Device for detecting easily-cleaning property of ceramic by using oil residue method

A residue and ceramic technology, applied in the field of devices for detecting the cleanability of ceramics by oil residue method, can solve the problems of poor test result stability and repeatability, low test efficiency, complicated operation process, etc., to reduce environmental test errors, Intuitive effect and low detection cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

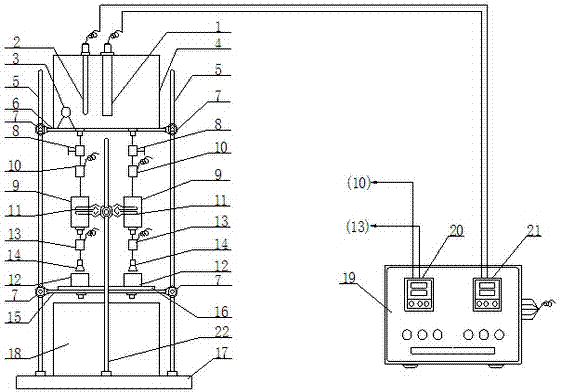

[0055] according to the above figure 1 The shown implementation assembles the ceramic easy-to-clean test device of this implementation, wherein the size of the upper water tank 4 is: length 150mm, width 150mm and height 100mm; the size of the lower water tank 18 is: length 150mm, width 150mm and height 100mm; The size of the test piece holder 12 at an angle of 45° is: length 50mm, width 50mm and height 50mm; the quantitative container 9 with a hole in the top is a cylinder with a diameter of 70 mm and a height of 130 mm; the top of the quantitative container 9 with a hole in the top is punched The hole diameter is 2mm; the distance between the 45o angle test piece holder and the test punch is 29cm.

[0056] Using the ceramic easy-to-clean test device, the specific operation steps to test the ceramic easy-to-clean according to the oil residue method, namely the gravimetric method, are as follows:

[0057] The first step, the preparation of ceramic samples to be tested

[0058...

Embodiment 2

[0086] according to the above figure 1 The shown implementation assembles the ceramic easy-to-clean test device of this implementation, wherein the size of the upper water tank 4 is: length 175mm, width 175mm and height 125mm; the size of the lower water tank 18 is: length 175mm, width 175mm and height 125mm; The size of the test piece holder 12 at an angle of 45° is: length 55mm, width 55mm and height 55mm; the quantitative container 9 with a hole in the top is a cylinder with a diameter of 70 mm and a height of 130 mm; the top of the quantitative container 9 with a hole in the top is punched The hole diameter is 4mm; the distance between the test piece support and the test punch is 30cm at an angle of 45o.

[0087] Using the ceramic easy-to-clean test device, the specific operation steps to test the ceramic easy-to-clean according to the oil residue method, namely the gravimetric method, are as follows:

[0088] The first step, the preparation of ceramic samples to be teste...

Embodiment 3

[0117] according to the above figure 1 The shown implementation assembles the ceramic easy-to-clean test device of this implementation, wherein the size of the upper water tank 4 is: length 200mm, width 200mm and height 150mm; the size of the lower water tank 18 is: length 200mm, width 200mm and height 150mm; The size of the test piece holder 12 at an angle of 45° is: length 60mm, width 60mm and height 60mm; the quantitative container 9 with a hole in the top is a cylinder with a diameter of 70 mm and a height of 130 mm; the top of the quantitative container 9 with a hole in the top is punched The hole diameter is 6mm; the distance between the 45o angle test piece support and the test punch is 31cm.

[0118] Using the ceramic easy-to-clean test device, the specific operation steps to test the ceramic easy-to-clean according to the oil residue method, namely the gravimetric method, are as follows:

[0119] The first step, the preparation of ceramic samples to be tested

[012...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com