiment 1 is a two-stage step structure. In this embodiment, the sealing structure is arranged on the molding surface The outer lateral street surface is a rectangular flange.

[0070] The specific embodiment of the lower mold of the vacuum automatic skinning mold in the present invention, the structure of the lower mold of the vacuum automatic skinning mold is the same as the structure, manufacturing method and use method of the lower mold in the above-mentioned vacuum automatic skinning mold embodiment 1-5, No further details will be given here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com