Wood-working machine dust collector and packing foam thereof

A technology for woodworking machinery and vacuum cleaners, used in wood processing appliances, containers to prevent mechanical damage, transportation and packaging, etc., can solve the problems of poor cleaning effect, complex structure, inconvenient cleaning, etc., and achieve easy maintenance and vacuuming effects. Good, use flexible effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

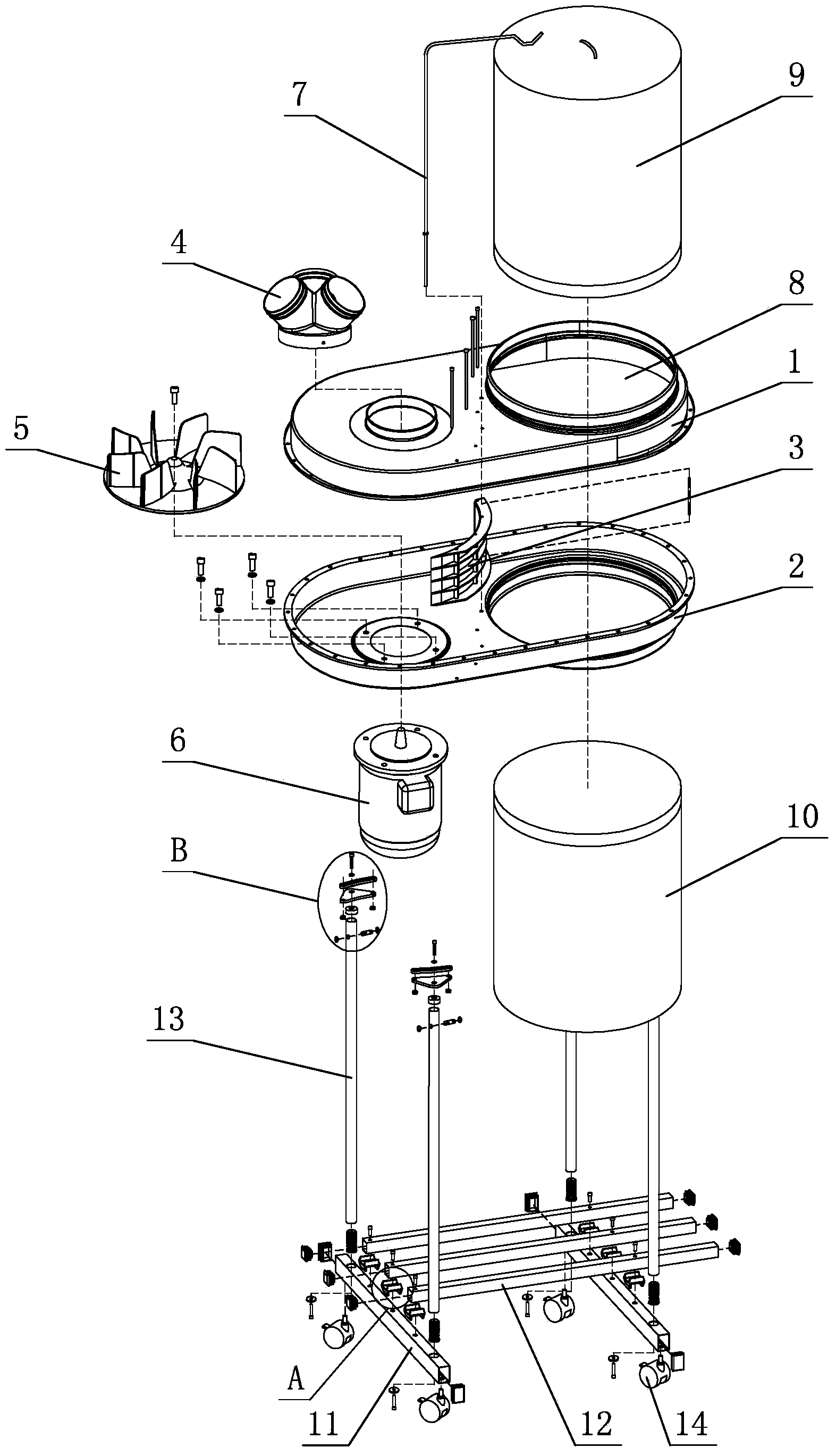

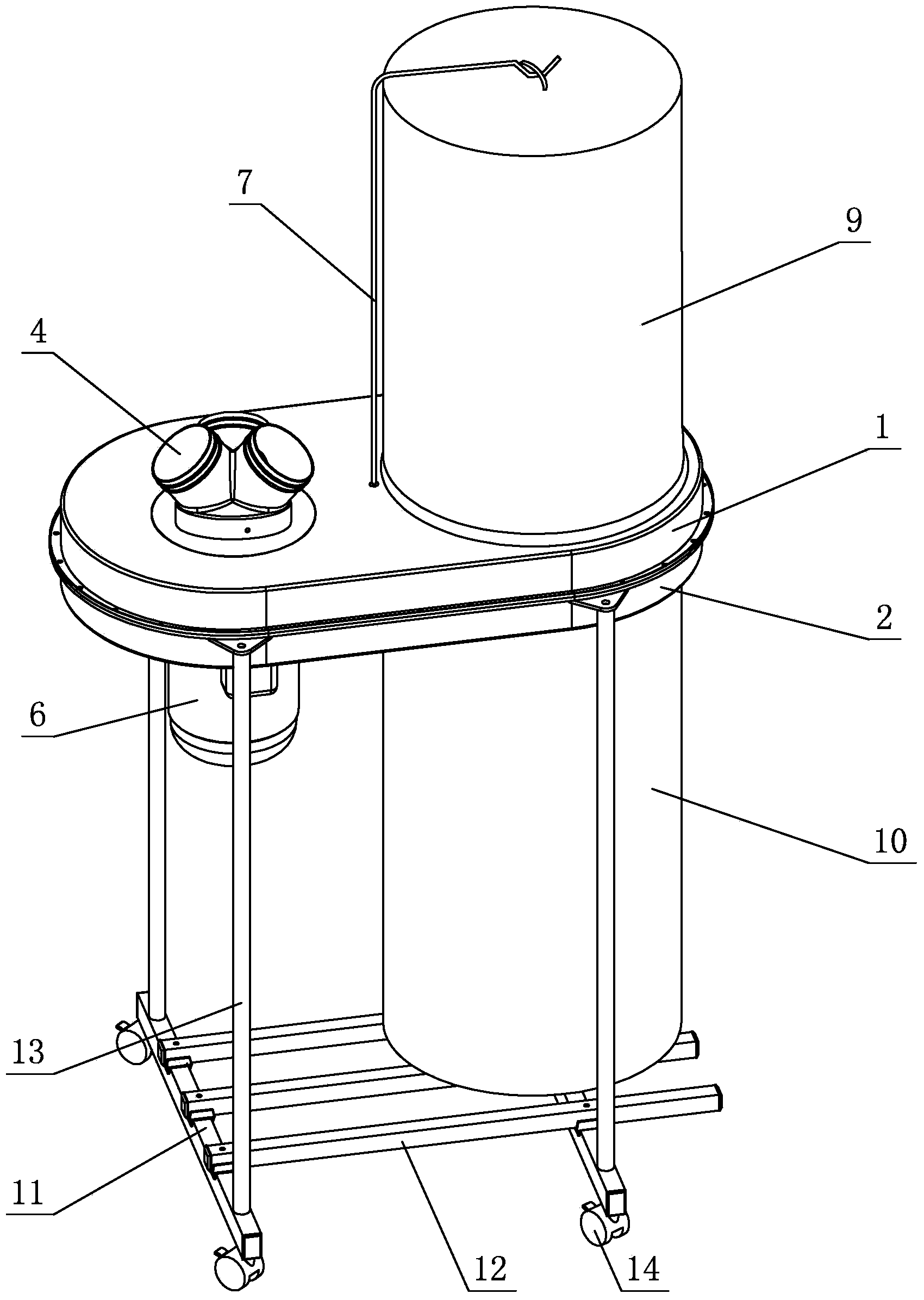

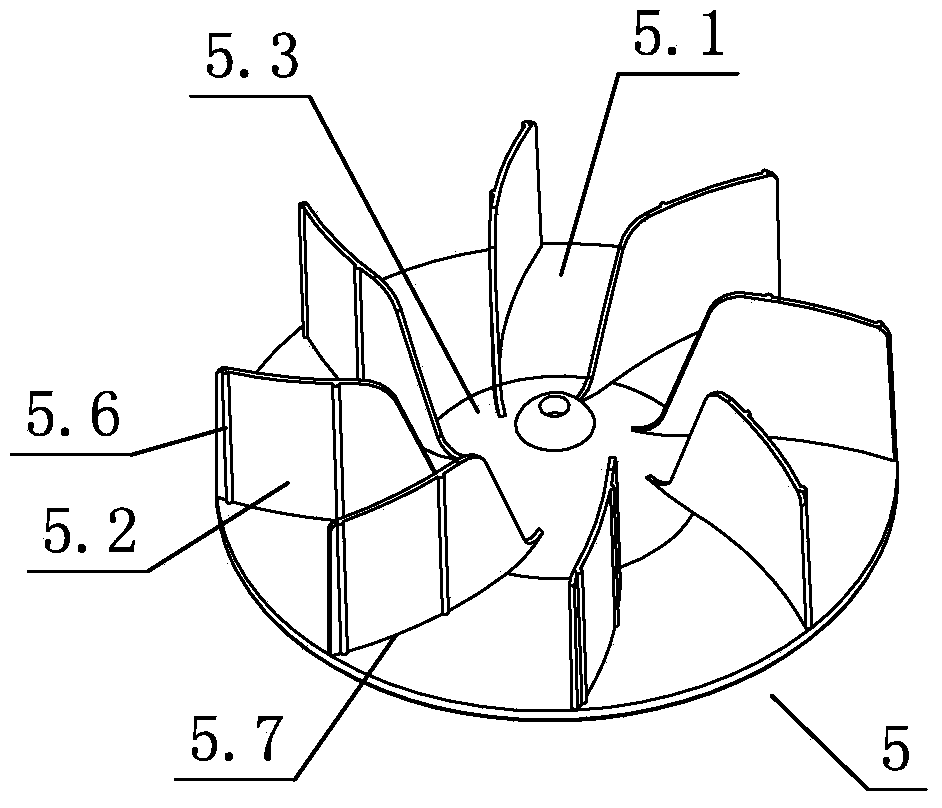

[0032] see figure 1 - Figure 14 , this vacuum cleaner for woodworking machinery includes a bracket assembly with a universal moving wheel 14, an upper cover body 1 and a lower cover body 2 arranged above the bracket assembly, and the upper cover body 1 and the lower cover body 2 are rotated by a driving device. There are fan blades 5, the air inlet of the fan blades 5 is connected with the dust suction head 4, and the air outlet is connected with more than one set of filter bag assemblies, and a volute guide device is arranged between the filter bag assemblies and the fan blades 5.

[0033] The upper cover body 1 and the lower cover body 2 are fixed by clamping, welding, pasting or fasteners, and the upper cover body 1 and the lower cover body 2 in this embodiment are fixed by bolts and fasteners; The deflector includes a C-shaped deflector 3, the deflector 3 is made of ABS plastic, and is provided with four longitudinal through holes 3.1, which are fixed on the upper cover ...

no. 2 example

[0042] see Figure 15 , The woodworking machinery vacuum cleaner, the motor 6 is arranged on the upper cover body 1, and the dust suction head 4 is arranged on the lower cover body 2 corresponding to the motor 6. Other unmentioned parts are the same as the first embodiment.

no. 3 example

[0044] see Figure 16 , Figure 17 , the woodworking machinery vacuum cleaner, the air outlet of the fan blade 5 is connected with two groups of filter bag assemblies, the filter bag assembly is arranged on one side of the upper cover body 1, the dust suction head 4 is arranged on the other side of the upper cover body 1, and the motor 6 is arranged on the lower cover body 2 corresponding to the suction head 4 . The hanger 7 is T-shaped and includes a hanger connecting rod 7.1 and a hanger hanging rod 7.2. Hang on the two ends of hanger hanger rod 7.2, realize that it is articulated on the upper cover body 1. Other unmentioned parts are the same as the first embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com