Cyclone separation type dust collector

A cyclone separation and vacuum cleaner technology, which is applied in the directions of vacuum cleaners, suction filters, suction nozzles, etc., can solve problems such as misoperation, and achieve the effects of reasonable air duct structure, strong dust collection ability and good overall stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

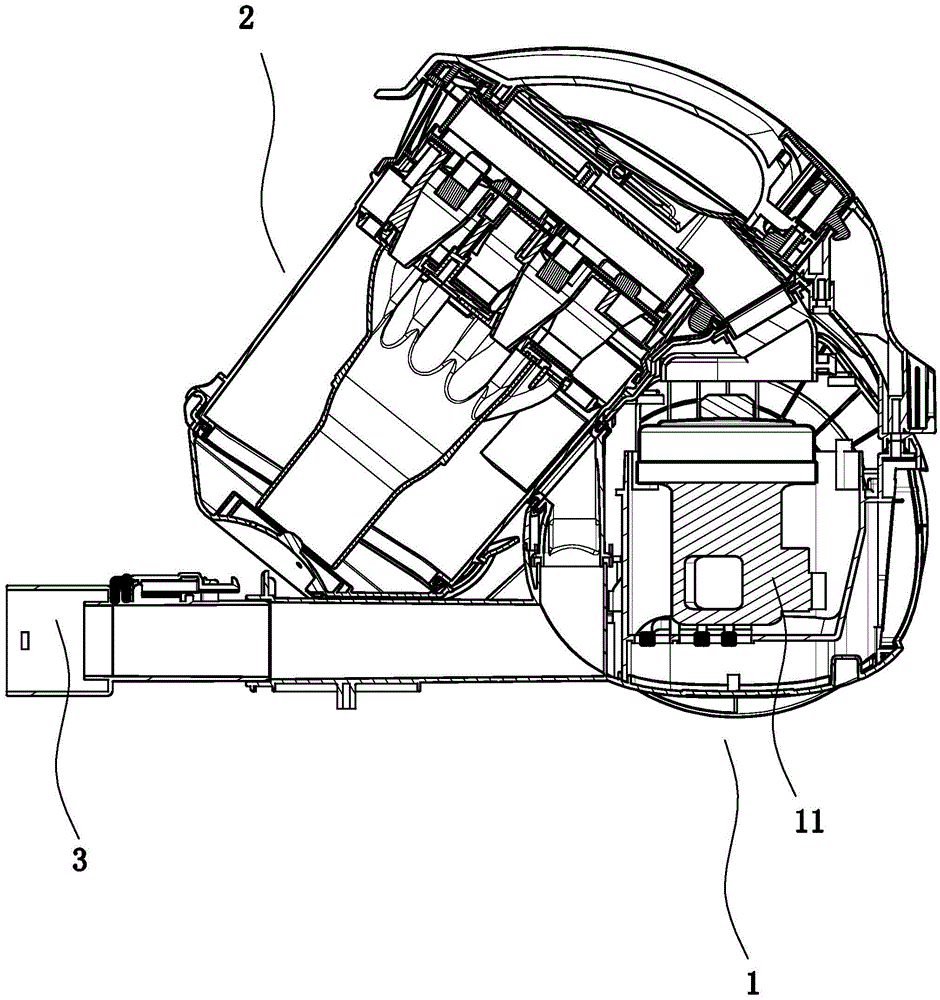

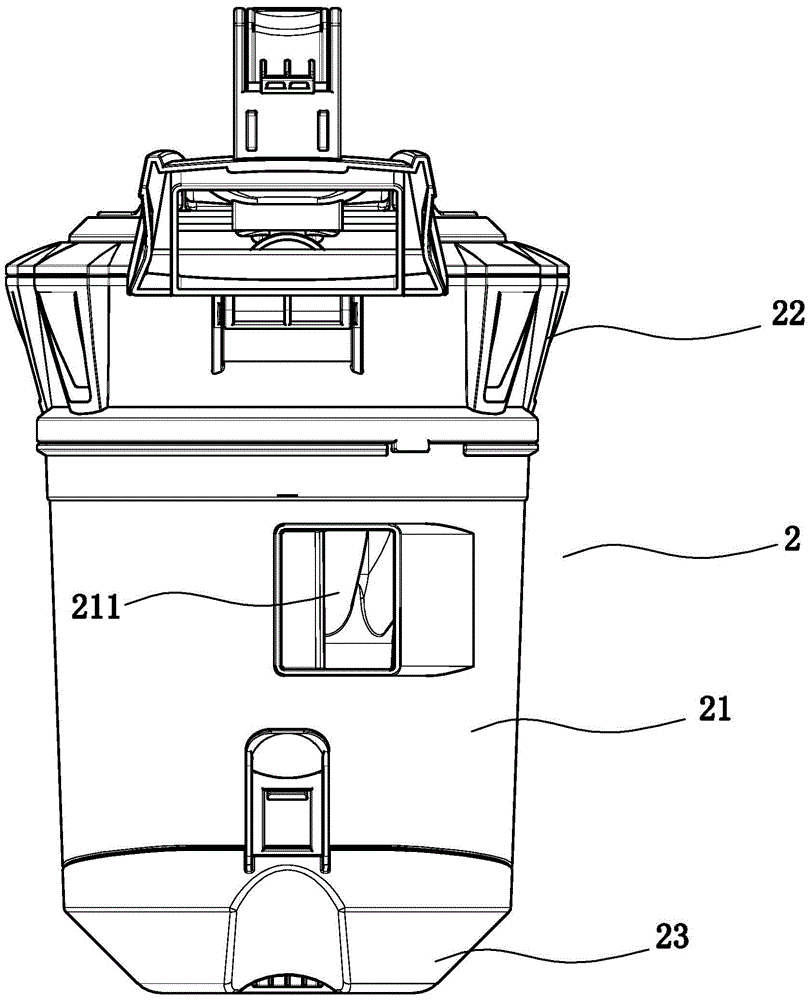

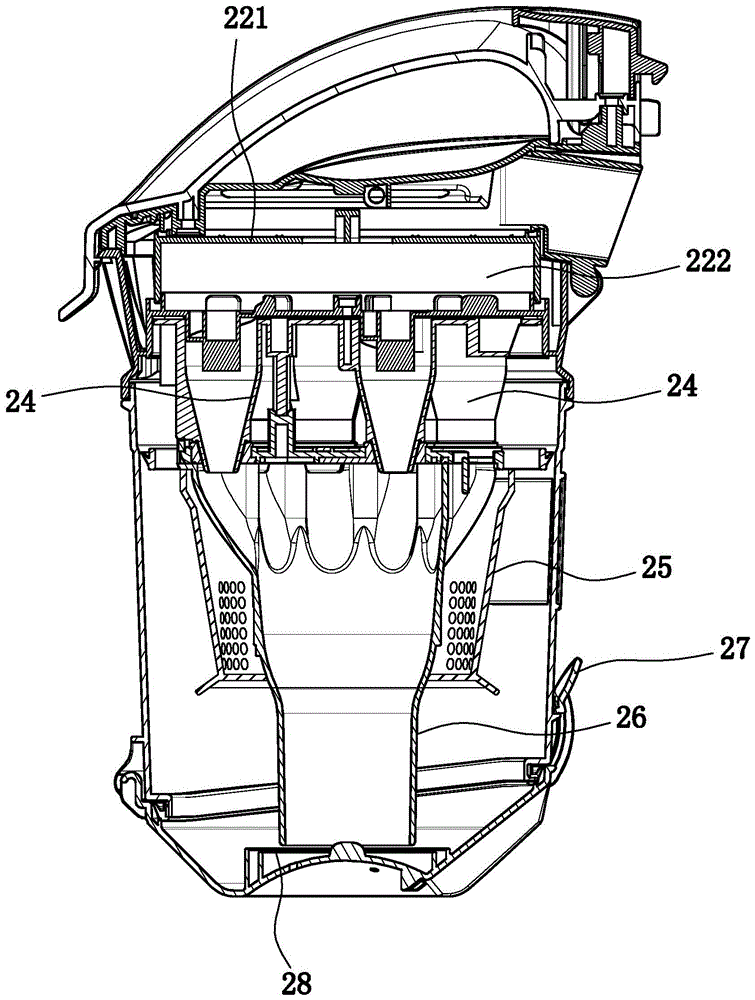

[0027] Embodiment 1: as Figure 1 to Figure 6 In the shown embodiment, a cyclone-separated vacuum cleaner includes a main body 1 and a suction motor 11. The main body is provided with a dust cup body 2 and a suction socket 3 for docking with a dust suction pipe. The dust cup body It includes a cup body 21, a cup cover 22 cooperating with the cup body, and a cup bottom 23 cooperating with the cup body. The cup body is provided with a cup body air inlet connected to the suction seat, and a number of shunt cyclone cones 24 are arranged in the dust cup body. , the split cyclone cone is provided with a tangential air inlet branch pipe 242 communicating with the inside of the split cyclone cone, the upper and lower ends of the split cyclone cone are open and the upper opening is larger than the lower opening, and the upper openings of each split cyclone cone pass through the middle The air duct is connected with the air inlet end of the suction motor, and the air outlet end of the s...

Embodiment 2

[0030] Embodiment 2: the basic structure and implementation mode of this embodiment are the same as embodiment 1, and its difference is, as Figure 7 to Figure 10 As shown in , it also includes a dust-absorbing mop, which is connected to the suction socket through a dust-absorbing pipe. The ground mop base is provided with several rear ground wheels 42 and at least one front ground wheel 43, the bottom of the ground mop base is provided with a direct suction port 44, the air intake direction of the direct suction port is upward, and the ground mop base is provided with a ground mop inner air duct 45. The inner air duct of the mop is connected to the direct suction inlet, the elbow pipe is connected to the inner air duct of the mop, and the mop base is provided with a brush bar 461 for scrubbing the ground, and the brush bar is located in front of the direct suction inlet. The rear ground wheel and the front ground wheel are conveniently dragged and moved on the cleaning surfac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com