Spindle central oil feeding burner

A burner and shaft technology, which is applied to the oil burner and gas at the center of the shaft. It can solve the problems that affect the rotation of the fan blades, affect the uniformity of oil vaporization, and affect the rotational speed of the rotating shaft, and achieve the effects of uniform rotating speed of the rotating shaft, high oil vaporization rate and uniformity, and high combustion efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

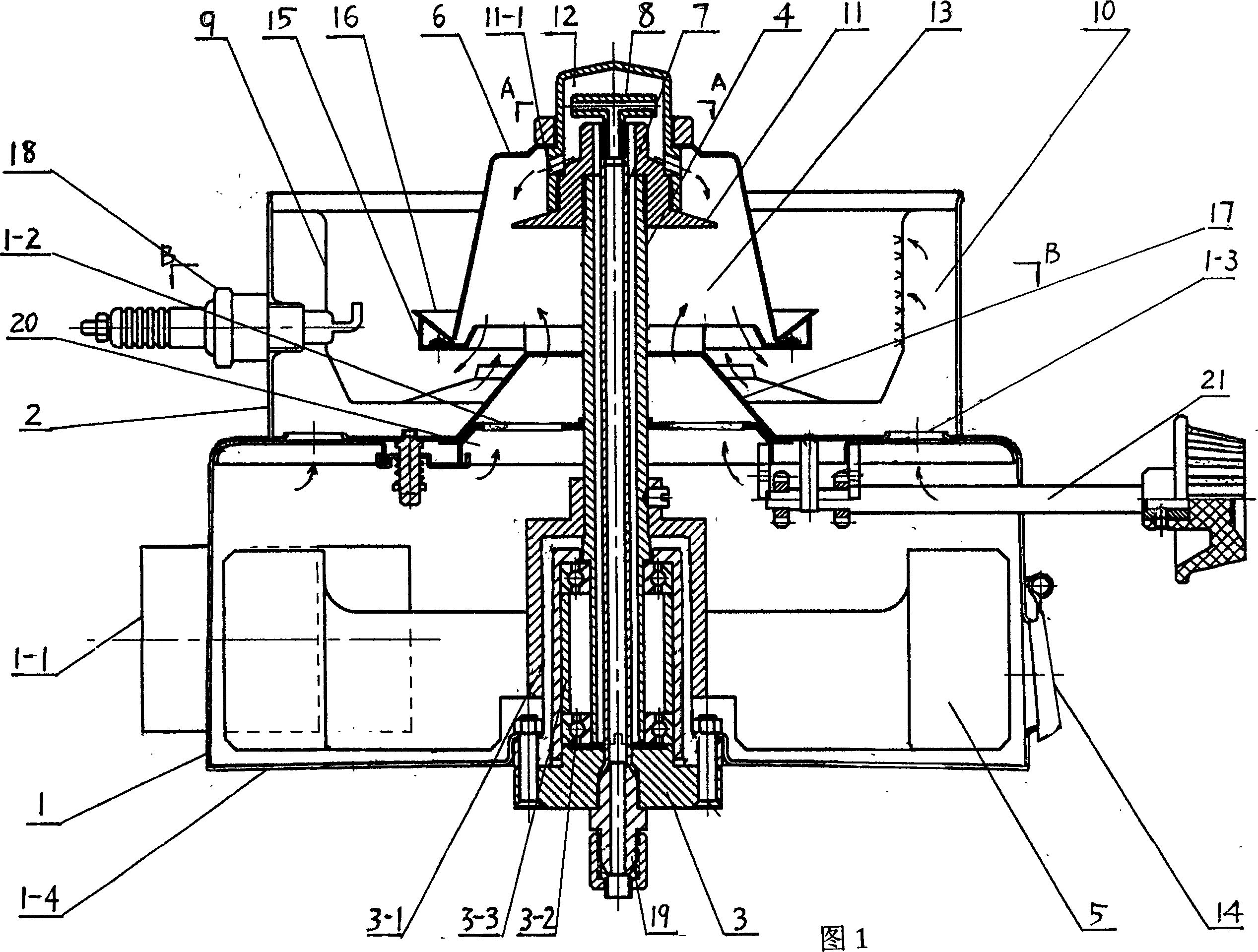

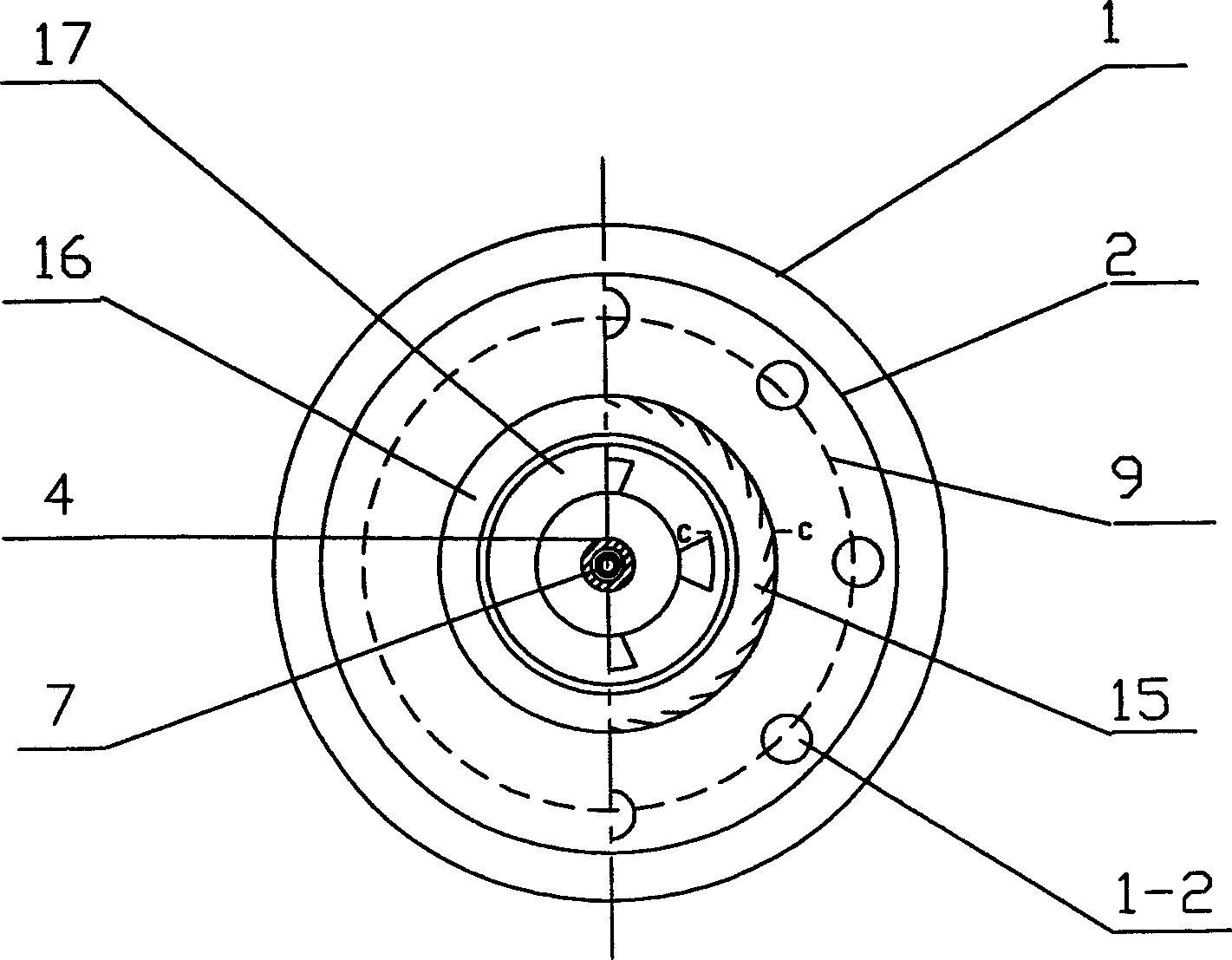

[0017] Example 1. See Figure 1. The central oil supply burner of the rotating shaft of this example includes two major parts: the air chamber shell 1 and the combustion chamber shell 2 on it; the combustion chamber 2 has a meshed combustion bowl 9 and an annular air chamber is formed between them. 10. Between the two shells, there are 8 tuyere 1-2, 1-3 arranged in an inner and outer ring shape each to form a gas channel (see image 3 ), the inner ring tuyere 1-2 is provided with a wind collecting hood 17 opposite to the vaporization rotating cap 6, the outer ring tuyere 1-3 is opposite to the annular air chamber; there can be an air volume adjustment plate 20 and a gear adjustment mechanism 21 under the inner and outer ring tuyere . The air chamber 1 is sealed with a base 1-4, and is provided with a tangential air inlet 1-1 and a pressure relief structure 14. The pressure relief structure is a gradually thicker gravity door cover; the bearing part 3 at the bottom supports a rotati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com