Combined lock washer

An anti-loose washer and combined technology, applied in the directions of washers, threaded fasteners, connecting components, etc., can solve the problems of difficulty in fitting, high vibration intensity, weakened anti-loose effect, etc., to achieve good anti-vibration and anti-corrosion effect, strengthen Anti-vibration effect, good effect of anti-vibration effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] In order to make the purpose, technical solutions and advantages of the present invention clearer, below in conjunction with embodiment and accompanying drawing, the present invention is described in further detail:

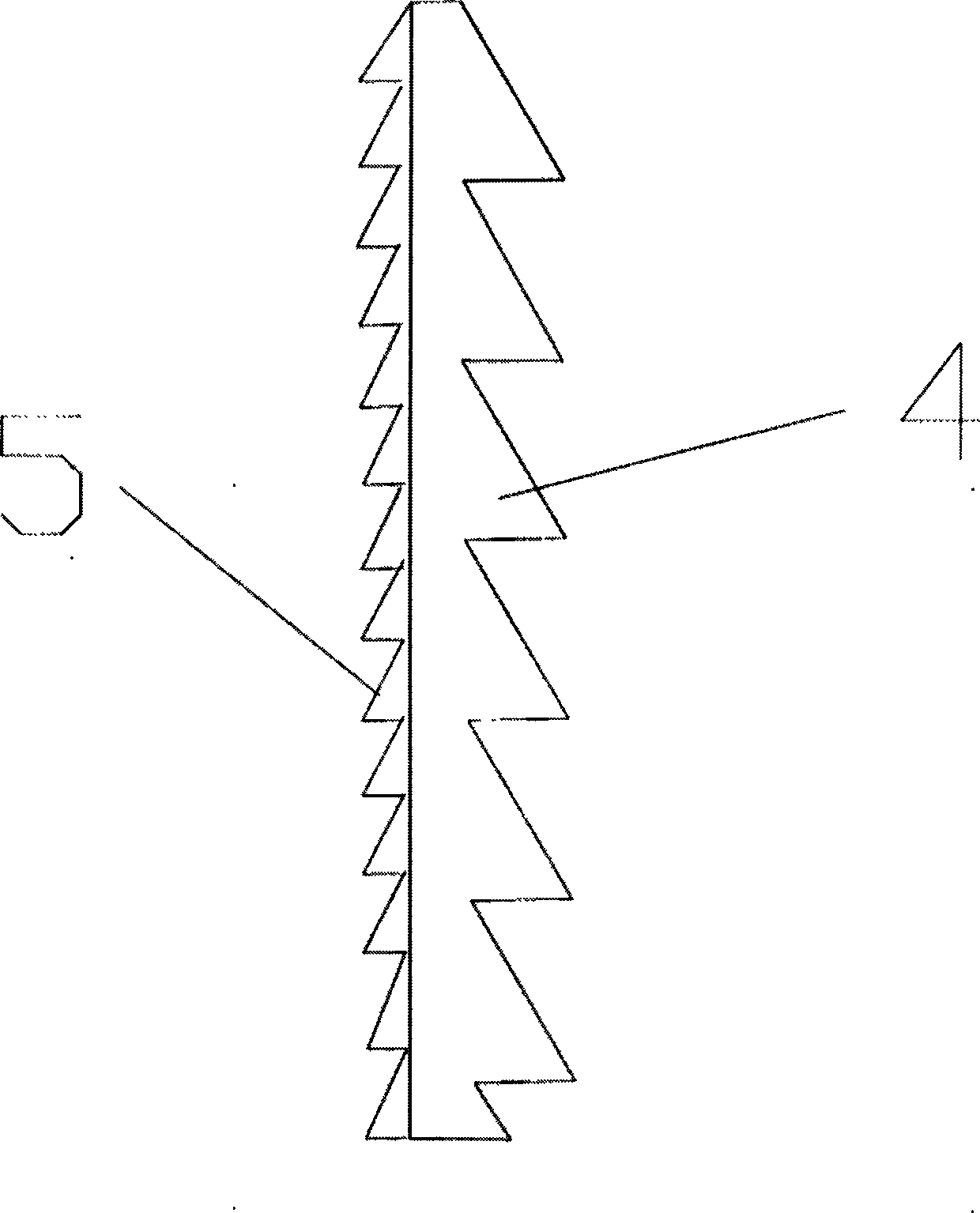

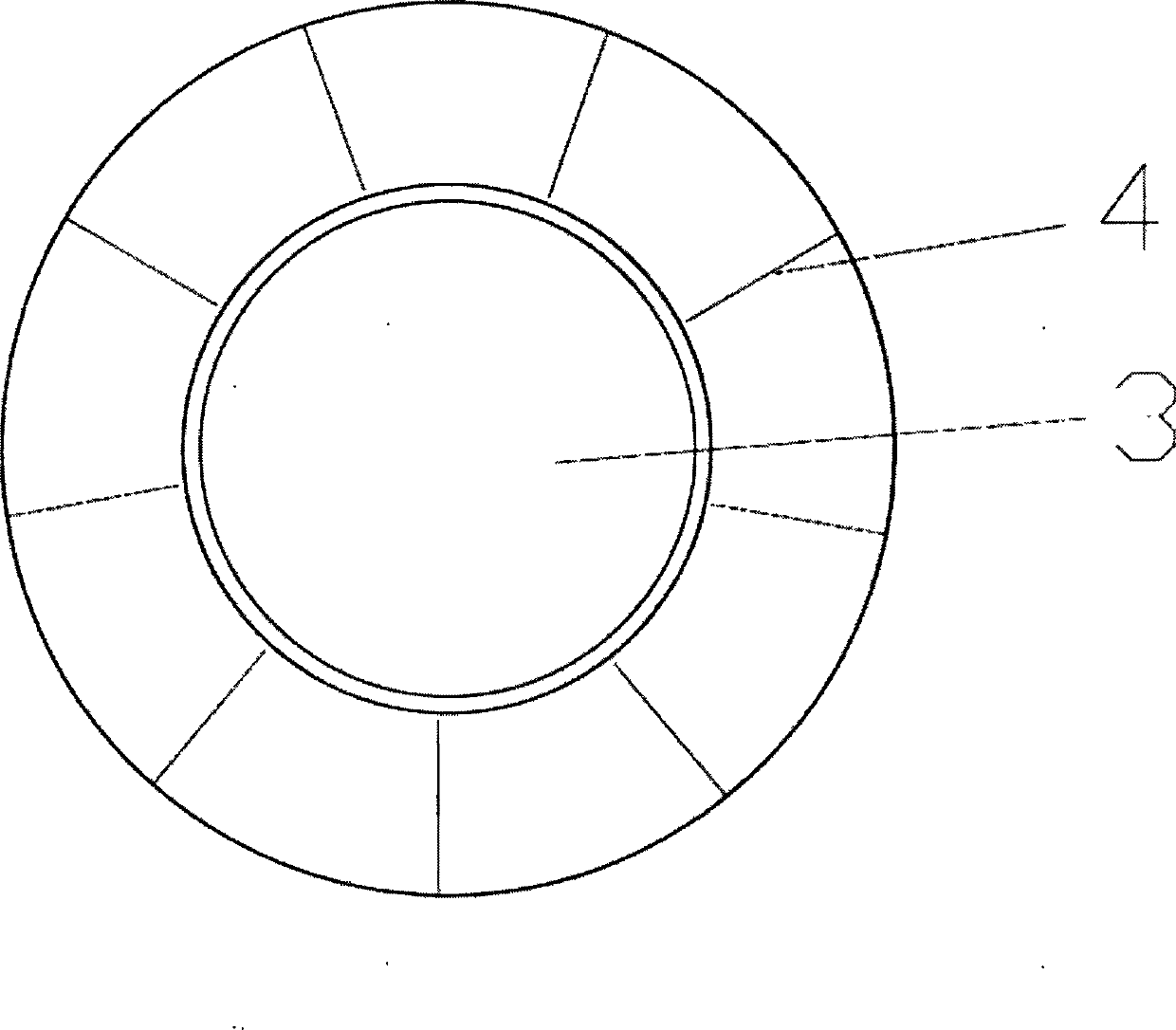

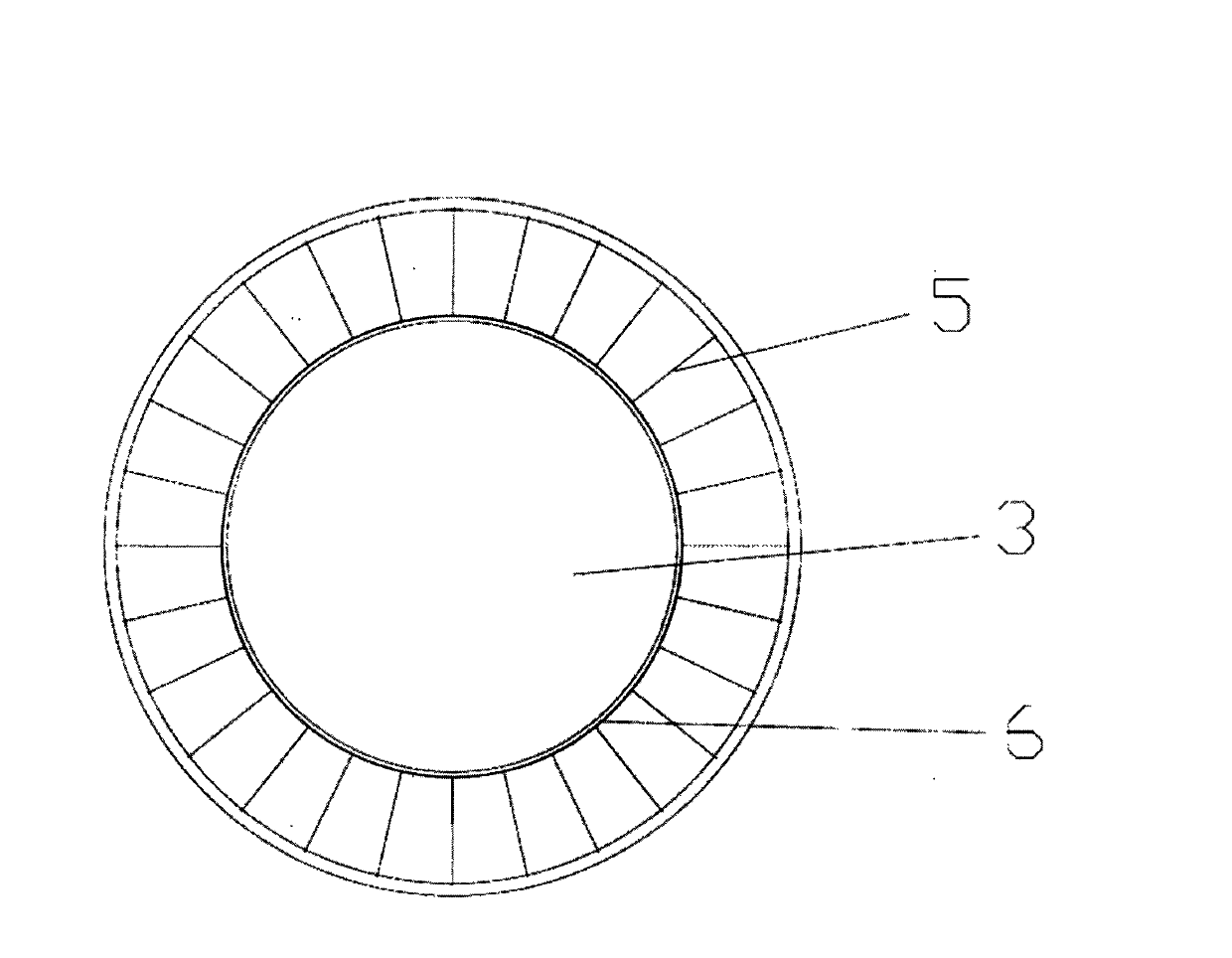

[0039] Figure 1 to Figure 4 The structure of the combined anti-loosening washer of the present invention is illustrated, and the combined anti-loosening washer includes a first washer 1 and a second washer 2 . The first washer 1 is circular, with a central through hole 3, the size of the central through hole 3 is suitable for the bolts used in the combined anti-loosening washer, the shape and size of the second washer 2 and the first washer 1 are the same.

[0040] Wherein, the first washer 1 and the second washer 2 are bonded together, and the two contact surfaces of the two washers are respectively provided with interlaced radial serrations 4 , and the two washers are tightly meshed together through the contact surface serrations 4 . The shape of the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Surface hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com