Dust collection and suction device for woodworking circular saw machine

A technology of dust collection device and circular saw machine, which is applied in the direction of circular saws, wood processing appliances, manufacturing tools, etc., which can solve the problems of dust splashing and dust suction, and achieve the effect of strong stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

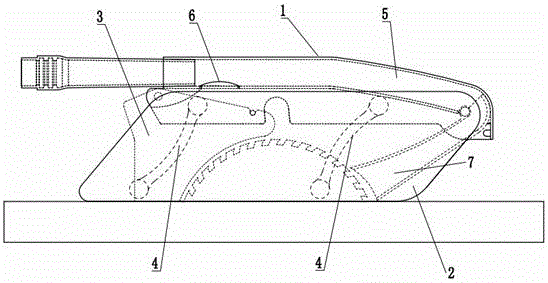

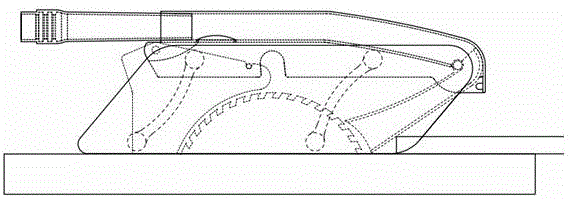

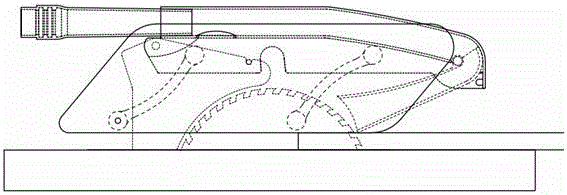

[0022] The preferred technical solutions of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0023] Such as figure 1 As shown, a kind of dust collecting device for woodworking circular saw machine of the present invention comprises a pipe shield 1, two dust baffles 2 and a positioning plate 3 arranged in parallel to each other;

[0024] The pipe shield 1 is a tank structure covering the gap between two dust-shielding plates 2, the notch of the tank body structure is set towards the gap between the two dust-shielding plates 2, and the two sides of the tank body structure respectively pull the connecting rods 4. One end of the traction link 4 is hinged on the tank wall of the tank structure, and the other end is hinged on the side of the dust shield 2 in the gap. Through the synchronous movement of the traction linkage 4, the two dust shields 2 and the pipeline protection The cover 1 can be relatively movable, that is, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com