Metal anticorrosive paint preparation and coating method thereof

A metal anti-corrosion and anti-corrosion coating technology, applied in metal processing equipment, coatings, manufacturing tools, etc., can solve the problems of increasing the labor of spraying workers, the impact of coating on the accuracy of parts, secondary spraying, etc., and achieve simple and convenient repair operations. , good grinding effect, reduce waste effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

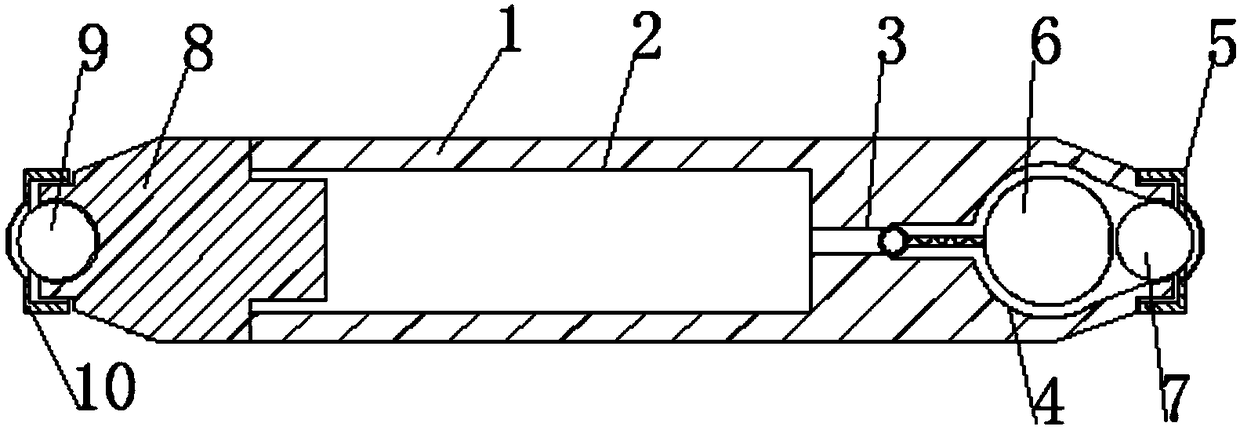

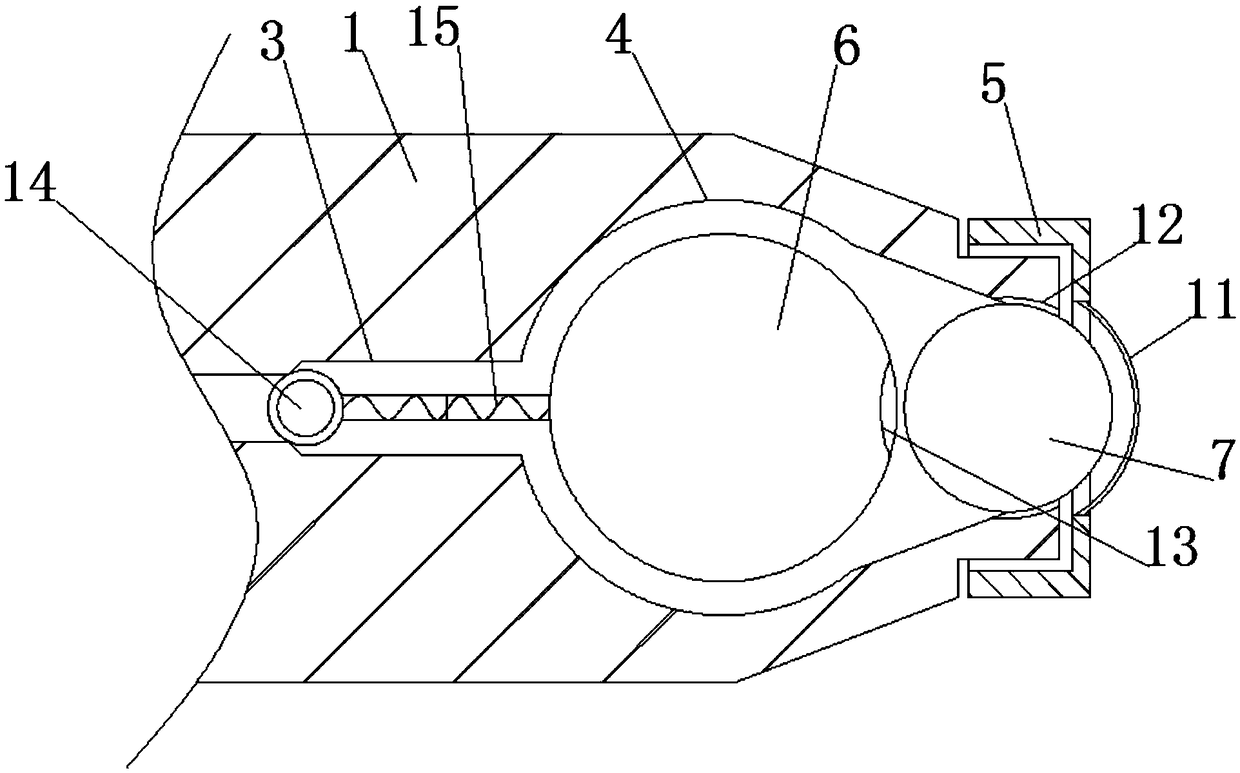

[0047] see figure 1 and 4 , a metal anti-corrosion paint preparation, comprising a coating repair device 1, the inner end of the coating repair device 1 is dug with a storage tank 2, the inner end of the storage tank 2 is equipped with anti-corrosion paint, and the notch of the storage tank 2 is covered with a rear cover 8 , the left end of the back cover 8 is provided with a grinding mechanism, and the inner end of the coating repairer 1 is dug with a one-way discharge groove 3, a gourd-shaped groove 4 and a limit groove 12, and a one-way discharge groove 3, a gourd-shaped groove 4 and a limit groove The grooves 12 are all located on the right side of the storage tank 2, and the storage tank 2, the one-way discharge groove 3, the gourd-shaped groove 4 and the limit groove 12 are sequentially connected from left to right, and the inner end of the one-way discharge groove 3 is provided with a single to mobile institutions.

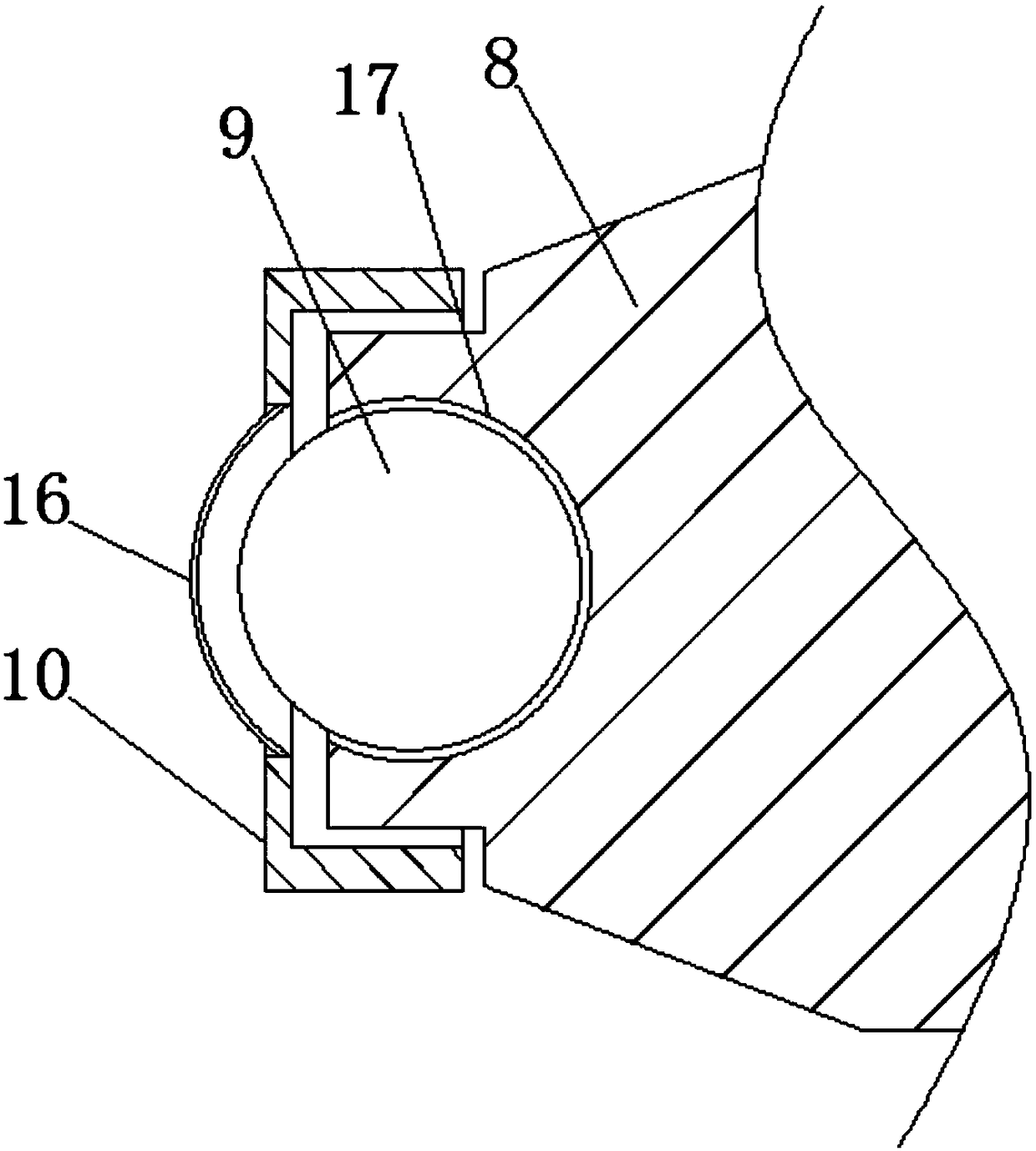

[0048] see image 3 , the grinding mechanism inclu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com