Numerical control laser cutting control system for power battery pole piece

A numerical control laser and power battery technology, applied in laser welding equipment, manufacturing tools, welding equipment and other directions, can solve the problems of high equipment cost, polluted cutting working environment, and high laser heat, achieve increased operating efficiency, avoid high temperature deformation, avoid The effect of circulating countercurrent

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

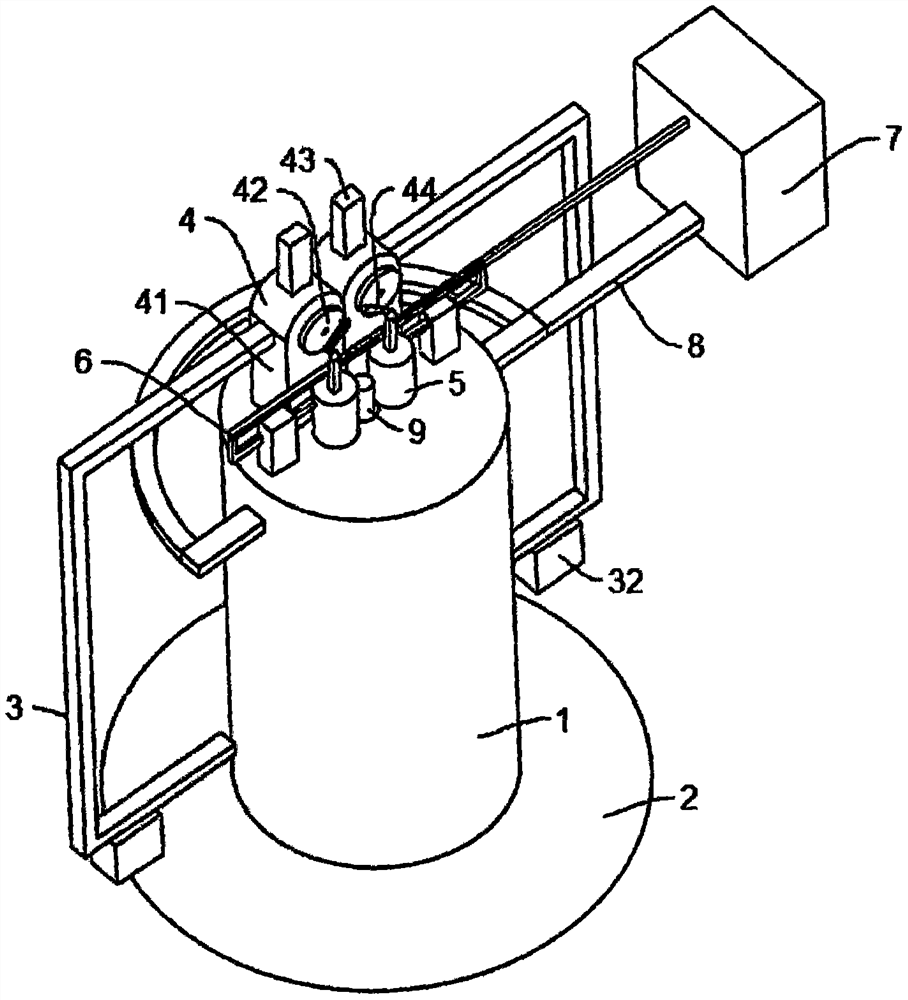

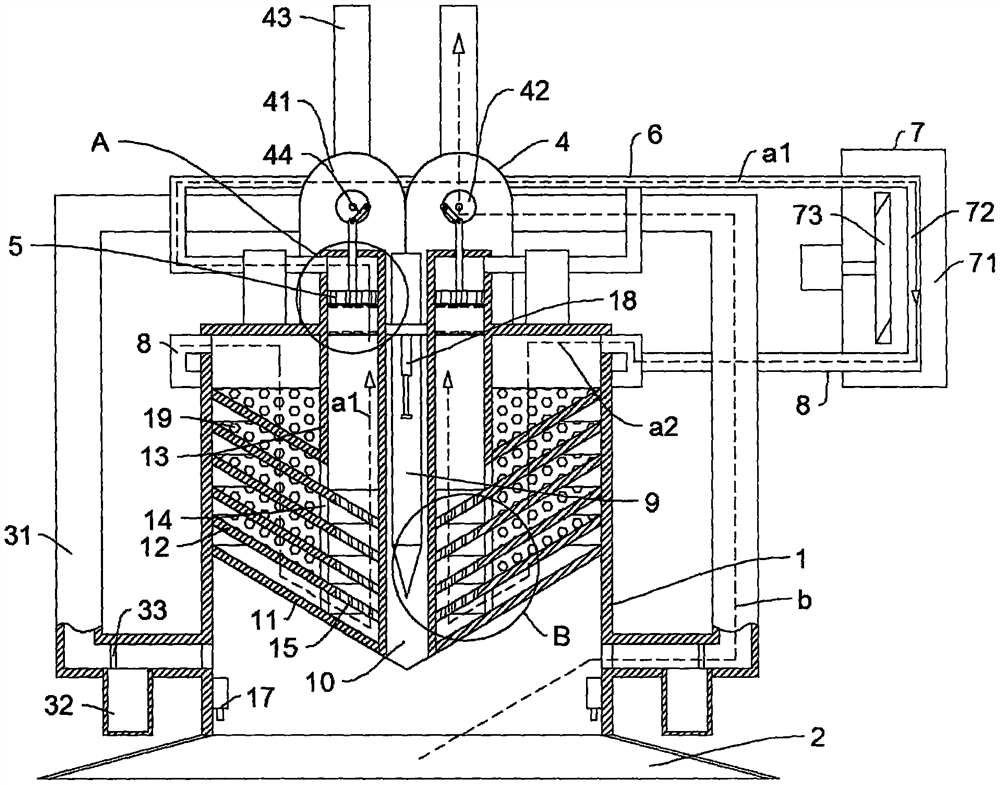

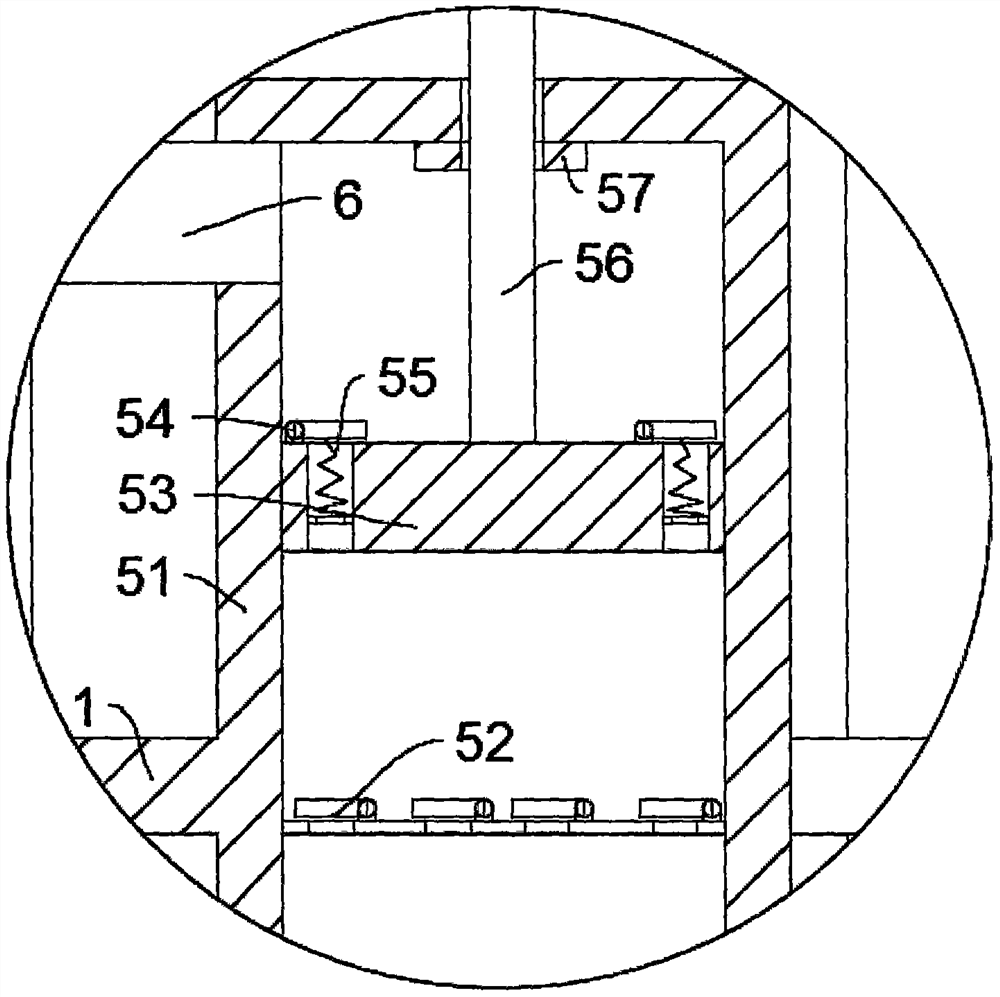

[0029] Such as Figure 1-5 As shown, in the embodiment of the present invention, a power battery pole piece numerical control laser cutting control system includes a cylindrical sleeve 1, and also includes: a conical dust collection cover 2 connected to the bottom of the cylindrical sleeve 1; a dust suction pipeline 3. Symmetrically connected to the outer side of the lower half of the cylindrical sleeve 1, wherein the dust suction pipeline 3 is connected to the blast structure 4; the pneumatic piston cylinder 5 is connected to the coaxial position of the blast structure 4; the steam pipe 6 is connected to the pneumatic piston On the cylinder 5, the steam pipe 6 is connected to the air-cooled water-cooled equipment 7; the liquid pipe 8 is connected to the air-cooled water-cooled equipment 7; the high-pressure laser gun 9 is installed in the center of the cylindrical sleeve 1, and the inside of the cylindrical sleeve 1 is equipped with heat dissipation structure.

[0030] The h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com