Jet flow flash condensation pot for continuous preparation of hydrogenated nitrile rubber

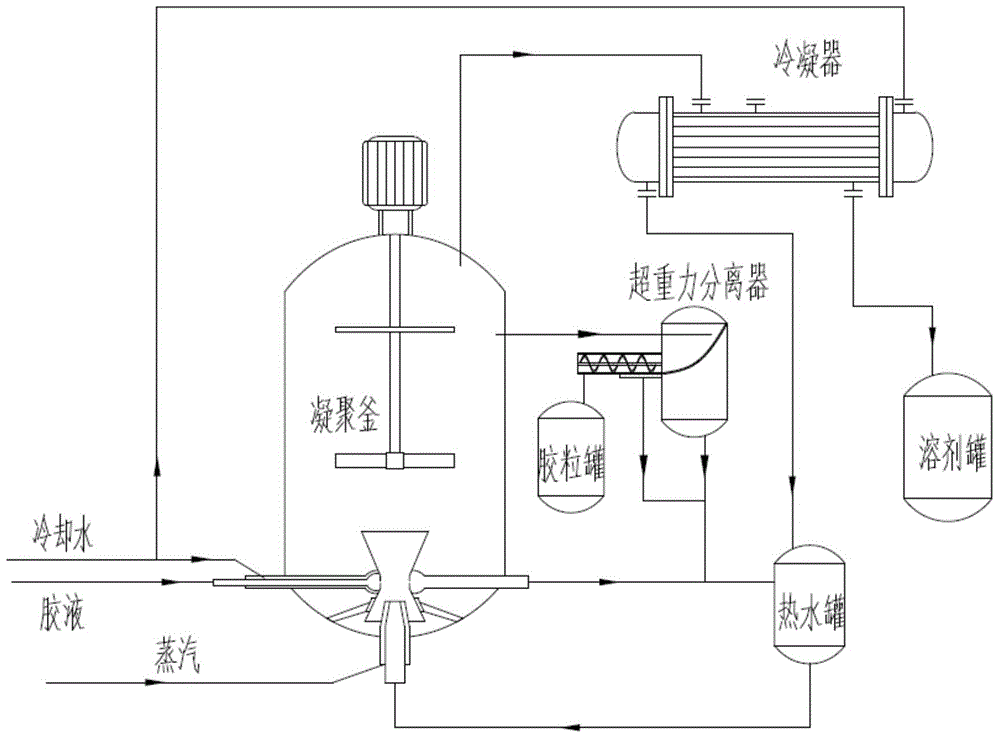

A technology of coagulation kettle and flash evaporation, which is applied in the field of hydrogenated nitrile rubber coagulation process, can solve the problems of reducing the amount of steam used, the size of the rubber particles is different, and the high solvent content, so as to reduce the amount of steam used, the processing capacity is high, and the coagulation time is reduced. short effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

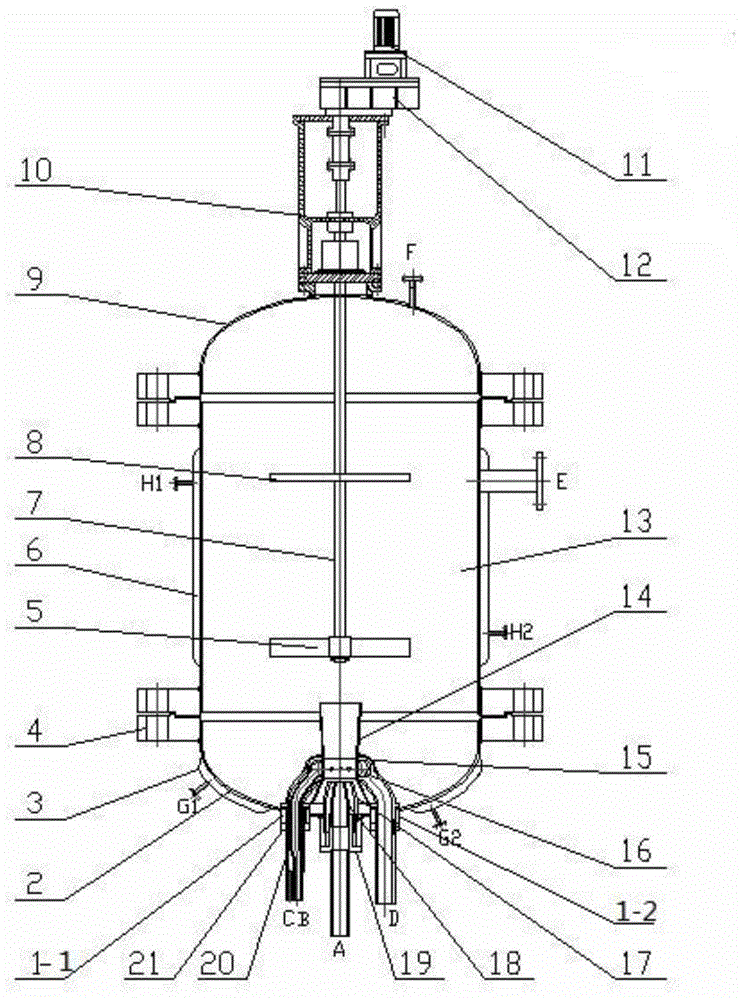

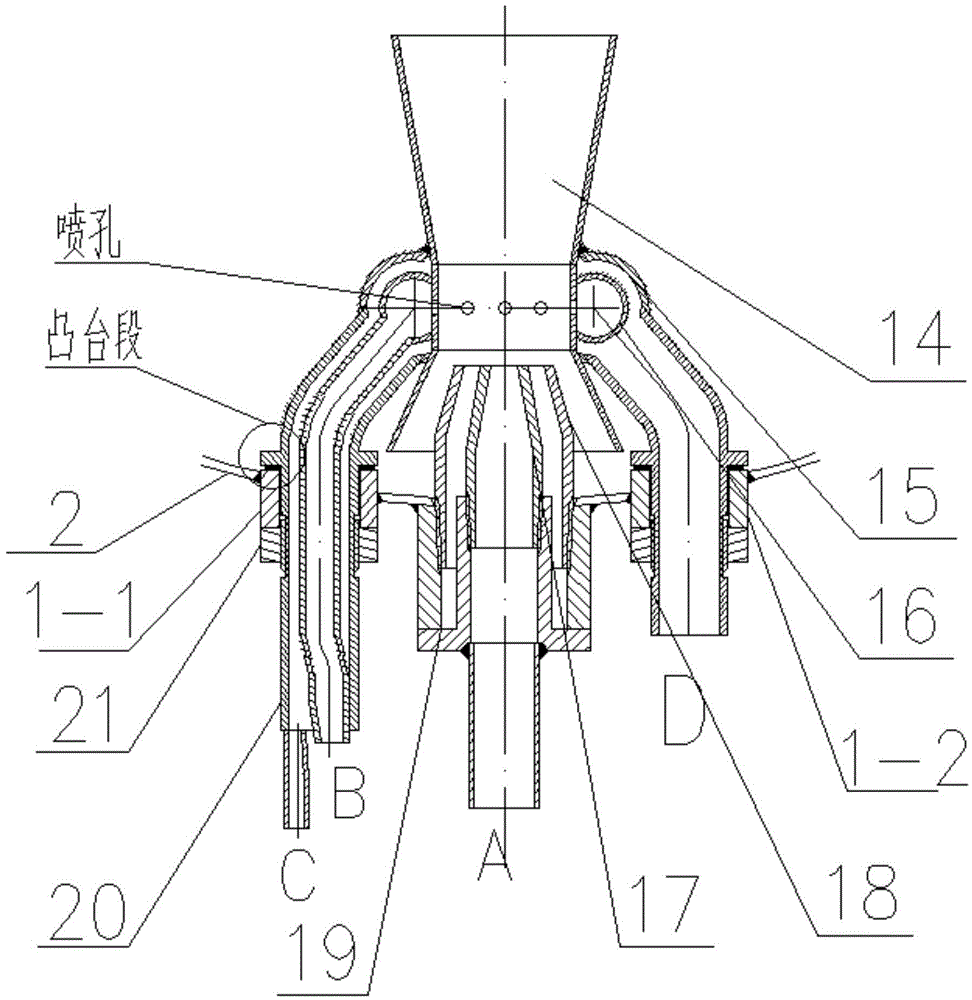

[0043] Example: Before the operation of the coagulation kettle, the kettle is filled with water, and the heat carrier is passed into the jacket. Control the water temperature in the kettle at about 95°C and the pressure at 0.03MPa. At the beginning of condensation, in the Venturi jet, at 8m 3 / h flow into the hot water pipe (A) into the hot water, with 15m 3 Inject 110°C steam into the steam connection pipe (I) at a flow rate of / h; then pass HNBR glue at a temperature of about 25°C into the glue inlet pipe (B), and feed cooling water into the cooling water inlet pipe (C) at the same time Water, to ensure the low temperature of the glue. Open the rubber outlet connection (E) to ensure a constant liquid level in the coagulation kettle and leave enough space for the solvent vapor and water vapor at the top of the kettle.

[0044] Hot water is accelerated through hot water nozzles (17) to form jets. Due to the entrainment and turbulent diffusion between the jet and the inhale...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com