Rotational dust suction mechanism for dust filter

A dust suction mechanism and dust filter technology, which is applied in the fields of dispersed particle filtration, chemical instruments and methods, textiles and papermaking, etc., can solve the problems of large number of suction points, large fan power, complex mechanism, etc., and achieve strong dust suction ability, Reduce energy consumption and save the effect of reciprocating motion mechanism

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

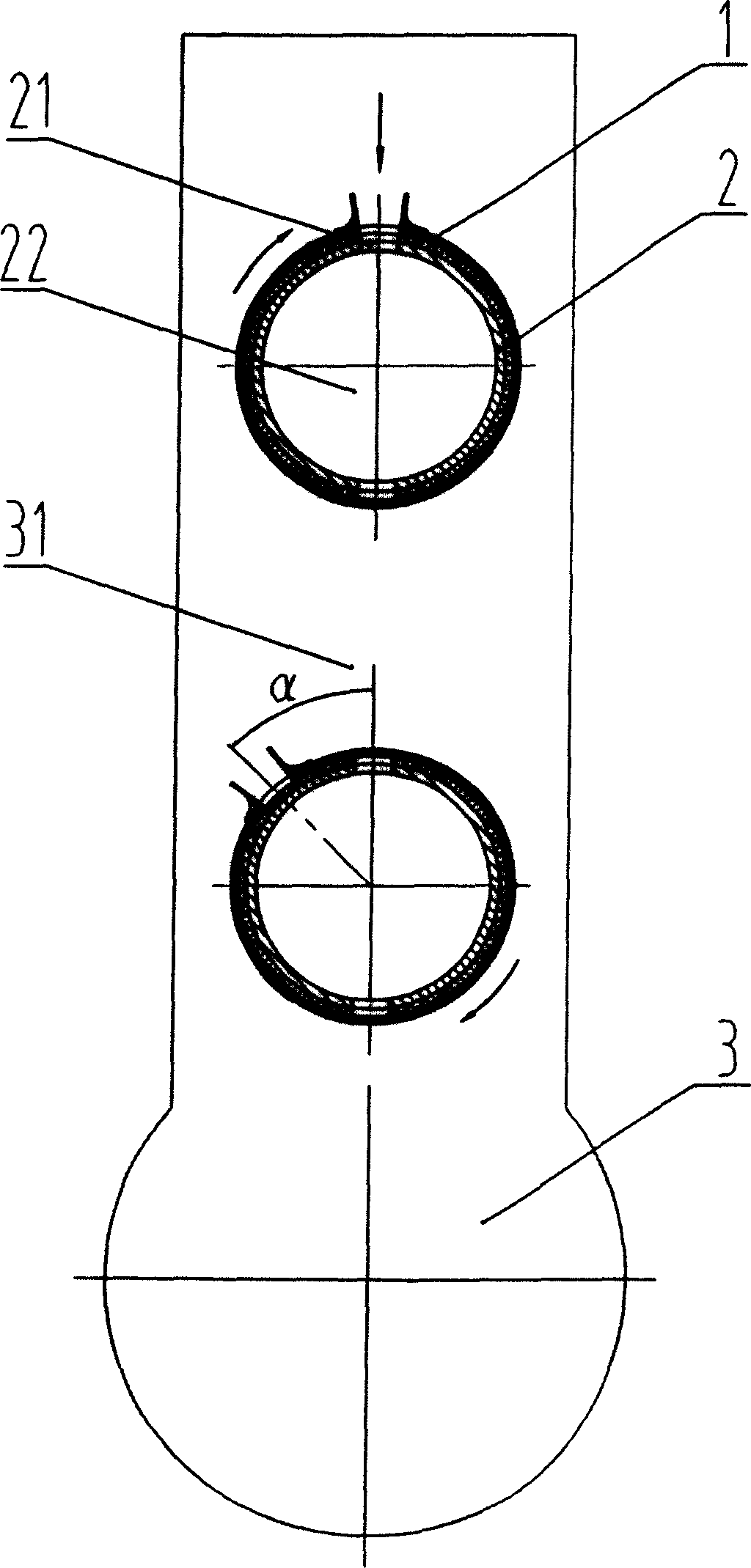

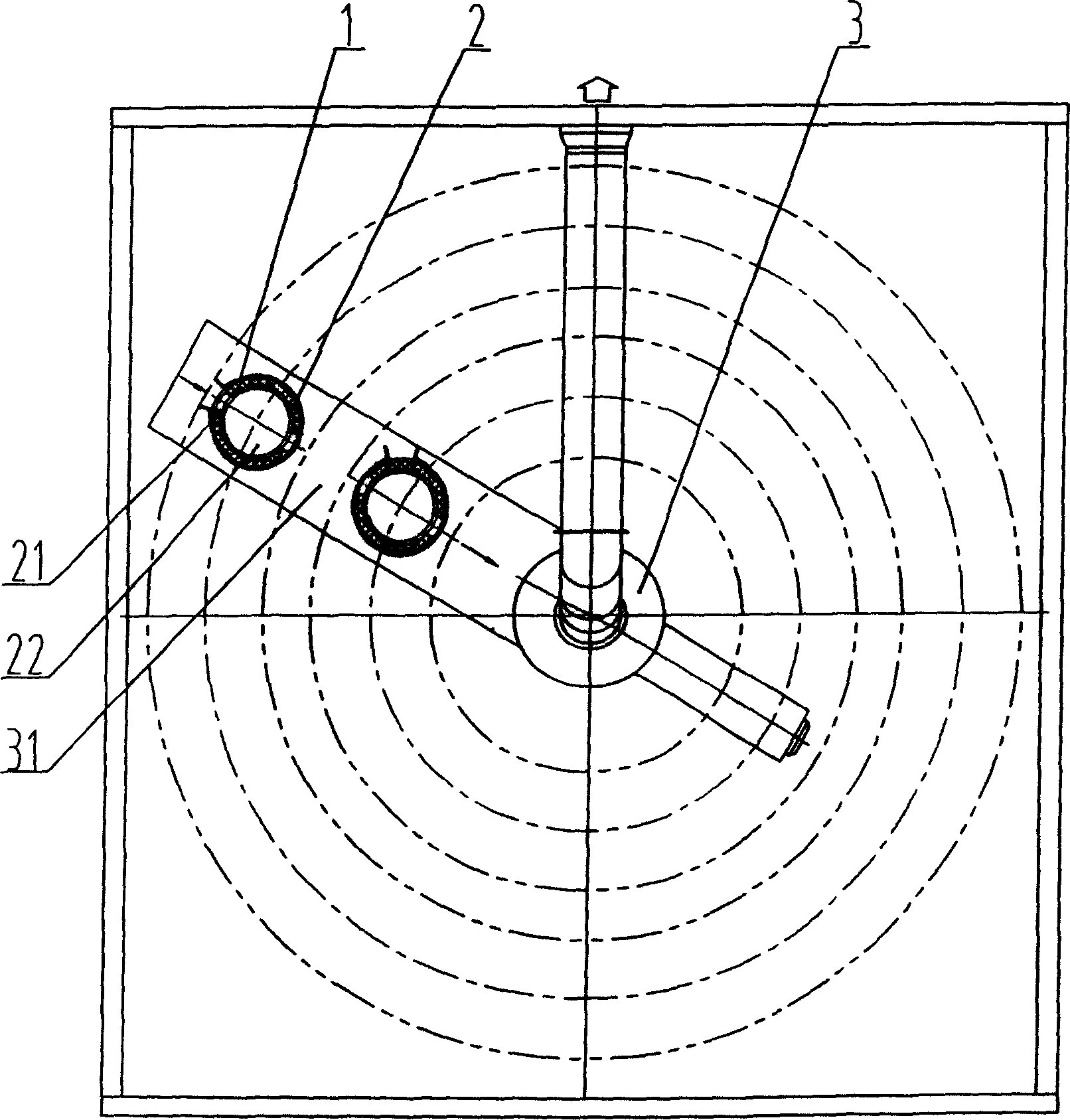

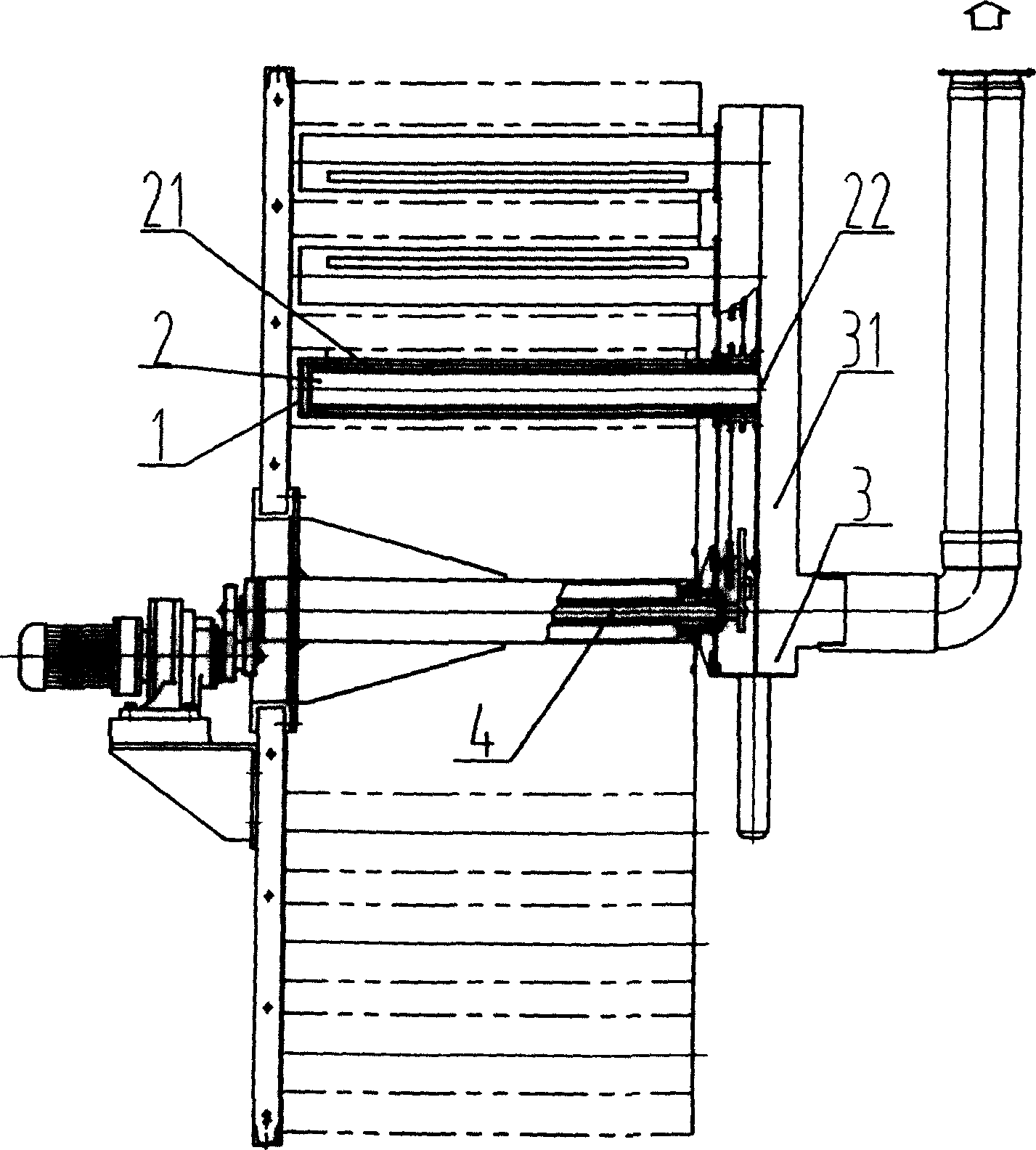

[0032] Please refer to the attached figure 1 , 2 As shown, the device is composed of a suction chamber, a suction arm, a suction nozzle, a suction pipe and a transmission mechanism, etc. The switching suction nozzle 1 is provided with an opening, and the suction pipe 2 is set coaxially inside, and the suction pipe 2 is provided with an inlet. The tuyeres 21 and the air outlets 22 communicated with the suction cavity 3 , the switching suction nozzle 1 is connected with the rotation mechanism 4 .

[0033] A suction arm 31 is provided on the suction chamber 3 of the dust filter in turn dust suction mechanism, the suction nozzle 1 and the concentric suit suction pipe 2 are installed on the suction arm 31 of the suction chamber 3, and the suction arm 31 communicates with the suction chamber 3, The suction chamber 3 and the suction arm 31 are connected with the rotation mechanism 4 .

[0034] After the position of the upper opening of the switching suction nozzle 1 of the dust fil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com