A portable cyclone vacuum cleaner

A vacuum cleaner and cyclone technology, which is applied in the field of portable cyclone vacuum cleaners, can solve problems such as deficiencies, and achieve the effects of comprehensive functions, high-efficiency cleaning ability, and reasonable air duct structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

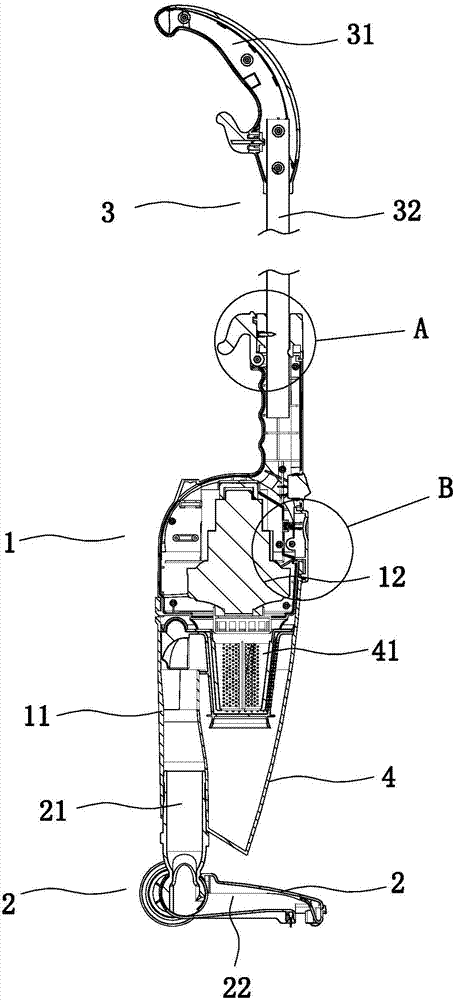

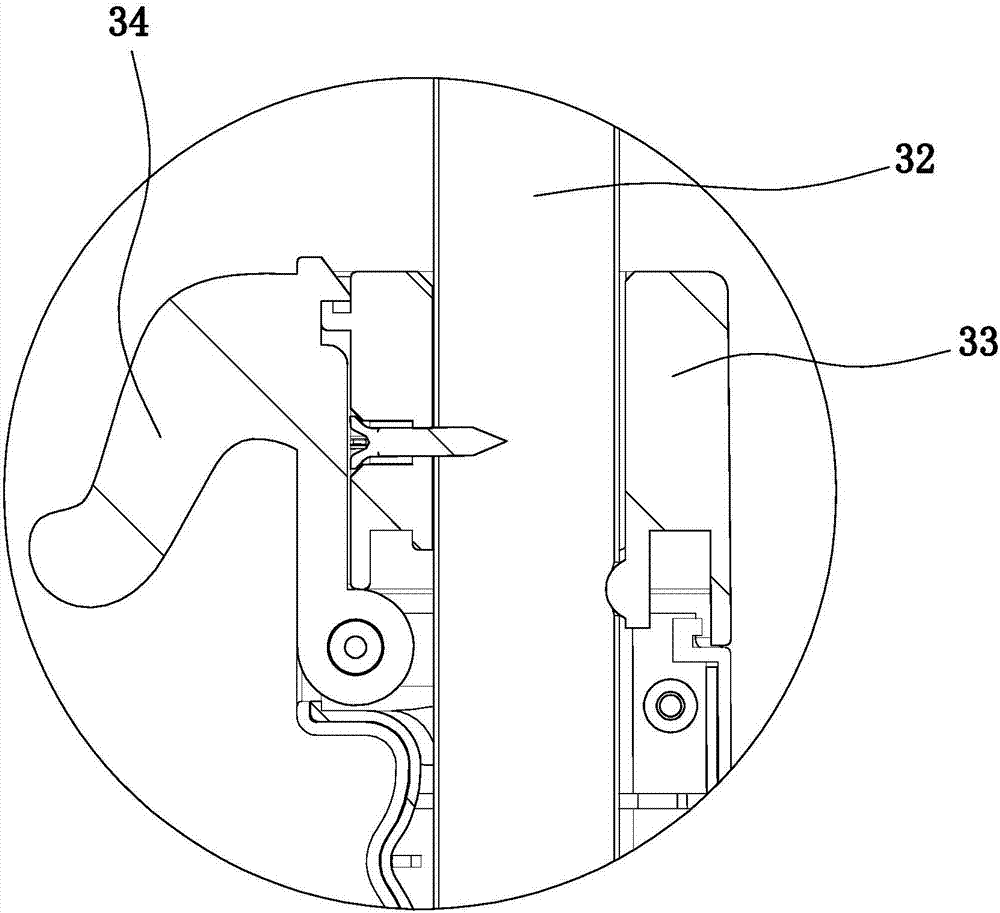

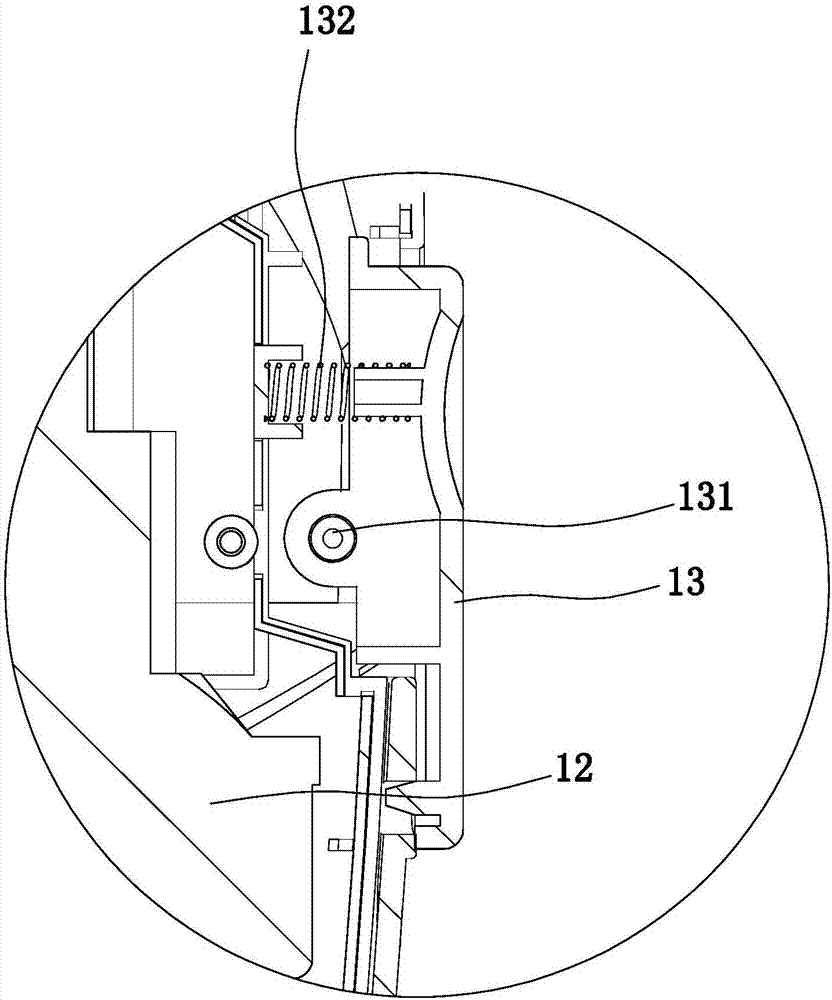

[0025] Embodiment 1: as Figure 1 to Figure 4 In the shown embodiment, a portable cyclone vacuum cleaner includes a main body 1 and a dust mop 2. The main body is provided with a handle 3, a dust cup 4, and a body air inlet pipe 11. The main body is provided with a suction motor. Machine 12, the dust-absorbing floor mop includes a floor mop base body, an insertion pipe 21 located on the floor mop base body, the floor mop base body is provided with a floor mop inner air duct 22, the lower end of the insertion pipe communicates with the floor mop inner air duct, and the upper end of the insertion pipe It is clamped and communicated with the air inlet pipe of the fuselage. The dust cup is provided with a filter screen tube 41. The dust cup is provided with a tangential air inlet and an upper end air outlet. The filter screen tube separates the tangential air inlet from the upper end air outlet. Open, there are multiple filter holes on the filter cylinder, the tangential air inlet...

Embodiment 2

[0029] Embodiment 2: the basic structure and implementation mode of this embodiment are the same as embodiment 1, and its difference is, as Figure 5 to Figure 8 As shown in , the ground mop base is provided with several rear ground wheels 23 and at least one front ground wheel 24, the bottom of the ground mop base is provided with a direct suction port 25, the air inlet direction of the direct suction port is upward, and the air duct inside the ground mop Connected with the direct suction port, the base of the ground mop is provided with a brush bar 261 for brushing the ground, and the brush bar is located in front of the direct suction port. The rear ground wheel and the front ground wheel are conveniently dragged and moved on the cleaning surface (floor, carpet, etc.), and the direct suction port is the position for the initial vacuuming. The brush bar can brush up the impurities on the cleaning surface and improve the cleaning effect on the cleaning surface (floor, ground,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com